ASTM C1804-14

(Specification)Standard Specification for Spun Cast Prestressed Concrete Bases for Tapered Steel Lighting Poles

Standard Specification for Spun Cast Prestressed Concrete Bases for Tapered Steel Lighting Poles

SCOPE

1.1 This specification covers spun cast prestressed concrete bases used in lighting structures.

1.2 Units—The values stated in SI units are to be regarded as standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1804 −14

StandardSpecification for

Spun Cast Prestressed Concrete Bases for Tapered Steel

Lighting Poles

This standard is issued under the fixed designation C1804; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C39/C39M Test Method for Compressive Strength of Cylin-

drical Concrete Specimens

1.1 This specification covers spun cast prestressed concrete

C42/C42M Test Method for Obtaining and Testing Drilled

bases used in lighting structures.

Cores and Sawed Beams of Concrete

1.2 Units—The values stated in SI units are to be regarded

C143 Test Method for Slump of Hydraulic-Cement Concrete

as standard.

C150 Specification for Portland Cement

C172 Practice for Sampling Freshly Mixed Concrete

2. Referenced Documents

C192 Practice for Making and Curing Concrete Test Speci-

2.1 ASTM Standards:

mens in the Laboratory

A416/A416M Specification for Steel Strand, Uncoated

C260 Specification for Air-Entraining Admixtures for Con-

Seven-Wire for Prestressed Concrete

crete

A421/A421M Specification for Uncoated Stress-Relieved

C289 Test Method for Potential Alkali-Silica Reactivity of

Steel Wire for Prestressed Concrete

Aggregates (Chemical Method)

A615/A615M Specification for Deformed and Plain Carbon-

C330 Specification for Lightweight Aggregates for Struc-

Steel Bars for Concrete Reinforcement

tural Concrete

A496/A496M Specification for Steel Wire, Deformed, for

C494 Specification for Chemical Admixtures for Concrete

Concrete Reinforcement (Withdrawn 2013)

C595 Specification for Blended Hydraulic Cements

A617/A617M Specification for Axle-Steel Deformed and

C618 Specification for Coal Fly Ash and Raw or Calcined

Plain Bars for Concrete Reinforcement (Withdrawn

Natural Pozzolan for Use in Concrete

1999)

C989 Specification for Slag Cement for Use in Concrete and

A641/A641M Specification for Zinc–Coated (Galvanized)

Mortars

Carbon Steel Wire

C1064 Test Method for Temperature of Freshly Mixed

A722/A722M Specification for Uncoated High-Strength

Hydraulic-Cement Concrete

Steel Bars for Prestressing Concrete

C1089 Specification for Spun Cast Prestressed Concrete

A1064/A1064M Specification for Carbon-Steel Wire and

Poles

Welded Wire Reinforcement, Plain and Deformed, for

C1157 Performance Specification for Hydraulic Cement

Concrete

C1240 Specification for Silica Fume Used in Cementitious

B86 Specification for Zinc and Zinc-Aluminum (ZA) Alloy

Mixtures

Foundry and Die Castings

F593 Specification for Stainless Steel Bolts, Hex Cap

C31/C31M Practice for Making and Curing Concrete Test

Screws, and Studs

Specimens in the Field

C33 Specification for Concrete Aggregates 2.2 AASHTO Standard:

Specification for Structural Supports for Highway Signs,

Luminaries and Traffic Signals (LTS-6)

This test method is under the jurisdiction ofASTM Committee C27 on Precast 5

2.3 ASCE7 Standard:

Concrete Products and is the direct responsibility of Subcommittee C27.20 on

Minimum Design Loads for Buildings and Other Structures

Architectural and Structural Products.

Current edition approved Nov. 1, 2014. Published November 2014. DOI:

10.1520/C1804-14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Association of State Highway and Transportation

Standards volume information, refer to the standard’s Document Summary page on Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

the ASTM website. http://www.transportation.org.

3 5

The last approved version of this historical standard is referenced on Available from American Society of Civil Engineers (ASCE), 1801 Alexander

www.astm.org. Bell Dr., Reston, VA 20191, http://www.asce.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1804−14

2.4 PCI Guides: contain concentration of chloride ions in excess of 500 ppm or

Guide for Design of Prestressed Concrete Poles sulfate ions in excess of 1000 ppm.

Guide Specification for Prestressed Concrete Poles

5.4 Admixture—Chemical admixtures shall conform to

Specification C494.Air-entraining admixtures shall conform to

3. Terminology

Specification C260. Admixtures shall not cause the chloride

3.1 Definitions: ion content of the concrete to exceed 0.06 % by mass of

3.1.1 cracking load—a load which creates a bending mo-

cementitious materials.

ment of enough magnitude to produce a tensile stress greater

5.5 Steel—Prestressing steel shall conform to Specification

than the sum of induced compression plus the tensile strength

A416/A416M, A421/A421M,or A722/A722M. Nontensioned

of the concrete resulting in tensile cracks on the tension face of

longitudinal reinforcement shall conform to Specification

the base.

