ASTM C14M-99

(Specification)Standard Specification for Concrete Sewer, Storm Drain, and Culvert Pipe (Metric)

Standard Specification for Concrete Sewer, Storm Drain, and Culvert Pipe (Metric)

SCOPE

1.1 This specification covers nonreinforced concrete pipe intended to be used for the conveyance of sewage, industrial wastes, storm water, and for the construction of culverts.

1.2 This specification is the metric counterpart of Specification C14. Note 1-This specification is a manufacturing and purchase specification only and does not include requirements for bedding, backfill, or the relationship between field load condition and the strength classification of pipe. However, experience has shown that the successful performance of this product depends upon the proper selection of the class of pipe, type of bedding and backfill, and care that the installation conforms to the construction specifications. The owner is cautioned that he must correlate the field requirements with the class of pipe specified and provide for or require inspection at the construction site.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 14M – 99

METRIC

Standard Specification for

Concrete Sewer, Storm Drain, and Culvert Pipe [Metric]

This standard is issued under the fixed designation C 14M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Terminology

1.1 This specification covers nonreinforced concrete pipe 3.1 Definitions of Terms Specific to This Standard—For

intended to be used for the conveyance of sewage, industrial definitions of terms relating to concrete pipe, see Terminology

wastes, storm water, and for the construction of culverts. C 822.

1.2 This specification is the metric counterpart of Specifi-

4. Classification

cation C 14.

4.1 Pipe manufactured according to this specification shall

NOTE 1—This specification is a manufacturing and purchase specifica-

be of three classes identified as “Class 1 Nonreinforced

tion only and does not include requirements for bedding, backfill, or the

Concrete Pipe,” “Class 2 Nonreinforced Concrete Pipe,” and

relationship between field load condition and the strength classification of

“Class 3 Nonreinforced Concrete Pipe.” The corresponding

pipe. However, experience has shown that the successful performance of

this product depends upon the proper selection of the class of pipe, type

strength requirements are prescribed in Table 1.

of bedding and backfill, and care that the installation conforms to the

construction specifications. The owner is cautioned that he must correlate 5. Basis of Acceptance

the field requirements with the class of pipe specified and provide for or

5.1 The acceptability of the pipe shall be determined by the

require inspection at the construction site.

results of the test prescribed in this section, when required, and

by inspection to determine whether the pipe conforms to this

2. Referenced Documents

specification as to design and freedom from defects.

2.1 ASTM Standards:

2 5.2 Acceptance as to Strength Properties—Pipe shall be

C 33 Specification for Concrete Aggregates

acceptable under the strength tests when they have met the

C 150 Specification for Portland Cement

requirements as prescribed in 10.3.

C 309 Specification for Liquid Membrane-Forming Com-

5.3 Acceptance as to Absorption Properties—Pipe shall be

pounds for Curing Concrete

acceptable under the absorption test when they have met the

C 443M Specification for Joints for Circular Concrete

requirements as prescribed in 10.4.

Sewer and Culvert Pipe, Using Rubber Gaskets [Metric]

5.4 Acceptance as to Permeability Properties—Pipe shall

C 497M Test Methods for Concrete Pipe, Manhole Sec-

be acceptable under the permeability test when they have met

tions, or Tile [Metric]

the requirements as prescribed in 10.5.

C 595 Specification for Blended Hydraulic Cements

C 618 Specification for Coal Fly Ash and Raw or Calcined

NOTE 2—Prior to purchase, the owner may specify the hydrostatic test

prescribed in 10.6 instead of the permeability test.

Natural Pozzolan for Use as a Mineral Admixture in

Concrete

5.5 Acceptance as to Hydrostatic Properties—Pipe shall be

C 822 Terminology Relating to Concrete Pipe and Related

acceptable under the hydrostatic test when they have met the

Products

requirements as prescribed in 10.6.

C 1116 Specification for Fiber-Reinforced Concrete and

6. Materials

Shotcrete

6.1 Concrete—The concrete shall consist of cementitious

materials, mineral aggregates, and water.

This specification is under the jurisdiction of ASTM Committee C-13 on

Concrete Pipe and is the direct responsibility of Subcommittee C13.01 on

6.2 Cementitious Materials:

Reinforced Concrete Sewer, Drain, and Irrigation Pipe.

