ASTM E2597-07e1

(Practice)Standard Practice for Manufacturing Characterization of Digital Detector Arrays

Standard Practice for Manufacturing Characterization of Digital Detector Arrays

SIGNIFICANCE AND USE

This practice provides a means to compare DDAs on a common set of technical measurements, realizing that in practice adjustments can be made to achieve similar results even with disparate DDAs given geometric magnification, or other industrial radiologic settings that may compensate for one shortcoming of a device.

A user must understand the definitions and corresponding performance parameters used in this practice in order to make an informed decision on how a given DDA can be used in the target application.

The factors that will be evaluated for each DDA are: basic spatial resolution (SRb), efficiency (Detector SNR-normalized (dSNRn) at 1 mGy, for different energies and beam qualities), achievable contrast sensitivity (CSa), specific material thickness range (SMTR), image lag, burn-in, bad pixels and internal scatter radiation (ISR).

SCOPE

1.1 This practice describes the evaluation of Digital Detector Arrays (DDAs), and assures that one common standard exists for quantitative comparison of DDAs so that an appropriate DDA is selected to meet NDT requirements.

1.2 This practice is intended for use by manufacturers or integrators of DDAs to provide quantitative results of DDA characteristics for NDT user or purchaser consumption. Some of these tests require specialized test phantoms to assure consistency among results among suppliers or manufacturers. These tests are not intended for users to complete, nor are they intended for long term stability tracking and lifetime measurements. However, they may be used for this purpose, if so desired.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E2597 − 07

StandardPractice for

1

Manufacturing Characterization of Digital Detector Arrays

This standard is issued under the fixed designation E2597; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Editorial corrections were made throughout in April 2008.

1. Scope E2445PracticeforQualificationandLong-TermStabilityof

Computed Radiology Systems

1.1 This practice describes the evaluation of Digital Detec-

E2446Practice for Classification of Computed Radiology

tor Arrays (DDAs), and assures that one common standard

Systems

exists for quantitative comparison of DDAs so that an appro-

2.2 Other Standards:

priate DDA is selected to meet NDT requirements.

ISO7004 Photography—Industrial Radiographic Films—

1.2 This practice is intended for use by manufacturers or

Determination of ISO Speed, ISO Average Gradient and

integrators of DDAs to provide quantitative results of DDA

ISO Gradients G2 and G4 When Exposed to X- and

characteristics for NDT user or purchaser consumption. Some 3

Gamma-Radiation

of these tests require specialized test phantoms to assure

IEC 62220-1Medical Electrical Equipment Characteristics

consistency among results among suppliers or manufacturers.

ofDigitalX-rayImagingDevicesPart1:Determinationof

These tests are not intended for users to complete, nor are they 4

the Detective Quantum Efficiency

intended for long term stability tracking and lifetime measure-

ments. However, they may be used for this purpose, if so

3. Terminology

desired.

3.1 Definitions of Terms Specific to This Standard:

1.3 The values stated in SI units are to be regarded as

3.1.1 digital detector array (DDA) system—an electronic

standard. The values given in parentheses are for information

device that converts ionizing or penetrating radiation into a

only.

discrete array of analog signals which are subsequently digi-

tized and transferred to a computer for display as a digital

1.4 This standard does not purport to address all of the

image corresponding to the radiologic energy pattern imparted

safety concerns, if any, associated with its use. It is the

upon the input region of the device. The conversion of the

responsibility of the user of this standard to establish appro-

ionizing or penetrating radiation into an electronic signal may

priate safety and health practices and determine the applica-

transpire by first converting the ionizing or penetrating radia-

bility of regulatory limitations prior to use.

tionintovisiblelightthroughtheuseofascintillatingmaterial.

2. Referenced Documents

These devices can range in speed from many seconds per

2

2.1 ASTM Standards: image to many images per second, up to and in excess of

real-time radioscopy rates (usually 30 frames per seconds).

E1316Terminology for Nondestructive Examinations

E1647Practice for Determining Contrast Sensitivity in Ra-

3.1.2 active DDA area—the size and location of the DDA,

diology

which is recommended by the manufacturer as usable.

