ASTM D2509-20a

(Test Method)Standard Test Method for Measurement of Load-Carrying Capacity of Lubricating Grease (Timken Method)

Standard Test Method for Measurement of Load-Carrying Capacity of Lubricating Grease (Timken Method)

SIGNIFICANCE AND USE

5.1 The test method is used widely for specification purposes and is used to differentiate between greases having low, medium, or high levels of extreme pressure characteristics. The results may not correlate with results from service.

SCOPE

1.1 This test method covers the determination of the load-carrying capacity of lubricating greases by means of the Timken Extreme Pressure Tester.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 7.1, 7.2, and 9.4.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2509 − 20a

Standard Test Method for

Measurement of Load-Carrying Capacity of Lubricating

1

Grease (Timken Method)

This standard is issued under the fixed designation D2509; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

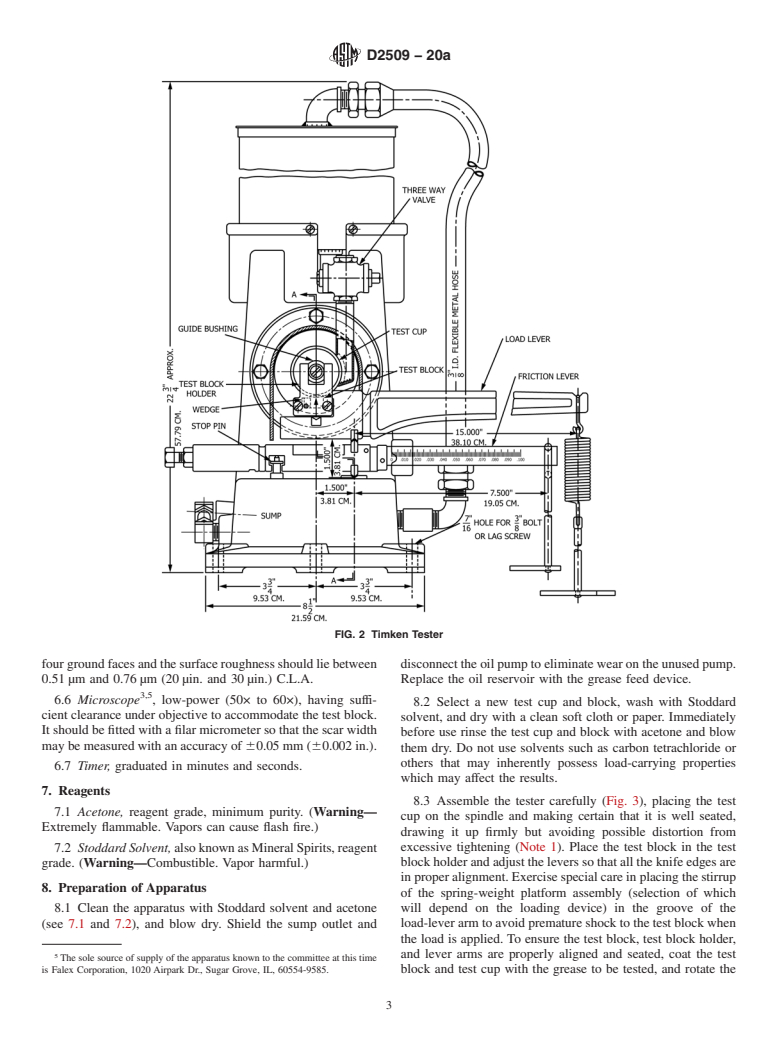

1. Scope* 3.1.2.1 Discussion—Whenthelubricantfilmissubstantially

maintained, a smooth scar is obtained on the test block, but

1.1 This test method covers the determination of the load-

when there is a breakdown of the lubricant film, scoring or

carrying capacity of lubricating greases by means of the

surface failure of the test block takes place as shown in Fig. 1.

Timken Extreme Pressure Tester.

Initssimplestandrecognizedform,scoringischaracterizedby

1.2 The values stated in SI units are to be regarded as the

a wide scar on the test block and by the transfer of metal from

standard. The values given in parentheses are for information

thetestblocktothecontactingsurfaceofthetestcup.Theform

only.

of surface failure more usually encountered, however, consists

1.3 This standard does not purport to address all of the

of a comparatively smooth scar, which shows local damage

safety concerns, if any, associated with its use. It is the

that usually extends beyond the width of the scar. Scratches or

responsibility of the user of this standard to establish appro-

striationsthatoccurinanotherwisesmoothscarandthatdonot

priate safety, health, and environmental practices and deter-

extend beyond the width of the scar are not considered scoring

mine the applicability of regulatory limitations prior to use.

in this test method. The term scuffing is sometimes used as a

For specific warning statements, see 7.1, 7.2, and 9.4.

synonym for scoring.

