ASTM D4542-95

(Test Method)Standard Test Method for Pore Water Extraction and Determination of the Soluble Salt Content of Soils by Refractometer

Standard Test Method for Pore Water Extraction and Determination of the Soluble Salt Content of Soils by Refractometer

SCOPE

1.1 This test method covers a rapid procedure for squeezing pore water from fine-grained soils for the purpose of determining the amount of soluble salts present in the extracted pore water.

1.2 This test method was developed for soils having a water content equal to or greater than approximately 14 %, for example, marine soils. An extensive summary of procedures for extracting pore water from soils has been presented by Kriukov and Manheim (1).

1.3 This test method is not generally applicable for determining the soluble salt content of the pore water extracted from coarse-grained soils, such as clean sands and gravels.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4542 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Pore Water Extraction and Determination of the Soluble Salt

Content of Soils by Refractometer

This standard is issued under the fixed designation D 4542; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope within the soil sample.

1.1 This test method covers a rapid procedure for squeezing

NOTE 1—Hulbert and Brindle (2) and Torrance (3) have shown that

pore water from fine-grained soils for the purpose of determin-

prolonged storage should be avoided as unpredictable and nonreproduc-

ible chemical changes may occur.

ing the amount of soluble salts present in the extracted pore

water.

4. Apparatus

1.2 This test method was developed for soils having a water

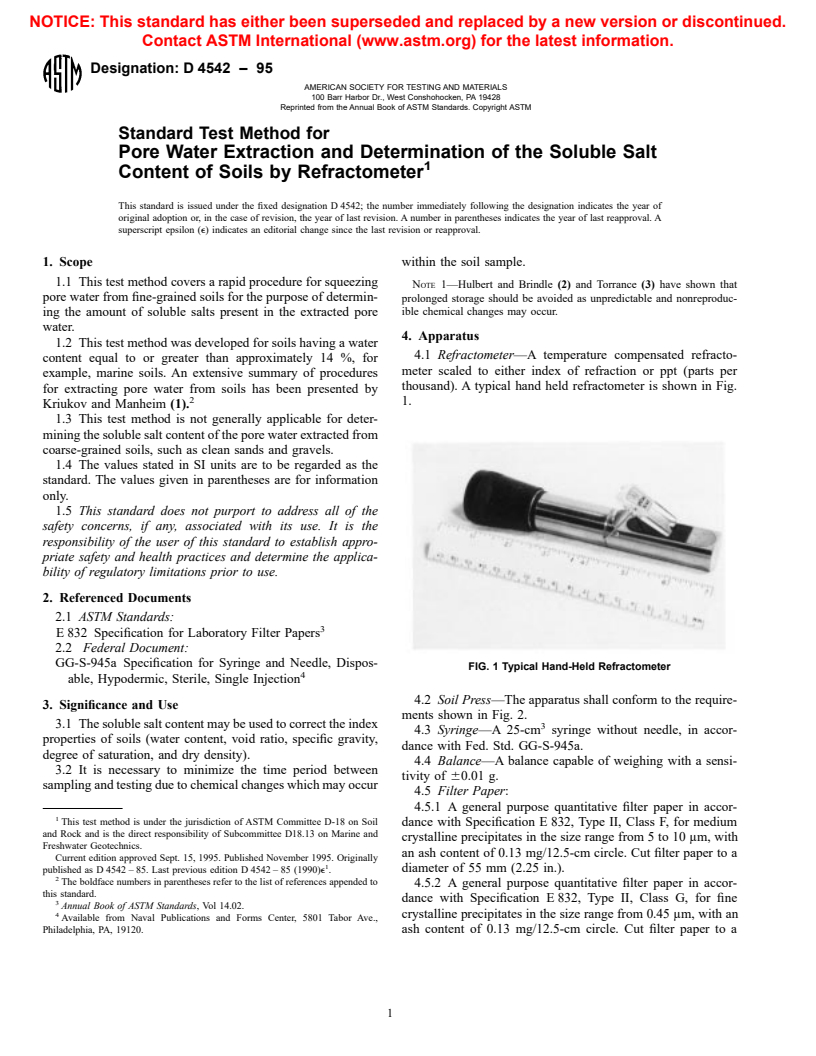

4.1 Refractometer—A temperature compensated refracto-

content equal to or greater than approximately 14 %, for

meter scaled to either index of refraction or ppt (parts per

example, marine soils. An extensive summary of procedures

thousand). A typical hand held refractometer is shown in Fig.

for extracting pore water from soils has been presented by

1.

