ASTM F1941-00(2006)

(Specification)Standard Specification for Electrodeposited Coatings on Threaded Fasteners (Unified Inch Screw Threads (UN/UNR))

Standard Specification for Electrodeposited Coatings on Threaded Fasteners (Unified Inch Screw Threads (UN/UNR))

SCOPE

1.1 This specification covers application, performance and dimensional requirements for electrodeposited coatings on threaded fasteners with unified inch screw threads. It specifies coating thickness, supplementary chromate finishes, corrosion resistance, precautions for managing the risk of hydrogen embrittlement and hydrogen embrittlement relief for high-strength and surface-hardened fasteners. It also highlights the differences between barrel and rack plating and makes recommendations as to the applicability of each process.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

The following precautionary statement pertains to the test method portion only, Section , of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1941 – 00 (Reapproved 2006)

Standard Specification for

Electrodeposited Coatings on Threaded Fasteners (Unified

Inch Screw Threads (UN/UNR))

This standard is issued under the fixed designation F 1941; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This specification covers the coating of steel unified inch screw threaded fasteners by electrodepo-

sition. The properties of the coatings shall conform to theASTM standards for the individual finishes

listed.

Coating thickness values are based on the tolerances for 1A and 2A external Unified Inch Screw

Threads. The coating must not cause the basic thread size to be transgressed by either the internal or

external threads. The method of designating coated threads shall comply with ASME B1.1.

With normal methods for depositing metallic coatings from aqueous solutions, there is a risk of

delayed failure due to hydrogen embrittlement for case hardened fasteners and fasteners having a

hardness 40 HRC or above.Although this risk can be managed by selecting raw materials suitable for

the application of electrodeposited coatings and by using modern methods of surface treatment and

post heat-treatment (baking), the risk of hydrogen embrittlement cannot be completely eliminated.

Therefore, the application of a metallic coating by electrodeposition is not recommended for such

fasteners.

1. Scope 2. Referenced Documents

1.1 This specification covers application, performance and 2.1 ASTM Standards:

dimensional requirements for electrodeposited coatings on B117 Practice for Operating Salt Spray (Fog) Apparatus

threaded fasteners with unified inch screw threads. It specifies B 487 Test Method for Measurement of Metal and Oxide

coating thickness, supplementary chromate finishes, corrosion Coating Thickness by Microscopical Examination of a

resistance, precautions for managing the risk of hydrogen Cross Section

embrittlement and hydrogen embrittlement relief for high- B 499 Test Method for Measurement of Coating Thick-

strength and surface-hardened fasteners. It also highlights the nessesbytheMagneticMethod:NonmagneticCoatingson

differences between barrel and rack plating and makes recom- Magnetic Basis Metals

mendations as to the applicability of each process. B 504 Test Method for Measurement of Thickness of Me-

1.2 The values stated in SI units are to be regarded as the tallic Coatings by the Coulometric Method

standard. The values given in parentheses are for information B 567 Test Method for Measurement of Coating Thickness

only. by the Beta Backscatter Method

1.3 The following precautionary statement pertains to the B 568 Test Method for Measurement of Coating Thickness

test method portion only, Section 9, of this specification: This by X-Ray Spectrometry

standard does not purport to address all of the safety concerns, B 659 Guide for Measuring Thickness of Metallic and

if any, associated with its use. It is the responsibility of the user Inorganic Coatings

of this standard to establish appropriate safety and health E 376 Practice for Measuring Coating Thickness by

practices and determine the applicability of regulatory limita- Magnetic-FieldorEddy-Current(Electromagnetic)Exami-

tions prior to use. nation Methods

This specification is under the jurisdiction of ASTM Committee F16 on

Fasteners and is the direct responsibility of Subcommittee F16.03 on Coatings on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Fasteners. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved June 1, 2006. Published June 2006. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1998. Last previous edition approved in 2000 as F 1941 – 00. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1941 – 00 (2006)

NOTE 1—Black dot (•) indicates test surface.

FIG. 1 Significant Surfaces on Externally Threaded Fasteners

F 606 Test Methods for Determining the Mechanical Prop-

erties of Externally and Internally Threaded Fasteners,

Washers, and Rivets

F 1470 GuideforFastenerSamplingforSpecifiedMechani-

cal Properties and Performance Inspection

NOTE 1—Black dot (•) indicates test surface.

