ASTM C494/C494M-05a

(Specification)Standard Specification for Chemical Admixtures for Concrete

Standard Specification for Chemical Admixtures for Concrete

SCOPE

1.1 This specification covers materials for use as chemical admixtures to be added to hydraulic-cement concrete mixtures in the field for the purpose or purposes indicated for the seven types as follows:

1.1.1 Type A—Water-reducing admixtures,

1.1.2 Type B—Retarding admixtures,

1.1.3 Type C—Accelerating admixtures,

1.1.4 Type D—Water-reducing and retarding admixtures,

1.1.5 Type E—Water-reducing and accelerating admixtures,

1.1.6 Type F—Water-reducing, high range admixtures, and

1.1.7 Type G—Water-reducing, high range, and retarding admixtures.

1.2 This specification stipulates tests of an admixture with suitable concreting materials as described in 11.1-11.3 or with cement, pozzolan, aggregates, and an air-entraining admixture proposed for specific work (11.4). Unless specified otherwise by the purchaser, the tests shall be made using concreting materials as described in 11.1-11.3.

Note 1—It is recommended that, whenever practicable, tests be made using the cement, pozzolan, aggregates, air-entraining admixture, and the mixture proportions, batching sequence, and other physical conditions proposed for the specific work (11.4) because the specific effects produced by chemical admixtures may vary with the properties and proportions of the other ingredients of the concrete. For instance, Types F and G admixtures may exhibit much higher water reduction in concrete mixtures having higher cement factors than that listed in 12.1.1.

Mixtures having a high range water reduction generally display a higher rate of slump loss. When high-range admixtures are used to impart increased workability (6 to 8-in. slump [150 to 200-mm]), the effect may be of limited duration, reverting to the original slump in 30 to 60 min depending on factors normally affecting rate of slump loss. The use of chemical admixtures to produce high-slump (flowing) concrete is covered by Specification C 1017.

Note 2—The purchaser should ensure that the admixture supplied for use in the work is equivalent in composition to the admixture subjected to test under this specification (see Section 6, Uniformity and Equivalence).

Note 3—Admixtures that contain relatively large amounts of chloride may accelerate corrosion of prestressing steel. Compliance with the requirements of this specification does not constitute assurance of acceptability of the admixture for use in prestressed concrete.

1.3 This specification provides for three levels of testing.

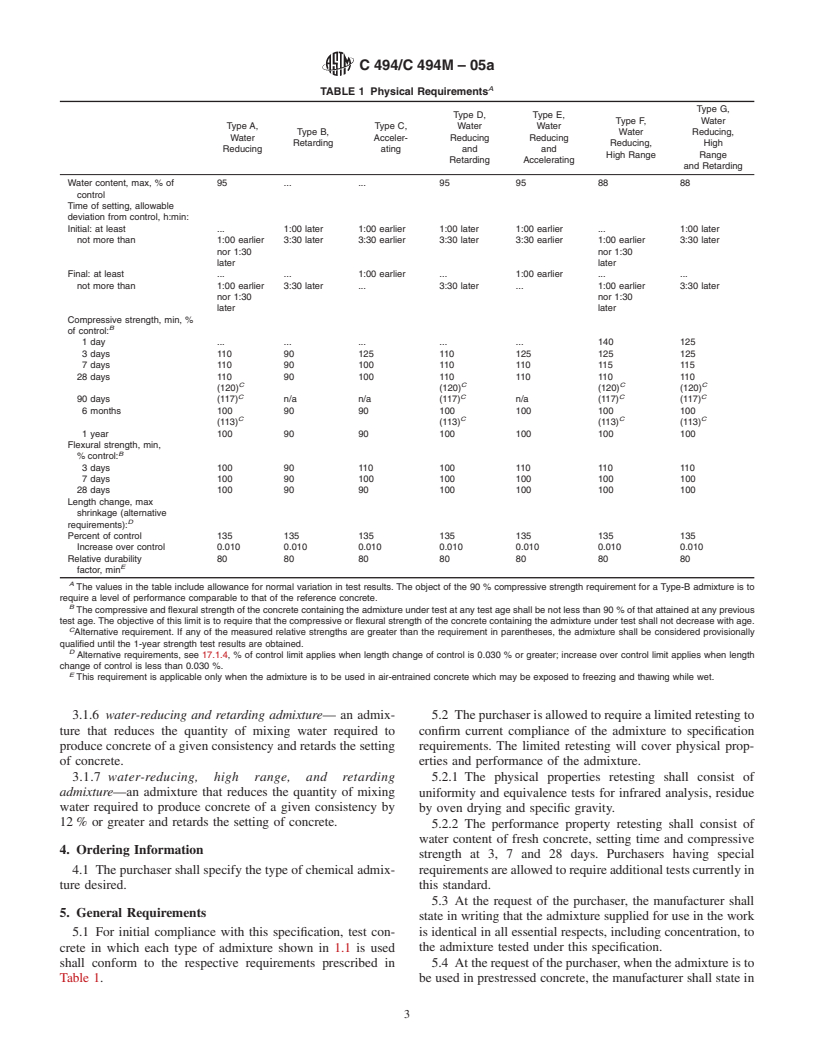

1.3.1 Level 1—During the initial approval stage, proof of compliance with the performance requirements defined in Table 1 demonstrates that the admixture meets the requirements of this specification. Admixtures (except for Types B, C, and E) shall qualify for provisional compliance when the alternative compressive strength requirements in Table 1 are met. If subsequent test results at 6 months or one year fail to meet the standard requirement of 100 % of reference strength, the compliance of the admixture to this standard is withdrawn and all users of the admixture shall be notified immediately. Uniformity and equivalence tests of Section 6 shall be carried out to provide results against which later comparisons can be made (See Note 4).

