ASTM D7191-10

(Test Method)Standard Test Method for Determination of Moisture in Plastics by Relative Humidity Sensor

Standard Test Method for Determination of Moisture in Plastics by Relative Humidity Sensor

SIGNIFICANCE AND USE

This test method is intended for use as a control, acceptance, and assessment test.

Moisture can seriously affect the processability of plastics. It is possible that high moisture content will cause surface imperfections (that is, splay or bubbling) or degradation by hydrolysis. Low moisture (with high temperature) has been known to cause solid phase polymerization.

The physical properties of some plastics are greatly affected by the moisture content.

SCOPE

1.1 This test method covers the quantitative determination of water down to 20 ppm in plastics using a relative humidity sensor.

1.2 Values stated in SI units are to be regarded as standard.

1.3 Specimens tested in this test method can reach or exceed 250°C, use caution when handling them after testing has completed.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7191 − 10

Standard Test Method for

Determination of Moisture in Plastics by Relative Humidity

1

Sensor

This standard is issued under the fixed designation D7191; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the quantitative determination 3.1 Definitions—The definitions used in this test method are

in accordance with Terminology D883.

of water down to 20 ppm in plastics using a relative humidity

sensor.

4. Summary of Test Method

1.2 Values stated in SI units are to be regarded as standard.

4.1 Asample is loaded into a septum-capped glass vial that

1.3 Specimenstestedinthistestmethodcanreachorexceed

is moved into a heater to evolve the volatiles from the sample

250°C, use caution when handling them after testing has into the headspace.Acoaxial needle, or two needle set, pierces

completed. the septum of the vial as it enters the heater. A dry carrier gas

then flows into the vial and carries the evolved volatiles in the

1.4 This standard does not purport to address all of the

headspace into the sensor manifold. In the sensor manifold, the

safety concerns, if any, associated with its use. It is the

carriergasiscooledtoallowhigh-boilingvolatilestocondense

responsibility of the user of this standard to establish appro-

on a hydrophobic filter. The filter’s hydrophobic properties

priate safety and health practices and determine the applica-

allow the moisture in the carrier gas to pass through and then

bility of regulatory limitations prior to use.

be measured as an increase in potential at the relative humidity

NOTE 1—There is no known ISO equivalent to this standard.

sensor. This sensor signal is integrated over time to provide a

measurementofthetotalmassofwaterinthesample.Thetotal

2. Referenced Documents

moisture is then divided by sample mass to yield moisture

2

2.1 ASTM Standards:

content.

D1193 Specification for Reagent Water

4.2 This test method utilizes a sealed, airtight flow system

D883 Terminology Relating to Plastics

that prevents contamination of the analyzer from water present

D1600 TerminologyforAbbreviatedTermsRelatingtoPlas-

in the atmosphere.

tics

5. Significance and Use

D6869 Test Method for Coulometric and Volumetric Deter-

mination of Moisture in Plastics Using the Karl Fischer

5.1 This test method is intended for use as a control,

Reaction (the Reaction of Iodine with Water)

acceptance, and assessment test.

E177 Practice for Use of the Terms Precision and Bias in

5.2 Moisture can seriously affect the processability of plas-

ASTM Test Methods

tics. It is possible that high moisture content will cause surface

E691 Practice for Conducting an Interlaboratory Study to

imperfections (that is, splay or bubbling) or degradation by

Determine the Precision of a Test Method

hydrolysis. Low moisture (with high temperature) has been

known to cause solid phase polymerization.

5.3 The physical properties of some plastics are greatly

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

affected by the moisture content.

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

Current edition approved April 1, 2010. Published June 2010. Originally

6. Interferences

approved in 2005. Last previous edition approved in 2005 as D7191 - 05.

DOI:10.1520/D7191-10.

6.1 Elevated concentrations of some common solvents such

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

as methanol, ethanol and acetone will give biased high read-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ings due to their polar characteristics and ability to permeate

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the thermoset polymer layers of the relative humidity sensor.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

