ASTM D4680-98(2017)

(Test Method)Standard Test Method for Creep and Time to Failure of Adhesives in Static Shear by Compression Loading (Wood-to-Wood)

Standard Test Method for Creep and Time to Failure of Adhesives in Static Shear by Compression Loading (Wood-to-Wood)

SIGNIFICANCE AND USE

4.1 Creep data that are obtained over a relatively short period of time in this test method can provide a measure of an adhesive bond's ability to withstand static loading in shear over a relatively long period of time. Creep measurements are made over a range of expected service conditions, including level of stress, temperature, relative humidity, and duration of load. Creep rate, creep strain, and creep modulus are calculated at the various service conditions.

4.2 Creep data can be used to (1) predict performance of an adhesive under long-term loading, (2) characterize an adhesive, (3) compare adhesives with each other and against specifications, and (4) design structural members fabricated with an adhesive.

4.3 Time-to-failure data provide a measure of the ultimate load-carrying ability of an adhesive bond as a function of time at various levels of stress, temperature, and relative humidity.

4.4 With proper caution, time-to-failure data derived from relatively short loading periods can be extrapolated to estimate the useful service life of an adhesive at working levels of static stress. This property may also be used with creep data to accomplish purposes listed in 4.2.

4.5 This test method is a research tool intended for development or evaluation of new adhesives and new product designs. The researcher may select from suggested tests those that are appropriate. However, creep and time-to-failure tests are nonroutine and can be time-consuming and expensive, so tests must be selected with care.

4.6 The apparatus and procedures may be suitable for measuring creep properties of adhesives on substrates other than wood, such as metal, plastic, and glass, but such considerations are not within the scope of this test method.

SCOPE

1.1 This test method covers the determination of time-dependent properties of structural adhesives in wood-to-wood bonds when specimens are subjected to shearing stresses at various levels of static load, constant temperature, and relative humidity. Apparatus and procedures are provided for direct measurement of time-dependent shear deformation (creep) and time to failure of adhesive bonds under static load. Guidelines for selecting test conditions, methods for calculating creep rate, creep strain, creep modulus, and extrapolation of time to failure, are given along with methods of presenting these data.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4680 − 98 (Reapproved 2017)

Standard Test Method for

Creep and Time to Failure of Adhesives in Static Shear by

1

Compression Loading (Wood-to-Wood)

This standard is issued under the fixed designation D4680; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D907 Terminology of Adhesives

D2016 Methods of Test for Moisture Content of Wood

1.1 This test method covers the determination of time-

3

(Withdrawn 1987)

