ASTM F55-82

(Specification)Specification for Stainless Steel Bar and Wire for Surgical Implants (Withdrawn 1989)

Specification for Stainless Steel Bar and Wire for Surgical Implants (Withdrawn 1989)

General Information

Standards Content (Sample)

ASTM F55 82 O759530 0052373 2 W

~~~ ~~__ ~~ ___ ~________~ ~

______

--&QQ-d/

Designation: F 55 - 82

AMERICAN SOCIETY FOR TESTING AND MATERIAIS

1916 Race St., Phiiadelphia,Pa. 19103

Reprinted from the Annual Book of ASTM Stanaards, Copyright ASTM

if not listed in the current combined index, will appear in the next edition.

Standard Specification for

STAINLESS STEEL BAR AND WIRE FOR SURGICAL

IMPLANTS’

Thisstandard is issued under the fixed desinnation F 55: the number immediatelyfoiiowing the designationindicates the year

of onginaiadoption or, in the case of ievihn, the year of Iast revision. A number h parentheses indicates the year of 1st

reapproval. A superscript epsilon (E) indicates an editorial change since the last revKsion or reapproval.

This spec@ca;ion has teen approved for use by agemies of the Depariment of Dqénse and for Iisiing in the DoD Index of

Spec$cotions and Standards.

1. scope

editions of SpecXicationsA 484 and A 555 shali

apply-

1.1 This specification covers the require-

3.2 In the case where a confiict exists be-

ments for two compositions of stainless steeI

tween this standard and those listed in 2.1 and

bar and wire, except suture wire, used for the

2.2, this standard shall take precedence.

manufacture of surgical implants.

NOTE L-Expasure to temperatures above 60°F

4. Ordering information

(425’C) during fabrication may impair corrosion re-

4.€ Inquiries and orders for material under

sistance unless such exposure is fozowed by a solu-

tion-annealing treatment.

this specification shall include thv foliowing

information:

1.2 The values stated in inch-pound units

4.1. L Quantity (weight or number of pieces),

are to be regarded as the standard.

4.1.2 Grade (1 or 2),

2, Applicable Documents 4.1.3 ASTM designation,

4.1.4 Form (bar, wire, fme wire),

2.1 ASTMStandardx

4.1.5 Condition (see 5. i),

A262 Recommended Practices for Detecting

4.1.6 Mechanical properties (if applicable,

Susceptibility to Intergranular Attack in

for special conditions),

Stainless Steel’

4.1.7 Finish (see 5.2),

A 484 Specification for General Require-

4.1.8 Applicable dimensions including size,

ments for Stainless and Heat-Resisting

thickness, width, and length (exact, random or

Wrought Steel Products (Except Wire)’

multiples) or print number, and

A555 Specification for General Require-

4.1.9 Special requirements.

ments for Stainless and Heat-Resisting

