ASTM D950-03(2011)

(Test Method)Standard Test Method for Impact Strength of Adhesive Bonds

Standard Test Method for Impact Strength of Adhesive Bonds

SIGNIFICANCE AND USE

Adhesives can fail under a sudden impact load and not under a slowly applied load of the same or greater force.

This test method can be used to compare the sensitivity of various adhesives to suddenly applied loads.

SCOPE

1.1 This test method covers the determination of the comparative impact strength of adhesive bonds in shear, when tested on standard specimens under specified conditions of preparation, conditioning, and testing.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D950 − 03 (Reapproved 2011)

Standard Test Method for

Impact Strength of Adhesive Bonds

This standard is issued under the fixed designation D950; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

INTRODUCTION

The accuracy of the results of strength tests of adhesive bonds will depend on the conditions under

which the bonding process is carried out. Unless otherwise agreed upon between the manufacturer and

the purchaser, the bonding conditions shall be prescribed by the manufacturer of the adhesive. In order

to ensure that complete information is available to the individual conducting the tests, the

manufacturer of the adhesive shall furnish numerical values and other specific information for each of

the following variables:

(1) Procedure for preparation of surfaces prior to application of the adhesive the cleaning and

drying of metal surfaces, and special surface treatments such as sanding which are not specifically

limited by the pertinent test method.

(2) Complete mixing directions for the adhesive.

(3) Conditions for application of the adhesive including the rate of spread or thickness of film,

number of coats to be applied, whether to be applied to one or both surfaces, and the conditions of

drying where more than one coat is required.

(4) Assembly conditions before application of pressure, including the room temperature, length of

time, and whether open or closed assembly is to be used.

(5) Curing conditions, including the amount of pressure to be applied, the length of time under

pressure and the temperature of the assembly when under pressure. It should be stated whether this

temperature is that of the bond line, or of the atmosphere at which the assembly is to be maintained.

(6) Conditioning procedure before testing, unless a standard procedure is specified, including the

length of time, temperature, and relative humidity.

Arange may be prescribed for any variable by the manufacturer of the adhesive if it can be assumed

by the test operator that any arbitrarily chosen value within such a range or any combination of such

values for several variables will be acceptable to both the manufacturer and the purchaser of the

adhesive.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This test method covers the determination of the com-

bility of regulatory limitations prior to use.

parative impact strength of adhesive bonds in shear, when

tested on standard specimens under specified conditions of

2. Referenced Documents

preparation, conditioning, and testing.

2.1 ASTM Standards:

1.2 The values stated in SI units are to be regarded as the

A108 Specification for Steel Bar, Carbon and Alloy, Cold-

standard. The values in parentheses are for information only.

Finished

1.3 This standard does not purport to address all of the

B16/B16M Specification for Free-Cutting Brass Rod, Bar

safety concerns, if any, associated with its use. It is the

and Shapes for Use in Screw Machines

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.80 on Metal

Bonding Adhesives. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2011. Published April 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1952. Last previous edition approved in 2003 as D950 – 03. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D0950-03R11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D950 − 03 (2011)

