ASTM E884-82(1993)

(Practice)Standard Practice for Sampling Airborne Microorganisms at Municipal Solid-Waste Processing Facilities

Standard Practice for Sampling Airborne Microorganisms at Municipal Solid-Waste Processing Facilities

SCOPE

1.1 This practice covers sampling of airborne microorganisms at municipal solid-waste processing facilities, hereafter referred to as facilities. Investigators should consult Practice D1357 for the general principles of conducting an air-sampling program.

1.2 This practice applies only to sampling airborne bacteria and fungi, not viruses. Since sampling airborne viruses is significantly more difficult than sampling bacteria and fungi, reliable methods of sampling viruses are not yet available.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 884 – 82 (Reapproved 1993)

Standard Practice for

Sampling Airborne Microorganisms at Municipal Solid-

Waste Processing Facilities

This standard is issued under the fixed designation E 884; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.2 Procedures are included for selecting sampling loca-

tions; determining numbers of samples, types of microorgan-

1.1 This practice covers sampling of airborne microorgan-

isms to be sampled, intervals between sample collection and

isms at municipal solid-waste processing facilities, hereafter

analysis; choosing sampling equipment; preserving samples;

referred to as facilities. Investigators should consult Practice

and reporting results.

D 1357 for the general principles of conducting an air-

sampling program.

5. Significance and Use

1.2 This practice applies only to sampling airborne bacteria

5.1 Bacteria and fungi present in municipal solid wastes (as

and fungi, not viruses. Since sampling airborne viruses is

well as in other forms of waste) may become airborne as dusts

significantly more difficult than sampling bacteria and fungi,

during waste processing. Several investigations to determine

reliable methods of sampling viruses are not yet available.

the health significance of these microbiological aerosols have

2. Referenced Documents been hindered by the lack of standardized procedures for

sampling airborne bacteria and fungi in an industrial environ-

2.1 ASTM Standards:

ment and by the absence of standards for assessing their health

D 1356 Terminology Relating to Atmospheric Sampling

2 significance. Because it is difficult to correlate airborne levels

and Analysis

of bacteria and fungi with epidemiological data, this standard is

D 1357 Practice for Planning the Sampling of the Ambient

2 designed to permit the formation of a data base to aid in the

Atmosphere

assessment of the health significance of airborne microorgan-

2.2 Other Standards:

isms. It is intended that the use of this practice will improve

Microbiological Methods for Monitoring the Environment,

sampling precision and thereby facilitate comparisons between

Water and Wastes

sampling results.

Air Sampling Instruments for the Evaluation of Atmo-

spheric Contaminants

6. Apparatus

3. Definitions 6.1 Two types of samplers are used in each sampling

program for microbiological aerosols at waste processing

3.1 microbiological aerosol—an airborne particle partially

facilities (5).

or exclusively composed of microorganisms including bacteria

6.1.1 Multi-Stage Impactor, for collection of airborne mi-

and fungi.

crobes on agar plates. It is recommended that an impactor be

3.2 For definitions of other terms used in this practice, refer

used for sampling all of the types of bacteria and fungi listed

to Terminology D 1356.

in 10.6.1.

4. Summary of Practice 6.1.2 All-Glass Impinger, for collection of airborne mi-

crobes in a liquid medium. It is recommended that an impinger

4.1 Concentrations of selected airborne bacteria and fungi

be used for sampling fecal coliforms and for determination of

are determined using both liquid impinger and multi-stage

total plate count.

impactor samplers.

6.2 Air Sampling Pumps, providing approximately 40 L per

min (1.4 CFM) free-flow capacity.

6.3 Additional equipment such as carts, stands, and tool

This practice is under the jurisdiction of ASTM Committee D-34 on Waste

Management and is the direct responsibility of Subcommittee D34.01 on Sampling

and Monitoring.

Current edition approved July 30, 1982. Published May 1983. The boldface numbers in the parentheses refer to the list of references at the end

Annual Book of ASTM Standards, Vol 11.03. of the method.

3 6

Available from the National Technical Information Service, 5285 Port Royal The six-stage and two-stage microbiological samplers manufactured by Ander-

Road, Springfield, Va. 22161. Request EPA-600/8-78-017. son Samplers, Inc. have been found to be satisfactory.