Note 0&38212;Allowing for provisional compliance while retaining longer term compressive strength requirements promotes more rapid qualification of new materials, but also provides assurance that new admixture technologies will not exhibit unexpected longer term performance. The alternative compressive strength requirements in are based on statistical analysis of 103 Specification C 494/C 494M evaluation tests. The alternative requirements correspond to a 99 % probability of passing subsequent test age requirements.

1.3.2 Level 2—Limited retesting is described in 5.2, 5.2.1 and 5.2.2. Proof of compliance with the requirements of demonstrates continued conformity of the admixture with the requirements of the specification.

1.3.3 Level 3—For acceptance of a lot o...

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 494/C 494M – 05a

Standard Specification for

1

Chemical Admixtures for Concrete

ThisstandardisissuedunderthefixeddesignationC494/C494M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

test under this specification (see Section 6, Uniformity and Equivalence).

1. Scope

NOTE 3—Admixtures that contain relatively large amounts of chloride

1.1 This specification covers materials for use as chemical

may accelerate corrosion of prestressing steel. Compliance with the

admixtures to be added to hydraulic-cement concrete mixtures

requirements of this specification does not constitute assurance of accept-

in the field for the purpose or purposes indicated for the seven

ability of the admixture for use in prestressed concrete.

types as follows:

1.3 This specification provides for three levels of testing.

1.1.1 Type A—Water-reducing admixtures,

1.3.1 Level 1—During the initial approval stage, proof of

1.1.2 Type B—Retarding admixtures,

compliance with the performance requirements defined in

1.1.3 Type C—Accelerating admixtures,

Table 1 demonstrates that the admixture meets the require-

1.1.4 Type D—Water-reducing and retarding admixtures,

mentsofthisspecification.Admixtures(exceptforTypesB,C,

1.1.5 Type E—Water-reducing and accelerating admixtures,

and E) shall qualify for provisional compliance when any of

1.1.6 Type F—Water-reducing, high range admixtures, and

the alternative compressive strength requirements in Table 1

1.1.7 Type G—Water-reducing, high range, and retarding

are met. If subsequent test results at 6 months or one year fail

admixtures.

to meet the standard requirement of 100% of reference

1.2 This specification stipulates tests of an admixture with

strength, the compliance of the admixture to this standard is

suitable concreting materials as described in 11.1-11.3 or with

withdrawn and all users of the admixture shall be notified

cement, pozzolan, aggregates, and an air-entraining admixture

immediately. Uniformity and equivalence tests of Section 6

proposed for specific work (11.4). Unless specified otherwise

shall be carried out to provide results against which later

by the purchaser, the tests shall be made using concreting

comparisons can be made (See Note 4).

materials as described in 11.1-11.3.

NOTE 4—Allowing for provisional compliance while retaining longer

NOTE 1—It is recommended that, whenever practicable, tests be made

termcompressivestrengthrequirementspromotesmorerapidqualification

using the cement, pozzolan, aggregates, air-entraining admixture, and the

of new materials, but also provides assurance that new admixture

mixture proportions, batching sequence, and other physical conditions

technologies will not exhibit unexpected longer term performance. The

proposedforthespecificwork(11.4)becausethespecificeffectsproduced

alternative compressive strength requirements in Table 1 are based on

by chemical admixtures may vary with the properties and proportions of

statistical analysis of 103 Specification C494/C494M evaluation tests.

the other ingredients of the concrete. For instance, Types F and G

The alternative requirements correspond to a 99% probability of passing

admixturesmayexhibitmuchhigherwaterreductioninconcretemixtures 2

subsequent test age requirements.

having higher cement factors than that listed in 12.1.1.

1.3.2 Level 2—Limited retesting is described in 5.2, 5.2.1

Mixtureshavingahighrangewaterreductiongenerallydisplayahigher

rate of slump loss. When high-range admixtures are used to impart and 5.2.2. Proof of compliance with the requirements of Table

increased workability (6 to 8-in. slump [150 to 200–mm]), the effect may

1demonstratescontinuedconformityoftheadmixturewiththe

be of limited duration, reverting to the original slump in 30 to 60 min

requirements of the specification.

depending on factors normally affecting rate of slump loss. The use of

1.3.3 Level 3—For acceptance of a lot or for measuring

chemical admixtures to produce high-slump (flowing) concrete is covered

uniformity within or between lots, when specified by the

by Specification C1017.

purchaser, the uniformity and equivalence tests of Section 6

NOTE 2—The purchaser should ensure that the admixture supplied for

shall be used.

use in the work is equivalent in composition to the admixture subjected to

1.4 The values stated in either inch-pound or SI units shall

be regarded separately as standard. The values stated in each

1

This specification is under the jurisdiction of ASTM Committee C09 on

Concrete Aggregates and is the direct responsibility

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.