Kriukov and Manheim (1).

1.3 This test method is not generally applicable for deter-

mining the soluble salt content of the pore water extracted from

coarse-grained soils, such as clean sands and gravels.

1.4 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

only.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E 832 Specification for Laboratory Filter Papers

2.2 Federal Document:

GG-S-945a Specification for Syringe and Needle, Dispos-

FIG. 1 Typical Hand-Held Refractometer

able, Hypodermic, Sterile, Single Injection

4.2 Soil Press—The apparatus shall conform to the require-

3. Significance and Use

ments shown in Fig. 2.

3.1 The soluble salt content may be used to correct the index

4.3 Syringe—A 25-cm syringe without needle, in accor-

properties of soils (water content, void ratio, specific gravity,

dance with Fed. Std. GG-S-945a.

degree of saturation, and dry density).

4.4 Balance—A balance capable of weighing with a sensi-

3.2 It is necessary to minimize the time period between

tivity of 60.01 g.

sampling and testing due to chemical changes which may occur

4.5 Filter Paper:

4.5.1 A general purpose quantitative filter paper in accor-

This test method is under the jurisdiction of ASTM Committee D-18 on Soil dance with Specification E 832, Type II, Class F, for medium

and Rock and is the direct responsibility of Subcommittee D18.13 on Marine and

crystalline precipitates in the size range from 5 to 10 μm, with

Freshwater Geotechnics.

an ash content of 0.13 mg/12.5-cm circle. Cut filter paper to a

Current edition approved Sept. 15, 1995. Published November 1995. Originally

diameter of 55 mm (2.25 in.).

published as D 4542 – 85. Last previous edition D 4542 – 85 (1990)e .

The boldface numbers in parentheses refer to the list of references appended to

4.5.2 A general purpose quantitative filter paper in accor-

this standard.

dance with Specification E 832, Type II, Class G, for fine

Annual Book of ASTM Standards, Vol 14.02.

crystalline precipitates in the size range from 0.45 μm, with an

Available from Naval Publications and Forms Center, 5801 Tabor Ave.,

Philadelphia, PA, 19120. ash content of 0.13 mg/12.5-cm circle. Cut filter paper to a

D 4542

FIG. 2 Soil Press

diameter of 25 mm (0.98 in.). 10-μm (55-mm) filter paper.

4.6 Refrigerator—Cooling unit capable of maintaining a 6.2 Apply pressure slowly until the first drops of water are

uniform temperature between 1 and 5°C. expelled, then insert a clean, disposable, plastic syringe (25

4.7 Micro-Syringe Filter Holder—A device to filter a liquid mL) in the effluent passage shown in Fig. 2. This is done to

directly from a syringe. minimize the amount of air in the syringe and therefore, the

4.8 100-mL Polyethylene or Glass Bottle and Cap. amount of evaporation.

4.9 Miscellaneous Supplies—Distilled water, alcohol, di- 6.3 Apply pressure gradually to a maximum of 80 MPa

luted HCl (1:10), detergent, and optional sterile bags for (11 520 psi), and hold until no more water is expelled or until

sample storage (see 6.6). the syringe is full (see Note 3 and Note 4).

6.4 Withdraw the syringe when the pressure is at a maxi-

5. Preparation of Apparatus

mum and immediately expel the fluid from the syringe through

5.1 Wash all parts of the press thoroughly. Rinse twice with

a stainless steel micro-syringe holder, fitted with fresh 0.45-μm

distilled water and dry. Normally, rust should not be present,

(25-mm) filter paper, into a clean 100-mL bottle (see Note 5).

but if it is to be removed, especially inside or around the top of

Cap the bottle. Expose the collected water to the atmosphere as

the cylinder, scrub gently with steel wool and soap or chromic

little as possible.

acid. Rinse well with tap water and then twice with distilled

6.5 Repeat 6.1-6.4, using the same syringe and filter if

water and dry.

additional water is needed for experimentation and can be

5.2 If the press parts have been coated with rust preventive,

collected. Usually about 25 mL of pore water may be collected

wash them with alcohol and rinse once with tap water and

from 50 g of sediment (see Note 6 and Note 7). Store the water

twice with distilled water.

at a temperature between 1 and 5°C (see Note 8 and Sections

5.3 Dry by a method that will not contaminate the press.

7 and 8).

