ASTM D1187-97(2002)e1

(Specification)Standard Specification for Asphalt-Base Emulsions for Use as Protective Coatings for Metal

Standard Specification for Asphalt-Base Emulsions for Use as Protective Coatings for Metal

ABSTRACT

This specification establishes the manufacture, testing, and performance requirements of two types of asphalt-based emulsions for use in a relatively thick film as a protective coating for metal surfaces. Type I are quick-setting emulsified asphalt suitable for continuous exposure to water within a few days after application and drying. Type II, on the other hand, are emulsified asphalt suitable for continuous exposure to the weather, only after application and drying. Upon being sampled appropriately, the materials shall conform to composition requirements as to density, residue by evaporation, nonvolatile matter soluble in trichloroethylene, and ash and water content. They shall also adhere to performance requirements as to uniformity, consistency, stability, wet flow, firm set, heat test, flexibility, resistance to water, and loss of adhesion.

SCOPE

1.1 This specification covers emulsified asphalt suitable for application in a relatively thick film as a protective coating for metal surfaces.

1.2 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D1187 – 97 (Reapproved 2002)

Standard Specification for

Asphalt-Base Emulsions for Use as Protective Coatings for

Metal

This standard is issued under the fixed designation D1187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorial switched from inch/pound dominant to SI dominant in April 2002.

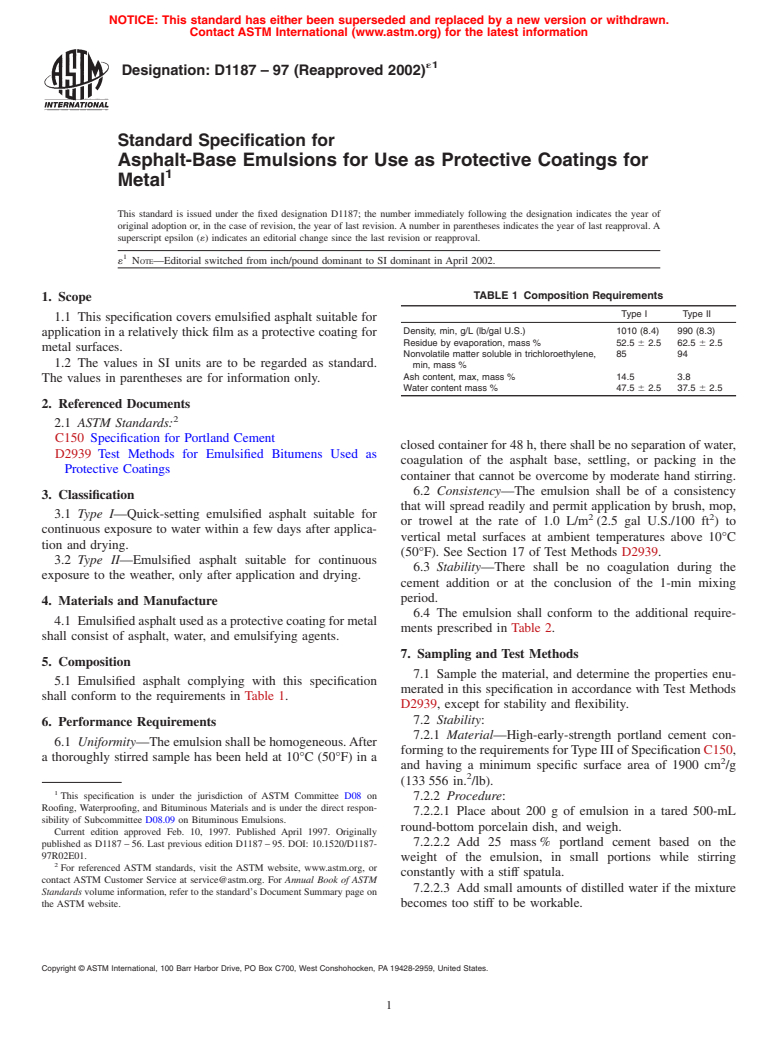

TABLE 1 Composition Requirements

1. Scope

Type I Type II

1.1 This specification covers emulsified asphalt suitable for

Density, min, g/L (lb/gal U.S.) 1010 (8.4) 990 (8.3)

application in a relatively thick film as a protective coating for

Residue by evaporation, mass % 52.5 6 2.5 62.5 6 2.5

metal surfaces.

Nonvolatile matter soluble in trichloroethylene, 85 94

1.2 The values in SI units are to be regarded as standard.

min, mass %

Ash content, max, mass % 14.5 3.8

The values in parentheses are for information only.

Water content mass % 47.5 6 2.5 37.5 6 2.5

2. Referenced Documents

2.1 ASTM Standards:

C150 Specification for Portland Cement

closed container for 48 h, there shall be no separation of water,

D2939 Test Methods for Emulsified Bitumens Used as

coagulation of the asphalt base, settling, or packing in the

Protective Coatings

container that cannot be overcome by moderate hand stirring.

6.2 Consistency—The emulsion shall be of a consistency

3. Classification

that will spread readily and permit application by brush, mop,

3.1 Type I—Quick-setting emulsified asphalt suitable for

2 2

or trowel at the rate of 1.0 L/m (2.5 gal U.S./100 ft)to

continuous exposure to water within a few days after applica-

vertical metal surfaces at ambient temperatures above 10°C

tion and drying.

(50°F). See Section 17 of Test Methods D2939.

3.2 Type II—Emulsified asphalt suitable for continuous

6.3 Stability—There shall be no coagulation during the

exposure to the weather, only after application and drying.

cement addition or at the conclusion of the 1-min mixing

period.

4. Materials and Manufacture

6.4 The emulsion shall conform to the additional require-

4.1 Emulsified asphalt used as a protective coating for metal

ments prescribed in Table 2.

shall consist of asphalt, water, and emulsifying agents.

7. Sampling and Test Methods

5. Composition

7.1 Sample the material, and determine the properties enu-

5.1 Emulsified asphalt complying with this specification

merated in this specification in accordance with Test Methods

shall conform to the requirements in Table 1.

D2939, except for stability and flexibility.

7.2 Stability:

6. Performance Requirements

7.2.1 Material—High-early-strength portland cement con-

6.1 Uniformity—The emulsion shall be homogeneous.After

forming to the requirements forType III of Specification C150,

a thoroughly stirred sample has been held at 10°C (50°F) in a

and having a minimum specific surface area of 1900 cm /g

(133 556 in. /lb).

This specification is under the jurisdiction of ASTM Committee D08 on 7.2.2 Procedure:

Roofing, Waterproofing, and Bituminous Materials and is under the direct respon-

7.2.2.1 Place about 200 g of emulsion in a tared 500-mL

sibility of Subcommittee D08.09 on Bituminous Emulsions.

round-bottom porcelain dish, and weigh.

Current edition approved Feb. 10, 1997. Published April 1997. Originally

7.2.2.2 Add 25 mass % portland cement based on the

published as D1187 – 56. Last previous edition D1187 – 95. DOI: 10.1520/D1187-

97R02E01.

weight of the emulsion, in small portions while stirring

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

constantly with a stiff spatula.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.2.2.3 Add small amounts of distilled water if the mixture

Standards volume inf

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.