ASTM D3433-99(2012)

(Test Method)Standard Test Method for Fracture Strength in Cleavage of Adhesives in Bonded Metal Joints

Standard Test Method for Fracture Strength in Cleavage of Adhesives in Bonded Metal Joints

SIGNIFICANCE AND USE

Note 2—Crack growth in adhesive bond specimens can proceed in two ways: (1) by a slow-stable extension where the crack velocity is dictated by the crosshead rate or (2) by a run-arrest extension where the stationary crack abruptly jumps ahead outrunning the crosshead-predicted rate. The first type of crack extension is denoted flat; the second type peaked because of the appearance of the autographic record. The flat behavior is characteristic of adhesives or test temperatures, or both, for these adhesives where there is no difference between initiation, G1c, and arrest, G1a. For example, the rubber modified film adhesives tested above − 17.8°C (0°F) all exhibit flat autographic records. Peaked curves are exhibited for all modified materials tested below −73°C (−100°F) and in general for unmodified epoxies.

It should be noted that both peaked and flat behaviors are determined from a crack-length-independent specimen. For other specimens or structures where G increases with a at constant load the onset of crack growth would result in rapid complete fracturing whatever the adhesive characteristics.

5.1 The property G1c (and G1a if relevant) determined by this test method characterizes the resistance of a material to slow-stable or run-arrest fracturing in a neutral environment in the presence of a sharp crack under severe tensile constraint, such that the state of stress near the crack front approaches tritensile plane strain, and the crack-tip plastic region is small compared with the crack size and specimen dimensions in the constraint direction. It has not been proven that tough adhesive systems fully meet this criteria. Therefore, data developed using equations based on this assumption may not represent plane-strain fracture values. Comparison of fracture toughness between adhesive systems widely different in brittleness or toughness should take this into consideration. In general, systems of similar type toughness (3, 4, 7, 8, 10) can be compared as can ...

SCOPE

1.1 This test method(1, 2, 5, 6, 9)2 covers the determination of fracture strength in cleavage of adhesives when tested on standard specimens and under specified conditions of preparation and testing (Note 1).

1.2 This test method is useful in that it can be used to develop design parameters for bonded assemblies. Note 1—While this test method is intended for use in metal-to-metal applications it may be used for measuring fracture properties of adhesives using plastic adherends, provided consideration is given to the thickness and rigidity of the plastic adherends.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3433 − 99 (Reapproved 2012)

Standard Test Method for

Fracture Strength in Cleavage of Adhesives in Bonded Metal

Joints

This standard is issued under the fixed designation D3433; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B36/B36MSpecification for Brass Plate, Sheet, Strip, And

2 Rolled Bar

1.1 Thistestmethod (1, 2, 3, 4, 5) coversthedetermination

B152/B152MSpecification for Copper Sheet, Strip, Plate,

of fracture strength in cleavage of adhesives when tested on

and Rolled Bar

standard specimens and under specified conditions of prepara-

B209 Specification for Aluminum and Aluminum-Alloy

tion and testing (Note 1).

Sheet and Plate

1.2 This test method is useful in that it can be used to

B265Specification for Titanium and Titanium Alloy Strip,

develop design parameters for bonded assemblies.

Sheet, and Plate

D907Terminology of Adhesives

NOTE 1—While this test method is intended for use in metal-to-metal

applications it may be used for measuring fracture properties of adhesives E4Practices for Force Verification of Testing Machines

using plastic adherends, provided consideration is given to the thickness

E399Test Method for Linear-Elastic Plane-Strain Fracture

and rigidity of the plastic adherends.

Toughness K of Metallic Materials

Ic

1.3 The values stated in SI units are to be regarded as the

3. Terminology

standard. The values given in parentheses are for information

only. 3.1 Definitions: Many of the terms used in this test method

are defined in Terminology D907.

1.4 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.2.1 crack-extension force, G,—the system isolated (fixed

responsibility of the user of this standard to establish appro-

load-displacement) loss of stress field energy for an infinitesi-

priate safety and health practices and determine the applica-

mal increase, d A, of separational area. In equation form,

bility of regulatory limitations prior to use.