4 7

Available from American Conference of Governmental and Industrial Hygien- Air sampling impinger No. 7540 manufactured by Ace Glass, Inc. (AGI 30) has

ists, 6500 Glenway Avenue, Building D-5, Cincinnati, Ohio 45211. been found to be satisfactory.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 884

boxes are routinely used during dust-sampling programs. 9.1.2 Use not less than two sampling locations inside the

facility at work sites or zones where employees are most likely

7. Reagents and Materials

to be exposed to airborne dust concentrations (7). (Note 2)

7.1 Agars for Use with the Multi-Stage Impactor:

Among these locations, those where sampling equipment can

7.1.1 Littman Oxgall, for total number of fungi present and

be located without interfering with facility operations shall be

for identification of the following species of fungi: (a) As-

preferred.

pergillus flavus and (b) A. fumigatus.

NOTE 2—Examples of potential sampling locations are (a) on a tipping

7.1.2 Vogel and Johnson, selective for Staphylococcus au-

floor near or on a front end loader; (b) at a hand-picking station along a

reus.

conveyor belt; and (c) along catwalks or platforms in frequent use by

employees.

NOTE 1—A fungicide such as nystatin should be used with these agars.

9.1.3 Outside the facility, locate at least one sampling site

7.1.3 Levine eosin methylene blue, specific for enterics

300 m (1000 ft) upwind from the facility and at least one

including Klebsiella spp. (Note 1)

sampling site 100 m (330 ft) downwind from the facility.

7.1.4 Trypticase soy, for total bacteria count. (Note 1)

Measure the distances upwind and downwind from the same

7.2 Liquid Media for Use in Impingers:

point, the point at which the emissions leave the facility or, in

7.2.1 Lactose Broth with Antifoam A, for analysis of fecal

the case of multiple discharge points, from a central point

coliform and total plate count.

equidistant from the discharge points.

7.2.2 The exact amount of Antifoam A to be added should

9.1.4 Carefully measure and record the actual distances of

be determined prior to field sampling. Sufficient antifoam

the sampling sites from the points of emission and wind

should be added to prevent loss of fluid from the impinger, but

direction and velocity.

excess should be avoided.

9.2 Position of Sampling Inlet—Locate the sampling inlet(s)

7.3 Media Preparation:

1.5 m (5 ft) above the floor level to approximate the breathing

7.3.1 Conduct the following according to Microbiological

zone of a worker or other person exposed to the dusts. Locate

Methods for Monitoring the Environment, Water and Wastes

the vacuum pumps where they will not disturb the air flow

(14):(a) laboratory quality assurance, (b) selection and use of

patterns around the sampling inlet(s).

laboratory apparatus, (c) washing and sterilization, and (d)

9.3 Number of Samples:

preparation of culture media.

9.3.1 Inside the facility, collect not less than 5 replicate

7.3.2 Preincubate all sampling media to determine if con-

samples at each sampling site.

tamination has occurred and to dry the agar surface. Excessive

9.3.2 Outside the facility, collect not less than 3 replicate

evaporation from the media or excessive contamination of the

samples at the upwind site(s) and not less than 5 replicate

exterior surfaces of the petri dishes must be guarded against

samples at the downwind site(s).

during this preliminary incubation.

9.3.3 Wide variations in reported microbiological aerosol

7.3.3 Media level in the sampling container is critical to

levels within facilities make it unlikely that the collection of

collection efficiency.

five samples will yield a tight distribution of results; therefore,

7.3.3.1 Impactor—The petri dishes must be of such a size

where economically feasible, it is recommended that the

that the agar surface is at the manufacturer’s specified distance

sample size be increased to more than five.

below each stage. The manufacturer of the Andersen impactor

9.4 Air Temperature:

specifies 27 mL of agar per standard Andersen petri dish. The

9.4.1 Collect samples when the air temperature at the

agar surface must be smooth and free of bubbles to ensure an

sampling site is above 5°C (40°F).

even air flow.

9.4.2 At temperatures below 5°C (40°F), the sampling

7.3.3.2 Impinger—For the all glass impinger, 20 mL of

medium may crystallize, thus affecting recovery of microor-

broth is recommended (17). Autoclave impingers, and then

ganisms.

aseptically add 20 mL of sterile broth. Mark its level on the

impinger, and record any significant loss during sampling.

