ASTM D7082-04(2010)

(Specification)Standard Specification for Polyethylene Stay In Place Form System for End Walls for Drainage Pipe

Standard Specification for Polyethylene Stay In Place Form System for End Walls for Drainage Pipe

ABSTRACT

This specification addresses the requirements for polyethylene stay in place forms for end walls or head walls for use with standard storm drainage systems. The wall form system consists of a base wall form, a cap, an optional riser to adjust the height of the wall above the pipe, and an optional adaptor to adjust the pipe opening to accommodate smaller pipe sizes. The form system is manufactured using the rotational molding process and is available in different colors. The plastic shall be tested for its deflection temperature, flexural properties, melt flow rate, and density.

SCOPE

1.1 This specification addresses the requirements for polyethylene stay in place forms for end walls or head walls for use with standard storm drainage systems.

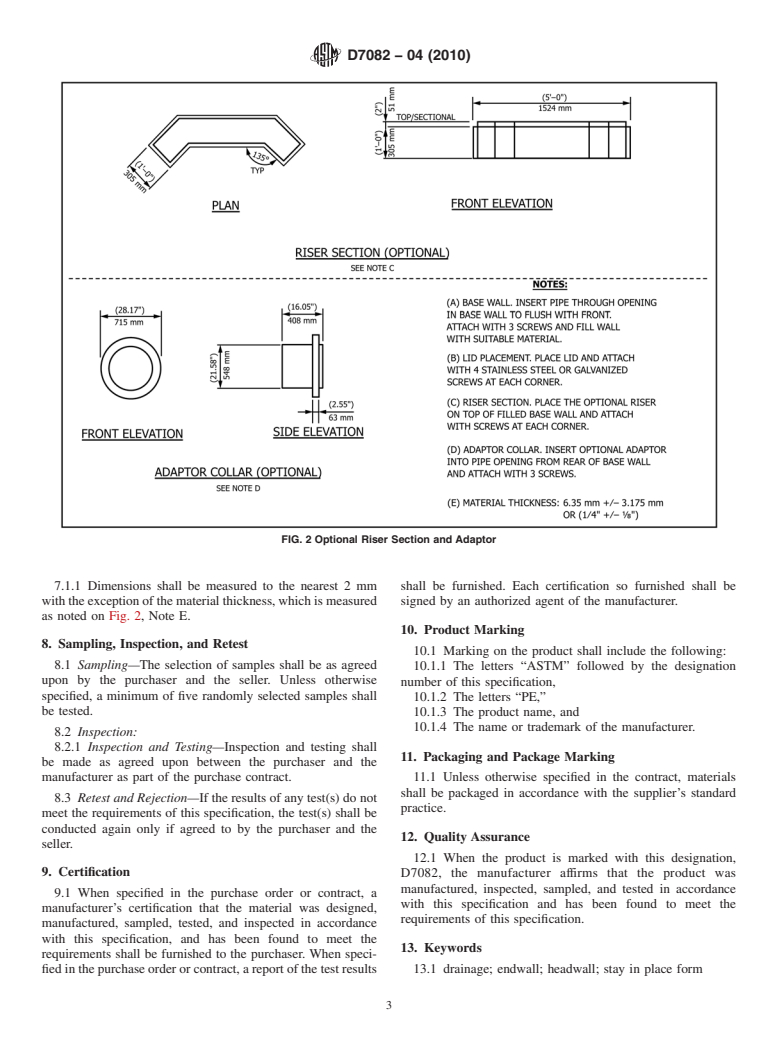

1.2 The wall form system consists of a base wall form, a cap, an optional riser to adjust the height of the wall above the pipe, and an optional adaptor to adjust the pipe opening to accommodate smaller pipe sizes.

