ASTM D1425/D1425M-09e1

(Test Method)Standard Test Method for Unevenness of Textile Strands Using Capacitance Testing Equipment

Standard Test Method for Unevenness of Textile Strands Using Capacitance Testing Equipment

SIGNIFICANCE AND USE

This test method for the determination of evenness of textile strands is used extensively for acceptance testing of commercial shipments of filament or spun staple yarn, comber laps, roving, sliver, or tops. 6.2 6.3 6.4 6.5 Evenness values obtained on different instruments will be comparable for strands from the same sample provided the following parameters are the same in all cases: (1) the measure of evenness used; (2) the capacitive length zone L (see 3.1.5 and 3.1.5.1); (3) the sample length, Ls (see 3.1.8); (4) instrument test speed, (5) laboratory temperature and humidity conditions (see 12.1 and 12.1.1); and (6) test specimen variation. When different models of an instrument are used, and one or more of the six parameters are not identical, test results may differ.

Values of strand evenness are also used in quality control, process optimization, and together with yarn strength measurements, is the first appraisal of a strand's quality. A low evenness value is, in general, preferred. Higher evenness values generally indicate difficult spinning, lower yarn strength, and poorer fabric appearance. Experience has shown that the relationship of evenness to the prediction of yarn performance and to fabric appearance is not a simple one. An evenness value must, therefore, be used cautiously and be supplemented by additional evenness information, such as mid-term and long-term mass variations, thin, thick, and nep imperfection counts, diagram chart spectrogram chart, length variation curve, and histogram analyses.

Continuous filament yarns should be tested for mass variation on instruments specifically designed to them.; failure to do so will result in inaccurate test results. Further, low-twist, continuous yarns tend to flatten to a ribbon configuration while passing through the condenser of a capacitance instrument. These specific instruments are designed to insert false twist in the condenser during testing to overcome the flattening effect and may result in ...

SCOPE

1.1 This test method covers the indirect measurement of evenness (mass variation) of non-conductive textile strands, including top, comber lap, sliver, roving, and yarn produced from staple fibers and continuous filament yarns, by means of capacitance testing equipment.

1.2 Strands made from fiber blends can be tested using this test method only if the different fibers are uniformly distributed throughout the strand.

1.3 The test method provides numeric values for the measurement and evaluation of short-, mid-, and long-term mass variations of the tested strand in terms of frequently occurring faults classified as thin places, thick places, and neps and graphical representations of evenness values in the form of diagram charts, spectrograms, length variation curves, and histograms.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D1425/D1425M − 09

StandardTest Method for

Unevenness of Textile Strands Using Capacitance Testing

1

Equipment

This standard is issued under the fixed designation D1425/D1425M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