10. Procedure

After sampling, the volume must be reconstituted to the

10.1 Record air temperature and relative humidity for each

original or the actual volume carefully calculated because a

location sampled.

known volume must be used for quantitative work.

10.2 Label all impingers to denote sampling run and loca-

tion. Label all petri dishes to denote sampling run, location,

8. Precautions

and stage of impactor.

8.1 Due to the nature of municipal refuse, common sense

10.3 Air-Flow Rates:

dictates that some precautions should be observed when

10.3.1 Determine the air-flow rate by an in-line flow meter.

sampling dusts at municipal solid-waste processing facilities.

Where this is not possible, calibrate air-flow rate with a

Recommended safety practices include wearing hard hats,

gas-flow meter according to the procedure described in Ref

safety shoes, safety glasses, gloves, and respirators as well as

(16). The recommended flow rate for the Andersen impactor is

washing hands before eating or smoking.

28.3 L/min. The optimum flow rate for the all-glass impinger is

9. Sampling

12.5 L/min.

9.1 Location and Number of Sampling Sites: 10.3.2 Maintain a constant air-flow rate through the sampler

9.1.1 All sampling shall be carried out during normal plant during the sampling time. Before sampling, allow the vacuum

operations. pump to warm up for not less than 1 min. Use clamps, T-shaped

E 884

connectors, and in-line membrane filters with 1-mm pore size Sanitize the impactor with a 70 % alcohol solution and dry

to pull filtered air through the pump during the warmup without thoroughly between samplings. Do not sanitize in the glove

pulling air through the sampler. Select clamps and T-shaped bag. To provide a control check for contamination, load and

connectors that will not alter the flow rate through the unload the impactor without sampling using a set of trypticase

samplers. soy agar petri dishes, and then subject these petri dishes to the

10.3.3 Secure all connections to keep the air loss less than same processing steps and analytical procedures applied to the

4 % of the average sampling rate or less than 0.00057 m /min samples.

(0.02 ft /min), whichever is smaller. Measure the leakage-flow 10.5.1.2 Minimize uneven distribution of colonies on the

rate with a suitable dry-gas meter connected to the discharge plates by centering the plates on the three pegs in each stage of

side of the vacuum pump while the inlet to the sampling the impactor and, once loaded, handling the impactor carefully

apparatus is plugged and a 380-mm (15-in. Hg) vacuum is to maintain this position.

drawn. A lower vacuum may be used provided it is not 10.5.2 Care During Sampling with the Impinger:

exceeded during sampling. 10.5.2.1 Include a negative (sterile) control with the im-

pingers to determine whether the samples become contami-

NOTE 3—Many of the vane-type air sampling pumps (including the one

nated while in transit or at the test site.

furnished for use with the Andersen sampler) use a needle valve to control

10.5.3 Preserve all samples by placing each one in a closed

the air flow through the sampler by bleeding in air that bypasses the

container at 4 6 2°C immediately after taking them. Protect the

sampler. The air flow through the pump is therefore constant, and a

meaningful measure of the flow through the sampler can only be made at

plates from direct contact with the ice to prevent contamina-

this location in the sample stream.

tion.

10.4 Sampling time—The length of time needed to collect

NOTE 4—Sealed ice packets have been found to be satisfactory and

each sample is dependent upon the type of sampler used and

convenient for this purpose.

the concentration of microbiological aerosols present in the air.

10.5.4 Return the samples to the laboratory as soon as

Trial sampling runs may be necessary to determine if a

possible and not later than 6 h after sampling. Process the

satisfactory plate loading can be obtained within the limitations

samples and place in a incubator as soon as possible.

of the equipment used.

