ASTM D4674-02

(Test Method)Standard Test Method for Accelerated Testing for Color Stability of Plastics Exposed to Indoor Fluorescent Lighting and Window-Filtered Daylight

Standard Test Method for Accelerated Testing for Color Stability of Plastics Exposed to Indoor Fluorescent Lighting and Window-Filtered Daylight

SCOPE

1.1 This test method covers an accelerated procedure intended to determine the resistance to color change of plastics in typical office environments, where overhead fluorescent light and window-filtered daylight are used for illumination, and where temperature and humidity conditions are in accordance with American Society of Heating, Refrigerating, and Airconditioning Engineers (ASHRAE) recommendations for workers' comfort.

1.2 This standard does not purport to address all of the safety concerns, is any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4674 – 02

Standard Test Method for

Accelerated Testing for Color Stability of Plastics Exposed

to Indoor Fluorescent Lighting and Window-Filtered

1

Daylight

This standard is issued under the fixed designation D 4674; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope separately as the product of UV irradiance at the start of the test

2 2

and exposure time, in Watt-hours/m (W–h/m ).

1.1 This test method covers an accelerated procedure in-

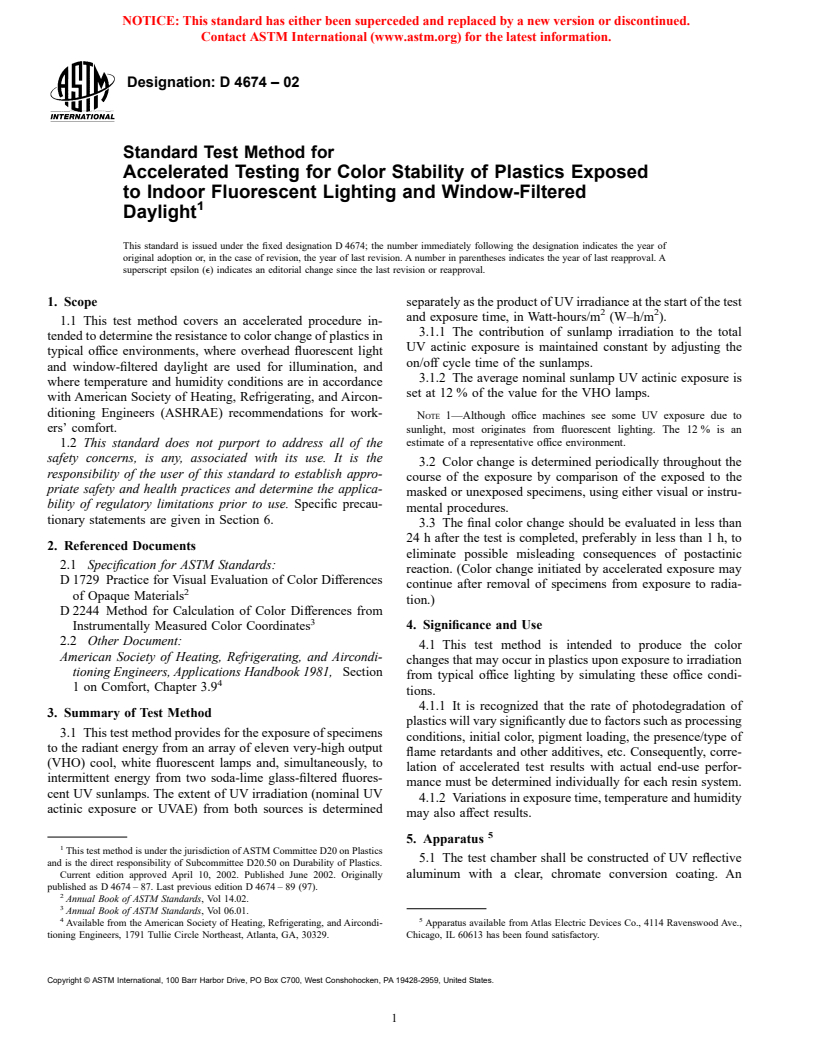

3.1.1 The contribution of sunlamp irradiation to the total

tended to determine the resistance to color change of plastics in

UV actinic exposure is maintained constant by adjusting the

typical office environments, where overhead fluorescent light

on/off cycle time of the sunlamps.

and window-filtered daylight are used for illumination, and

3.1.2 The average nominal sunlamp UV actinic exposure is

where temperature and humidity conditions are in accordance

set at 12 % of the value for the VHO lamps.

with American Society of Heating, Refrigerating, and Aircon-

ditioning Engineers (ASHRAE) recommendations for work-

NOTE 1—Although office machines see some UV exposure due to

ers’ comfort.

sunlight, most originates from fluorescent lighting. The 12 % is an

estimate of a representative office environment.

1.2 This standard does not purport to address all of the

safety concerns, is any, associated with its use. It is the

3.2 Color change is determined periodically throughout the

responsibility of the user of this standard to establish appro-

course of the exposure by comparison of the exposed to the

priate safety and health practices and determine the applica-

masked or unexposed specimens, using either visual or instru-

bility of regulatory limitations prior to use. Specific precau-

mental procedures.

tionary statements are given in Section 6.

3.3 The final color change should be evaluated in less than

24 h after the test is completed, preferably in less than 1 h, to

2. Referenced Documents

eliminate possible misleading consequences of postactinic

2.1 Specification for ASTM Standards:

reaction. (Color change initiated by accelerated exposure may

D 1729 Practice for Visual Evaluation of Color Differences

continue after removal of specimens from exposure to radia-

2

of Opaque Materials

tion.)

D 2244 Method for Calculation of Color Differences from

3

Instrumentally Measured Color Coordinates 4. Significance and Use

2.2 Other Document:

4.1 This test method is intended to produce the color

American Society of Heating, Refrigerating, and Aircondi-

changes that may occur in plastics upon exposure to irradiation

tioning Engineers, Applications Handbook 1981, Section

from typical office lighting by simulating these office condi-

4

1 on Comfort, Chapter 3.9

tions.

4.1.1 It is recognized that the rate of photodegradation of

3. Summary of Test Method

plastics will vary significantly due to factors such as processing

3.1 This test method provides for the exposure of specimens

conditions, initial color, pigment loading, the presence/type of

to the radiant energy from an array of eleven very-high output

flame retardants and other additives, etc. Consequently, corre-

(VHO) cool, white fluorescent lamps and, simultaneously, to

lation of accelerated test results with actual end-use perfor-

intermittent energy from two soda-lime glass-filtered fluores-

mance must be determined individually for each resin system.

cent UV sunlamps. The extent of UV irradiation (nominal UV

4.1.2 Variations in exposure time, temperature and humidity

actinic exposure or UVAE) from both sources is determined

may also affect results.

5

5. Apparatus

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics

5.1 The test chamber shall be constructed of UV reflective

and is the direct responsibility of Subcommittee D20.50 on Durability of Plastics.

Current edition approved April 10, 2002. Published June 2002. Originally aluminum with a clear, chromate conversion coating. An

published as D 4674 – 87. Last previous edition D 4674 – 89 (97).

2

Annual Book of ASTM Standards, Vol 14.02.

3

Annual Book of ASTM Standards, Vol 06.01.

4 5

Available from the American Society of Heating, Refrigerating, and Aircondi- Apparatus available from Atlas Electric Devices Co., 4114 Ravenswood Ave.,

tioning Engineers, 1791 Tullie Circle Northeast, Atlanta, GA, 30329. Chicago, IL 60613 has been found satisfactory.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This stand

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.