ASTM E2478-06

(Practice)Standard Practice for Determining Damage-Based Design Criteria for Fiberglass Reinforced Plastics (FRP) Materials

Standard Practice for Determining Damage-Based Design Criteria for Fiberglass Reinforced Plastics (FRP) Materials

SCOPE

1.1 This practice details procedures for establishing the direct stress and shear stress damage-based design values for use in the damage-based design criterion for FRP vessels and other composite structures. The practice uses data derived from acoustic emission examination of four-point beam bending tests and in-plane shear tests (see ASME Section X, Article RT-8).

1.2 The onset of lamina damage is indicated by the presence of significant acoustic emission during the reload portion of load/reload cycles. "Significant emission" is defined with historic index.

1.3 UnitsThe values stated in inch-pound units are to be regarded as standard. The values given in brackets are mathematical conversions to SI units which are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2478–06a

Standard Practice for

Determining Damage-Based Design Stress for Fiberglass

Reinforced Plastic (FRP) Materials Using Acoustic

Emission

This standard is issued under the fixed designation E 2478; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 543 Specification for Agencies Performing Nondestruc-

tive Testing

1.1 This practice details procedures for establishing the

E 976 Guide for Determining the Reproducibility ofAcous-

direct stress and shear stress damage-based design values for

tic Emission Sensor Response

use in the damage-based design criterion for materials to be

E 1316 Terminology for Nondestructive Examinations

used in FRP vessels and other composite structures. The

E 2374 Guide for Acoustic Emission System Performance

practice uses data derived from acoustic emission examination

Verification

of four-point beam bending tests and in-plane shear tests (see

2.2 ASME Documents:

ASME Section X, Article RT-8).

ASME Section X, Article RT-8 Test Method for Determin-

1.2 Theonsetoflaminadamageisindicatedbythepresence

ing Damage-Based Design Criterion

of significant acoustic emission during the reload portion of

ASME Section V, Article 11 Acoustic Emission Examina-

load/reload cycles. “Significant emission” is defined with

tion of Fiber-Reinforced Plastic Vessels

historic index.

2.3 Other Standards:

1.3 Units—The values stated in inch-pound units are to be

ANSI/ASNT-CP-189 Qualification and Certification of

regarded as standard. The values given in brackets are math-

Nondestructive Testing Personnel

ematical conversions to SI units which are provided for

SNT-TC-1A Recommended Practice for Personnel Qualifi-

information only and are not considered standard.

cation and Certification in Nondestructive Testing

1.4 This standard does not purport to address all of the

NAS-410 Certification and Qualification of Nondestructive

safety concerns, if any, associated with its use. It is the

Test Personnel

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use.

3.1 Definitions of terms related to conventional acoustic

2. Referenced Documents emission are in Terminology E 1316, Section B.

2 3.2 Definitions of Terms Specific to This Standard:

2.1 ASTM Standards:

3.2.1 historic index—a measure of the change in MARSE

D 790 TestMethodsforFlexuralPropertiesofUnreinforced

(or other AE feature parameter such as AE Signal Strength or

and Reinforced Plastics and Electrical Insulating Materials

AE Energy) throughout an examination.

D 4255/D 4255M Test Method for In-Plane Shear Proper-

3.2.2 measured area of the rectified signal envelope

ties of Polymer Matrix Composite Materials by the Rail

(MARSE)—a measure of the area under the envelope of the

Shear Method

rectified linear voltage time signal from the sensor. (seeASME

D 3846 Test Method for In-Plane Shear Strength of Rein-

Section V, Article 11)

forced Plastics

3.2.3 significant emission—a level of emission that corre-

sponds to the first time during reloading that the historic index

attains a value of 1.4.

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.04 on

Acoustic Emission Method.

Current edition approved Dec. 1, 2006. Published January 2007. Originally Available from American Society of Mechanical Engineers (ASME), ASME

approved in 2006. Last previous edition approved in 2006 as E 2478 - 06. International Headquarters, Three Park Ave., New York, NY 10016-5990.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518.

Standards volume information, refer to the standard’s Document Summary page on Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1250

the ASTM website. Eye St., NW, Washington, DC 20005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2478–06a

3.2.4 knee in the curve—a dramatic change in the slope of 6.1.5 Extent of Examination—The extent of examination

the cumulative AE versus time curve. shall be in accordance with Sections 9 and 10 unless otherwise

specified.