GdA52dU (1)

T

2. Referenced Documents

where U =total elastic energy in the system (component or

T

2.1 ASTM Standards:

test specimen). In the test specimens of this method, the crack

A167 Specification for Stainless and Heat-Resisting

front is nearly straight through the specimen thickness, B,so

Chromium-Nickel Steel Plate, Sheet, and Strip (With-

that dA=B da, where da is an infinitesimal forward motion of

drawn 2014)

the leading edge of the crack. Completely linear-elastic behav-

A366/A366M Specification for Commercial Steel (CS)

ior is assumed in the calculations (See AnnexA1)of G used in

Sheet, Carbon, (0.15 Maximum Percent) Cold-Rolled

this method, an allowable assumption when the zone of

(Withdrawn 2000)

nonlinear deformation in the adhesive is small relative to

specimen dimensions and crack size.

3.2.1.1 When the shear stress on the plane of crack and

forward to its leading edge is zero, the stress state is termed

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.80 on Metal

“opening mode.” The symbol for an opening mode G is G for

I

Bonding Adhesives.

plane-strain and G when the connotation of plane-strain is not

Current edition approved Oct. 1, 2012. Published October 2012. Originally

wanted.

approved in 1975. Last previous edition approved in 2005 as D3433–99 (2005).

DOI: 10.1520/D3433-99R12. 3.2.2 opening mode fracture toughness, G —thevalueof G

1c

The boldface numbers in parentheses refer to the references at the end of this

justpriortoonsetofrapidfracturingwhen Gisincreasingwith

test method.

time.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.3 opening mode crack arrest toughness, G —the value

1a

Standards volume information, refer to the standard’s Document Summary page on

of Gjustafterarrestofarun-arrestsegmentofcrackextension.

the ASTM website.

3.2.3.1 It is assumed that the dimensions of the part con-

The last approved version of this historical standard is referenced on

www.astm.org. taining the crack are large compared to the run-arrest segment

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3433 − 99 (2012)

whichprecedescrackarrestandthatthequasi-staticstressfield basis for development of this test method in terms of linear

enclosingthecracktipjustaftercrackarrestcanbeassumedin elastic fracture mechanics may be found in Refs (4) and (8).

calculating G . 5.1.1 Cyclic loads can cause crack extension at G values

1a 1

less than G value. Furthermore, progressive stable crack

1c

4. Summary of Test Method

extension under cyclic or sustained load may be promoted by

the presence of certain environments.Therefore, application of

4.1 This test method involves cleavage testing bonded

G in the design of service components should be made with

1c

specimenssuchthatacrackismadetoextendbyatensileforce

awareness of the G increase for a prior crack which may occur

acting in a direction normal to the crack surface.

in service due to slow-stable crack-extension.

4.2 Load versus load-displacement across the bondline is

5.2 This test method can serve the following purposes:

recordedautographically.The G and G valuesarecalculated

1 1a

5.2.1 In research and development to establish, in quantita-

from this load by equations that have been established on the

tive terms, significant to service performance, the effects of

basis of elastic stress analysis of specimens of the type

adhesive composition, primers, adherend surface treatments,

described below. The validity of the determination of G and

1c

supporting adhesive carriers (scrim), processing variables, and

G values by this test method depends upon the establishment

1a

environmental effects.

of a sharp-crack condition in the bondline in a specimen of

5.2.2 In service evaluation to establish the suitability of an

adequate size. This test method will measure the fracture

adhesive system for a specific application for which the stress

strength of a bonded joint which is influenced by adherend

conditions are prescribed and for which maximum flaw sizes

surface condition, adhesive, adhesive-adherend interactions,

can be established with confidence.

primers, adhesive-supporting scrims, etc., and in which of the

5.2.3 For specifications of acceptance and manufacturing

above possible areas the crack grows.

quality control, but only when there is a sound basis for

specification of minimum G values. The specification of G

5. Significance and Use

1c 1c

NOTE2—Crackgrowthinadhesivebondspecimenscanproceedintwo values in relation to a particular application should signify that

ways: (1) by a slow-stable extension where the crack velocity is dictated

a fracture control study has been conducted on the component

by the crosshead rate or (2) by a run-arrest extension where the stationary

in relation to the expected history of loading and environment,

crack abruptly jumps ahead outrunning the crosshead-predicted rate. The

and in relation to the sensitivity and reliability of the crack

first type of crack extension is denoted flat; the second type peaked

detection procedures that are to be applied prior to service and

because of the appearance of the autographic record. The flat behavior is

characteristic of adhesives or test temperatures, or both, for these subsequently during the anticipated life.

