ASTM F1674-11

(Test Method)Standard Test Method for Joint Restraint Products for Use with PVC Pipe

Standard Test Method for Joint Restraint Products for Use with PVC Pipe

ABSTRACT

This test method describes a procedure for qualifying the performance of joint restraint products for use on PVC pressure pipe systems by evaluating the effect of the joint restraint product on the performance characteristics of PVC pipe during cyclic pressure tests and static pressure tests. This test method is useful for establishing any effects that a joint restraint product has on the performance of PVC pressure pipe. This test method is designed so that success in all three parts of the test provides reasonable assurance that a joint restraint product may be used on PVC pipe at the full pressure rating and capacity of the pipe. Pipe specimen length, minimum burst pressure test, sustained pressure test, and cyclic surge pressure test shall be performed to conform with the specified requirements.

SIGNIFICANCE AND USE

This test method is useful for establishing any effects that a joint restraint product has on the performance of PVC pressure pipe. This test method is designed so that success in all three parts of the test provides reasonable assurance that a joint restraint product may be used on PVC pipe at the full pressure rating and capacity of the pipe.

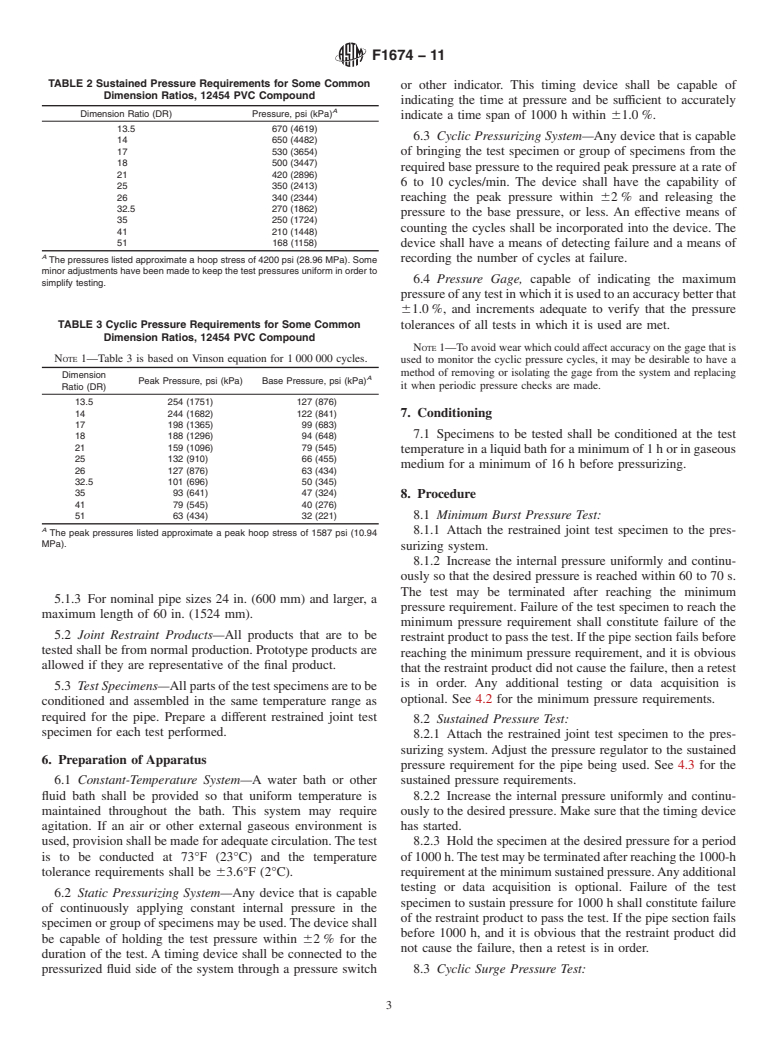

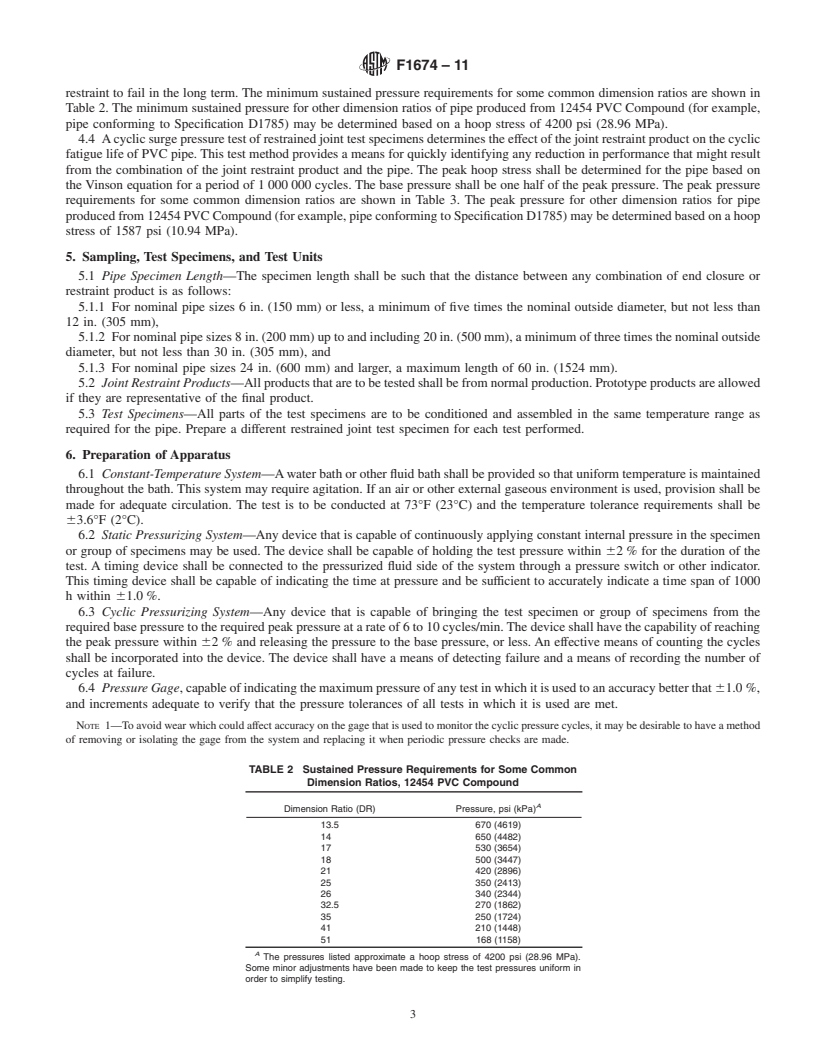