dependent properties of structural adhesives in wood-to-wood

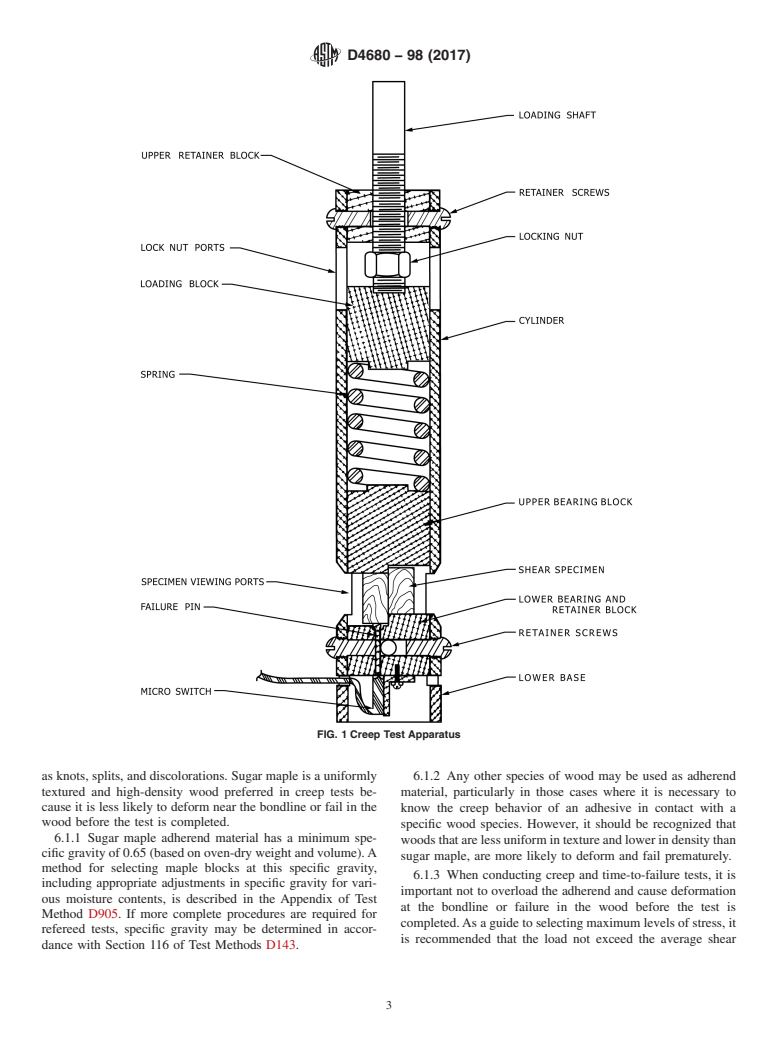

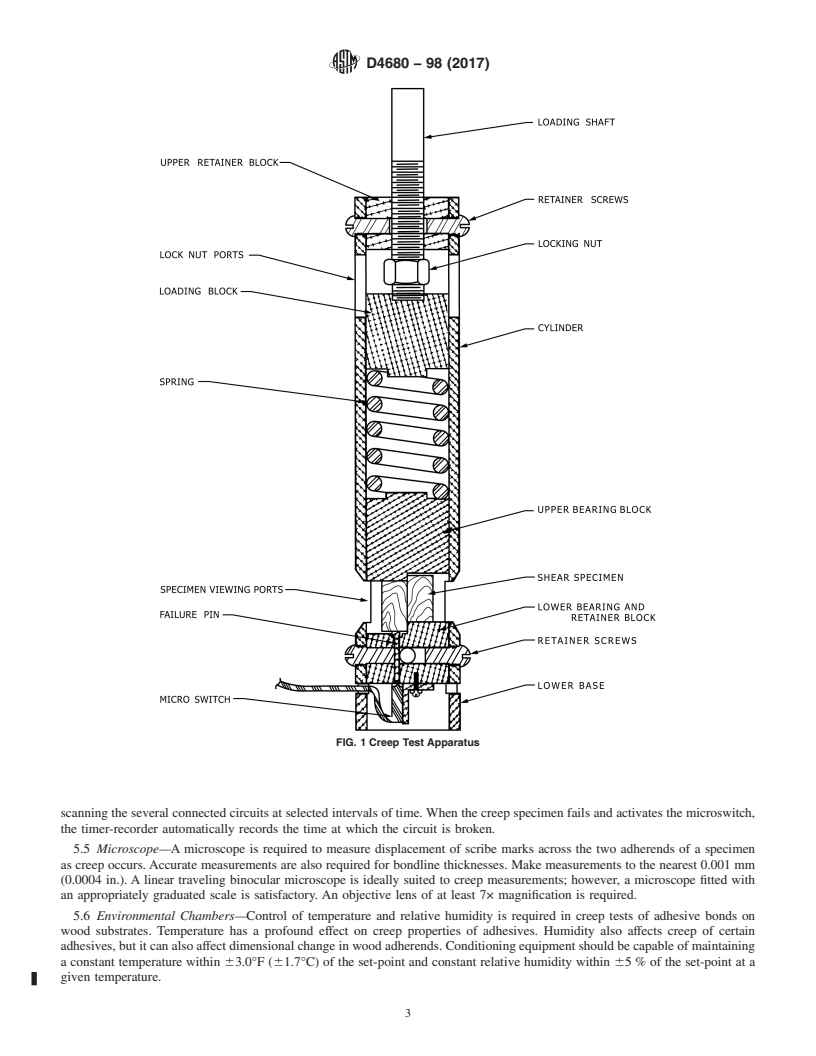

2.2 ASTM Adjuncts:

bonds when specimens are subjected to shearing stresses at

4

Compression-Shear Creep Test Apparatus

various levels of static load, constant temperature, and relative

humidity. Apparatus and procedures are provided for direct

3. Terminology

measurement of time-dependent shear deformation (creep) and

3.1 Definitions:

time to failure of adhesive bonds under static load. Guidelines

3.1.1 Many terms in these test methods are defined in

for selecting test conditions, methods for calculating creep rate,

Terminology D907.

creep strain, creep modulus, and extrapolation of time to

3.1.2 creep, n—the dimensional change with time of a

failure, are given along with methods of presenting these data.

material under load, following the initial instantaneous elastic

1.2 The values stated in inch-pound units are to be regarded

or rapid deformation. Creep at room temperature is sometimes

as standard. The values given in parentheses are mathematical

called cold flow.

conversions to SI units that are provided for information only

3.1.3 creep modulus, n—the ratio of initial applied stress to

and are not considered standard.

creep strain.