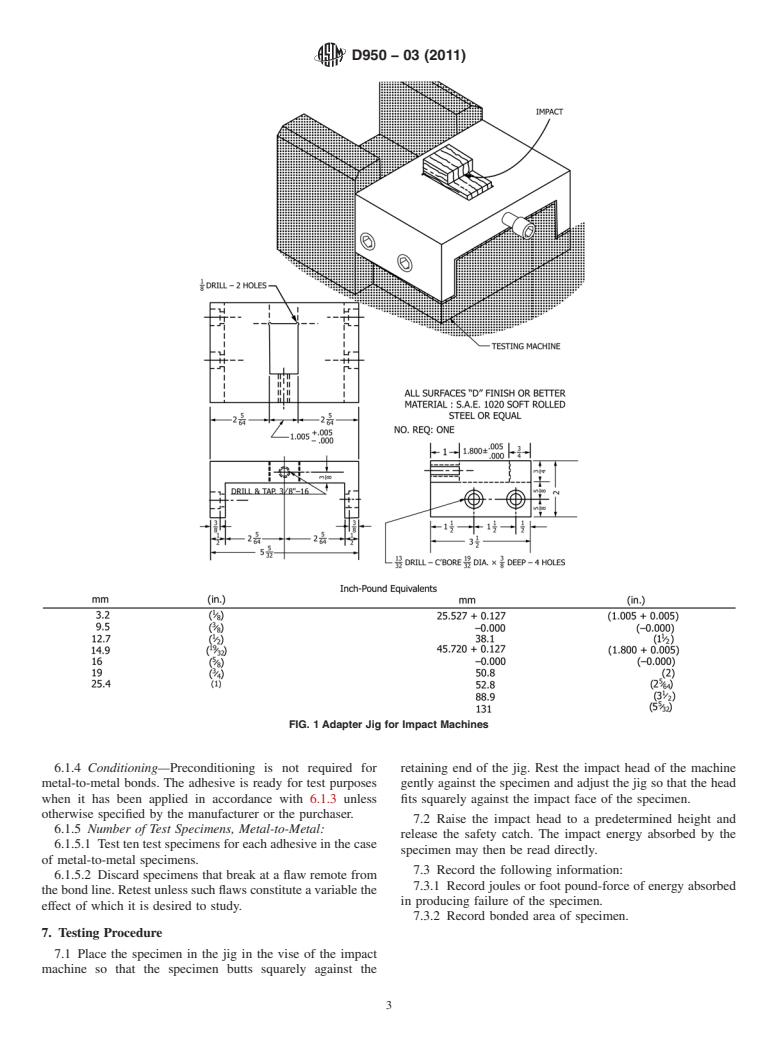

B107/B107M Specification for Magnesium-Alloy Extruded 5.1.1.3 Vise or Bolts to hold the jig rigid and immobile

Bars, Rods, Profiles, Tubes, and Wire under the stress of the testing machine hammer with the total

B133 Specification for Copper Rod, Bar,And Shapes (With- height of the vise, jig, and test specimen such that the lower

drawn 1994) edge of the striking face of the impact head strikes the

B139/B139M Specification for Phosphor Bronze Rod, Bar, specimen as near the adhesive line as possible, preferably

and Shapes within 0.79 mm ( ⁄32 in.). Ordinarily the distance between the

B151/B151M Specification for Copper-Nickel-Zinc Alloy top of the jaws of the vise of the machine and the bottom of the

(Nickel Silver) and Copper-Nickel Rod and Bar striking face of the head is 22 mm (0.866 in.), and proper

B211 Specification for Aluminum and Aluminum-Alloy height of the specimen may be obtained by adjusting its height

Rolled or Cold Finished Bar, Rod, and Wire in the jig.

D905 Test Method for Strength Properties of Adhesive

5.1.2 See Test Methods E23 for additional information on

Bonds in Shear by Compression Loading

impact testing machines and their calibration.

D907 Terminology of Adhesives

5.2 Conditioning Room or Desiccators—A conditioning

E23 Test Methods for Notched Bar Impact Testing of Me-

room capable of maintaining a relative humidity of 50 62%

tallic Materials

at 23 6 1.1°C (73.4 6 2°F), or desiccators filled with a

saturatedsaltsolution(Note1)togivearelativehumidityof50

3. Terminology

6 2 % at 23 6 1.1°C.

3.1 Definitions—Many terms in this test method are defined

in Terminology D907. NOTE 1—A saturated salt solution of calcium nitrate will give approxi-

mately 51 % relative humidity at the test temperature.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 impact strength, n—the energy absorbed expressed in

6. Test Specimens

joules per square metre or foot-pounds-force (ft-lbf) per square

inch, by a specimen of standard design when impacted to

6.1 Metal-to-Metal Specimens:

failure by a single blow of a testing-machine hammer. (Syn-

6.1.1 Material—Metals conforming to the following speci-

onym impact value.)

fications are recommended:

3.2.2 impact value, n—synonym for impact strength.

Metal Designation

Brass ASTM B16/B16M, C36000; half-hard temper

Copper ASTM B133, C11000; hard temper

4. Significance and Use

Aluminum ASTM B211, A92024; G-3

Steel AISI 1020, G10200; cold-finished bar

4.1 Adhesives can fail under a sudden impact load and not

Phosphor bronze ASTM B139/B139M, C54400

under a slowly applied load of the same or greater force.

Magnesium ASTM B107/B107M, AZ61A or M1A-F

Nickel silver ASTM B151/B151M, C77000; quarter-hard

4.2 This test method can be used to compare the sensitivity

of various adhesives to suddenly applied loads.

6.1.1.1 Run tests on adhesives with high-impact strength

preferably on steel to minimize deformation. The reuse of

5. Apparatus

specimens is allowed, provided that the face receiving the

impact is not deformed.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.