F 1624 Test Method for Measurement of Hydrogen Em-

FIG. 2 Significant Surfaces on Internally Threaded Fasteners

brittlement Threshold in Steel by the Incremental Step

Loading Technique

TABLE 1 Designation of Common Coating Materials

F 1940 Test Method for Process Control Verification to

Coating Designation Coating Type

Prevent Hydrogen Embrittlement in Plated or Coated

Fasteners

Fe/Zn Zinc

2.2 ASME Standard:

Fe/Cd Cadmium

B1.1 Unified Inch Screw Threads (UN and UNR Thread

Fe/Zn-Co Zinc Cobalt Alloy

Fe/Zn-Ni Zinc Nickel Alloy

Form)

Fe/Zn-Fe Zinc Iron Alloy

2.3 National Aerospace Standard (AIA):

NASM-1312-5 Fast Test Method - Method 5: Stress Dura-

bility

2.4 IFI Standard:

4.2 Coating Thickness—The coating thickness shall be

IFI-142 Hydrogen Embrittlement Risk Management

selected and designated in accordance with Table 2:

4.3 Chromate Finish— The chromate finish shall be se-

3. Terminology

lected and designated in accordance with Table 3.

3.1 Definitions:

3.1.1 local thickness—the mean of the thickness measure-

5. Ordering Information for Electroplating

ments, of which a specified number is made within a reference

5.1 When ordering threaded fasteners to be coated by

area.

electrodeposition in accordance with this specification, the

3.1.2 minimum local thickness—the lowest local thickness

following information shall be supplied to the electroplater:

value on the significant surface of a single article.

5.1.1 The desired coating, coating thickness and the chro-

3.1.3 reference area—the area within which a specified

mate finish, or the classification codes as specified in Tables

number of single measurements are required to be made.

1-3. (for example, Fe/Zn 5C denotes yellow zinc plated with a

3.1.4 significant surface—significant surfaces are areas

minimum thickness of 0.0002 in. on significant surfaces.)

where the minimum thickness to be met shall be designated on

5.1.2 The identification of significant surfaces (optional).

theapplicabledrawingorbytheprovisionofasuitablymarked

5.1.3 The requirement, if any, for stress relief before elec-

sample. However, if not designated, significant surfaces shall

troplating, in which case the stress-relief conditions must be

be defined as those normally visible, directly or by reflection,

specified.

which are essential to the appearance or serviceability of the

5.1.4 The requirements, if any, for hydrogen embrittlement

fastener when assembled in normal position, or which can be

relief by heat treatment (baking) stating the tensile strength or

the source of corrosion products that deface visible surfaces on

surface hardness of the fasteners and/or baking time and

the assembled fastener. Figs. 1 and 2 illustrate significant

temperature.

surfaces on standard externally threaded and internally

NOTE 1—Fasteners with a specified maximum hardness of 34 HRC and

threaded fasteners.

4. Classification

TABLE 2 Designation of Coating Thickness

4.1 Coating Material— The coating material shall be se-

NOTE 1—Theconversionfactorfrominchtomicronsis2.54 310 (for

lected and designated in accordance with Table 1.

example, 0.0001 in. = 2.54 µm).

Thickness Designation Minimum Thickness in.

Available from American Society of Mechanical Engineers (ASME), ASME

International Headquarters, Three Park Ave., New York, NY 10016-5990.

3 0.0001

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

5 0.0002

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

8 0.0003

Available from Industrial Fasteners Institute (IFI), 1717 East 9th Street, Suite 12 0.0005

1105, Cleveland, OH 44114–2879.

