ASTM C148-17

(Test Method)Standard Test Methods for Polariscopic Examination of Glass Containers

Standard Test Methods for Polariscopic Examination of Glass Containers

SIGNIFICANCE AND USE

4.1 These two test methods are provided for evaluating the quality of annealing. These test methods can be used in the quality control of glass containers or other products made of similar glass compositions, where the degree of annealing must be verified to ensure quality products. These test methods apply to glass containers manufactured from commercial soda-lime-silica glass compositions.

SCOPE

1.1 These test methods describe the determination of relative optical retardation associated with the state of anneal of glass containers. Two alternative test methods are covered as follows:

Sections

Test Method A—Comparison with Reference Standards

Using a Polariscope

6 – 9

Test Method B—Determination with Polarimeter

10 – 12

1.2 Test Method A is useful in determining retardations less than 150 nm, while Test Method B is useful in determining retardations less than 565 nm.

Note 1: The apparent temper number as determined by these test methods depends primarily on (1) the magnitude and distribution of the residual stress in the glass, (2) the thickness of the glass (optical path length at the point of grading), and (3) the composition of the glass. For all usual soda-lime silica bottle glass compositions, the effect of the composition is negligible. In an examination of the bottom of a container, the thickness of glass may be taken into account by use of the following formula, which defines a real temper number, TR, in terms of the apparent temper number, TA, and the bottom thickness, t:

This thickness should be measured at the location of the maximum apparent retardation. Interpretation of either real or apparent temper number requires practical experience with the particular ware being evaluated.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C148 − 17

Standard Test Methods for

1

Polariscopic Examination of Glass Containers

This standard is issued under the fixed designation C148; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 These test methods describe the determination of rela-

ization established in the Decision on Principles for the

tive optical retardation associated with the state of anneal of

Development of International Standards, Guides and Recom-

glass containers. Two alternative test methods are covered as

mendations issued by the World Trade Organization Technical

follows:

Barriers to Trade (TBT) Committee.

Sections

Test Method A—Comparison with Reference Standards 6–9

2. Referenced Documents

Using a Polariscope

Test Method B—Determination with Polarimeter 10–12

2

2.1 ASTM Standards:

1.2 Test MethodAis useful in determining retardations less

C162 Terminology of Glass and Glass Products

than 150 nm, while Test Method B is useful in determining

C224 Practice for Sampling Glass Containers

retardations less than 565 nm.

C1426 Practices for Verification and Calibration of Polarim-

eters

NOTE 1—The apparent temper number as determined by these test

methods depends primarily on (1) the magnitude and distribution of the

residual stress in the glass, (2) the thickness of the glass (optical path

3. Terminology

length at the point of grading), and (3) the composition of the glass. For

3.1 Definitions— For definitions of terms used in these test

all usual soda-lime silica bottle glass compositions, the effect of the

methods see Terminology C162.

composition is negligible. In an examination of the bottom of a container,

the thickness of glass may be taken into account by use of the following

formula, which defines a real temper number, T , in terms of the apparent

4. Significance and Use

R

temper number, T , and the bottom thickness, t:

A

4.1 These two test methods are provided for evaluating the

T 5 T 0.160 ⁄ t , where t is in inches, or

~ !

R A quality of annealing. These test methods can be used in the

quality control of glass containers or other products made of

T 5 T 4.06 ⁄ t , where t is in millimetres.

~ !

R A

similarglasscompositions,wherethedegreeofannealingmust

This thickness should be measured at the location of the maximum ap-

be verified to ensure quality products. These test methods

parent retardation. Interpretation of either real or apparent temper num-

apply to glass containers manufactured from commercial

ber requires practical experience with the particular ware being evalu-

soda-lime-silica glass compositions.

ated.

1.3 The values stated in SI units are to be regarded as the

5. Sampling

standard. The values given in parentheses are for information

5.1 Methods of sampling a minimum lot from a group of

only.

containers of a given type are given in Practice C224 for the

1.4 This standard does not purport to address all of the

various situations to which that method may apply.

safety concerns, if any, associated with its use. It is the

TEST METHOD A—COMPARISON WITH

responsibility of the user of this standard to establish appro-

REFERENCE STANDARDS USING A POLARISCOPE

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

6. Apparatus

6.1 Polariscope, conforming to the following requirements:

1

These test methods are under the jurisdiction of ASTM Committee C14 on

Glass and Glass Products and are the direct responsibility of Subcommittee C14.07

2

on Glass Containers. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2017. Published May 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1939. Last previous edition approved in 2014 as C148 – 14. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0148-17. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

