ASTM B361-08

(Specification)Standard Specification for Factory-Made Wrought Aluminum and Aluminum-Alloy Welding Fittings

Standard Specification for Factory-Made Wrought Aluminum and Aluminum-Alloy Welding Fittings

ABSTRACT

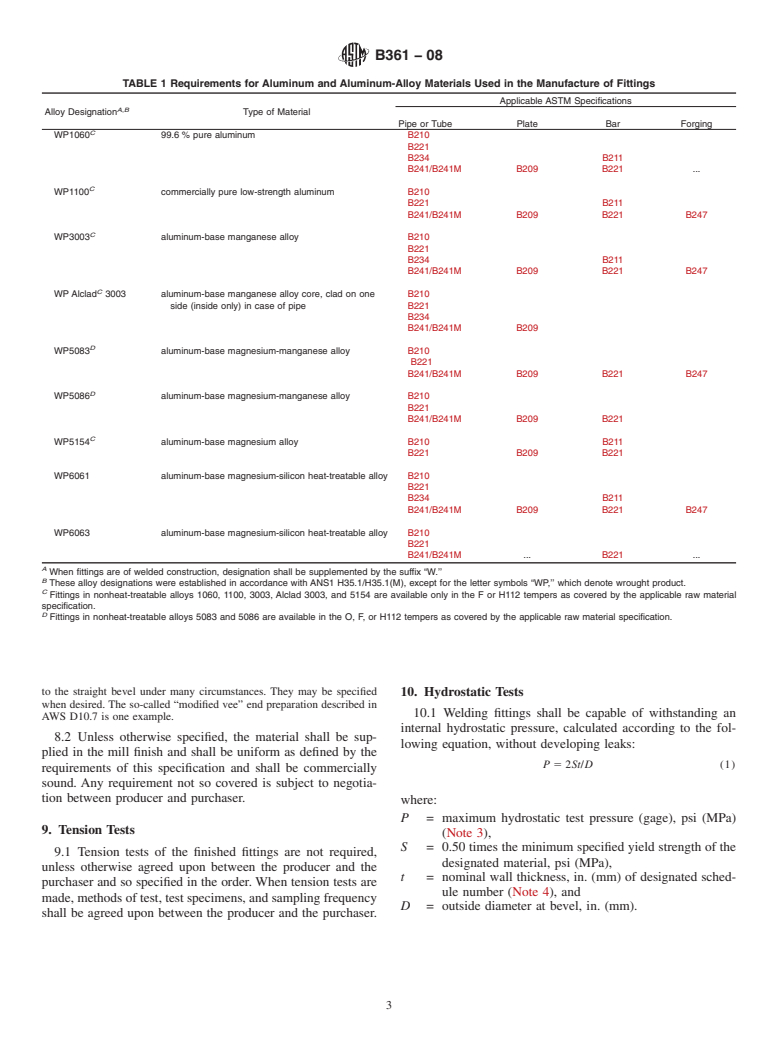

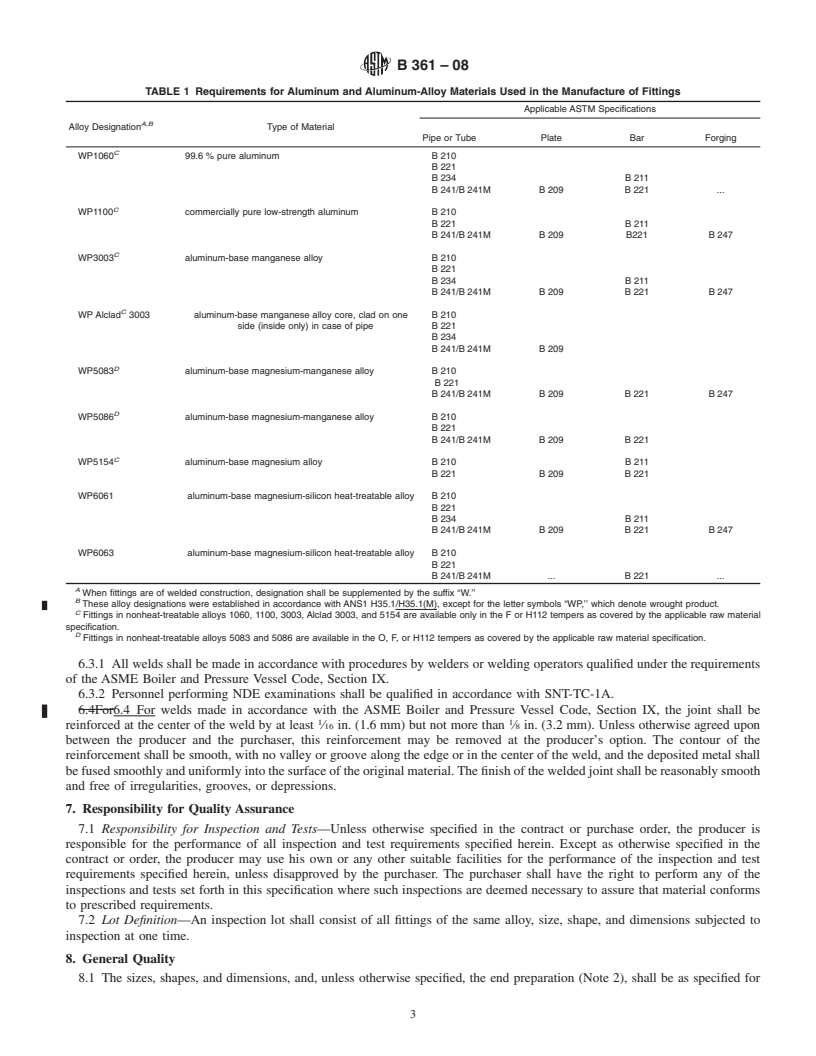

This specification covers only factory-made wrought aluminum and aluminum-alloy welding fittings in contrast to field-made fittings. The aluminum or aluminum-alloy material used in the manufacture of the fittings shall be in accordance with the alloy and temper specified. The material shall be in the form of rod, bar, forgings, sheet, plate, seamless pipe or seamless tube, each of which conforms to all requirements. Forging or shaping operations may be performed by hammering, pressing, piercing, rolling, extruding, upsetting, bending, or fusion welding, or by a combination of two or more of these operations. Tension tests and hydrostatic tests shall be made to conform to the specified requirements.

SCOPE

1.1 This specification covers only factory-made wrought aluminum and aluminum-alloy welding fittings in contrast to field-made fittings. The term “welding fittings” applies to butt-welding or socket-end parts, such as 45° elbows, 180° return bends, 90° short radius elbows, and other types made to the dimensional standards specified by ASME B16.9 and B16.11.

Note 1—Throughout this specification use of the term alloy in the general sense includes aluminum as well as aluminum-alloy.

1.2 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A1.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and heal practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B361 −08

StandardSpecification for

Factory-Made Wrought Aluminum and Aluminum-Alloy

1

Welding Fittings

This standard is issued under the fixed designation B361; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* B211 Specification for Aluminum and Aluminum-Alloy