Restrained joint test specimens shall be subjected to internal pressures that are equal to the minimum burst pressure requirements for the pipe alone. The minimum burst pressure requirements for some common dimension ratios are shown in Table 1. The minimum burst pressures for other dimension ratios of pipe produced from 12454 PVC Compound (that is, pipe conforming to Specification D1785) may be determined based on a hoop stress of 6400 psi (44.13 MPa).

Testing of restrained joint test specimens for 1000 h at the sustained pressure requirements indicates any tendency of the restraint to fail in the long term. The minimum sustained pressure requirements for some common dimension ratios are shown in Table 2. The minimum sustained pressure for other dimension ratios of pipe produced from 12454 PVC Compound (for example, pipe conforming to Specification D1785) may be determined based on a hoop stress of 4200 psi (28.96 MPa).

A cyclic surge pressure test of restrained joint test specimens determines the effect of the joint restraint product on the cyclic fatigue life of PVC pipe. This test method provides a means for quickly identifying any reduction in performance that might result from the combination of the joint restraint product and the pipe. The peak hoop stress shall be determined for the pipe based on the Vinson equation for a period of 1 000 000 cycles. The base pressure shall be one half of the peak pressure. The peak pressure requirements for some common dimension ratios are shown in Table 3. The peak pressure for other dimension ratios for pipe produced from 12454 PVC Compound (for example, pipe conforming to ...