F 1941 – 00 (2006)

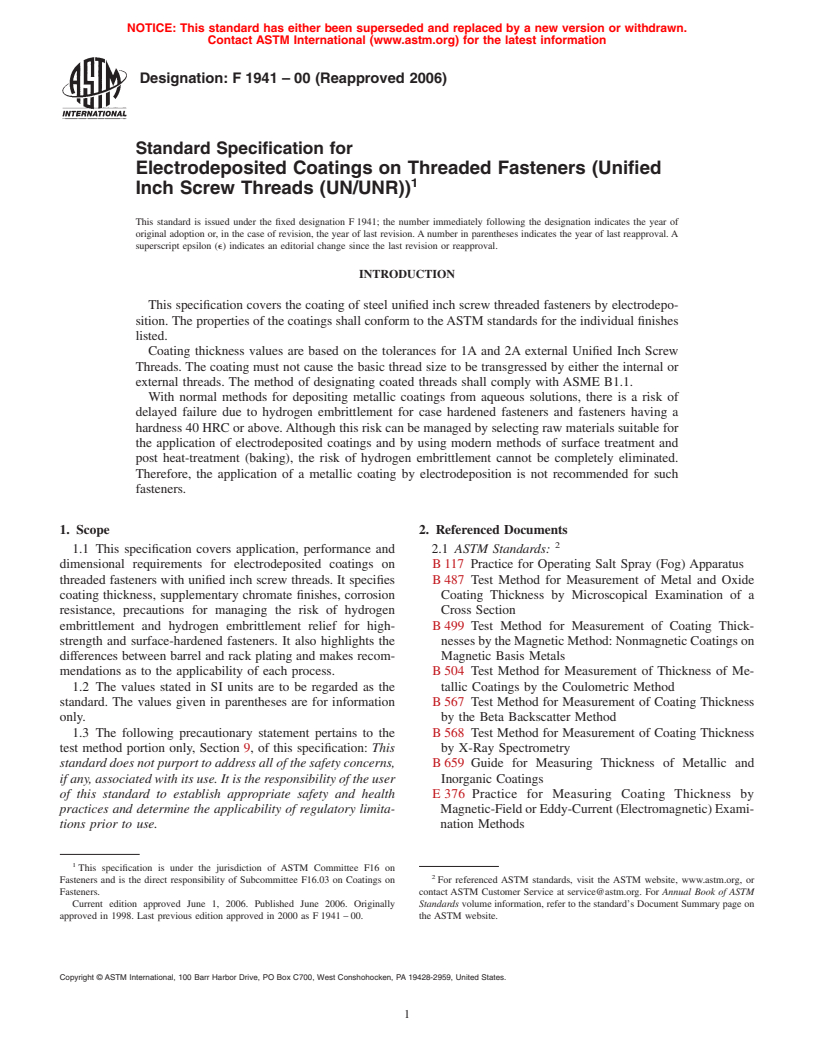

TABLE 3 Designation of Chromate Finish

6.3.1.3 Internal Threads— Maximum coating thickness of

Designation Type Typical Appearance internalthreadsmustprovideforclass1B,2B,or3BGothread

gage acceptance.

A Clear Transparent colorless with slight iridescence

6.3.1.4 Surfaces such as threads, holes, deep recesses, bases

B Blue-bright Transparent with a bluish tinge and slight

of angles, and similar areas on which the specified thickness of

iridescence

deposit cannot readily be controlled, are exempted from

C Yellow Yellow iridescent

D Opaque Olive green, shading to brown or bronze

minimum thickness requirements unless they are specially

E Black Black with slight iridescence

designated as not being exempted.When such areas are subject

F Organic Any of the above plus organic topcoat

to minimum thickness requirements, the purchaser and the

manufacturer shall recognize the necessity for either thicker

below have a very low susceptibility to hydrogen embrittlement and do

deposits on other areas or special racking.

not require baking.

6.3.2 Applicability to Unified Inch Screw Threads:

5.1.5 The requirements, if any, for the type of electroplating 6.3.2.1 The applicability of the required coating to unified

process (barrel-plating or rack-plating). See Section 10 and inch screw threads is limited by the basic deviation of the

Appendix X1. threads,andhencelimitedbythepitchdiameter,allowanceand

tolerance positions. Refer to Appendix X3 as a guideline for

5.1.6 The designation of coated thread class shall comply

with ASME B1.1. the tolerances of the various thread sizes and classes and the

coating thickness they will accommodate.