1.3 This standard does not purport to address all of the

3.1.4 creep strain, n—the total strain, at any given time,

safety concerns, if any, associated with its use. It is the

produced by the applied stress during a creep test.

responsibility of the user of this standard to establish appro-

3.1.4.1 Discussion—In this test method, creep strain is

priate safety and health practices and determine the applica-

calculated by dividing displacement at any given time by the

bility of regulatory limitations prior to use.

estimated apparent thickness of the adhesive bondline.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3.1.5 rate of creep, n—the slope of the creep-time curve at

ization established in the Decision on Principles for the

a given time.

Development of International Standards, Guides and Recom-

3.1.6 shear stress, n—the stress component tangential to the

mendations issued by the World Trade Organization Technical

plane on which the forces act, that is, in the plane of the bond

Barriers to Trade (TBT) Committee.

line.

3.1.7 strain, n—the unit change, due to stress, in the size or

2. Referenced Documents

shape of a body referred to its original size or shape.

2

2.1 ASTM Standards:

3.1.8 stress, n—the force exerted per unit area at a point

D143 Test Methods for Small Clear Specimens of Timber

within the plane.

D905 Test Method for Strength Properties of Adhesive

Bonds in Shear by Compression Loading

4. Significance and Use

4.1 Creep data that are obtained over a relatively short

1

This test method is under the jurisdiction of ASTM Committee D14 on period of time in this test method can provide a measure of an

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood

adhesive bond’s ability to withstand static loading in shear over

Adhesives.

a relatively long period of time. Creep measurements are made

Current edition approved Aug. 1, 2017. Published August 2017. Originally

approved in 1987. Last previous edition approved in 2011 as D4680 – 98 (2011).

DOI: 10.1520/D4680-98R17.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from ASTM International Headquarters. Order Adjunct No.

the ASTM website. ADJD4680. Original adjunct produced in 1987.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4680 − 98 (2017)

over a range of expected service conditions, including level of test temperature before the test load is applied to the spring.

stress, temperature, relative humidity, and duration of load. The p

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4680 − 98 (Reapproved 2011) D4680 − 98 (Reapproved 2017)

Standard Test Method for

Creep and Time to Failure of Adhesives in Static Shear by

1

Compression Loading (Wood-to-Wood)

This standard is issued under the fixed designation D4680; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of time-dependent properties of structural adhesives in wood-to-wood bonds

when specimens are subjected to shearing stresses at various levels of static load, constant temperature, and relative humidity.

Apparatus and procedures are provided for direct measurement of time-dependent shear deformation (creep) and time to failure

of adhesive bonds under static load. Guidelines for selecting test conditions, methods for calculating creep rate, creep strain, creep

modulus, and extrapolation of time to failure, are given along with methods of presenting these data.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D143 Test Methods for Small Clear Specimens of Timber

D905 Test Method for Strength Properties of Adhesive Bonds in Shear by Compression Loading

D907 Terminology of Adhesives

3

D2016 Methods of Test for Moisture Content of Wood (Withdrawn 1987)

2.2 ASTM Adjuncts:

4

Compression-Shear Creep Test Apparatus

3. Terminology

3.1 Definitions:

3.1.1 Many terms in these test methods are defined in Terminology D907.

3.1.2 creep, n—the dimensional change with time of a material under load, following the initial instantaneous elastic or rapid

deformation. Creep at room temperature is sometimes called cold flow.

3.1.3 creep modulus, n—the ratio of initial applied stress to creep strain.

3.1.4 creep strain, n—the total strain, at any given time, produced by the applied stress during a creep test.

1

This test method is under the jurisdiction of ASTM Committee D14 on Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood Adhesives.

Current edition approved April 1, 2011Aug. 1, 2017. Published April 2011August 2017. Originally approved in 1987. Last previous edition approved in 20042011 as

D4680 – 98 (2004).(2011). DOI: 10.1520/D4680-98R11.10.1520/D4680-98R17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from ASTM International Headquarters. Order Adjunct No. ADJD4680. Original adjunct produced in 1987.

3.1.4.1 Discussion—

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4680 − 98 (2017)

In this test method, creep strain is calculated by dividing displacement at any given time by the estimated apparent thickness of

the adhesive bondline.

3.1.5 rate of creep, n—the slope of the creep-time curve at a given time.

3.1.6 shear stress, n—the stress component tangential to the plane on which the forces act, that is, in the plane of the bond line.

3.1.7 strain, n—the unit change, due to stress, in the size or shape of a body referred to its original size or shape.

3.1.8 stress, n—the force exerted per unit area at a point within the plane.

4. Significance and Use

4.1 Creep data that are obtained over a relatively short period of time in this test method can

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.