E1742Practice for Radiographic Examination

3.1.3 signal-to-noise ratio (SNR)—quotient of mean value

E1815Test Method for Classification of Film Systems for

of the intensity (signal) and standard deviation of the intensity

Industrial Radiography

(noise). The SNR depends on the radiation dose and the DDA

E2002PracticeforDeterminingTotalImageUnsharpnessin

system properties.

Radiology

3.1.4 contrast-to-noise ratio (CNR)—quotient of the differ-

enceofthemeansignallevelsbetweentwoimageareasandthe

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

standarddeviationofthesignallevels.Asappliedhere,thetwo

structive Testing and is the direct responsibility of Subcommittee E07.01 on

Radiology (X and Gamma) Method.

Current edition approved Dec. 1, 2007. Published January 2008. DOI: 10.1520/

3

E2597-07E01. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4th Floor, New York, NY 10036, http://www.ansi.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from International Electrotechnical Commission (IEC), 3 rue de

Standards volume information, refer to the standard’s Document Summary page on Varembé, Case postale 131, CH-1211, Geneva 20, Switzerland, http://www.iec.ch.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

E2597 − 07

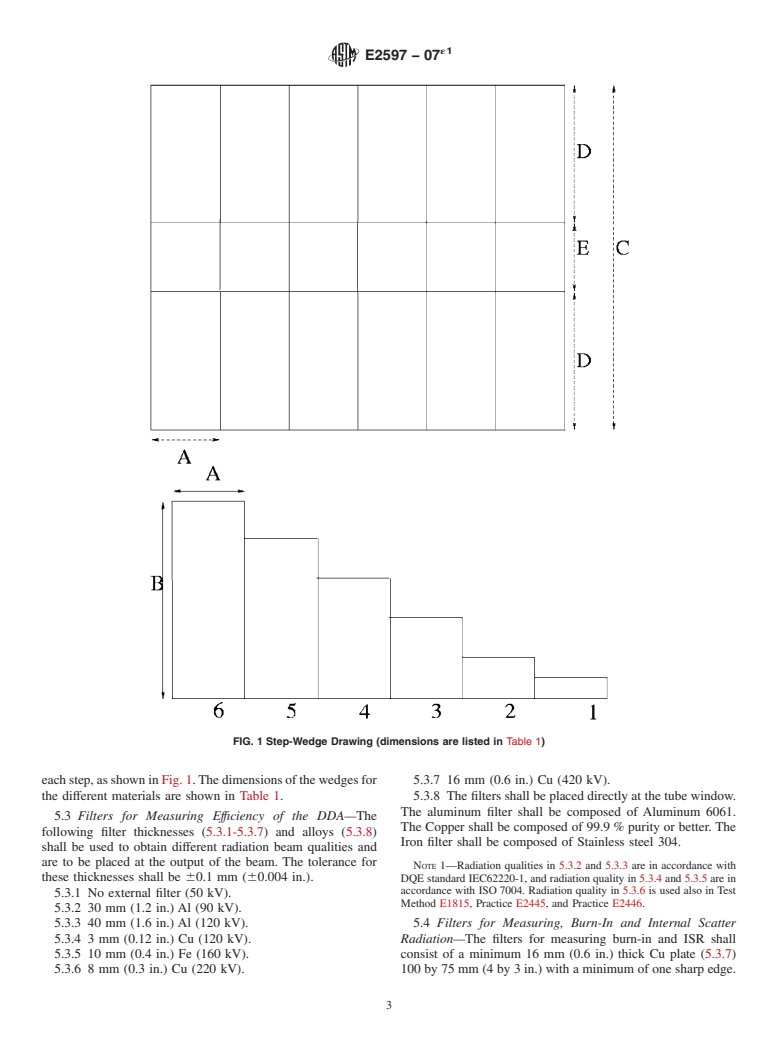

image areas are the step-wedge groove and base material. The 3.1.19 phantom—apartoritembeingu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.