Rolled or Cold Finished Bar, Rod, and Wire

1.1 This specification covers only factory-made wrought

B221 Specification forAluminum andAluminum-Alloy Ex-

aluminum and aluminum-alloy welding fittings in contrast to

truded Bars, Rods, Wire, Profiles, and Tubes

field-made fittings. The term “welding fittings” applies to

B234 Specification for Aluminum and Aluminum-Alloy

butt-welding or socket-end parts, such as 45° elbows, 180°

Drawn Seamless Tubes for Condensers and Heat Ex-

return bends, 90° short radius elbows, and other types made to

changers

the dimensional standards specified by ASME B16.9 and

B241/B241M Specification for Aluminum and Aluminum-

B16.11.

Alloy Seamless Pipe and Seamless Extruded Tube

NOTE 1—Throughout this specification use of the term alloy in the

B247 Specification forAluminum andAluminum-Alloy Die

general sense includes aluminum as well as aluminum-alloy.

Forgings, Hand Forgings, and Rolled Ring Forgings

1.2 For acceptance criteria for inclusion of new aluminum

B660 Practices for Packaging/Packing of Aluminum and

and aluminum alloys in this specification, see Annex A1.

Magnesium Products

B881 Terminology Relating toAluminum- and Magnesium-

1.3 The values stated in inch-pound units are to be regarded

Alloy Products

as standard. The values given in parentheses are mathematical

D3951 Practice for Commercial Packaging

conversions to SI units that are provided for information only

and are not considered standard. 2.3 ANSI Standards:

H35.1/H35.1(M) Alloy and Temper Designation Systems

1.4 This standard does not purport to address all of the

3

for Aluminum

safety concerns, if any, associated with its use. It is the

2.4 ASME Standards:

responsibility of the user of this standard to establish appro-

4

B16.9 Factory-Made Wrought Butt-Welding Fittings

priate safety and heal practices and determine the applicability

4

B16.11 Forged Fittings, Socket-Welding and Threaded

of regulatory limitations prior to use.