SCOPE

1.1 This test method describes a procedure for qualifying the performance of joint restraint products for use on PVC pressure pipe systems by evaluating the effect of the joint restraint product on the performance characteristics of PVC pipe during cyclic pressure tests and static pressure tests. The PVC pipe property values referenced in this test method are for the 12454 compound as described in Specification D1784 and a 4,000 HDB shall be obtained by categorizing the LTHS in accordance with Table 1 in Test Method D2837. That includes, but is not limited to, pipe produced in accordance with the following standards: Specifications D1785 and D2241, AWWA C900 , and AWWA C905.

1.2 This test method determines the short-term performance of a joint restraint product on PVC pipe, which involves the testing of restrained joint test sections to the minimum burst pressure requirements of the pipe to determine quick burst performance.

1.3 This test method determines the long-term effect of a joint restraint product on PVC pipe, which involves the testing of restrained joint test sections to the sustained pressure req...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1674 − 11 An American National Standard

Standard Test Method for

1

Joint Restraint Products for Use with PVC Pipe

This standard is issued under the fixed designation F1674; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.6 Thevaluesstatedininch-poundunitsaretoberegarded

as the standard. The values in parentheses are for information

1.1 This test method describes a procedure for qualifying

purposes only.

the performance of joint restraint products for use on PVC

1.7 This standard does not purport to address all of the

pressure pipe systems by evaluating the effect of the joint

safety concerns, if any, associated with its use. It is the

restraint product on the performance characteristics of PVC

responsibility of the user of this standard to establish appro-

pipe during cyclic pressure tests and static pressure tests. The

priate safety and health practices and determine the applica-

PVCpipepropertyvaluesreferencedinthistestmethodarefor

bility of regulatory limitations prior to use.

the 12454 compound as described in Specification D1784 and

a 4,000 HDB shall be obtained by categorizing the LTHS in

2. Referenced Documents

accordance withTable 1 inTest MethodD2837.That includes,

3

2.1 ASTM Standards:

but is not limited to, pipe produced in accordance with the

D1784Specification for Rigid Poly(Vinyl Chloride) (PVC)

followingstandards:SpecificationsD1785andD2241,AWWA

Compounds and Chlorinated Poly(Vinyl Chloride)

C900 , and AWWA C905.

(CPVC) Compounds

1.2 Thistestmethoddeterminestheshort-termperformance

D1785Specification for Poly(Vinyl Chloride) (PVC) Plastic

of a joint restraint product on PVC pipe, which involves the

Pipe, Schedules 40, 80, and 120

testing of restrained joint test sections to the minimum burst

D2241 Specification for Poly(Vinyl Chloride) (PVC)

pressure requirements of the pipe to determine quick burst

Pressure-Rated Pipe (SDR Series)

performance.

D2837Test Method for Obtaining Hydrostatic Design Basis

forThermoplasticPipeMaterialsorPressureDesignBasis

1.3 This test method determines the long-term effect of a

for Thermoplastic Pipe Products

joint restraint product on PVC pipe, which involves the testing

F412Terminology Relating to Plastic Piping Systems

of restrained joint test sections to the sustained pressure

2.2 AWWA Standards:

requirements of the pipe for a period of 1000 h.

AWWA C900Polyvinyl Chloride (PVC) Pressure Pipe and

1.4 This test method addresses restraint products that are

Fabricated Fittings, 4 In. through 12 In. (100 mm through

4

rated at the full pressure capacity of the PVC pipe on which

300 mm), for Water Distribution

theyareused.Therearejointrestraintdevicesavailablethatare

AWWA C905Polyvinyl Chloride (PVC) Pressure Pipe and

not rated at the full pressure capacity of the pipe. While those

Fabricated Fittings Pipe, Nominal Diameters 14 In.

productshaveprovenacceptableandusefulinthemarketplace,

through 48 In. (350 mm through 1,200 mm), for Water

4

this test method does not apply to those products.

Transmission and Distribution

1.5 This test method determines the performance of a joint

3. Terminology

restraint product on PVC pipe subjected to cyclic pressure

3.1 Definitions—Definitions are in accordance with Termi-

surges. The performance is compared to the baseline perfor-

nology F412 unless otherwise specified.

mance of pipe without joint restraint products established by

2

3.2 Definitions of Terms Specific to This Standard:

Herbert W. Vinson.