adhesives where there is no difference between initiation, G , and arrest,

1c

G . For example, the rubber modified film adhesives tested

1a

6. Apparatus

above−17.8°C (0°F) all exhibit flat autographic records. Peaked curves

are exhibited for all modified materials tested below −73°C (−100°F) and

6.1 Testing Machine, conforming to the requirements of

in general for unmodified epoxies.

Practices E4. Select the testing machine such that the cracking

It should be noted that both peaked and flat behaviors are determined

load of the specimens falls between 15 and 85% of the

from a crack-length-independent specimen. For other specimens or

full-scale capacity and that is provided with a suitable pair of

structures where G increases with a at constant load the onset of crack

growth would result in rapid complete fracturing whatever the adhesive self-aligning pinned fixtures to hold the specimen.

characteristics.

6.2 Ensure that the pinned fixtures and attachments are

5.1 The property G (and G if relevant) determined by

1c 1a constructed such that they will move into alignment with the

this test method characterizes the resistance of a material to

test specimen as soon as the load is applied.

slow-stable or run-arrest fracturing in a neutral environment in

6.3 For a discussion of the calculation of separation rates

the presence of a sharp crack under severe tensile constraint,

see Annex A1.

such that the state of stress near the crack front approaches

tritensile plane strain, and the crack-tip plastic region is small

7. Test Specimens

compared with the crack size and specimen dimensions in the

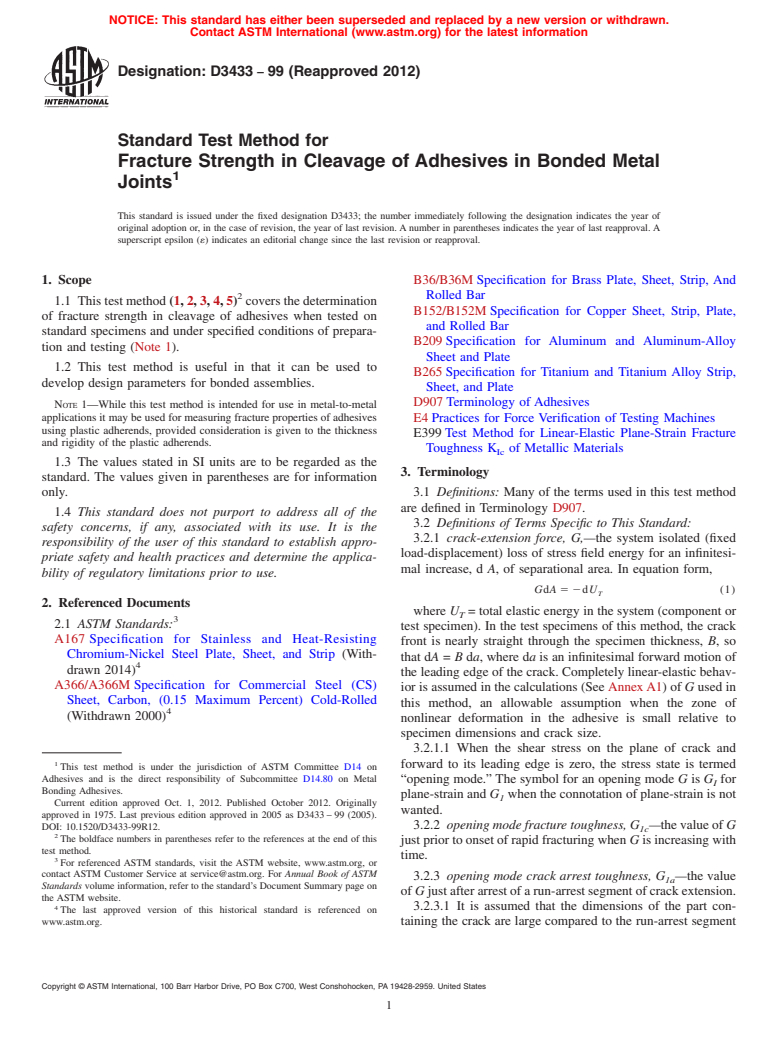

7.1 Flat Adherend, conforming to the form and dimensions

constraint direction. It has not been proven that tough adhesive

shown in Fig. 1, cut from test joints as in Fig. 2, prepared as

systems fully meet this criteria. Therefore, data developed

prescribed in Section 8.

