ASTM D5316-98(2004)

(Test Method)Standard Test Method for 1,2-Dibromoethane and 1,2-Dibromo-3-Chloropropane in Water by Microextraction and Gas Chromatography

Standard Test Method for 1,2-Dibromoethane and 1,2-Dibromo-3-Chloropropane in Water by Microextraction and Gas Chromatography

SIGNIFICANCE AND USE

This test method is useful for the analysis of drinking water and groundwaters. Other waters may be analyzed by this method, see 1.2.

EDB and DBCP have been widely used as soil fumigants. EDB is also used as a lead scavenger in leaded gasolines. These compounds are very water soluble and are often found in groundwater and drinking water. Since they are highly toxic and are suspected carcinogens, there is concern about the potential health impact of even extremely low concentrations in potable water.

SCOPE

1.1 This test method covers the determination of 1,2-dibromoethane (commonly referred to as ethylene dibromide or EDB) and 1,2-dibromo-3-chloropropane (commonly referred to as DBCP) in water at a minimum detection level of 0.010 μg/L by liquid-liquid extraction combined with gas-liquid chromatography. This test method is applicable to the analysis of drinking waters and groundwaters. It is not recommended for wastewaters, due to the potential for interferences from high concentrations of other extractable organics. Similar information can be found in EPA Method 504.

1.2 This test method was used successfully with reagent water and groundwater. It is the user's responsibility to ensure the validity of this test method for waters of untested matrices.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Sections 6 and 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5316–98 (Reapproved 2004)

Standard Test Method for

1,2-Dibromoethane and 1,2-Dibromo-3-Chloropropane in

Water by Microextraction and Gas Chromatography

This standard is issued under the fixed designation D5316; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4210 Practice for Intralaboratory Quality Control Proce-

dures and a Discussion on Reporting Low-Level Data

1.1 This test method covers the determination of 1,2-

D5789 Practice for Writing Quality Control Specifications

dibromoethane (commonly referred to as ethylene dibromide

for Standard Test Methods for Organic Constituents

or EDB) and 1,2-dibromo-3-chloropropane (commonly re-

2.2 U.S. Environmental Protection Agency Standards:

ferred to as DBCP) in water at a minimum detection level of

Winfield, T. W., “U.S. EPA Method 504, Revision 2.0,”

0.010 µg/L by liquid-liquid extraction combined with gas-

Methods for the Determination of Organic Compounds in

liquid chromatography. This test method is applicable to the

Drinking Water, 1989

analysis of drinking waters and groundwaters. It is not recom-

mended for wastewaters, due to the potential for interferences

3. Terminology

from high concentrations of other extractable organics. Similar

3.1 Definitions—For definitions of terms used in this test

information can be found in EPA Method 504.

method, refer to Terminology D1129.

1.2 This test method was used successfully with reagent

water and groundwater. It is the user’s responsibility to ensure

4. Summary of Test Method

the validity of this test method for waters of untested matrices.

4.1 This test method consists of microextraction of the

1.3 This standard does not purport to address all of the

sample followed by gas chromatographic analysis of the

safety concerns, if any, associated with its use. It is the

extract.

responsibility of the user of this standard to establish appro-

4.2 An aliquot of the sample is extracted with hexane. Two

priate safety and health practices and determine the applica-

µL of the extract are then injected into a gas chromatograph

bility of regulatory limitations prior to use. For specific hazard

equipped with a linearized electron capture detector for sepa-

statements, see Sections 6 and 9.

ration and analysis. Aqueous calibration standards are ex-

2. Referenced Documents tracted and analyzed in an identical manner as the samples in

2 order to compensate for possible extraction losses.

2.1 ASTM Standards:

4.3 The extraction and analysis time is 30 to 50 min per

D1066 Practice for Sampling Steam

sample, depending upon the analytical conditions chosen.

D1129 Terminology Relating to Water

4.4 Confirmatory evidence can be obtained using a dissimi-

D1192 Guide for Equipment for SamplingWater and Steam

3 lar column. When component concentrations are sufficiently

in Closed Conduits

high, Gas Chromatography/Mass Spectrometric (GC/MS)

D1193 Specification for Reagent Water

methods may be used for confirmation analysis. (See EPA

D3370 Practices for Sampling Water from Closed Conduits

Method 524.2.)

D3856 Guide for Good Laboratory Practices in Laborato-

ries Engaged in Sampling and Analysis of Water

5. Significance and Use

5.1 This test method is useful for the analysis of drinking

This test method is under the jurisdiction of ASTM Committee D19 on Water

water and groundwaters. Other waters may be analyzed by this

andisthedirectresponsibilityofSubcommitteeD19.06onMethodsforAnalysisfor

method, see 1.2.

