ASTM F1940-07a(2019)

(Test Method)Standard Test Method for Process Control Verification to Prevent Hydrogen Embrittlement in Plated or Coated Fasteners

Standard Test Method for Process Control Verification to Prevent Hydrogen Embrittlement in Plated or Coated Fasteners

SIGNIFICANCE AND USE

5.1 This test method establishes a means to verify the prevention, to the extent possible, of IHE in steel fasteners during manufacture by maintaining strict controls during production operations such as surface preparation, pretreatments, and plating or coating. It is intended to be used as a qualification test for new or revised plating or coating processes and as a periodic inspection audit for the control of a plating or coating process.

5.2 Passing this test allows fasteners to be stressed in tension to the minimum specified tensile load in air with almost no possibility of time delayed fracture in air as a result of IHE from processing. If the amount of residual hydrogen is not sufficient to induce cracking or fracture in the specimen under worst case conditions, then it can be concluded that all of the lots of fasteners processed during that period will not have sufficient residual hydrogen from processing to induce hydrogen embrittlement of the fasteners under stress in air if the process remains in control, unchanged and stable.

5.3 If certified specimens with demonstrated sensitivity to IHE, processed with the fasteners, have a threshold ≥75 % of the incremental step load notched bend fracture stress, NFS(B)F1624, it is assumed that all fasteners processed the same way during the period will also pass any sustained load IHE test.