6. Requirements

6.3.2.2 Because of the inherent variability in coating thick-

6.1 Coating Requirements—Theelectrodepositedcoatingas

ness by the barrel-plating process, the application of a mini-

ordered shall cover all surfaces and shall meet the following

mum coating thickness of 0.0005 in. is not recommended for a

requirements:

standard screw thread by this method due to the fact that

6.1.1 The coating metal deposit shall be bright or semi-

dimensional allowance of most threaded fasteners normally

brightunlessotherwisespecifiedbythepurchaser,smooth,fine

does not permit it. If the size of the fastener is large enough to

grained, adherent and uniform in appearance.

economically use the rack-plating process, then the latter shall

6.1.2 The coating shall be free of blisters, pits, nodules,

be used to obtain this thickness requirement. If heavier

roughness, cracks, unplated areas, and other defects that will

coatingsarerequiredallowanceforthedepositbuildupmustbe

affect the function of the coating.

made during the manufacture of fasteners.

6.1.3 The coating shall not be stained, discolored or exhibit

6.3.3 Applicability to Wood Screws and Thread Forming

any evidence of white or red corrosion products.

Screws—Any classification code in Table 2 may be applied to

6.1.3.1 Slight discoloration that results from baking, drying,

screws that cut or form their own threads.

or electrode contact during rack-plating, or all of these, as well

6.4 Hydrogen Embrittlement Relief:

as slight staining that results from rinsing shall not be cause for

6.4.1 Requirement for Baking—Coatedfastenersmadefrom

rejection.

steel heat treated to a specified hardness of 40 HRC or above,

6.2 Corrosion Resistance—Coated fasteners, when tested

case-hardened steel fasteners, and fasteners with captive wash-

bycontinuousexposuretoneutralsaltsprayinaccordancewith

ers made from hardened steel shall be baked to minimize the

9.3, shall show neither corrosion products of coatings (white

risk of hydrogen embrittlement. Unless otherwise specified by

corrosion) nor basis metal corrosion products (red rust) at the

the purchaser, baking is not mandatory for fasteners with

end of the test period. The appearance of corrosion products

specified maximum hardness below 40 HRC.

visible to the unaided eye at normal reading distance shall be

NOTE 2—With proper care many steel fasteners can be plated without

cause for rejection, except when present at the edges of the

baking by correlating process conditions to the susceptibility of the

tested fasteners. Refer to Annex A1 for neutral salt spray

fastener material to hydrogen embrittlement, and by applying adequate

performance requirements for zinc, zinc alloy and cadmium

process control procedures, such as those outlined inAppendix X4.2. Test

coatings.

Method F 1940 is a recognized verification method for process control to

minimize the risk of hydrogen embrittlement. Upon agreement between

6.3 Thickness—The coating thickness shall comply with

the supplier and the purchaser, this test method can be used as a basis for

requirements of Table 2 when measured in accordance with

determining if baking should be mandated in a controlled process

9.1.

environment.

6.3.1 Restrictions on Coating Thickness—This specification

imposes minimum local thickness requirements at significant 6.4.2 Baking Conditions—At the time of publication of this

surfaces in accordance with Table 2. Thick or thin local specification it was not considered possible to give an exact

thickness in a location other than a significant surface shall not bakingduration.Eighthoursisconsideredatypicalexampleof

be a cause for rejection. However the following restrictions baking duration. However, upon agreement between the pur-

apply: chaser and the manufacturer, baking times between 2 and 24 h

6.3.1.1 Minimum coating thickness at low current density at temperatures of 350 to 450°F are suitable depending on the

areas,suchasthecenterofaboltorrecesses,mustbesufficient type and size of the fastener, geometry, mechanical properties,

to provide for adequate chromate adhesion. cleaning process and cathodic efficiency of the electroplating

6.3.1.2 External Threads— Maximum coating thickness at process used. The baking conditions shall be selected based on

high current density threaded tips must provide for class 3A the results of recognized embrittlement test procedures such as

GO thread gauge acceptance. Test Methods F 606, F 1624, F 1940, or NASM–1312–5.

F 1941 – 00 (2006)

6.4.2.1 Bake time and temperatures may require lowering to 8. Sampling

minimize the risk of solid or liquid metal embrittlement

8.1 Samplingforcoatingthickness,saltsprayandembrittle-

resultingfromalloycompositionssuchasthosecontaininglead

ment testing shall be conducted based on lot size in accordance

or from the lower melting point of cadmium (610°F) in

with Guide F 1470.

comparison to zinc (786°F).

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.