Organic Substances in Water.

5.2 EDB and DBCP have been widely used as soil fumi-

Current edition approved June 1, 2004. Published June 2004. Originally

approved in 1992. Last previous edition approved in 1998 as D5316–98. DOI: gants.EDBisalsousedasaleadscavengerinleadedgasolines.

10.1520/D5316-98R04.

Thesecompoundsareverywatersolubleandareoftenfoundin

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

groundwater and drinking water. Since they are highly toxic

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Withdrawn. The last approved version of this historical standard is referenced Available from U.S. Environmental Protection Agency, 26 W. Martin Luther

on www.astm.org. King Ave., Cincinnati, OH 45268.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5316–98 (2004)

TABLE 1 Chromatographic Conditions for 1,2-dibromethane

(EDB) and 1,2-dibromo-3-chloropropane (DBCP)

Analyte Retention Time (min)

Column A Column B Column C

EDB 9.5 8.9 4.1

DBCP 17.3 15.0 12.8

and are suspected carcinogens, there is concern about the

potential health impact of even extremely low concentrations

in potable water.

6. Interferences

6.1 Impurities contained in the extracting solvent usually

account for the majority of the analytical problems. Solvent

blanksshouldbeanalyzedoneachnewbottleofsolventbefore

use.Indirectdailychecksontheextractingsolventareobtained

by monitoring the water blanks. Whenever an interference is

noted in the water blank, the analyst should reanalyze the

extracting solvent. Low-level interferences generally can be

removed by distillation or column chromatography.

NOTE 1—When a solvent is purified, stabilizers put into the solvent by

the manufacturer are removed, thus potentially making the solvent

hazardous. Also, when a solvent is purified, preservatives put into the

solvent by the manufacturer are removed, thus potentially making the

FIG. 1 Extract of Reagent Water Spiked at 0.114 µg/L with EDB

shelf-life short. However, it is generally more economical to obtain a new and DBCP

source of solvent. Interference-free solvent is defined as a solvent

containing less than 0.1 µg/L individual analyte interference. Protect

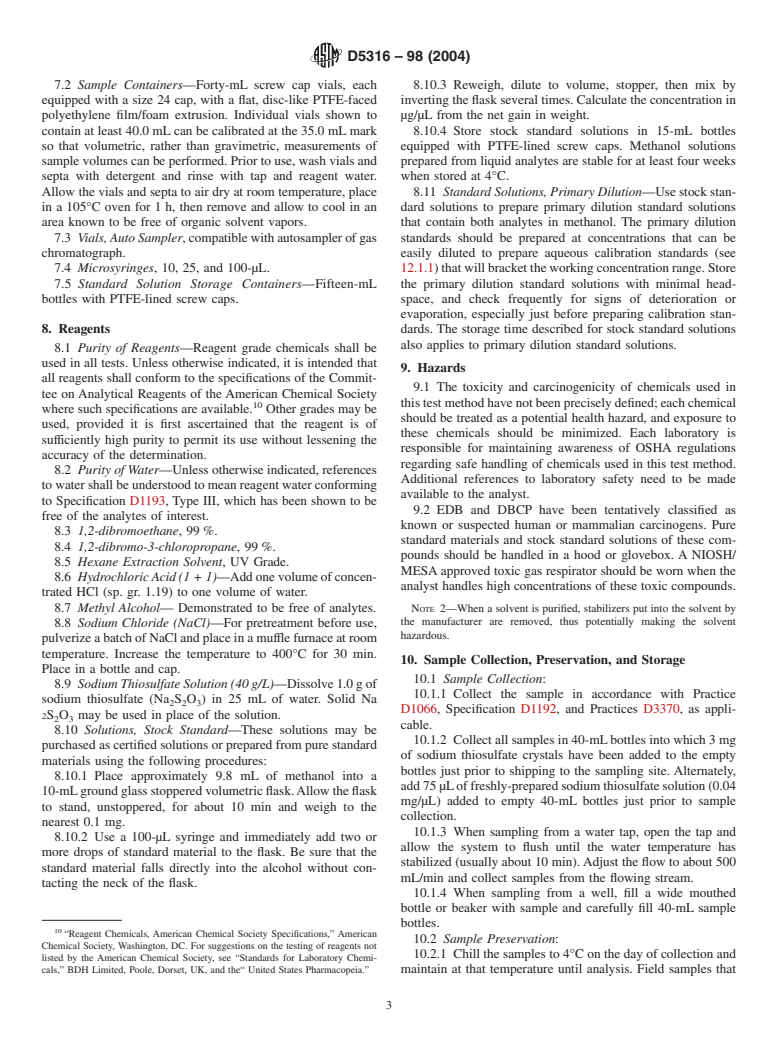

7.1.3 Column A—A 0.32-mm ID by 30-m long fused silica

interference-free solvents by storing them in an area known to be free of

capillary with dimethyl silicone mixed phase. The linear

organochlorine solvents.