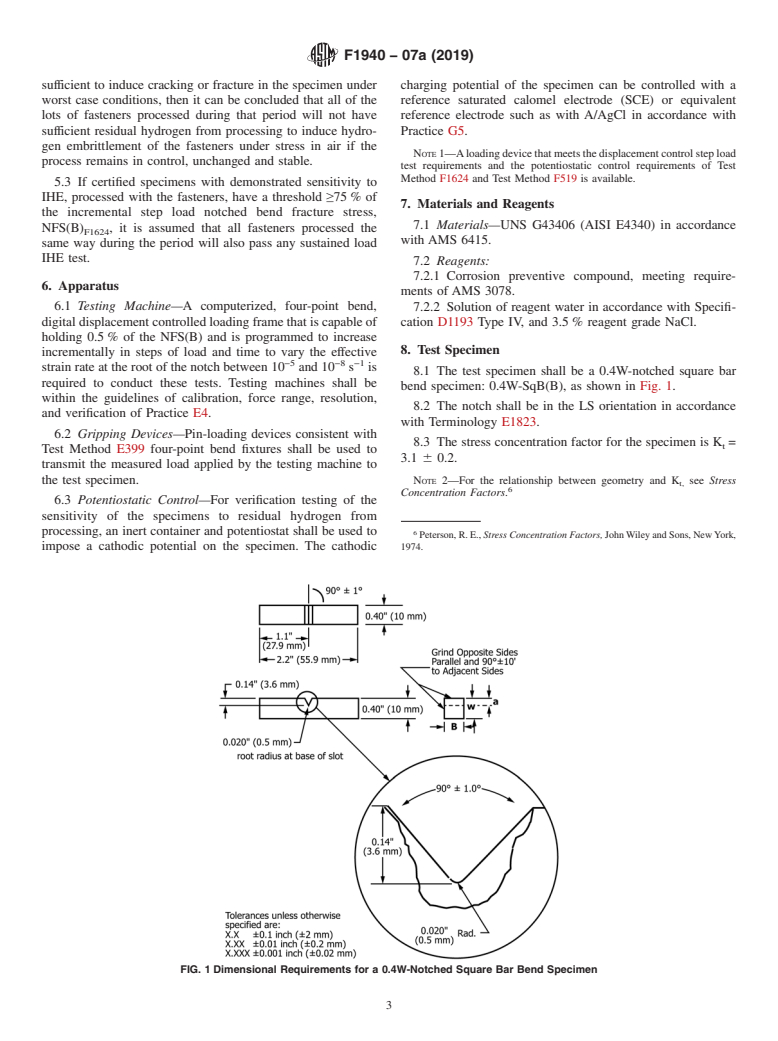

FIG. 1 Dimensional Requirements for a 0.4W-Notched Square Bar Bend Specimen

SCOPE

1.1 This test method covers a procedure to prevent, to the extent possible, internal hydrogen embrittlement (IHE) of fasteners by monitoring the plating or coating process, such as those described in Specifications F1137 and F1941. The process is quantitatively monitored on a periodic basis with a minimum number of specimens as compared to qualifying each lot of fasteners being plated or coated. Trend analysis is used to ensure quality as compared to statistical sampling analysis of each lot of fasteners. This test method consists of a mechanical test for the evaluation and control of the potential for IHE that may arise from various sources of hydrogen in a plating or coating process.

1.2 This test method consists of a mechanical test, conducted on a standard specimen used as a witness, for the evaluation and control of the potential for IHE that may arise from various sources of hydrogen in a plating or coating process.

1.3 This test method is limited to evaluating hydrogen induced embrittlement due only to processing (IHE) and not due to environmental exposure (EHE, see Test Method F1624).

1.4 This test method is not intended to measure the relative susceptibility of steels to either IHE or EHE.

1.5 This test method is limited to evaluating processes used for plating or coating ferrous fasteners.

1.6 This test method uses a notched square bar specimen that conforms to Test Method F519, Type 1e, except that the radius is increased to accommodate the deposition of a larger range of platings and coatings. For the background on Test Method F519 testing, see publications ASTM STP 5432 and ASTM STP 962.3 The stress concentration factor is at a Kt = 3.1 ± 0.2. The sensitivity is demonstrated with a constant imposed cathodic potential to control the amount of hydrogen. Both the sensitivity and the baseline for residual hydrogen will be established with tests on bare metal specimens in air.

1.7 The sensitivity of each lot of specimens to IHE shall be demonstrated. A specimen made of AISI E4340 steel heat treated to a hardness range of 50 to 52 HRC is used to produce a “worst case” condition and maximize sensitivity to IHE.

1.8 The test is an accelerated (≤24 h) test method to measure the threshold for hydrogen stress cracking, and is used to quantify the amount of residual hydrogen in the specimen. The specimen undergoes sustained load and slow strain rate testing by using incremental loads and hold times under displacement control to measure a threshol...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F1940 −07a (Reapproved 2019)

Standard Test Method for

Process Control Verification to Prevent Hydrogen

Embrittlement in Plated or Coated Fasteners

This standard is issued under the fixed designation F1940; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Method F519 testing, see publications ASTM STP 543 and

ASTM STP 962. The stress concentration factor is at a K =

t

1.1 This test method covers a procedure to prevent, to the

3.1 6 0.2. The sensitivity is demonstrated with a constant

extent possible, internal hydrogen embrittlement (IHE) of

imposed cathodic potential to control the amount of hydrogen.

fasteners by monitoring the plating or coating process, such as

Boththesensitivityandthebaselineforresidualhydrogenwill

those described in Specifications F1137 and F1941. The

be established with tests on bare metal specimens in air.

process is quantitatively monitored on a periodic basis with a

minimumnumberofspecimensascomparedtoqualifyingeach 1.7 The sensitivity of each lot of specimens to IHE shall be

lotoffastenersbeingplatedorcoated.Trendanalysisisusedto demonstrated. A specimen made of AISI E4340 steel heat

ensure quality as compared to statistical sampling analysis of treatedtoahardnessrangeof50to52HRCisusedtoproduce

eachlotoffasteners.Thistestmethodconsistsofamechanical a “worst case” condition and maximize sensitivity to IHE.

test for the evaluation and control of the potential for IHE that

1.8 The test is an accelerated (≤24 h) test method to

may arise from various sources of hydrogen in a plating or

measurethethresholdforhydrogenstresscracking,andisused

coating process.

to quantify the amount of residual hydrogen in the specimen.

