ASTM C1540-02

(Specification)Standard Specification for Heavy Duty Shielded Couplings Joining Hubless Cast Iron Soil Pipe and Fittings

Standard Specification for Heavy Duty Shielded Couplings Joining Hubless Cast Iron Soil Pipe and Fittings

SCOPE

1.1 This specification covers the evaluating of the performance of heavy duty shielded couplings to join hubless cast iron soil pipe and fittings.

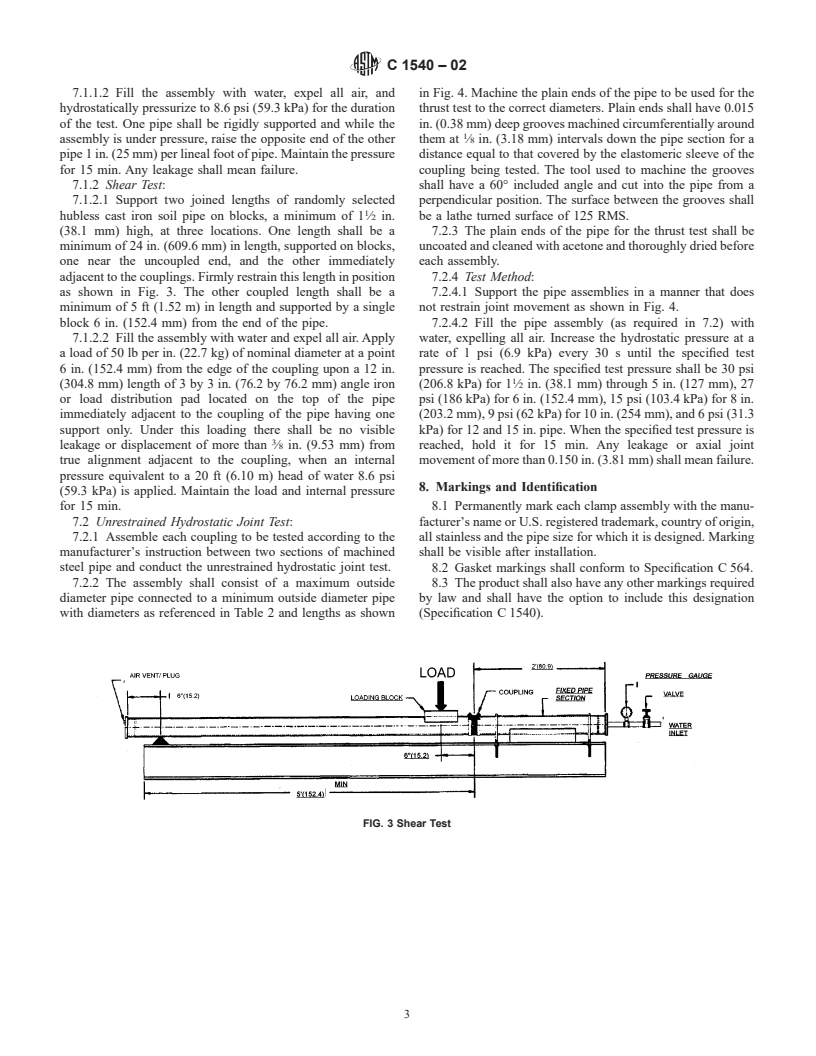

1.2 Couplings covered by this standard shall have minimum dimensions as found in Table 1 and Fig. 1 of this standard.

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.4 The committee with jurisdiction over this standard is aware of comparable standards published by other organizations, namely Cast Iron Soil Pipe Institute specification CISPI 310 and Factory Mutual Research standard FM 1680.

1.5 The following precautionary caveat pertains only to the test method portion, Section 7, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1540 – 02

Standard Specification for

Heavy Duty Shielded Couplings Joining Hubless Cast Iron

Soil Pipe and Fittings

This standard is issued under the fixed designation C 1540; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

TABLE 1

1. Scope

Nominal Pipe Size Coupling Width

1.1 This specification covers the evaluating of the perfor-

1 ⁄2 to 4 in. (38 to 100 mm) 3 in. (76 mm) Minimum Width

mance of heavy duty shielded couplings to join hubless cast

5 to 10 in. (127 to 254 mm) 4 in. (100 mm) Minimum Width

iron soil pipe and fittings.

12 to 15 in. (305 to 381 mm) 5 ⁄2 in. (140 mm) Minimum Width

1.2 Couplings covered by this standard shall have minimum

dimensions as found in Table 1 and Fig. 1 of this standard.

1.3 The values stated in inch-pound units are to be regarded

CISPI-310 Specification for coupling for use in Connection

as the standard. The SI units given in parentheses are for

with Hubless Cast Iron Soil Pipe and Fittings for Sanitary

information only.

and Storm Drain, Waste and Vent Piping Applications

1.4 The committee with jurisdiction over this standard is

FM 1680 Approval Standard Couplings used in Hubless

aware of comparable standards published by other organiza-

Cast Iron Systems for Drain, Waste or Vent Systems above

tions, namely Cast Iron Soil Pipe Institute specification CISPI

or below ground Industrial, Commercial, and Residential

310 and Factory Mutual Research standard FM 1680.