velocity of the helium carrier gas should be about 25 cm/s at

6.2 This liquid-liquid extraction technique efficiently ex-

100°C. The column temperature is programmed to hold at

tracts a wide boiling range of nonpolar organic compounds

40°C for 4 min, to increase to 190°C at 8°C/min, and hold at

and, in addition, extracts polar organic components of the

190°C for 25 min or until all expected compounds have eluted.

sample with varying efficiencies.

(See Fig. 1 for a sample chromatogram.)

6.3 Current column technology suffers from the fact that

7.1.4 Column B (alternative column)—A 0.32-mm ID by

EDB at low concentrations may be masked by very high levels

30-m long fused silica capillary with methyl polysiloxane

of dibromochloromethane (DBCM), a common disinfection

phase. The linear velocity of the helium carrier gas should be

by-product of chlorinated drinking waters.

about 25 cm/s at 100°C. The column temperature is pro-

grammed to hold at 40°C for 4 min, to increase to 270°C at

7. Apparatus and Equipment

10°C/min, and hold at 270°C for 10 min or until all expected

7.1 Gas Chromatography (GC) System:

compounds have eluted.

7.1.1 The GC system must be capable of temperature

7.1.5 Column C (alternative column, wide bore)—A 0.53-

programming and should be equipped with a linearized elec-

mm ID by 30-m long fused silica capillary with dimethyl

troncapturedetectorandacapillarycolumnsplitlessinjectorat

diphenyl polysiloxane, bonded phase with 2.0 µm film. The

200°C. Separate heated zones for the injector and detector

hydrogen carrier gas flow is about 80 cm/s linear velocity,

components are recommended.

measured at 50°C. The oven temperature is programmed to

7.1.2 Two gas chromatography columns are recommended.

hold at 200°C until all expected compounds have eluted.

Column A (7.1.3) is a highly efficient column that provides

7.1.6 Other Heated Zones—Injector temperature: 250°C.

separations for EDB and DBCP without interferences from 9

Detector temperature: 350°C.

trihalomethanes. Column A should be used as the primary

analytical column unless routinely occurring analytes are not

adequatelyresolved.ColumnB(7.1.4)isrecommendedforuse J & W Durawax DX-3, 0.25 µm, available from J & W Scientific, 91 Blue

Ravine Rd., Folsom, CA 95630, or its equivalent, has been found suitable for this

as a confirmatory column when GC/MS confirmation is not

purpose.

viable. Retention times for EDB and DBCPon these columns

J & W DB-1, 1.0 µm film, available from J & W Scientific, or its equivalent,

are presented in Table 1.

has been found suitable for this purpose.

Rt –Volatiles,2.0µmfilmthickness.Restekpart#10902,availablefromRestek

x

Corp., 110 Benner Circle, Bellefonte, PA 16823, or its equivalent has been found

suitable for this purpose.

5 9

An alternative column has been recommended by the Restek Corporation and These parameters were obtained by Restek Corporation during preliminary

is described in 7.1.5 as Column C. attempts to improve the separation of EDB and DBCM.

D5316–98 (2004)

7.2 Sample Containers—Forty-mL screw cap vials, each 8.10.3 Reweigh, dilute to volume, stopper, then mix by

equipped with a size 24 cap, with a flat, disc-like PTFE-faced inverting the flask several times. Calculate the concentration in

polyethylene film/foam extrusion. Individual vials shown to µg/µL from the net gain in weight.

contain at least 40.0 mLcan be calibrated at the 35.0 mLmark 8.10.4 Store stock standard solutions in 15-mL bottles

so that volumetric, rather than gravimetric, measurements of equipped with PTFE-lined screw caps. Methanol solutions

sample volumes can be performed. Prior to use, wash vials and prepared from liquid analytes are stable for at least four weeks

septa with detergent and rinse with tap and reagent water. when stored at 4°C.