4. Summary of Practice

6.1.6 Reporting Criteria—Reporting criteria for the exami-

nationresultsshallbeinaccordancewith15.1unlessotherwise

4.1 This practice uses acoustic emission instrumentation

specified.

and examination techniques during load/reloading of materials

being examined, to determine the onset of significant acoustic

7. Apparatus

emission. The onset of significant emission is related to the

,

6 7

damage-based design stress by the Felicity ratio.

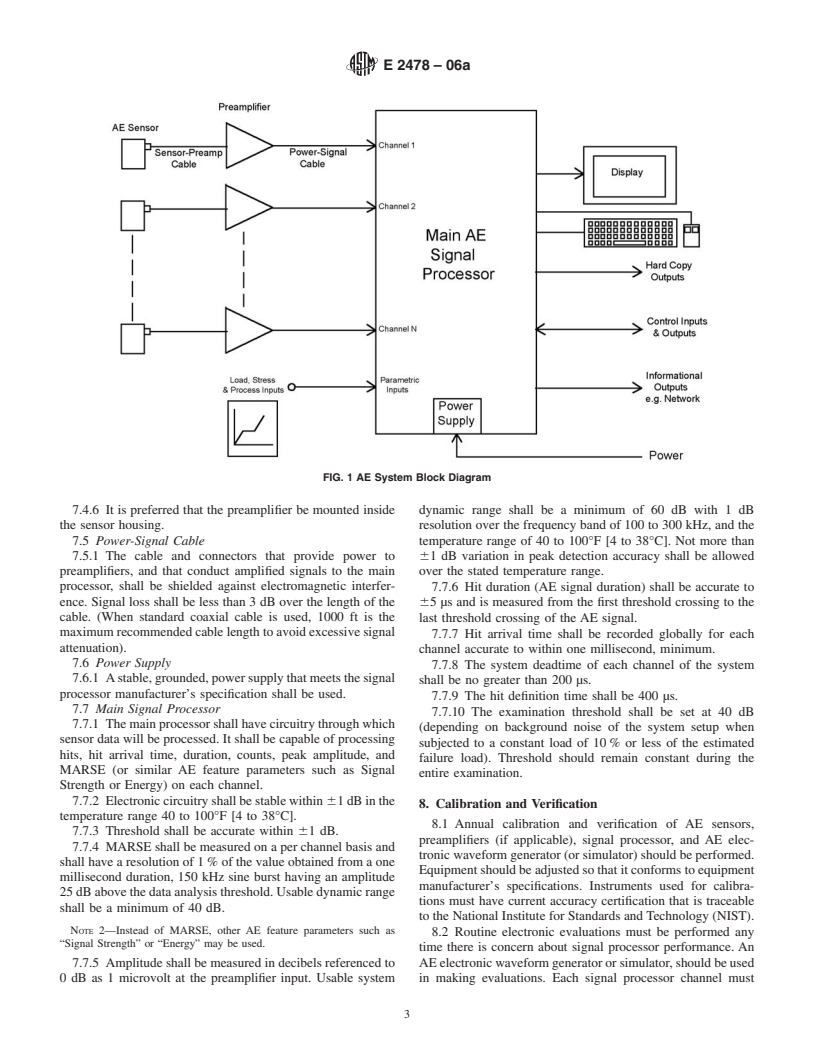

NOTE 1—Refer to Fig. 1 for AE system block diagram showing key

components of the AE system. It is recommended to use two AE sensors

5. Significance and Use

to monitor the specimen, evaluated on a per channel basis.

5.1 The damage-based design approach will permit an

7.1 AE Sensors

additional method of design for FRP materials. This is a very

7.1.1 AE sensors shall be resonant in a 100 to 300 kHz

useful technique to determine the performance of different

frequency band.

types of resins and composition of FRP materials in order to

7.1.2 Sensors shall have a peak sensitivity greater than –77

develop a damage tolerant and reliable design. This AE-based

dB (referred to 1 volt per microbar, determined by face-to-face

method is not unique, other damage-sensitive evaluation meth-

ultrasonic examination) within the frequency range 100 to 300

ods can also be used.

kHz.Sensitivitywithinthe100to300kHzrangeshallnotvary

5.2 This practice involves the use of acoustic emission

more than 3 dB within the temperature range of intended use.

instrumentation and examination techniques as a means of

7.1.3 Sensors shall be shielded against electromagnetic

damage detection to support a destructive test, in order to

interference through proper design practice or differential

derive the damage-based design stress.