using equations based on this assumption may not represent

plane-strain fracture values. Comparison of fracture toughness

7.2 Contoured Double-Cantilever Beam (CDCB), conform-

between adhesive systems widely different in brittleness or

ing to the form and dimensions shown in Fig. 3.

toughness should take this into consideration. In general,

7.3 Thefollowinggradesofmetalsaresuggestedforthetest

systems of similar type toughness (6, 7, 8, 9, 10) can be

specimens (Note 3):

compared as can the effect of environment on toughness of a

Metal ASTM Designation

single system. A G value is believed to represent a lower

1c

Brass B36/B36M, Alloy 260 (4), quarter hard tem-

limiting value of fracture toughness for a given temperature,

per

strainrate,andadhesiveconditionasdefinedbymanufacturing Copper B152/B152M, cold rolled, Type 110, hard

temper

variables. This value may be used to estimate the relation

Aluminum B209, Alclad 2024, T3 temper, mill finish

between failure stress and defect size for a material in service

Steel A366/A366M, regular matte finish

wherein the conditions of high constraint described above Corrosion-resisting steel A167, Type 304, No. 2B finish

Titanium B265, Grade 3

would be expected. Background information concerning the

D3433 − 99 (2012)

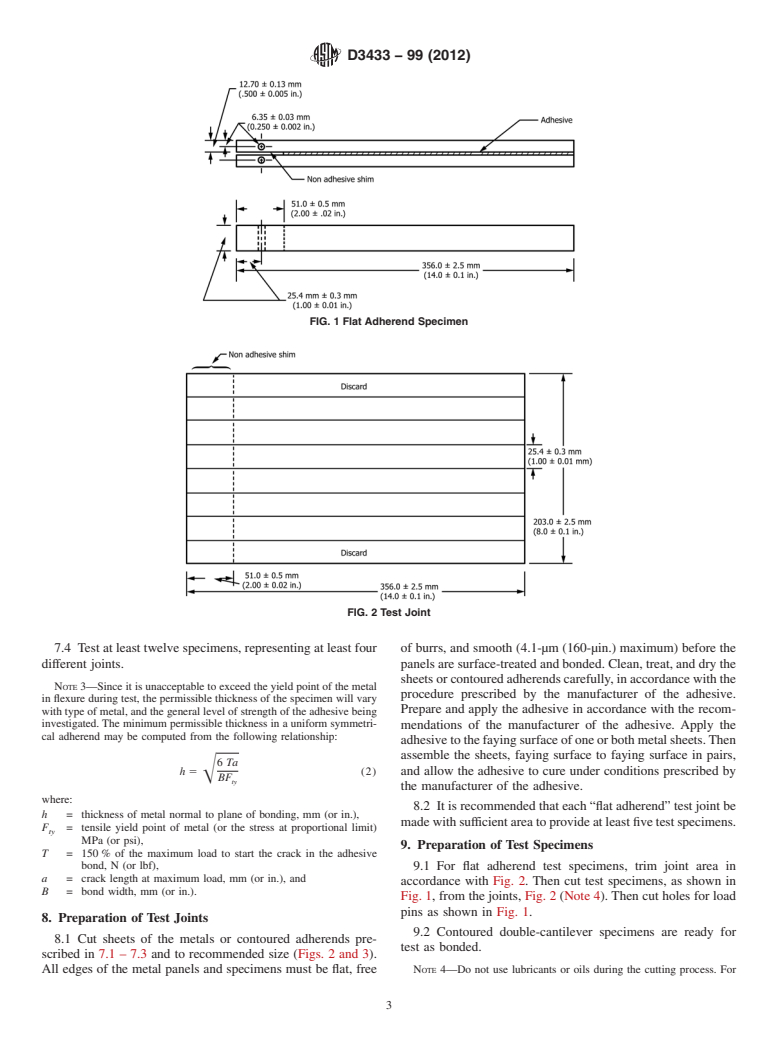

FIG. 1 Flat Adherend Specimen

FIG. 2 Test Joint

7.4 Test at least twelve specimens, representing at least four of burrs, and smooth (4.1-µm (160-µin.) maximum) before the