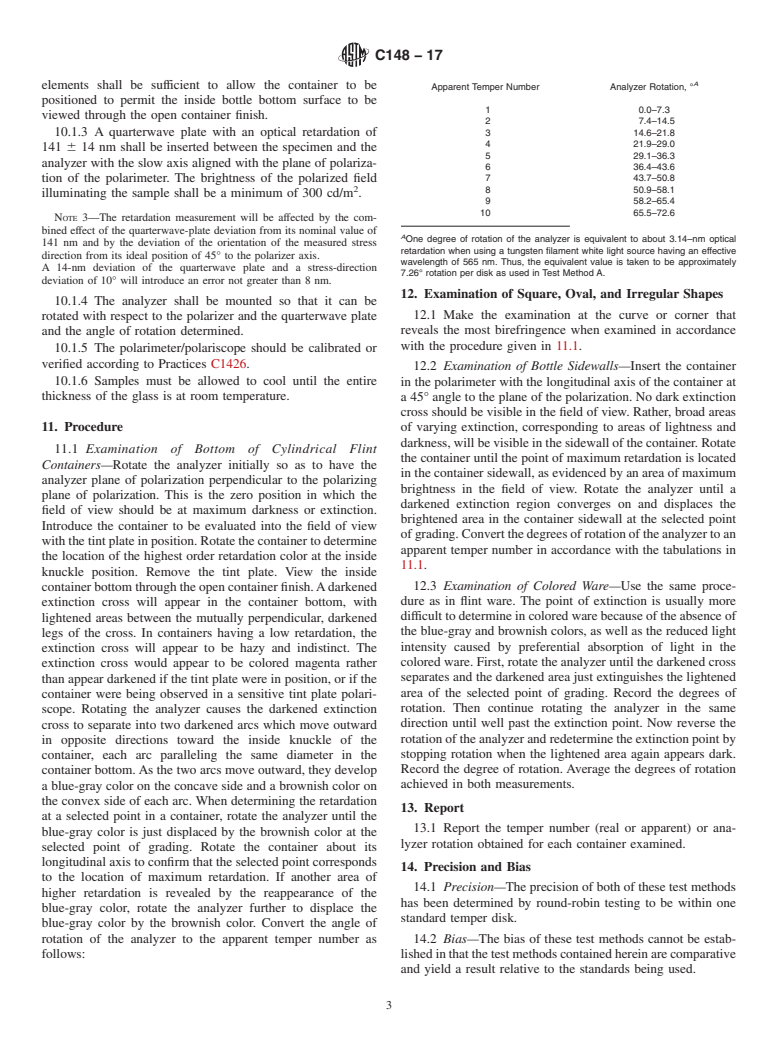

C148 − 17

6.1.1 The degree of polarization of the field at all points apparent temper grade is judged to be that of N + 1 disks. The

shall not be less than 99 %. apparent temper number is always determined to be the next

6.1.2 The field shall be a minimum of 51 mm (2 in.) in integral temper number greater in value

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C148 − 14 C148 − 17

Standard Test Methods for

1

Polariscopic Examination of Glass Containers

This standard is issued under the fixed designation C148; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods describe the determination of relative optical retardation associated with the state of anneal of glass

containers. Two alternative test methods are covered as follows:

Sections

Test Method A—Comparison with Reference Standards 6 – 9

Using a Polariscope

Test Method B—Determination with Polarimeter 10 – 12

Sections

Test Method A—Comparison with Reference 6 to 9

Standards Using a Polariscope

Test Method B—Determination with Polarimeter 10 to 12

1.2 Test Method A is useful in determining retardations less than 150 nm, while Test Method B is useful in determining

retardations less than 565 nm.

NOTE 1—The apparent temper number as determined by these test methods depends primarily on (1) the magnitude and distribution of the residual

stress in the glass, (2) the thickness of the glass (optical path length at the point of grading), and (3) the composition of the glass. For all usual soda-lime

silica bottle glass compositions, the effect of the composition is negligible. In an examination of the bottom of a container, the thickness of glass may

be taken into account by use of the following formula, which defines a real temper number, T , in terms of the apparent temper number, T , and the bottom

R A

thickness, t:

T 5 T ~0.160 ⁄ t!, where t is in inches, or

R A

T 5 T 4.06 ⁄ t , where t is in millimetres.

~ !

R A

This thickness should be measured at the location of the maximum apparent retardation. Interpretation of either real or apparent temper number re-

quires practical experience with the particular ware being evaluated.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C162 Terminology of Glass and Glass Products

C224 Practice for Sampling Glass Containers

C1426 Practices for Verification and Calibration of Polarimeters

1

These test methods are under the jurisdiction of ASTM Committee C14 on Glass and Glass Products and are the direct responsibility of Subcommittee C14.07 on Glass

Containers.

Current edition approved May 1, 2014May 1, 2017. Published May 2014May 2017. Originally approved in 1939. Last previous edition approved in 20122014 as

C148 – 12.C148 – 14. DOI: 10.1520/C0148-14.10.1520/C0148-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C148 − 17

3. Terminology

3.1 Definitions— For definitions of terms used in these test methods see Terminology C162.

4. Significance and Use

4.1 These two test methods are provided for evaluating the quality of annealing. These test methods can be used in the quality

control of glass containers or other products made of similar glass compositions, where the degree of annealing must be verified

to ensure quality products. These test methods apply to glass containers manufactured from commercial soda-lime-silica glass

compositions.

5. Sampling

5.1 Methods of sampling a minimum lot from a group of containers of a given type are given in Practice C224 for the various

situations to whi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.