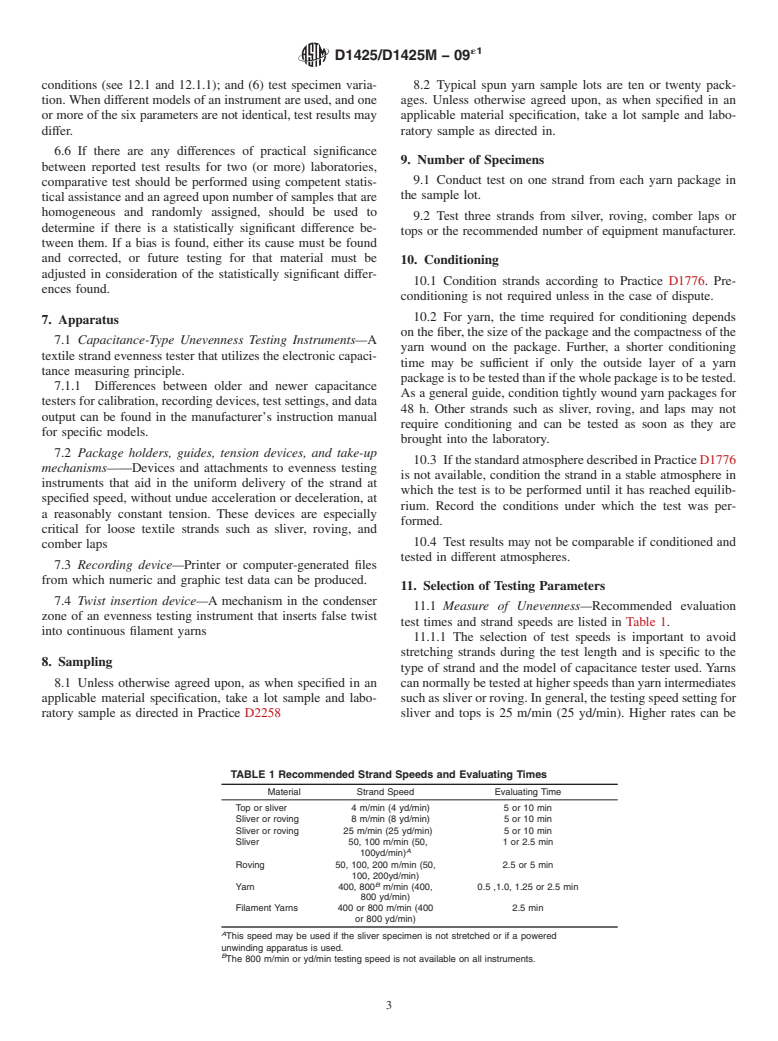

ε NOTE—Footnotes A and B were added to Table 1 in April 2012.

1. Scope D1776 Practice for Conditioning and Testing Textiles

D2258 Practice for Sampling Yarn for Testing

1.1 This test method covers the indirect measurement of

D4849 Terminology Related to Yarns and Fibers

evenness (mass variation) of non-conductive textile strands,

including top, comber lap, sliver, roving, and yarn produced

3. Terminology

from staple fibers and continuous filament yarns, by means of

capacitance testing equipment.

3.1 Definitions:

3.1.1 electric constant, n—in textile capacitance testing, the

1.2 Strands made from fiber blends can be tested using this

change in the electrical field as measured by the sensors

testmethodonlyifthedifferentfibersareuniformlydistributed

(capacitors) of an evenness instrument when a non-conductive

throughout the strand.

textile strand travels between capacitor plates.

1.3 The test method provides numeric values for the mea-

3.1.1.1 Discussion—The dielectric change is measured as

surement and evaluation of short-, mid-, and long-term mass

the ratio of the amount of stored energy between the capacitors

variations of the tested strand in terms of frequently occurring

without a strand and during the movement of a strand through

faults classified as thin places, thick places, and neps and

thesensorzoneandisindirectproportiontothemassvariation

graphical representations of evenness values in the form of

that is output to a diagram chart.

diagram charts, spectrograms, length variation curves, and

3.1.2 evenness, CV% (or U%), n— in textiles,thecoefficient

histograms.

of mass variation derived from the standard deviation of the

1.4 The values stated in either SI units or inch-pound units

mass variation of a specified strand length (L ) over the mass

s

are to be regarded separately as standard. The values stated in

variation (formerly known as unevenness).

each system may not be exact equivalents; therefore, each

3.1.2.1 Discussion—For strands with normal mass variation

system shall be used independently of the other. Combining

distribution, the relationship between CV% and U% is U% is

values from the two systems may result in non-conformance

multiplied by 1.25. Although both CV% and U% are used as

with the standard.

values of evenness, CV% is considered more accurate CV% is

1.5 This standard does not purport to address all of the

gradually replacing U% as the only calculated measurement of

safety concerns, if any, associated with its use. It is the

evenness.

responsibility of the user of this standard to establish appro-

3.1.3 imperfections, n—in textile evenness testing, the indi-

priate safety and health practices and determine the applica-

vidual number of thick places, thin places, and neps of a

bility of regulatory limitations prior to use.

sample strand length measured by a capacitive evenness tester

2. Referenced Documents

at selected sensitivity settings.

2

2.1 ASTM Standards:

3.1.4 length between, L ,, n—in textile evenness testing, the

b

D123 Terminology Relating to Textiles

length of strand segments weighed to determine evenness for

the direct method (cut & weigh) of measuring evenness.

1

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

3.1.5 length capacitance zone, L,n—, the width of the

c

and is the direct responsibility of Subcommittee D13.58 on Yarns and Fibers.

measurement field of the capacitive sensor.

Current edition approved July 1, 2009. Published August 2009. Originally

3.1.5.1 Discussion—The capacitive sensor measurement

approved in 1956. Discontinued May 2005 and reinstated as D1425/D1425M-09.

ε1

DOI: 10.1520/D1425_D1425M-09 .

field determines the length between the indirect method of

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

evennesstesting.TheLcisthelengthofstrandbeingmeasured

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

between the sensing elements at any moment. L is analogous

Standards volume information, refer to the standard’s Document Summary page on c

the ASTM website. to L of the direct method.

b

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D1425/D1425M − 09

3.1.6 mass variation, n—in textile evenness testing, the 5. S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.