1.5 The following precautionary caveat pertains only to the

3. Terminology

test method portion, Section 7, of this specification. This

3.1 Definitions:

standard does not purport to address all of the safety concerns,

3.1.1 Definitions of the following terms used in this speci-

if any, associated with its use. It is the responsibility of the user

fication are found in Terminology C 717.

of this standard to establish appropriate safety and health

3.2 Definitions of Terms Specific to This Standard:

practices and determine the applicability of regulatory limita-

3.2.1 center stop, n—an integral part of the gasket centered

tions prior to use.

on the axial length of the gasket intended to limit the insertion

depth of the pipe to be coupled.

2. Referenced Documents

3.2.2 clamp assembly, n—that portion of the coupling

2.1 ASTM Standards:

excluding the gasket.

A 240 Specification for Stainless and Heat-Resisting

3.2.3 coupling, n—the complete assembly.

Chromium-Nickel Steel Plate, Sheet, and Strip

3.2.4 fitting, n—parts of a pipeline other than straight pipes,

A 493 Specification for Stainless Wire and Wire Rods for

valves, or couplings.

Cold Heating and Cold Forging

3.2.5 gasket, n—the elastomeric portion of the coupling.

A 888 Specification for Hubless Cast Iron Soil Pipe and

3.2.6 heavy duty coupling, n—a shielded coupling that has

Fittings for Sanitary, Storm and Drain, Waste, and Vent

dimensions not less than those detailed in Table 1 and Fig. 1.

Piping Applications

3.2.7 joint, n—the point of assembly consisting of the

C 564 Specification for Rubber Gaskets for Cast Iron Soil

coupling and the joined pipes or fittings, or both.

Pipe and Fittings

3.2.8 shield, n—an external metallic protective device de-

C 717 Terminology of Building Seals and Sealants

signed to protect the sealing gasket from external elements that

2.2 CISPI Standards:

could cause failure of the sealing assembly.

CISPI-301 Specification for Hubless Cast Iron Soil Pipe and

Fittings for Sanitary and Storm Drain, Waste and Vent

4. Materials and Manufacture

Piping Applications

4.1 Physical properties of gaskets shall comply with Speci-

fication C 564 using the applicable durometer hardness re-

This specification is under the jurisdiction of ASTM Committee C24 on

quirement of the column of Table 2 of that document as

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.75

specified by the manufacturer.

on Gaskets and Couplings for Plumbing and Sewer Piping.

4.2 Clamp assembly screws or bolts shall not have screw-

Current edition approved July 10, 2002. Published August 2002.

Annual Book of ASTM Standards,Vol driver slots.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1540–02

FIG. 1 Typical Center Stop Detail

TABLE 2 Dimensions and Tolerances for Hubless Pipe and

6. Clamp Assembly Requirements

Fittings

6.1 The clamp assembly shall be made of material conform-

Size, Outside Diameter,

ing to the requirements as outlined in Sections 4 and 6.

in. (mm) in. (mm)

6.1.1 All metallic parts shall be of 300 series stainless steel

1 ⁄2 (38) 1.90 6 0.06 (48.26 6 1.52)

and shall conform to the requirements of Specification A 240.

2 (51) 2.35 6 0.09 (59.69 6 2.29)

3 (76) 3.35 6 0.09 (85.09 6 2.29)

All metallic parts made from round stock shall be of 300 series

4 (102) 4.38+0.09-0.05 (111.25+2.29/-1.27)

stainless steel and shall conform to the requirements of

5 (127) 5.30+0.09-0.05 (134.63+2.29/-1.27)

Specification A 493 (excluding copper bearing alloys).

6 (152) 6.30+0.09-0.05 (160.02+2.29/-1.27)

8 (203) 8.38+0.13-0.09 (212.85+3.30/-2.29)

6.1.2 Clamp assemblies shall be tested to withstand no less

10 (254) 10.56 6 0.09 (268.22 6 2.29)

than 125 % of the manufacturers stated installation torque

12 (305) 12.50 6 0.09 (317.5 6 2.29)

without visible signs of failure. The clamp assembly shall be

15 (381) 15.83 6 0.09 (402.08 6 2.29)

tested over a steel mandrel of the appropriate diameter and

torqued as required.

4.3 All stainless steel shall meet the physical requirements

7. Couplings Requirements and Test Methods

of Specification A 240.

7.1 Assemble each coupling to be tested according to the

5. Elastomeric Gasket Requirements

manufacturer’s instructions between two sections of randomly

5.1 The elastomeric gasket shall consist of one piece poly- selected hubless cast iro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.