10.5.5 For impinger samples, rinse the neck of the impinger

10.4.1 For the all-glass impinger operating at a flow rate of

and add this material to the sample. The volume of the rinse

12.5 L/min, the normal sampling time is 20 min.

solution must be measured so that the final sample volume is

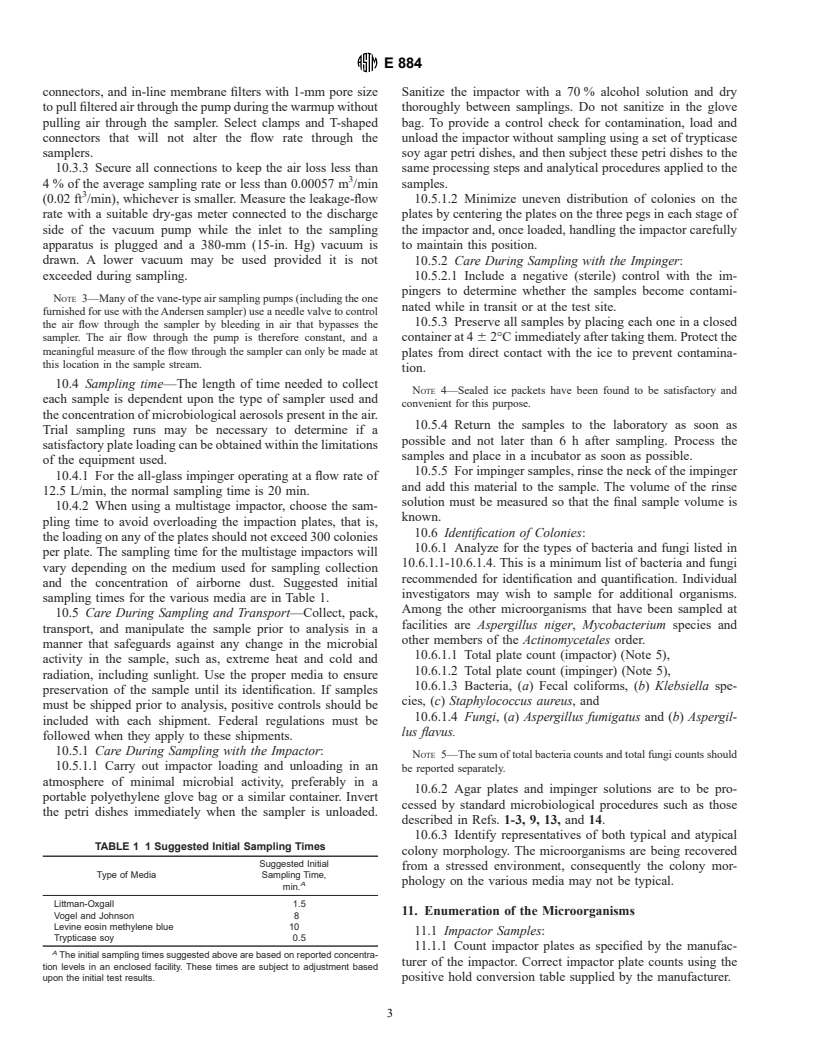

10.4.2 When using a multistage impactor, choose the sam-

known.

pling time to avoid overloading the impaction plates, that is,

10.6 Identification of Colonies:

the loading on any of the plates should not exceed 300 colonies

10.6.1 Analyze for the types of bacteria and fungi listed in

per plate. The sampling time for the multistage impactors will

10.6.1.1-10.6.1.4. This is a minimum list of bacteria and fungi

vary depending on the medium used for sampling collection

recommended for identification and quantification. Individual

and the concentration of airborne dust. Suggested initial

investigators may wish to sample for additional organisms.

sampling times for the various media are in Table 1.

Among the other microorganisms that have been sampled at

10.5 Care During Sampling and Transport—Collect, pack,

facilities are Aspergillus niger, Mycobacterium species and

transport, and manipulate the sample prior to analysis in a

other members of the Actinomycetales order.

manner that safeguards against any change in the microbial

10.6.1.1 Total plate count (impactor) (Note 5),

activity in the sample, such as, extreme heat and cold and

10.6.1.2 Total plate count (impinger) (Note 5),

radiation, including sunlight. Use the proper media to ensure

10.6.1.3 Bacteria, (a) Fecal coliforms, (b) Klebsiella spe-

preservation of the sample until its identification. If samples

cies, (c) Staphylococcus aureus, and

must be shipped prior to analysis, positive controls should be

10.6.1.4 Fungi,(a) Aspergillus fumigatus and (b) Aspergil-

included with each shipment. Federal regu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.