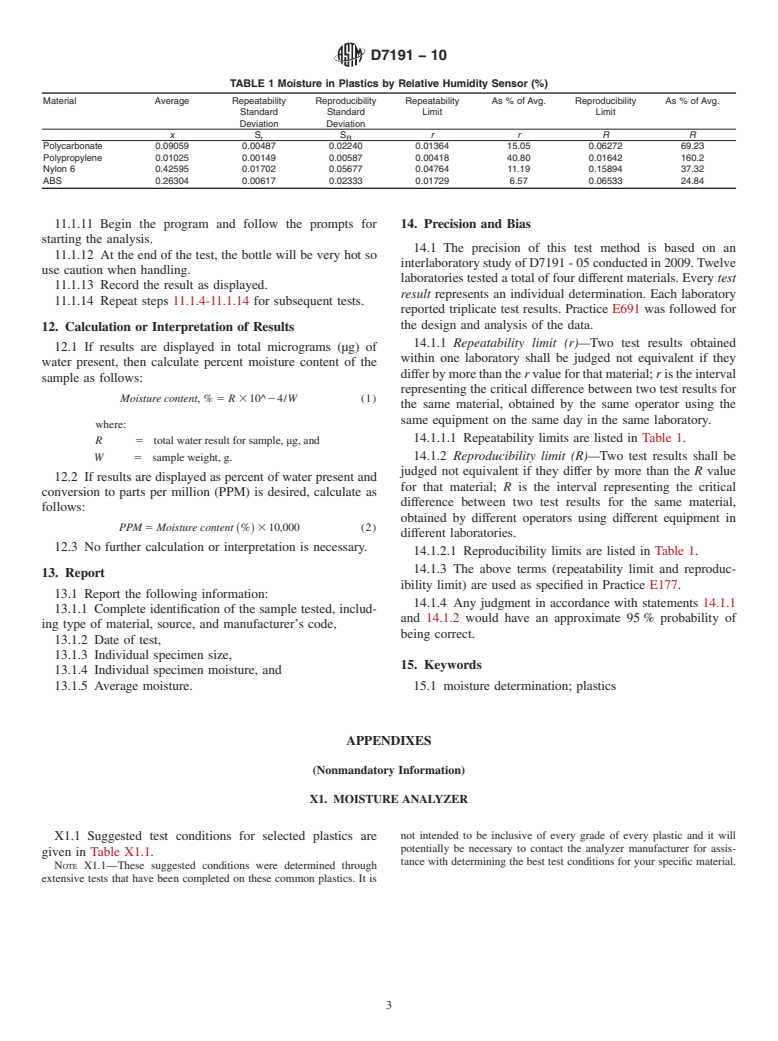

D7191 − 10

7. Apparatus 9.2 Duetothehygroscopicnatureofmanyplastics,samples

3 shall be stored in airtight containers made of glass or other

7.1 Moisture Analyzer , an apparatus that consists of:

qualified or suitable material.

7.1.1 Flow Regulator, capable of maintaining the carrier gas

flow rate within the manufacturer’s specified conditions. 9.3 Samples that have been heated to remove moisture prior

7.1.2 Flow Meter, capable of measuring the carrier gas flow to processing and testing shall be allowed to cool to room

rate in accordance with the manufacturer’s specified condi- temperature in a se

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D7191–05 Designation:D7191–10

Standard Test Method for

Determination of Moisture in Plastics by Relative Humidity

1

Sensor

This standard is issued under the fixed designation D7191; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the quantitative determination of water down to 20 ppm in plastics using a relative humidity sensor.

1.2 Values stated in SI units are to be regarded as standard.

1.3 Specimens tested in this test method can reach or exceed 250°C, use caution when handling them after testing has

completed.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE1—There is no similar or equivalent ISO standard. 1—There is no known ISO equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D883 Terminology Relating to Plastics D1600

D1600 Terminology for Abbreviated Terms Relating to Plastics

D6869 TestMethodforCoulometricandVolumetricDeterminationofMoistureinPlasticsUsingtheKarlFischerReaction(the

Reaction of Iodine with Water) Test Method for Coulometric and Volumetric Determination of Moisture in Plastics Using the

Karl Fischer Reaction (the Reaction of Iodine with Water)

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions—The definitions used in this test method are in accordance with Terminology D883.

4. Summary of Test Method

4.1 Asample is loaded into a septum-capped glass vial that is moved into a heater to evolve the volatiles from the sample into

the headspace.Acoaxial needle, or two needle set, pierces the septum of the vial as it enters the heater.Adry carrier gas then flows

into the vial and carries the evolved volatiles in the headspace into the sensor manifold. In the sensor manifold, the carrier gas is

cooled to allow high-boiling volatiles to condense on a hydrophobic filter. The filter’s hydrophobic properties allow the moisture

inthecarriergastopassthroughandthenbemeasuredasanincreaseinpotentialattherelativehumiditysensor.Thissensorsignal

is integrated over time to provide a measurement of the total mass of water in the sample. The total moisture is then divided by

sample mass to yield moisture content.

4.2 This test method utilizes a sealed, airtight flow system that prevents contamination of the analyzer from water present in

the atmosphere.

5. Significance and Use

5.1 This test method is intended for use as a control, acceptance, and assessment test.

5.2 Moisture can seriously affect the processability of plastics. It is possible that high moisture content will cause surface

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

Current edition approved November 1, 2005. Published November 2005. DOI: 10.1520/D7191-05.

CurrenteditionapprovedApril1,2010.PublishedJune2010.Originallyapprovedin2005.Lastpreviouseditionapprovedin2005asD7191 - 05.DOI:10.1520/D7191-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D7191–10

imperfections (that is, splay or bubbling) or degradation by hydrolysis. Low moisture (with high temperature) has been known to

cause solid phase polymerization.

5.3 The physical properties of some plastics are greatly affected by the moisture content.

6. Interferences

6.1 Elevatedconcentrationsofsomecommonsolventssuchasmethanol,ethanolandacetonewillgivebiasedhighreadingsdue

to their polar characteristics and ability to permeate the thermoset polymer layers of the relative humidity sensor.

7. Apparatus

3

7.1 Moisture Analyzer , an apparatus that

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.