6.2.1 Cement—Cement shall conform to the requirements

Current edition approved Aug. 10, 1999. Published September 1999. Originally

for portland cement of Specification C 150 or shall be portland

published as C 14M – 80. Last previous edition C 14M –95.

Annual Book of ASTM Standards, Vol 04.02. blast-furnace slag cement or portland-pozzolan cement con-

Annual Book of ASTM Standards, Vol 04.01.

forming to the requirements of Specification C 595, except that

Annual Book of ASTM Standards, Vol 04.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 14M

A

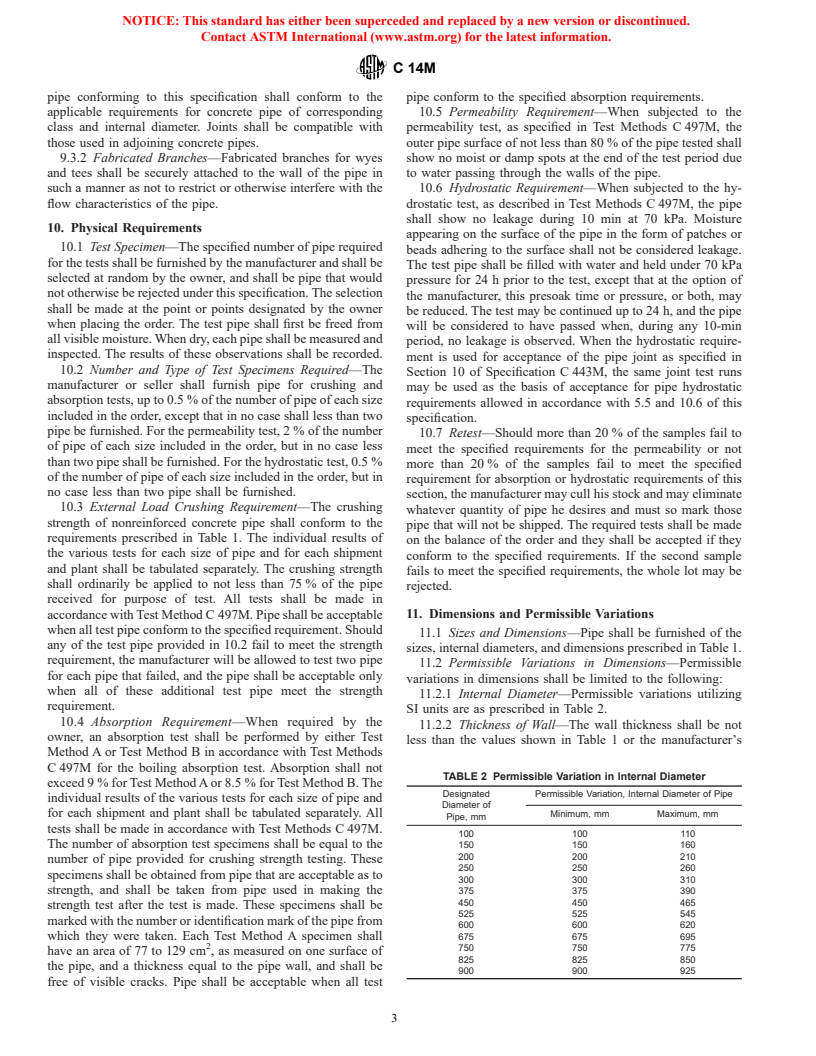

TABLE 1 Physical and Dimensional Requirements for Nonreinforced Concrete Pipe

Class 1 Class 2 Class 3

Minimum Minimum Minimum

Internal Designated

Minimum Strength, kN/ Minimum Strength, kN/ Minimum Strength, kN/

Diameter, mm

Thickness of linear m, Thickness of linear m, Thickness of linear m,

Wall, mm Three-Edge Wall, mm Three-Edge Wall, mm Three-Edge

Bearing Bearing Bearing

100 16 22.0 19 29.0 19 35.0

150 16 22.0 19 29.0 22 35.0

200 19 22.0 22 29.0 29 35.0

250 22 23.5 25 29.0 32 35.0

300 25 26.5 35 33.0 44 38.0

375 32 29.0 41 38.0 47 42.0

450 38 32.0 50 44.0 57 48.0

525 44 35.0 57 48.0 69 56.0

600 54 38.0 75 52.5 85 64.0

675 82 41.0 94 57.5 94 67.0

750 88 44.0 107 63.0 107 69.5

825 94 46.0 113 64.0 113 71.0

900 100 48.0 119 65.5 119 73.0

A

Subject to tolerance in Section 11.