1.3 The form system is manufactured using the rotational molding process and is available in different colors.

1.4 The values stated in SI units are to be regarded as the standard, the inch-pounds in brackets are given for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

Note 1—There is no known ISO equivalent to this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7082 −04(Reapproved 2010) An American National Standard

Standard Specification for

Polyethylene Stay In Place Form System for End Walls for

Drainage Pipe

This standard is issued under the fixed designation D7082; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1505 Test Method for Density of Plastics by the Density-

Gradient Technique

1.1 This specification addresses the requirements for poly-

D1600 Terminology forAbbreviatedTerms Relating to Plas-

ethylene stay in place forms for end walls or head walls for use

tics

with standard storm drainage systems.

D1693 Test Method for Environmental Stress-Cracking of

1.2 The wall form system consists of a base wall form, a

Ethylene Plastics

cap, an optional riser to adjust the height of the wall above the

D4883 Test Method for Density of Polyethylene by the

pipe, and an optional adaptor to adjust the pipe opening to

Ultrasound Technique

accommodate smaller pipe sizes.

D7209 Guide for Waste Reduction, Resource Recovery, and

Use of Recycled Polymeric Materials and Products (With-

1.3 The form system is manufactured using the rotational

molding process and is available in different colors. drawn 2015)

1.4 The values stated in SI units are to be regarded as the

3. Terminology

standard, the inch-pounds in brackets are given for information

3.1 Definitions:

only.

3.1.1 Definitions used in this specification are in accordance

1.5 This standard does not purport to address all of the

with definitions in Terminology D883 and abbreviations in

safety concerns, if any, associated with its use. It is the

accordance with Terminology D1600 unless otherwise indi-

responsibility of the user of this standard to establish appro-

cated.

priate safety and health practices and determine the applica-

3.1.2 end wall—a wall installed at the outlet of a storm

bility of regulatory requirements prior to use.

drainage pipe.

NOTE 1—There is no known ISO equivalent to this standard.

3.1.3 head wall—a wall installed at the inlet of a storm

drainage pipe.

2. Referenced Documents

4. Ordering Information

2.1 ASTM Standards:

D638 Test Method for Tensile Properties of Plastics

4.1 Number and color of base wall forms,

D648 Test Method for Deflection Temperature of Plastics

4.2 Number and color of riser forms,

Under Flexural Load in the Edgewise Position

4.3 Number and color of caps, and

D790 Test Methods for Flexural Properties of Unreinforced

and Reinforced Plastics and Electrical Insulating Materi-

4.4 Number, color and size of adaptors.

als

5. Materials and Manufacture

D883 Terminology Relating to Plastics

D1238 Test Method for Melt Flow Rates of Thermoplastics

5.1 The material used shall be a polyethylene meeting the

by Extrusion Plastometer

criteria in Table 1.

5.2 Only virgin materials (Guide D7209) shall be used.

This specification is under the jurisdiction of ASTM Committee D20 on

5.3 This product shall be manufactured using a rotational

Plastics and is the direct responsibility of Subcommittee D20.24 on Plastic Building

molding process.

Products.

Current edition approved April 1, 2010. Published June 2010. Originally

6. Requirements

approved in 2004. Last previous edition approved in 2004 as D7082 - 04. DOI:

10.1520/D7082-04R10.

6.1 Wall System Description:

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7082−04 (2010)

TABLE 1 Material Specifications

Resin Properties ASTM Method Value Units

Density (Range) D1505 / D4883 0.9335 – 0.9395 g/cc

Melt Index (Range) D1238 Cond. 190°C, 2.16 kg 3.5 – 7.5 g/10 min

Environmental Stress Crack Resistance (ESCR), F D1693, Cond. A 275 Hr

100 % lgepal 55 Hr

10 % lgepal

Flexural Modulus (Minimum) D790 at 1 % secant Procedure B 600 (87) Mpa (kpsi)

Tensile Strength at Yield (Minimum) D638, Type IV specimen 17.2 (2500) Mpa (psi)

Tensile Break Elongation (Minimum) 50.8 mm/min @ 3.12 mm thick 420 %

(2 in./min @ ⁄8 in. thick)

Deflection Temperature (Minimum) D648 50 °C

@ 0.455 MPa (66 psi) 35 °C

@ 1.82 MPa (264 psi)

6.1.1 Base wall form is hollow with opening at the top to 6.2 Workman

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.