ASTM D5861-07(2017)

(Guide)Standard Guide for Significance of Particle Size Measurements of Coating Powders

Standard Guide for Significance of Particle Size Measurements of Coating Powders

SIGNIFICANCE AND USE

4.1 This guide describes the need to specify the measuring technique used whenever quoting the particle size distribution of a coating powder.

4.2 This guide is for use by manufacturers of coating powders and by specifiers for process control and product acceptance.

SCOPE

1.1 This guide covers the significance of referencing the techniques used whenever specifying the particle size distribution of a coating powder.

1.2 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5861 −07 (Reapproved 2017)

Standard Guide for

Significance of Particle Size Measurements of Coating

1

Powders

This standard is issued under the fixed designation D5861; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.2 This guide is for use by manufacturers of coating

powders and by specifiers for process control and product

1.1 This guide covers the significance of referencing the

acceptance.

techniques used whenever specifying the particle size distribu-

tion of a coating powder.

5. Particle Size of Coating Powders

1.2 This international standard was developed in accor-

5.1 The size of the particles comprising a coating powder

dance with internationally recognized principles on standard-

plays a critical role in the fluidization, application, and recla-

ization established in the Decision on Principles for the

mation of the powder, and in the final appearance of the coated

Development of International Standards, Guides and Recom-

part. Coating powders are comprised of particles of widely

mendations issued by the World Trade Organization Technical

differing sizes, from as low as about 1 µm to as high as about

Barriers to Trade (TBT) Committee.

150 µm. Collectively, the individual particles form a size

2. Referenced Documents distribution, defined by the percentages of particles present of

2 a given size or within a given size range. There are generally

2.1 ASTM Standards:

few particles at the low and high ends of the distribution, the

D1921 Test Methods for Particle Size (Sieve Analysis) of

majority being in the 25 to 65-µm range. The distribution can

Plastic Materials

be described by an actual plot of the particle size distribution,

D3451 Guide for Testing Coating Powders and Powder

or by numerical attributes of the distribution, such as the

Coatings

calculated values of its mean, median, mode, and span. The

3. Terminology mean represents the average particle size (the sum of all the

particle sizes divided by the number of particles). The median

3.1 Definitions:

represents a size such that half the particles are larger than it

3.1.1 coating powders, n—these are finely divided particles

and half the particles are smaller than it. The mode represents

of organic polymer that generally contain pigments, fillers, and

the most frequently occurring particle size. For all coating

additives and that remain finely divided during storage under

powders these three figures are numerically different. The span

suitable conditions.

is an indication of the width of the particle size distribution.

3.1.2 powder coatings, n—these are coatings that are

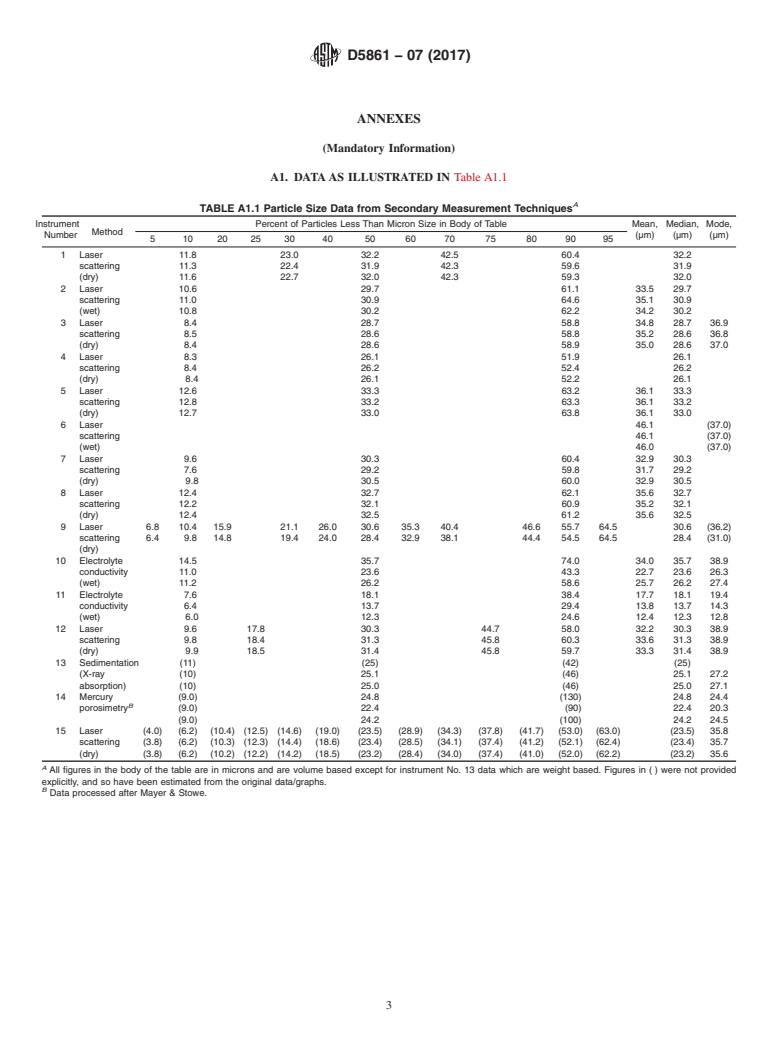

Referring to Table A1.1, the span is calculated by subtracting

protective, decorative, or both; and that are formed by the

the d10 from the d90 and then dividing by the d50 or median

application of a coating powder to a substrate and fused into

particle size.

continuous films by the application of heat or radiant energy.

5.2 The particle size distribution is generally chosen by the

4. Significance and Use

coating powder manufacturer from knowledge of the applica-

tion technique, the required cured film thickness, surface

4.1 This guide describes the need to specify the measuring

appearance, and performance. Once the desired particle size

technique used whenever quoting the particle size distribution

distribution has been selected, it needs to be monitored to

of a coating powder.

ensure consistency from batch to batch and, indeed, within

each batch. Occasionally the coating powder applicator may

1

This guide is under the jurisdiction of ASTM Committee D01 on Paint and

specify the particle size from knowledge of the specific

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.51 on Powder Coatings.

application equipment or customer requirements, or both.

Current edition approved June 1, 2017. Published June 2017. Originally

5.3 It is important for all involved to understand that the

approved in 1995. Last previous edition approved in 2013 as D5861 – 07 (2013).

DOI: 10.1520/D5861-07R17.

numerical data comprising a particle size distribution are

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

significantlydependentonthetechniqueusedtoobtainthem.It

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

is, therefore, of little use to quote or specify a particle size

Standards volume information, refer to the standard’s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.