the pozzolan constitutient in the Type IP portland-pozzolan tioned, and mixed with such proportions of cementitious

cement shall be fly ash. materials and water as will produce a homogeneous concrete

6.2.2 Fly Ash—Fly ash shall conform to the requirements of mixture of such quality that the pipe will conform to the test

Specification C 618, Class F or Class C. and design requirements of this specification. All concrete shall

6.2.3 Allowable Combinations of Cementitious Materials— have a water-cementitious materials ratio not exceeding 0.53

The combination of cementitious materials used in the concrete by weight. Cementitious materials shall be as specified in 6.2

shall be one of the following: and shall be added to the mix in a proportion not less than 280

6.2.3.1 Portland cement only, kg/m unless mix designs with a lower cementitious materials

6.2.3.2 Portland blast furnace slag cement only, content demonstrate that the quality and performance of the

6.2.3.3 Portland pozzolan cement only, or pipe meet the requirements of this specification.

6.2.3.4 A combination of portland cement and fly ash. 9.2 Curing—Pipe shall be subjected to any one of the

6.3 Aggregates—Aggregates shall conform to Specification methods of curing described in 9.2.1 through 9.2.4 or to any

C 33, except that the requirement for gradation shall not apply. other method or combination of methods approved by the

6.4 Admixtures and Blends—Admixtures and blends may be owner that will give satisfactory results. The pipe shall be

used with the approval of the owner. adequately cured to obtain the strength properties as prescribed

6.5 Synthetic Fibers—Collated fibrillated virgin polypropy- in 5.2.

lene fibers may be used, at the manufacturer’s option, in 9.2.1 Steam Curing—Pipe may be placed in a curing

concrete pipe as a nonstructural manufacturing material. Only chamber, free from outside drafts, and cured in a moist

Type III synthetic fibers designed and manufactured specifi- atmosphere maintained by the injection of steam for such time

cally for use in concrete and conforming to the requirements of and such temperature as may be needed to enable the pipe to

Specification C 1116 shall be accepted. meet the strength requirements. The curing chamber shall be so

constructed as to allow full circulation of steam around the

7. Design

entire pipe.

7.1 Design Tables—Design requirements shall be in accor-

9.2.2 Water Curing—Concrete pipe may be water-cured by

dance with Table 1. Wall thickness used may be more than but

covering with water-saturated material or by a system of

not less than the value shown, except as affected by the

perforated pipes, mechanical sprinklers, porous hose, or by any

tolerance herein specified and by the provision for modified

other approved method that will keep the pipe moist during the

design.

specified curing period.

7.2 Modified or Special Design—Manufacturers may sub-

9.2.3 The manufacturer may, at his option, combine the

mit to the owner for approval, prior to manufacture, wall

methods described in 9.2.1 and 9.2.2 provided the specified

thicknesses other than those shown in Table 1. Such pipe shall

strength is attained.

meet all of the physical requirements listed in Section 10 that

9.2.4 Membrane Curing—A sealing membrane conforming

are specified by the owner.

to the requirements of Specification C 309 may be applied and

left intact until the specified strength requirements are met. The

8. Joints

concrete at the time of application shall be within 6°C of the

8.1 The joints shall be of such design and the ends of the

atmospheric temperature. All surfaces shall be kept moist prior

concrete pipe sections so formed, that the pipe can be laid

to the application of the compounds and shall be damp when

together to make a continuous line of pipe compatible with the

the compound is applied.

permissible variations given in Section 11.

9.3 Specials:

9. Manufacture

9.3.1 General Requirements—Special shapes or fittings

9.1 Mixture—The aggregates shall be sized, graded, propor- such as wyes, tees, bends, and adapters for use with concrete

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 14M

pipe conforming to this specification shall conform to the pipe conform to the specified absorption requirements.

applicable requirements for concrete pipe of corresponding 10.5 Permeability Requirement—When subjected to the

class and internal diameter. Joints shall be compatible with permeability test, as specified in Test Methods C 497M, the

those used in adjoining concrete pipes. outer pipe surface of not less than 80 % of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.