Clean compressed air, oven or air drying, or rinsing with

6.6 Remove the soil from the press. If additional tests are

acetone followed by air drying are acceptable.

anticipated, store soil in a sterile plastic bag at a temperature

5.4 Assemble the press.

between 1 and 5°C (see Note 8).

NOTE 2—To prevent mud from circumventing the stainless steel wire

NOTE 3—Only a few drops (0.05 mL) of pore fluid are required to

screen use flexible TFE-fluorocarbon gaskets on each side.

conduct the soluble salt determination by refractometer. It is recom-

mended that 25 mL of pore water be collected, if possible, to allow for

6. Sampling and Test Specimen Squeezing

retesting or additional tests, or both.

NOTE 4—Kriukov and Komarova (4) have found that at a pressure of 59

6.1 Select a representative soil sample of approximately 50

MPa (8500 psi) the chloride content drops in homogeneous soils.

g and place into the cylinder on top of a single sheet of 5 to

Manheim (5) reports using 101 MPa (14 700 psi) routinely. An average of

these two recommendations is 80 MPa (11 520 psi).

NOTE 5—Polyethylene or glass bottles should be washed with detergent

An apparatus such as the stainless steel Millipore Micro-Syringe Filter Holder

XX30-025-00 is satisfactory for this purpose. and rinsed with tap water. They should then be rinsed once with diluted

D 4542

HCl (1:10) and twice with distilled water and then drained thoroughly. NOTE 9—A typical temperature-compensated instrument is accurate to

NOTE 6—The amount of water expelled will depend on the initial water 0.1 % between 15.6 and 37.8°C; the instrument is most accurate between

content of the s

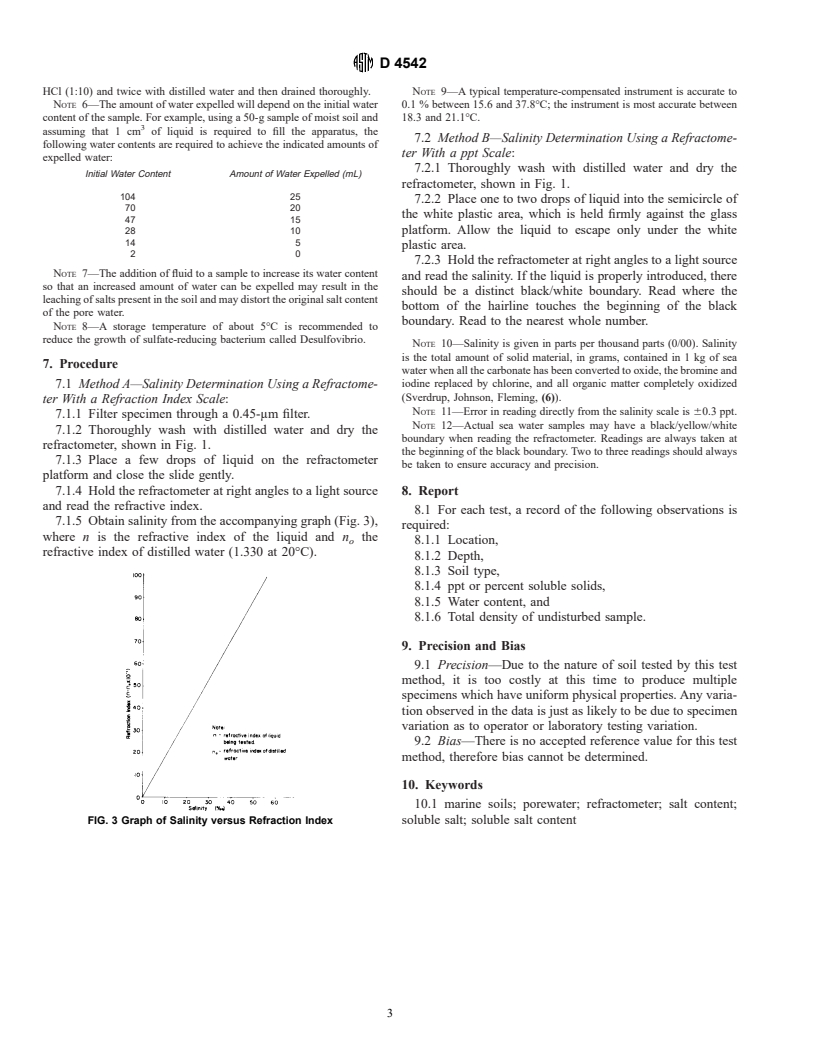

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.