1.4 This international standard was developed in accor-

3.1.3 seizure or welding, n—localized fusion of rubbing

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the metal, usually indicated by streaks of transferred metal, in-

Development of International Standards, Guides and Recom- creased friction and wear, or unusual noise and vibration.

mendations issued by the World Trade Organization Technical

3.1.4 wear, n—the removal of metal from a rubbing surface

Barriers to Trade (TBT) Committee.

by mechanical action, or by a combination of mechanical and

chemical actions.

2. Referenced Documents

3.2 Definitions of Terms Specific to This Standard:

2.1 ASTM Standards:

G40Terminology Relating to Wear and Erosion 3.2.1 extreme pressure (EP) additives, n—tribologically re-

active species that prevent mating metallic surfaces from

3. Terminology

adhering to each other under concentrated contact conditions

3.1 Definitions:

with high PV values. PV Product, G40

3.1.1 load-carrying capacity, of a lubricating grease, n—the

3.2.1.1 Discussion—The PV value is the product of the

maximum load or pressure that can be sustained by a lubricat-

contact pressure (MPa) and sliding velocity (m/s).

ing grease without failure of the sliding contact surfaces as

3.2.2 extreme pressure (EP) lubricants, n—formulations

evidenced by seizure or welding.

whose effects may become observable at different operating

3.1.1.1 Discussion—The values of load carrying capacity of

conditions,preventingadhesivewearundermixedorboundary

a lubricating grease vary according to test method.

lubrication regimes and are characterized by an increased load

3.1.2 scoring, in tribology, n—a severe form of wear char-

carrying capacity, or increased tribofilm strength.

acterized by the formation of extensive grooves and scratches

in the direction of sliding.

3.2.3 load carrying capacity, n—of a lubricant, the maxi-

mum PV value [PV Limit, G40] that can be sustained by the

lubricant at a reported temperature without failure of the

1

This test method is under the jurisdiction of ASTM Committee D02 on

sliding contact surfaces as evidenced by adhesive wear or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.G0.04 on Functional Tests - Tribology.

localized welding.

Current edition approved Nov. 15, 2020. Published January 2021. Originally

3.2.3.1 Discussion—The PV value is the product of the

approved in 1966. Last previous edition approved in 2020 as D2509–20.

DOI:10.1520/D2509-20A. contact pressure (MPa) and sliding velocity (m/s).

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2509 − 20a

FIG. 1 Test Blocks Sh

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2509 − 20 D2509 − 20a

Standard Test Method for

Measurement of Load-Carrying Capacity of Lubricating

1

Grease (Timken Method)

This standard is issued under the fixed designation D2509; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of the load-carrying capacity of lubricating greases by means of the Timken Extreme

Pressure Tester.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. For specific warning statements, see 7.1, 7.2, and 9.4.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

G40 Terminology Relating to Wear and Erosion

2.2 ASTM Adjuncts:

2

Glossy Prints of Test Blocks Showing Various Types of Scar

3. Terminology

3.1 Definitions:

3.1.1 load-carrying capacity, of a lubricating grease, n—the maximum load or pressure that can be sustained by a lubricating

grease without failure of the sliding contact surfaces as evidenced by seizure or welding.

3.1.1.1 Discussion—

The values of load carrying capacity of a lubricating grease vary according to test method.

3.1.2 scoring, in tribology, n—a severe form of wear characterized by the formation of extensive grooves and scratches in the

direction of sliding.

3.1.2.1 Discussion—

When the lubricant film is substantially maintained, a smooth scar is obtained on the test block, but when there is a breakdown

of the lubricant film, scoring or surface failure of the test block takes place as shown in Fig. 1. In its simplest and recognized form,

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.G0.04 on Functional Tests - Tribology.

Current edition approved May 1, 2020Nov. 15, 2020. Published June 2020January 2021. Originally approved in 1966. Last previous edition approved in 20142020 as

ɛ1

D2509 – 14D2509 – 20. . DOI:10.1520/D2509-20. DOI:10.1520/D2509-20A.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2509 − 20a

FIG. 1 Test Blocks Showing Various Types of Scar

scoring is characterized by a wide scar on the test block and by the transfer of metal from the test block to the contacting surface

of the test cup. The form of surface failure more usually encountered, however, consists of a comparatively smooth scar, which

shows local damage that usually extends beyond the width of the scar. Scratches or striations that occur in an otherwise smooth

scar and that do not extend beyond the width of the scar are not considered scoring in this test method. The term scuffing is

sometimes used as a synonym for scoring.

3.1.3 seizure or welding, n—localized fusion of rubbing metal, usually indicated by streaks of transferred metal, increased friction

and wear, or unusual noise and vibration.

3.1.4 wear, n—the removal of metal from a rubbing surface by mechanical action, or by a combination of mechanical and chemical

actions.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 extreme pressure (EP) additives, n—tribologically reactive species that prevent mating metallic surfaces from adhering to

each other under concentrated contact conditions with high PV values. PV Product, G40

3.2.1.1 Discussion—

The PV value is the product of the contact pressure (MPa) and sliding velocity (m/s).

3.2.2 extreme pressure (EP) lubricants, n—formulations whose effects may become observable at different operating conditions,

preventing adhesive wear un

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.