different joints. panelsaresurface-treatedandbonded.Clean,treat,anddrythe

sheetsorcontouredadherendscarefully,inaccordancewiththe

NOTE 3—Since it is unacceptable to exceed the yield point of the metal

procedure prescribed by the manufacturer of the adhesive.

in flexure during test, the permissible thickness of the specimen will vary

Prepare and apply the adhesive in accordance with the recom-

with type of metal, and the general level of strength of the adhesive being

investigated. The minimum permissible thickness in a uniform symmetri-

mendations of the manufacturer of the adhesive. Apply the

cal adherend may be computed from the following relationship:

adhesivetothefayingsurfaceofoneorbothmetalsheets.Then

assemble the sheets, faying surface to faying surface in pairs,

6 Ta

h 5 (2) and allow the adhesive to cure under conditions prescribed by

Œ

BF

ty

the manufacturer of the adhesive.

where:

8.2 Itisrecommendedthateach“flatadherend”testjointbe

h = thickness of metal normal to plane of bonding, mm (or in.),

madewithsufficientareatoprovideatleastfivetestspecimens.

F = tensile yield point of metal (or the stress at proportional limit)

ty

MPa (or psi),

9. Preparation of Test Specimens

T = 150% of the maximum load to start the crack in the adhesive

bond, N (or lbf), 9.1 For flat adherend test specimens, trim joint area in

a = crack length at maximum load, mm (or in.), and

accordance with Fig. 2. Then cut test specimens, as shown in

B = bond width, mm (or in.).

Fig. 1, from the joints, Fig. 2 (Note 4). Then cut holes for load

pins as shown in Fig. 1.

8. Preparation of Test Joints

9.2 Contoured double-cantilever specimens are ready for

8.1 Cut sheets of the metals or contoured adherends pre-

test as bonded.

scribed in 7.1 – 7.3 and to recommended size (Figs. 2 and 3).

All edges of the metal panels and specimens must be flat, free NOTE 4—Do not use lubricants or oils during the cutting process. For

D3433 − 99 (2012)

FIG. 3 Contoured Double-Cantilever Beam Specimen

aluminum it is suggested that the specimens be rough cut 3.2 mm ( ⁄8 in.)

mm/min (0.08 in./min) gives fracture in 1 min for a CDCB

−1

over-size using a four-pitch band saw traveling at approximately 4.2 m/s 1

⁄2-in. wide m=90-in. aluminum adherend specimen having

(800 ft/min) followed by finish dimensioning to a 1-in. wide 3.2-µm

a 3-in. long starter crack.

(125-µin.) surface using a five-blade 15-deg carbide fly cutter at 1115 rpm

and 0.015 to 0.035-m/s (3 to 7-in./min) feed rate.

10.3.1 The chart recording should be such that maximum

load occurs on the record and that at least 13 mm ( ⁄2 in.) of

10. Procedure

motion is represented on the abscissa (n) for each 100 mm (4

10.1 Test specimens, prepared as prescribed in Section 8,in

in.)ofordinatemotion(P).Forload-timerecordsachart speed

an atmosphere maintained at 50 6 4% relative humidity and

rate should be used such that the slope of the load versus time

23 6 1°C (73.4 6 1.8°F). Tests at other than ambient

record is similar to that specified for load versus load-

temperature may be run if desired. It is suggested that

displacement (for example, 5 mm/min (0.2 in./mm)).

specimens be conditioned for a minimum of 10 min and a

10.4 Apply load to specimen until Point A is reached. (See

maximum of 30 min at the temperature of test to assure

Point A, Fig. 4 for flat adherend and Fig. 5, Point A for

equilibrium. The manufacturer of the adhesive may, however,

contoured double-cantilever specimen.) Point A is the load at

prescribe a definite period of conditioning under specific

which the crack begins to grow rapidly. Then stop loading and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.