4

Section VIII Boiler and Pressure Vessel Code

4

2. Referenced Documents Section IX Boiler and Pressure Vessel Code

2.5 AWS Standards:

2.1 The following documents of the issue in effect on date

AWS D10.7M/D10.7 Recommended Practices for Gas

of material purchase form a part of this specification to the

Shielded-ArcWeldingofAluminumandAluminum-Alloy

extent referenced herein:

5

Pipe

2

2.2 ASTM Standards:

2.6 Manufacturers’ Standardization Society of the Valve and

B209 Specification for Aluminum and Aluminum-Alloy

Fittings Industry:

Sheet and Plate

MSS SP 25 Standard Marking System for Valves, Fittings,

B210 Specification for Aluminum and Aluminum-Alloy

6

Flanges and Unions

Drawn Seamless Tubes

1 3

This specification is under the jurisdiction of ASTM Committee B07 on Light Available from Aluminum Association, Inc., 1525 Wilson Blvd., Suite 600,

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on Arlington, VA 22209, http://www.aluminum.org.

4

Aluminum Alloy Wrought Products. Available from American Society of Mechanical Engineers (ASME), ASME

Current edition approved Nov. 1, 2008. Published December 2008. Originally International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

approved in 1960. Last previous edition approved in 2002 as B361 – 02. DOI: www.asme.org.

5

10.1520/B0361-08. Available from American Welding Society (AWS), 550 NW LeJeune Rd.,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Miami, FL 33126, http://www.aws.org.

6

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

Standards volume information, refer to the standard’s Document Summary page on Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

the ASTM website. hq.com.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B361−08

2.7 Federal Standards: 6. Manufacture

7

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

6.1 Forging or shaping operations may be performed by

2.8 American Society for Nondestructive Testing Standard:

hammering, pressing, piercing, rolling, extruding, upsetting,

ASNT

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B361–02 Designation: B 361 – 08

Standard Specification for

Factory-Made Wrought Aluminum and Aluminum-Alloy

1

Welding Fittings

This standard is issued under the fixed designation B 361; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers only factory-made wrought aluminum and aluminum-alloy welding fittings in contrast to

field-made fittings.The term “welding fittings” applies to butt-welding or socket-end parts, such as 45° elbows, 180° return bends,

90° short radius elbows, and other types made to the dimensional standards specified by ASME B16.9 and B16.11.

NOTE 1—Throughout this specification use of the term alloy in the general sense includes aluminum as well as aluminum-alloy.

1.2 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A1.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical

conversions to SI units whichthat are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and heal practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

B 209 Specification for Aluminum and Aluminum-Alloy Sheet and Plate

B 210 Specification for Aluminum and Aluminum-Alloy Drawn Seamless Tubes

B 211 Specification for Aluminum and Aluminum-Alloy Bar, Rod, and Wire

B 221 Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

B 234 Specification for Aluminum and Aluminum-Alloy Drawn Seamless Tubes for Condensers and Heat Exchangers

B 241/B 241M Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube

B 247 Specification for Aluminum and Aluminum-Alloy Die Forgings, Hand Forgings, and Rolled Ring Forgings

B 660 Practices for Packaging/Packing of Aluminum and Magnesium Products

2

B 881Standard Terminology Relating toAluminum and MagnesiumAlloy Products Terminology Relating toAluminum- and

Magnesium-Alloy Products

D 3951 Practice for Commercial Packaging

2.3 ANSI Standards:

3

H35.1H35.1/H35.1(M) Alloy and Temper Designation Systems for Aluminum

2.4 ASME Standards:

4

B16.9 Factory-Made Wrought Steel Butt-Welding Fittings

4

B16.11 Forged Steel Fittings, Socket-Welding and Threaded

4

Section VIII Boiler and Pressure Vessel Code

4

Section IX Boiler and Pressure Vessel Code

1

This specification is under the jurisdiction ofASTM Committee B07 on Light Metals andAlloys and is the direct responsibility of Subcommittee B07.03 onAluminum

Alloy Wrought Products.

Current edition approved June 10, 2002. Published July 2002. Originally published as B361–60T. Last previous edition B361–95.

Current edition approved Nov. 1, 2008. Published December 2008. Originally approved in 1960. Last previous edition approved in 2002 as B 361 – 02.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 02.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Annual Book of ASTM Standards, Vol 15.09.

3

Available from Aluminum Association, Inc., 1525 Wilson Blvd., Suite 600, Arlington, VA 22209, http://www.aluminum.org.

4

The Aluminum Association, 900 19th St., NW, Washington, DC 20006.

4

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B361–08

2.5 AWS Standards:

5

AWS D10.7M/D10.7 Recommended Practices for Gas Shielded-Arc Welding of Aluminum and Aluminum-Alloy Pipe

2.6 Manufacturers’ Standardization Society of the Valve and Fittings Industry:

6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.