A615/A615M, A617/A617M,or A496/A496M. Circumferen-

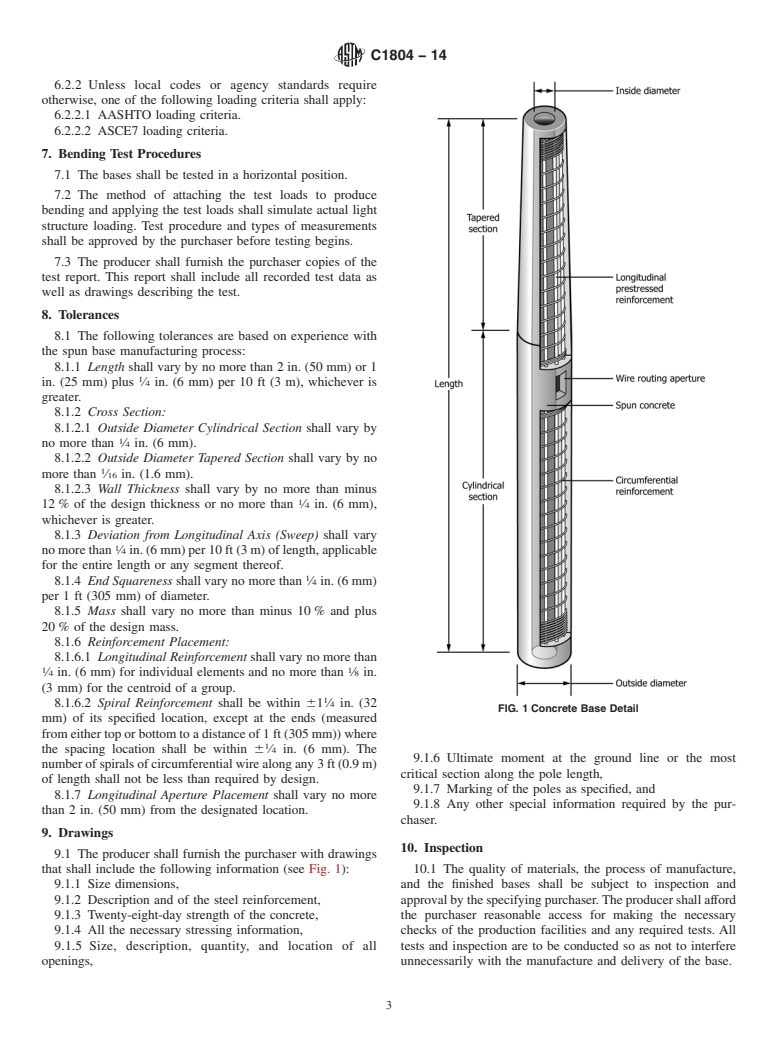

3.1.2 cylindrical section—lower portion of base designed to

tial wire reinforcement shall conform to Specification A1064/

be buried in concrete backfill below ground line.

A1064M, A496/A496M,or A641/A641M.

3.1.3 spun base—a base in which the concrete is distributed

5.6 All inserts shall be made from zinc alloy in accordance

and compacted through centrifugal force.

with Specification B86 or stainless steel in accordance with

3.1.4 tapered section—upper portion of base, which has a Specification F593. No aluminum inserts shall be allowed.

taper designed to match overlapping steel pole taper.

5.7 The top and bottom ends of the bases shall be sealed to

3.1.5 ultimate load—maximum load the base will carry in

preventgroundorrainwaterfromwickingintothestrandends.

the specified direction, before the concrete or steel will reach

The sealing compound shall be specified by the purchaser.

its limiting state.

6. Requirements

4. Basis of Acceptance

6.1 General Requirements:

4.1 Acceptability of spun prestressed concrete bases pro-

6.1.1 Concrete Cover—The minimum concrete cover over

duced in accordance with this specification shall be determined

longitudinal reinforcing steel shall be ⁄4 in. (19 mm). The

by the test results of compressive strength tests of concrete

concrete cover can be reduced to ⁄8 in. (16 mm) minimum for

cylinders and mill certificates for the reinforcing steel. The

portions of the base not exposed to soil or weather.

manufacturer shall certify that the cement, aggregates,

6.1.2 Circumferential Wire—Circumferential wire spacing

admixtures, and steel shall conform to the applicable specifi-

shall be 3 in. (76 mm) nominal, except at the ends (measured

cation for each material. The manufacturer shall also certify

from either the top or bottom to a distance of 1 ft (305 mm))

adherence to tolerance on dimensions and mass. In addition the

where the nominal spacing shall be 1 in. (25 mm).

acceptability of the bases, produced in accordance with this

6.1.3 Grounding—The purchaser shall specify any ground-

specification, shall be verified by the results of full scale

ing requirements needed.

bending tests. The purchaser shall specify the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.