(anti-coincidence) element design, or both.

5.3 This practice is not intended as a predictor of long-term

7.1.4 Sensors shall have omni-directional response, with

performance of FRP materials (such as those used in vessels).

variations not exceeding 2 dB from the peak response.

For this reason, many codes and standards require cyclic proof

7.2 Couplant

testingofprototypes(forexample,vessels)whicharenotapart

7.2.1 Commercially available couplants for ultrasonic flaw

of this practice.

detection may be used. Silicone-based high-vacuum grease has

5.4 Other design methods exist and are still permitted.

been found to be particularly suitable. Adhesives may also be

used.

6. Basis of Application

7.2.2 Couplant selection should be made to minimize

6.1 The following items are subject to contractual agree-

changesincouplingsensitivityduringacompleteexamination.

ment between the parties using or referencing this practice:

Consideration should be given to the time duration of the

6.1.1 Personnel Qualification—If specified in the contrac-

examination and maintaining consistency of coupling through-

tual agreement, personnel performing examinations to this

out the examination.

practice shall be qualified in accordance with a nationally or

7.3 Sensor-Preamplifier Cable

internationally recognized NDT personnel qualification prac-

7.3.1 The cable connecting the sensor to the preamplifier

tice or standard such as ANSI/ASNT-CP-189, SNT-TC-1A,

shall not attenuate the sensor peak voltage in the 100 to 300

NAS-410, or a similar document and certified by the employer

kHz frequency range more than 3 dB (6 ft [1.8 m] is a typical

or certifying agency, as applicable. The practice or standard

length). Integral preamplifier sensors meet this requirement.

used and its applicable revision shall be identified in the

They have inherently short, internal, signal cables.

contractual agreement between the using parties.

7.3.2 Thesensor-preamplifiercableshallbeshieldedagainst

6.1.2 Qualification of Nondestructive Agencies—If speci-

electromagnetic interference. Standard low-noise coaxial cable

fied in the contractual agreement, NDT agencies shall be

is generally adequate.

qualified and evaluated as described in Practice E 543. The

7.4 Preamplifier

applicable revision of Practice E 543 shall be specified in the

7.4.1 The preamplifier shall have a noise level no greater

contractual agreement.

thanfivemicrovoltsrms(referredtoashortedinput)withinthe

6.1.3 Procedure and Techniques—The procedures and tech-

100 to 300 kHz frequency range.

niques to be utilized shall be as specified in the contractual

7.4.2 Preamplifier gain shall vary no more than 61dB

agreement.

within the 100 to 300 kHz frequency band and temperature

6.1.4 Timing of Examination—The timing of examination

range of use.

shall be in accordance with 12.4 unless otherwise specified.

7.4.3 Preamplifiers shall be shielded from electromagnetic

interference.

7.4.4 Preamplifiers of differential design shall have a mini-

mum of 40 dB common-mode rejection.

Ramirez, G., Ziehl, P., Fowler, T., 2004, “Nondestructive Evaluation of FRP

Design Criteria with Primary Consideration to Fatigue Loading”, ASME Journal of

7.4.5 Preamplifiers shall include a bandpass filter with a

Pressure Vessel Technology, Vol. 126, pp. 1–13.

minimum bandwidth of 100 kHz to 300 kHz. Note that the

Ziehl, P. and Fowler, T., 2003, “Fiber Reinforced Polymer Vessel Design with

crystal resonant characteristics provide additional filtering as

a Damage Approach”, Journal of Composite Structures, Vol. 61, Issue 4, pp.

395-411. does the bandpass filter in the signal conditioner.

