ASTM D2094-00(2006)

(Practice)Standard Practice for Preparation of Bar and Rod Specimens for Adhesion Tests

Standard Practice for Preparation of Bar and Rod Specimens for Adhesion Tests

SIGNIFICANCE AND USE

The procedures outlined in this practice are designed to standardize the test specimens, surface preparations, combinations of materials, and adhesive selection. Because of the flexibility in the procedure, it is important to have some idea of the kind of properties that will be observed during testing.

SCOPE

1.1 This practice describes bar- and rod-type butt-joined adhesion test specimens and procedures for preparing and bonding them. The specimens are intended to be used with various adherend materials in like or unlike combinations for determining the strength properties of adhesives in accordance with Test Method D 2095.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.2 The values stated in SI units are considered to be the standard. The values in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2094 − 00(Reapproved 2006)

Standard Practice for

Preparation of Bar and Rod Specimens for Adhesion Tests

This standard is issued under the fixed designation D2094; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This practice describes bar- and rod-type butt-joined

4.1 The procedures outlined in this practice are designed to

adhesion test specimens and procedures for preparing and

standardize the test specimens, surface preparations, combina-

bonding them. The specimens are intended to be used with

tions of materials, and adhesive selection. Because of the

various adherend materials in like or unlike combinations for

flexibility in the procedure, it is important to have some idea of

determining the strength properties of adhesives in accordance

the kind of properties that will be observed during testing.

with Test Method D2095.

5. Test Specimens

1.2 The values stated in SI units are considered to be the

standard. The values in parentheses are for information only.

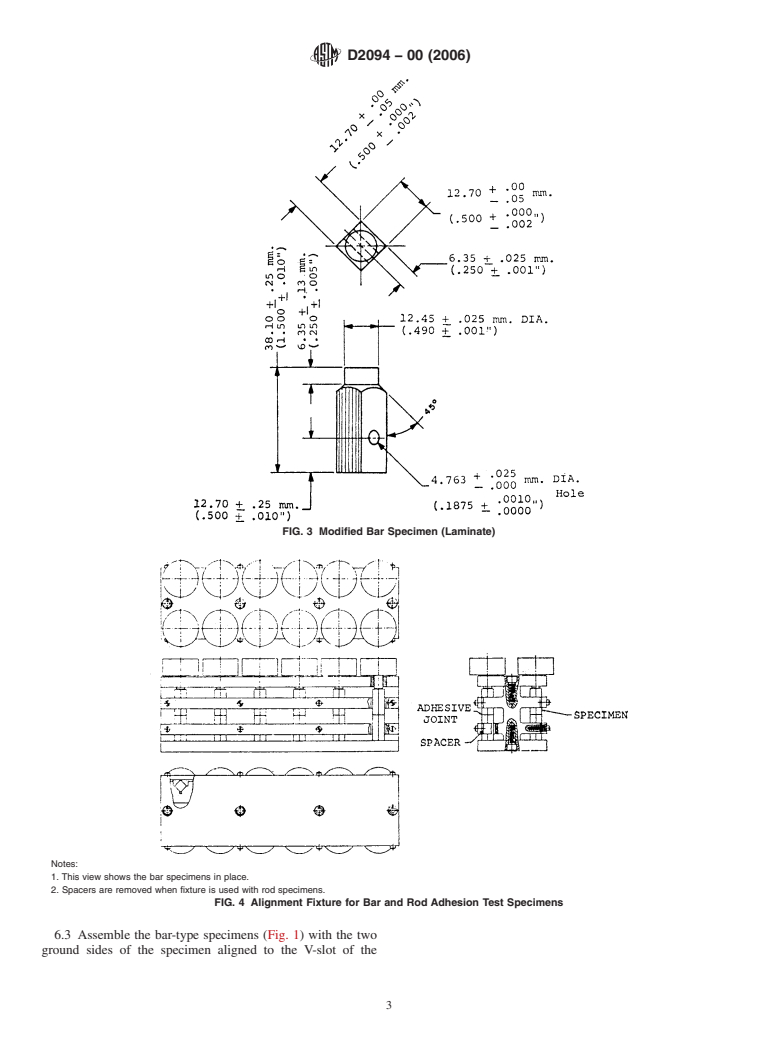

5.1 Geometry—Test specimens conform to the forms and

1.3 This standard does not purport to address all of the

dimensions shown in Fig. 1, Fig. 2,or Fig. 3. Only the bar

safety concerns, if any, associated with its use. It is the specimen (Fig. 1) shall be used for cleavage strength tests.

responsibility of the user of this standard to establish appro-

Only the rod specimen (Fig. 2) or the modified bar specimen

priate safety and health practices and determine the applica- (Fig. 3) shall be used for tests in torsional shear.Amodification

bility of regulatory limitations prior to use. of the specimen is permissible in tensile tests with dissimilar

adherends, particularly if one of the adherend materials is

2. Referenced Documents difficulttomachine(forexample,glass)orifthestrengthofthe

adherend is such that failure under stress occurs at the drilled

2.1 ASTM Standards:

hole. This modification consists of a sheet of the material

D907 Terminology of Adhesives

3 1 1

approximately 19 mm ( ⁄4 in.) square and 1 ⁄2to6mm( ⁄16 to

D2093 Practice for Preparation of Surfaces of Plastics Prior

⁄4 in.) thick inserted and bonded between the ends of the bar or

to Adhesive Bonding

rod specimens. For comparison purposes, specimen geometry

D2095 Test Method for Tensile Strength of Adhesives by

shall be the same unless the effect of insert dimensions is under

Means of Bar and Rod Specimens

study.

D2651 GuideforPreparationofMetalSurfacesforAdhesive

Bonding

5.2 Machining of Adherends:

2.2 ASTM Adjuncts:

5.2.1 Use metal adherends machined from bar or rod stock

Alignment Fixture Drawings

with the surface to be bonded finished to 1 µm.

5.2.2 Machine plastic from laminated flat panels using a

3. Terminology

diamond charged wheel for rough machining and a carbide-

tipped tool for finish machining. Do all machining dry using

3.1 Definitions—Many terms in this practice are defined in

care not to damage surfaces by overheating or contamination

Terminology D907.

with lubricants. Machine laminar materials so that the axis of

the specimen will lie in the plane of the lamina, and so that the

1 plane of the lamina coincides with one side of the specimen

This practice is under the jurisdiction of ASTM Committee D14 on Adhesives

and is the direct responsibility of Subcommittee D14.80 on Metal Bonding with the hole perpendicular to the plane of the lamina. Finish

Adhesives.

plastic to 80 µm or better unless studying surface finish.

Current edition approved Oct. 1, 2006. Published October 2006. Originally

ε1

5.2.3 Nonreinforced plastics (either thermoplastic or ther-

approved in 1962. Last previous edition approved in 2000 as D2094 – 00 . DOI:

10.1520/D2094-00R06. mosetting) molded in a 127 by 12.7 by 12.7-mm (5 by 0.5 by

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

0.5-in.) bar mold, machined to a 38.1 mm (1.5 in.) length and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

a hole drilled as shown in Fig. 1. Specimens machined from

Standards volume information, refer to the standard’s Document Summary page on

extruded, cast, or molded plastic rod or sheet are also accept-

the ASTM website.

Detailed working drawings of the fixtures shown in Fig. 4 and Fig. 5 and their

able.

parts are available from ASTM International Headquarters. Order Adjunct No.

ADJD2094. Original adjunct produced in 1966. 5.3 Surface Preparation of Adherends:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2094 − 00 (2006)

Machining Requirements:

1. Two adjacent sides shall be grou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.