1.2 This test method consists of a mechanical test, con- The specimen undergoes sustained load and slow strain rate

ducted on a standard specimen used as a witness, for the testing by using incremental loads and hold times under

evaluation and control of the potential for IHE that may arise displacement control to measure a threshold stress in an

from various sources of hydrogen in a plating or coating accelerated manner in accordance with Test Method F1624.

process.

1.9 In this test method, bending is used instead of tension

1.3 This test method is limited to evaluating hydrogen becauseitproducesthemaximumlocallimitloadtensilestress

induced embrittlement due only to processing (IHE) and not in a notched bar of up to 2.3 times the yield strength as

duetoenvironmentalexposure(EHE,seeTestMethodF1624). measured in accordance withTest Method E8/E8M.Afastener

that is unintentionally exposed to bending on installation may

1.4 This test method is not intended to measure the relative

attain this maximum local tensile stress.

susceptibility of steels to either IHE or EHE.

1.10 The values stated in inch-pound units are to be re-

1.5 This test method is limited to evaluating processes used

garded as standard. The values given in parentheses are

for plating or coating ferrous fasteners.

mathematical conversions to SI units that are provided for

1.6 This test method uses a notched square bar specimen

information only and are not considered standard.

that conforms to Test Method F519, Type 1e, except that the

1.11 This standard does not purport to address all of the

radius is increased to accommodate the deposition of a larger

safety concerns, if any, associated with its use. It is the

range of platings and coatings. For the background on Test

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

This test method is under the jurisdiction of ASTM Committee F16 on mine the applicability of regulatory limitations prior to use.

Fasteners and is the direct responsibility of Subcommittee F16.93 on Quality

Assurance Provisions for Fasteners.

Current edition approved Aug. 1, 2019. Published September 2019. Originally L. Raymond, ed., Hydrogen Embrittlement Testing.ASTM International, 1974.

published as approved in 1998. Last previous edition approved in 2014 as L. Raymond, ed., Hydrogen Embrittlement: Prevention and Control. ASTM

F1940–07a(2014). DOI: 10.1520/F1940-07AR19. International, 1988.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1940−07a (2019)

1.12 This international standard was developed in accor- 3.1.3 ISL —thresholdfromanincrementalsteploadteston

th

dance with internationally recognized principles on standard- a plated or processed specimen.

ization established in the Decision on Principles for the

3.1.4 NFS(B)—notched fracture strength in air of a bare

Development of International Standards, Guides and Recom-

specimeninbendingatloadingratesof50to250ksi/min(350

mendations issued by the World Trade Organization Technical

to 1700 MPa/min).

Barriers to Trade (TBT) Committee.

3.1.5 NFS(B) —notched fracture strength in air of a

F1624

bare specimen in bending at Test Method F1624 step loading

2. Referenced Documents

rates.

2.1 ASTM Standards:

3.1.6 process—a defined event or sequence of events that

D1193Specification for Reagent Water

may include pretreatments, plating, or coating and posttreat-

E4Practices for Force Verification of Testing Machines

ments that are being evaluated or qualified.

E8/E8MTest Methods for Tension Testing of Metallic Ma-

3.1.7 threshold—themaximumloadattheonsetofcracking

terials

that is identified by a 5% drop in load of NSF(B) under

E18Test Methods for Rockwell Hardness of Metallic Ma- F1624

displacement control.

terials

E29Practice for Using Significant Digits in Test Data to

4. Summary of Test Method

Determine Conformance with Specifications

E177Practice for Use of the Terms Precision and Bias in 4.1 Specimensoffixedgeometry,certifiedtohavebeenheat

ASTM Test Methods treated to a hardness range of 50 to 52 HRC, and which have

E399Test Method for Linear-Elastic Plane-Strain Fracture beencertifiedtoexhibitsensitivitytoembrittlementfromtrace

Toughness K of Metallic Materials amounts of residual hydrogen in steel, are processed with

Ic

E691Practice for Conducting an Interlaboratory Study to actual parts.