3.2.1 base hoop stress—the minimum hoop stress during

cyclic testing; the base hoop stress shall be one half the peak

hoop stress.

1

This test method is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining.

3

Current edition approved April 1, 2011. Published April 2011. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1996. Last previous edition approved in 2005 as F1674–05. DOI: contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

10.1520/F1674-11. Standards volume information, refer to the standard’s Document Summary page on

2

Vinson, Herbert W., Response of PVC Pipe to Large, Repetitive Pressure the ASTM website.

4

Surges, International Conference on Underground Plastic Pipe, American Society Available fromAmericanWaterWorksAssociation (AWWA), 6666W. Quincy

of Civil Engineers, New York, NY, 1981, p. 491. Ave., Denver, CO 80235, http://www.awwa.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor D

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F1674–05 Designation:F1674–11

Standard Test Method for

1

Joint Restraint Products for Use with PVC Pipe

This standard is issued under the fixed designation F1674; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method describes a procedure for qualifying the performance of joint restraint products for use on PVC pressure

pipe systems by evaluating the effect of the joint restraint product on the performance characteristics of PVC pipe during cyclic

pressure tests and static pressure tests. The PVC pipe property values referenced in this test method are for the 12454 compound

as described in Specification D1784 and a 4,000 HDB shall be obtained by categorizing the LTHS in accordance with Table 1 in

Test Method D2837. That includes, but is not limited to, pipe produced in accordance with the following standards: Specifications

D1785 and D2241, AWWA C900 , and AWWA C905.

1.2 This test method determines the short-term performance of a joint restraint product on PVC pipe, which involves the testing

of restrained joint test sections to the minimum burst pressure requirements of the pipe to determine quick burst performance.

1.3 This test method determines the long-term effect of a joint restraint product on PVC pipe, which involves the testing of

restrained joint test sections to the sustained pressure requirements of the pipe for a period of 1000 h.

1.4 This test method addresses restraint products that are rated at the full pressure capacity of the PVC pipe on which they are

used. There are joint restraint devices available that are not rated at the full pressure capacity of the pipe. While those products

have proven acceptable and useful in the marketplace, this test method does not apply to those products.

1.5 This test method determines the performance of a joint restraint product on PVC pipe subjected to cyclic pressure surges.

The performance is compared to the baseline performance of pipe without joint restraint products established by Herbert W.

2

Vinson.

1.6 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information

purposes only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC)

Compounds

D1785 Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80, and 120

D2241 Specification for Poly(Vinyl Chloride) (PVC) Pressure-Rated Pipe (SDR Series)

D2837 Test Method for Obtaining Hydrostatic Design Basis for Thermoplastic Pipe Materials or Pressure Design Basis for

Thermoplastic Pipe Products

F412 Terminology Relating to Plastic Piping Systems

2.2 AWWA Standards:

AWWAC900 Polyvinyl Chloride (PVC) Pressure Pipe and Fabricated Fittings, 4 In. through 12 In. (100 mm through 300 mm),

4

for Water Distribution

AWWA C905 Polyvinyl Chloride (PVC) Pressure Pipe and Fabricated Fittings Pipe, Nominal Diameters 14 In. through 48 In.

4

(350 mm through 1,200 mm), for Water Transmission and Distribution

1

This test method is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining.

Current edition approved Mar.April 1, 2005.2011. Published March 2005.April 2011. Originally approved in 1996. Last previous edition approved in 19962005 as

F1674–96.F1674–05. DOI: 10.1520/F1674-05. 10.1520/F1674-11.

2

Vinson, Herbert W., Response of PVC Pipe to Large, Repetitive Pressure Surges, International Conference on Underground Plastic Pipe, American Society of Civil

Engineers, New York, NY, 1981, p. 491.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from American Water Works Assn., Association (AWWA), 6666 W. Quincy Ave., Denver, CO 80235, http://ww

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.