E2478–06a

FIG. 1 AE System Block Diagram

7.4.6 It is preferred that the preamplifier be mounted inside dynamic range shall be a minimum of 60 dB with 1 dB

the sensor housing. resolution over the frequency band of 100 to 300 kHz, and the

7.5 Power-Signal Cable temperature range of 40 to 100°F [4 to 38°C]. Not more than

7.5.1 The cable and connectors that provide power to 61 dB variation in peak detection accuracy shall be allowed

preamplifiers, and that conduct amplified signals to the main over the stated temperature range.

processor, shall be shielded against electromagnetic interfer-

7.7.6 Hit duration (AE signal duration) shall be accurate to

ence. Signal loss shall be less than 3 dB over the length of the 65 µs and is measured from the first threshold crossing to the

cable. (When standard coaxial cable is used, 1000 ft is the

last threshold crossing of the AE signal.

maximumrecommendedcablelengthtoavoidexcessivesignal

7.7.7 Hit arrival time shall be recorded globally for each

attenuation).

channel accurate to within one millisecond, minimum.

7.6 Power Supply

7.7.8 The system deadtime of each channel of the system

7.6.1 Astable,grounded,powersupplythatmeetsthesignal

shall be no greater than 200 µs.

processor manufacturer’s specification shall be used.

7.7.9 The hit definition time shall be 400 µs.

7.7 Main Signal Processor

7.7.10 The examination threshold shall be set at 40 dB

7.7.1 Themainprocessorshallhavecircuitrythroughwhich

(depending on background noise of the system setup when

sensor data will be processed. It shall be capable of processing

subjected to a constant load of 10 % or less of the estimated

hits, hit arrival time, duration, counts, peak amplitude, and

failure load). Threshold should remain constant during the

MARSE (or similar AE feature parameters such as Signal

entire examination.

Strength or Energy) on each channel.

7.7.2 Electroniccircuitryshallbestablewithin 61dBinthe

8. Calibration and Verification

temperature range 40 to 100°F [4 to 38°C].

8.1 Annual calibration and verification of AE sensors,

7.7.3 Threshold shall be accurate within 61 dB.

preamplifiers (if applicable), signal processor, and AE elec-

7.7.4 MARSE shall be measured on a per channel basis and

tronic waveform generator (or simulator) should be performed.

shall have a resolution of 1 % of the value obtained from a one

Equipmentshouldbeadjustedsothatitconformstoequipment

millisecond duration, 150 kHz sine burst having an amplitude

manufacturer’s specifications. Instruments used for calibra-

25dBabovethedataanalysisthreshold.Usabledynamicrange

tions must have current accuracy certification that is traceable

shall be a minimum of 40 dB.

to the National Institute for Standards and Technology (NIST).

NOTE 2—Instead of MARSE, other AE feature parameters such as

8.2 Routine electronic evaluations must be performed any

“Signal Strength” or “Energy” may be used.

time there is concern about signal processor performance. An

7.7.5 Amplitude shall be measured in decibels referenced to AEelectronicwaveformgeneratororsimulator,shouldbeused

0 dB as 1 microvolt at the preamplifier input. Usable system in making evaluations. Each signal processor channel must

E2478–06a

respond with peak amplitude reading within 62dBofthe 11.2 For applications with a design operating temperature

electronic waveform generator output. above 120°F [49°C], the damage-based design stress shall be

8.3 A system performance verification must be conducted obtained by either:

immediately before, and immediately after, each examination. 11.2.1 Conductingtheexaminationwithintherangeof+5°F

Aperformance verification uses a mechanical device to induce [–15°C] to –10°F [–23°C] of the design operating temperature.

stress waves into the material under examination, at a specified 11.2.2 Conducting the examination at 120°F [49°C] or less

distance from each sensor. Induced stress waves stimulate a and adjusting the stress obtained by the ratio of the ultimate

sensor in the same way as emission from a flaw. Performance strength at the design operating temperature and the ultimate

verificationsverifyperformanceoftheentiresystem(including strength at the examination temperature.

couplant). (Refer to Guide E 2374 forAE system performance

12. Examination Procedure

verification techniques).

8.3.1 The preferred technique for conducting a performance

12.1 The loading procedure for determining the presence of

verification is a pencil lead break (PLB). Lead should be

the Felicity effect is very important and is detailed in Fig. 2.

brokenonthematerialsurfaceataspecifieddistancefromeach

12.2 Load shall be monitor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.