Determine the Precision of a Test Method

4.2 An unstressed test specimen is processed in accordance

E1823TerminologyRelatingtoFatigueandFractureTesting

with the plating or coating process being qualified. The

F519Test Method for Mechanical Hydrogen Embrittlement

specimenisthentestedunderincrementalsteploadtomeasure

Evaluation of Plating/Coating Processes and Service En-

the threshold stress. The loading rate must be slow enough to

vironments

ensure that the threshold stress will be detected if deleterious

F1137Specification for Phosphate/Oil Corrosion Protective

amounts of hydrogen are present in “worst case” sensitized

Coatings for Fasteners

specimens. Loading rate protocols are defined in 9.2 and Test

F1624Test Method for Measurement of Hydrogen Em-

Method F1624.

brittlement Threshold in Steel by the Incremental Step

4.3 If the threshold in air of the specimen is ≥75%

Loading Technique

NFS(B) , then the process is considered as to not produce

F1624

F1941 Specification for Electrodeposited Coatings on

sufficient hydrogen to induce time delayed IHE failures in the

Threaded Fasteners (Metric) F1941_F1941M

plated or coated fasteners. See 9.3 for optional limits.

G5Reference Test Method for Making Potentiodynamic

Anodic Polarization Measurements 4.4 If the threshold in air of the specimen is <75%

NFS(B) ,thentheprocessisconsideredpotentiallyembrit-

2.2 SAE Standards: F1624

tling.Actualfastenersmadewithsteelhavingahardnesslower

AMS 2759Hot Drawn, Normalized and Tempered Steel

than that of the square bar specimen have more tolerance for

Bars. UNS G43406 (AISI E4340)

residual hydrogen because of the process.Therefore, threshold

AMS 3078 Corrosion Preventive Compound, Solvent

requirements must be adjusted based upon the correlation

Cutback, Cold-Application

between the specimen fracture strength NBS(B) and

AMS 6415 F1624

actual fastener hardness. An example of this adjustment is

presented in Appendix X1.

3. Terminology

3.1 Terms and Symbols Specific to This Standard:

5. Significance and Use

3.1.1 environmental hydrogen embrittlement (EHE)—test

5.1 This test method establishes a means to verify the

conducted in a specified environment—embrittlement caused

prevention, to the extent possible, of IHE in steel fasteners

by hydrogen introduced into steel from external sources.

during manufacture by maintaining strict controls during

3.1.2 internal hydrogen embrittlement (IHE)—test con-

production operations such as surface preparation,

ducted in air—embrittlement caused by residual hydrogen

pretreatments, and plating or coating. It is intended to be used

from processing

as a qualification test for new or revised plating or coating

processes and as a periodic inspection audit for the control of

a plating or coating process.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2 Passing this test allows fasteners to be stressed in

Standards volume information, refer to the standard’s Document Summary page on

tensiontotheminimumspecifiedtensileloadinairwithalmost

the ASTM website.

no possibility of time delayed fracture in air as a result of IHE

Available from Society of Automotive Engineers (SAE), 400 Commonwealth

Dr., Warrendale, PA 15096-0001, http://www.sae.org. from processing. If the amount of residual hydrogen is not

F1940−07a (2019)

sufficient to induce cracking or fracture in the specimen under charging potential of the specimen can be controlled with a

worst case conditions, then it can be concluded that all of the reference saturated calomel electrode (SCE) or equivalent

lots of fasteners processed during that period will not have reference electrode such as with A/AgCl in accordance with

sufficient residual hydrogen from processing to induce hydro- Practice G5.

gen embrittlement of the fasteners under stress in air if the

NOTE1—Aloadingdevicethatmeetsthedisplacementcontrolstepload

process remains in control, unchanged and stable.

test requirements and the potentiostatic control requirements of Test

Method F1624 and Test Method F519 is available.

