ASTM D4161-96

(Specification)Standard Specification for "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe Joints Using Flexible Elastomeric Seals

Standard Specification for "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe Joints Using Flexible Elastomeric Seals

SCOPE

1.1 This specification covers axially unrestrained bell-and-spigot gasket joints including couplings required for machine-made "fiberglass" (glass-fiber-reinforced thermosetting-resin) pipe systems, 8 in. (200 mm) through 144 in. (3700 mm), using flexible elastomeric seals to obtain soundness. The pipe systems may be pressure (typically up to 250 psi) or nonpressure systems for water or for chemicals or gases that are not deleterious to the materials specified in this specification. This specification covers materials, dimensions, test requirements, and methods of test.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

Note 1—There is no similar or equivalent ISO standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4161 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

“Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin)

1,2

Pipe Joints Using Flexible Elastomeric Seals

This standard is issued under the fixed designation D 4161; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Types of Joints

1.1 This specification covers axially unrestrained bell-and- 4.1 This specification covers two types of axially unre-

spigot gasket joints including couplings required for machine- strained joints based on effecting soundness of the joint

made “fiberglass” (glass-fiber-reinforced thermosetting-resin) through compression of an elastomeric seal or ring:

pipe systems, 8 in. (200 mm) through 144 in. (3700 mm), using 4.1.1 Bell-and-spigot gasket or coupling joint with the

flexible elastomeric seals to obtain soundness. The pipe sys- gasket placed in the bell in circumferential compression. A

tems may be pressure (typically up to 250 psi) or nonpressure single elastomeric gasket joint design featuring a continuous

systems for water or for chemicals or gases that are not elastomeric ring gasket placed in an annular space provided in

deleterious to the materials specified in this specification. This the bell or socket of the pipe or fitting. The spigot end of the

specification covers materials, dimensions, test requirements, pipe or fitting is forced into the bell, thereby compressing the

and methods of test. gasket radially to form a positive seal.

1.2 The values stated in inch-pound units are to be regarded 4.1.2 Bell-and-spigot gasket or coupling joint with the

as the standard. The values given in parentheses are provided gasket placed on the spigot in circumferential tension: A push

for information purposes only. on joint design featuring a continuous elastomeric ring gasket

placed in an annular space provided on the spigot end of the

NOTE 1—There is no similar or equivalent ISO standard.

pipe or fitting. The spigot is forced into the bell of the pipe or

1.3 This standard does not purport to address all of the

fitting, thereby compressing the gasket radially to form a

safety concerns, if any, associated with its use. It is the

positive seal.

responsibility of the user of this standard to establish appro-

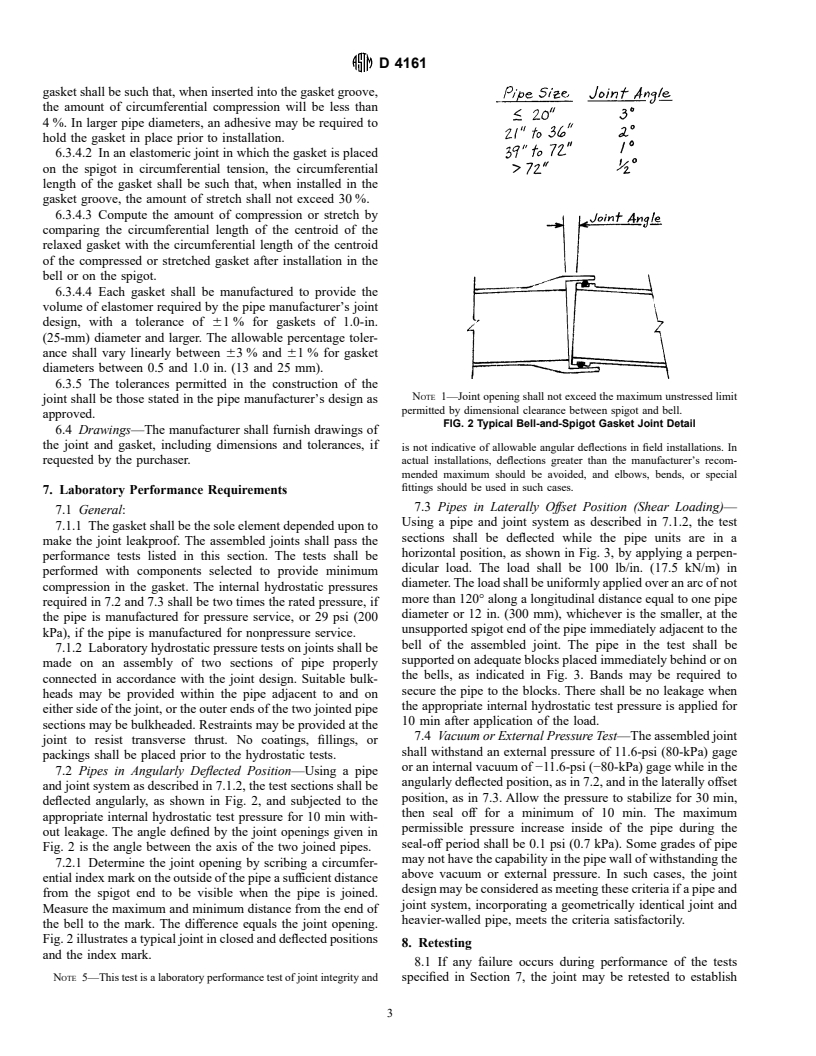

NOTE 2—A coupling joint of these types is a loose double-bell sleeve

priate safety and health practices and determine the applica-

used to connect pipes which have spigots at both ends (see Fig. 1). All

bility of regulatory limitations prior to use.

references to bells in this specification are applicable to the sleeve

coupling as well as to the integral bell of a bell-and-spigot gasket joint.

2. Referenced Documents

2.1 ASTM Standards: 5. Materials and Manufacture

3

D 883 Terminology Relating to Plastics

5.1 The gasket shall be a continuous elastomeric ring of

D 1600 Terminology for Abbreviated Terms Relating to

circular or other geometric cross section and shall meet the

3

Plastics

requirements of Specification F 477, unless otherwise specified

4

F 412 Terminology Relating to Plastic Piping Systems

in this specification. When a splice is used in the manufacture

F 477 Specification for Elastomeric Seals (Gaskets) for

of the gasket, no more than two splices shall be made in any

4

Joining Plastic Pipe

one gasket.

5.1.1 The chemical composition of the gasket shall be

3. Terminology

compatible with the type of environment to which it will be

3.1 Definitions:

subjected. Selection of the gasket composition shall be in

3.1.1 General—Definitions and abbreviations are in accor-

accordance with a purchaser and seller agreement.

dance with Terminology D 883 or Terminology F 412, and

NOTE 3—Consult the gasket manufacturer for advice as to the suitabil-

Terminology D 1600 unless otherwise indicated.

ity of specific rubber compounds for the intended service and joint

configurations. Items such as cold set when the joint is deflected under

low-temperature conditions and maximum and minimum stretch in the

1

This specification is under the jurisdiction of ASTM Committee D-20 on

gasket may be dependent upon the specific chemical compounds used.

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

Plastic Piping Systems and Chemical Equipment.

5.2 Materials in the bell and spigot of the joint shall meet

Current edition approved July 10, 1996. Published September 1996. Originally

the requirements of the applicable ASTM specification for the

published as D 4161 – 82. Last prev

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.