Allow the vials and septa to air dry at room temperature, place 8.11 Standard Solutions, Primary Dilution—Usestockstan-

in a 105°C oven for 1 h, then remove and allow to cool in an dard solutions to prepare primary dilution standard solutions

area known to be free of organic solvent vapors. that contain both analytes in methanol. The primary dilution

7.3 Vials,AutoSampler,compatiblewithautosamplerofgas standards should be prepared at concentrations that can be

chromatograph. easily diluted to prepare aqueous calibration standards (see

7.4 Microsyringes, 10, 25, and 100-µL. 12.1.1)thatwillbrackettheworkingconcentrationrange.Store

7.5 Standard Solution Storage Containers—Fifteen-mL the primary dilution standard solutions with minimal head-

bottles with PTFE-lined screw caps. space, and check frequently for signs of deterioration or

evaporation, especially just before preparing calibration stan-

8. Reagents

dards. The storage time described for stock standard solutions

also applies to primary dilution standard solutions.

8.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

9. Hazards

all reagents shall conform to the specifications of the Commit-

9.1 The toxicity and carcinogenicity of chemicals used in

tee on Analytical Reagents of the American Chemical Society

thistestmethodhavenotbeenpreciselydefined;eachchemical

where such specifications are available. Other grades may be

should be treated as a potential health hazard, and exposure to

used, provided it is first ascertained that the reagent is of

these chemicals should be minimized. Each laboratory is

sufficiently high purity to permit its use without lessening the

responsible for maintaining awareness of OSHA regulations

accuracy of the determination.

regarding safe handling of chemicals used in this test method.

8.2 Purity of Water—Unless otherwise indicated, references

Additional references to laboratory safety need to be made

towatershallbeunderstoodtomeanreagentwaterconforming

available to the analyst.

to Specification D1193, Type III, which has been shown to be

9.2 EDB and DBCP have been tentatively classified as

free of the analytes of interest.

known or suspected human or mammalian carcinogens. Pure

8.3 1,2-dibromoethane,99%.

standard materials and stock standard solutions of these com-

8.4 1,2-dibromo-3-chloropropane,99%.

pounds should be handled in a hood or glovebox. A NIOSH/

8.5 Hexane Extraction Solvent, UV Grade.

MESAapproved toxic gas respirator should be worn when the

8.6 HydrochloricAcid(1 + 1)—Addonevolumeofconcen-

analyst handles high concentrations of these toxic compounds.

trated HCl (sp. gr. 1.19) to one volume of water.

8.7 Methyl Alcohol— Demonstrated to be free of analytes. NOTE 2—When a solvent is purified, stabilizers put into the solvent by

the manufacturer are removed, thus potentially making the solvent

8.8 Sodium Chloride (NaCl)—For pretreatment before use,

hazardous.

pulverizeabatchofNaClandplaceinamufflefurnaceatroom

temperature. Increase the temperature to 400°C for 30 min.

10. Sample Collection, Preservation, and Storage

Place in a bottle and cap.

10.1 Sample Collection:

8.9 SodiumThiosulfateSolution(40g/L)—Dissolve1.0gof

10.1.1 Collect the sample in accordance with Practice

sodium thiosulfate (Na S O ) in 25 mL of water. Solid Na

2 2 3

D1066, Specification D1192, and Practices D3370, as appli-

2S O may be used in place of the solution.

2 3

cable.

8.10 Solutions, Stock Standard—These solutions may be

10.1.2 Collect all samples in 40-mLbottles into which 3 mg

purchased as certified solutions or prepared from pure standard

of sodium thiosulfate crystals have been added to the empty

materials using the following procedures:

bottles just prior to shipping to the sampling site. Alternately,

8.10.1 Place approximately 9.8 mL of methanol into a

add75µLoffreshly-preparedsodiumthiosulfatesolution(0.04

10-mLgroundglassstopperedvolumetricflask.Allowtheflask

mg/µL) added to empty 40-mL bottles just prior to sample

to stand, unstoppered, for about 10 min and weigh to the

collection.

nearest 0.1 mg.

10.1.3 When sampling from a water tap, open the tap and

8.10.2 Use a 100-µL syringe and immediately add two or

allow the system to flush until the water temperature has

more drops of standard material to the flask. Be sure that the

stabilized (usually about 10 min).Adjust the flow to about 500

standard material falls directly into the alcohol without con-

mL/min and collect samples from the flowing stream.

tacting the neck of the flask.

10.1.4 When sampling from a well, fill a wide mouthed

bottle or beaker with sample and carefully fill 4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.