5.3 If certified specimens with demonstrated sensitivity to

IHE, processed with the fasteners, have a threshold ≥75% of

7. Materials and Reagents

the incremental step load notched bend fracture stress,

7.1 Materials—UNS G43406 (AISI E4340) in accordance

NFS(B) , it is assumed that all fasteners processed the

F1624

with AMS 6415.

same way during the period will also pass any sustained load

IHE test.

7.2 Reagents:

7.2.1 Corrosion preventive compound, meeting require-

6. Apparatus

ments of AMS 3078.

6.1 Testing Machine—A computerized, four-point bend, 7.2.2 Solution of reagent water in accordance with Specifi-

digitaldisplacementcontrolledloadingframethatiscapableof cation D1193 Type IV, and 3.5% reagent grade NaCl.

holding 0.5% of the NFS(B) and is programmed to increase

8. Test Specimen

incrementally in steps of load and time to vary the effective

−5 −8 −1

strainrateattherootofthenotchbetween10 and10 s is

8.1 The test specimen shall be a 0.4W-notched square bar

required to conduct these tests. Testing machines shall be

bend specimen: 0.4W-SqB(B), as shown in Fig. 1.

within the guidelines of calibration, force range, resolution,

8.2 The notch shall be in the LS orientation in accordance

and verification of Practice E4.

with Terminology E1823.

6.2 Gripping Devices—Pin-loading devices consistent with

8.3 The stress concentration factor for the specimen is K =

t

Test Method E399 four-point bend fixtures shall be used to

3.1 6 0.2.

transmit the measured load applied by the testing machine to

the test specimen. NOTE 2—For the relationship between geometry and K see Stress

t,

Concentration Factors.

6.3 Potentiostatic Control—For verification testing of the

sensitivity of the specimens to residual hydrogen from

processing, an inert container and potentiostat shall be used to 6

Peterson,R.E., Stress Concentration Factors,JohnWileyandSons,NewYork,

impose a cathodic potential on the specimen. The cathodic 1974.

FIG. 1Dimensional Requirements for a 0.4W-Notched Square Bar Bend Specimen

F1940−07a (2019)

8.4 Manufacture: 8.6.4 The notched bend fracture strength, NFS(B), of bare

8.4.1 The test specimen blanks shall be heat treated in specimens is measured in air in four-point bending under

accordance withAMS 2759 to meet the hardness requirement displacementcontrolatloadingratesof50to250ksi/min(350

of 50 to 52 HRC in accordance with Test Methods E18. to 1700 MPa/min). The rupture load is used as a measure of

RoundinginaccordancewithPracticeE29permitsanabsolute strength.

hardness range of 49.6 to 52.5 HRC. The hardness shall be

8.7 Sensitivity Test:

determined by the average of three measurements made

8.7.1 The sensitivity to IHE must be demonstrated for each

approximately midway between the notch and the end of the

lot of specimens by exposing three trial specimens in air and

specimen.

three trial specimens in an embrittling environmental after

8.4.2 The surface finish of all notches shall be finished with

manufacture and inspection in accordance with 8.4 through

a tool capable of attaining a surface roughness of 16 RMS or

8.6. The specimens tested shall be representative of the lot.

better. The other surfaces shall have a finish of 32 RMS or

8.7.2 Sensitivity Specimen Preparation:

better.

8.7.2.1 Ultrasonically clean in acetone for 5 to 10 min to

8.4.3 Alldimensionsexceptforthelengthshallbeproduced

remove the corrosion preventive compound and oils/dirt.

after quenching and tempering to final hardness. The 0.40-in.

8.7.2.2 Do not acid clean.

(10-mm) dimension shall be produced by low stress grinding.

8.7.3 Based on the loading profile schedule in Table 2, the

The notch shall be rough machined by wire EDM to within

requirementsforsensitivityoftheheat-treatedlotofspecimens

0.020 in. (0.5 mm) of the final notch depth and low stress

shall be demonstrated if bare specimens fracture in less than 5

ground to the final depth. No chemical or mechanical cleaning

h at an imposed potential of −1.2 V versus SCE in a 3.5%

shall be allowed after final machining.

NaCl solution

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.