Steel Wire2

5. Manufacture

A 75 1 Methods, Practices, and Definitions

5.1 Condition:

for Chemical Analysis of Steel Products2

E 112 Estimating the Average Grain Size of

Metals4

‘This specification is under the jurisdiction of ASTM

Committee F-4 on Medical and Surgical Materiais and De-

2.2 American Society for Quality Control

vices and is the direct reswnsibilitvof SubcommitteeF04.02

(ASQC) Standard:

on Resources.

Cl-1968 Specification of General Require-

CuEent editionapproved March 26,1982. Published June

1982. Originally p~blished as F 55 - 65 T. Lact previous edi-

ments for a Quality Program5

tion F 55 - 16.

‘Annual Book of ASTM Sfandarh, Pari 3.

3. Cenerai Requirements for Delivery

:Annual Book of ASTM Siandar&, Part 5.

Annaol Book of ASTM Sianduth, Part 11.

3.1 In addition to the requirements of this

Available from American Society for Quaiity Control,

specification, all requirements of the current

161 W. WiiscoaskAve., Milwaukee, Wis. 53203.

---------------------- Page: 1 ----------------------

ASTM F55 82 W 0757510 0052374 4

F 55

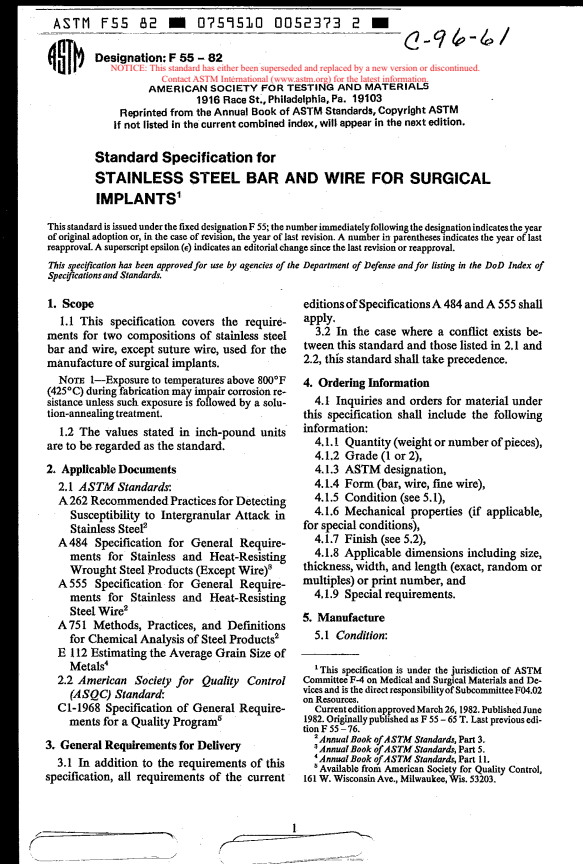

5.1.1 Bar and wire shall be furnished to the (HRC), limits may be specified. Hardness de-

termination on cold-worked material shall be

implant manufacturer; as specified, in the hot-

made on a product cross section, midway be-

worked, annealed, or cold-worked condition

tween the center and surface, if cross-section

(see Table i).

size is adequate.

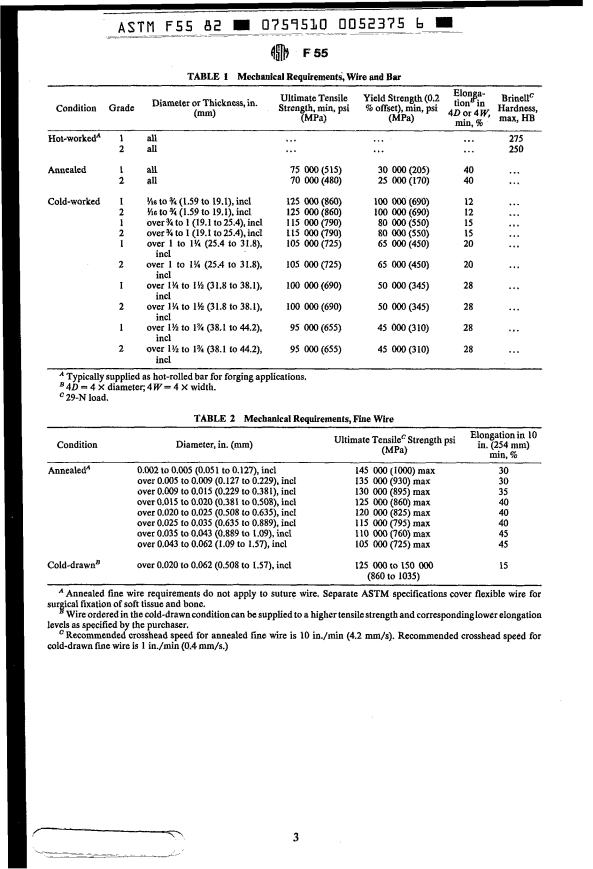

5.1.2 Fine wire shall be furnished to the

implant manufacturer, as specified, in the an-

nealed, or cold-drawn condition (see Table 2). 9. SpecidTests

5.2 Finish:

9.1 The steel shall be capable of passing the

5.2.1 Types of f~sh available in bar and

intergranular corrosion susceptibility test in ac-

wire products are cold-drawn, pickled, ground,

cordance with Recommended Practices A 262,

ground and polished, or as specified in the

Practice E.

implant manufacturer‘s purchase order.

9.1.1 Samples in the hot-worked condition

5.2.2 Types of fdsh available for fine wire

shall be annealed prior to Recommended Prac-

products are cold-drawn, bright-annealed,

tices A 262, Practice E, sensitization heat treat-

pickled, ground, ground and polished, or as

ment.

specified in the impIant manufacturer’s pur-

9.2 The grain size shall be five or fmer when

chase order.

tested in accordance with Methods E 112.

9.2.1 It is preferred that samples for grain

6. Chemical Requirements

sue determination be selected after the hot-

6.1 The heat analysis shall conform to the

working operation or aft

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.