ASTM D7043-04

(Test Method)Standard Test Method for Indicating Wear Characteristics of Petroleum and Non-Petroleum Hydraulic Fluids in a Constant Volume Vane Pump

Standard Test Method for Indicating Wear Characteristics of Petroleum and Non-Petroleum Hydraulic Fluids in a Constant Volume Vane Pump

SCOPE

1.1 This test method covers a constant volume high-pressure vane pump test procedure for indicating the wear characteristics of petroleum and non-petroleum hydraulic fluids.

1.2 The values stated in SI units are to be regarded as standard. The values in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D7043–04

Standard Test Method for

Indicating Wear Characteristics of Petroleum and Non-

Petroleum Hydraulic Fluids in a Constant Volume Vane

Pump

This standard is issued under the fixed designation D7043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope atthepumpinletis66 63°C(150 65°F)forallwaterglycols,

emulsions,andotherwatercontainingfluidsandforpetroleum

1.1 This test method covers a constant volume high-

and synthetic fluids of ISO Grade 46 or lighter.Atemperature

pressure vane pump test procedure for indicating the wear

of 80 6 3°C (175 6 5°F) is used for all other synthetic and

characteristics of petroleum and non-petroleum hydraulic flu-

petroleum fluids.

ids.

4.2 The result obtained is the total mass loss from the cam

1.2 The values stated in SI units are to be regarded as

ringandthetwelvevanesduringthetest.Otherreportedvalues

standard. The values in parentheses are provided for informa-

are initial flow rate and final flow rate.

tion only.

4.3 The total quantity of test oil required for a run is 26.5 L

1.3 This standard does not purport to address all of the

(7 gal).

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

5.1 This test method is an indicator of the wear character-

bility of regulatory limitations prior to use.

istics of petroleum and non-petroleum hydraulic fluids operat-

2. Referenced Documents ing in a constant volume vane pump. Excessive wear in vane

pumps could lead to malfunction of hydraulic systems in

2.1 ASTM Standards:

critical applications.

D2882 Test Method for Indicating Wear Characteristics of

Petroleum and Non-Petroleum Hydraulic Fluids in Con-

6. Apparatus

stant Volume Vane Pump

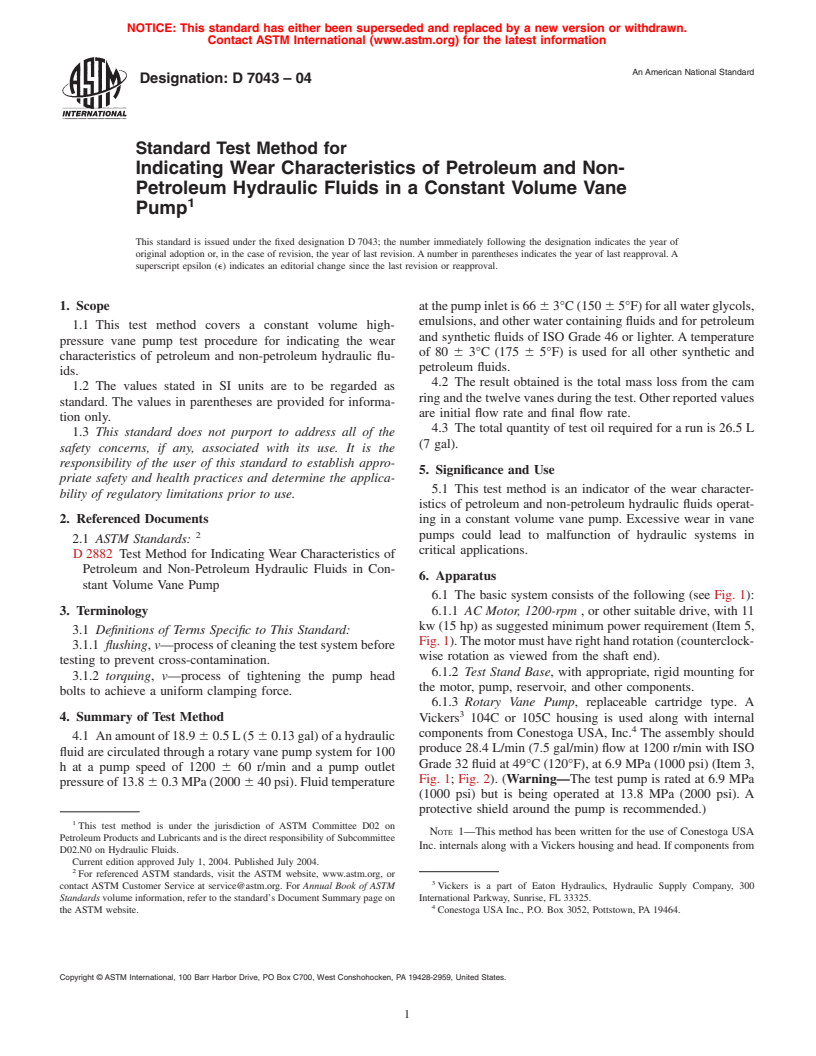

6.1 The basic system consists of the following (see Fig. 1):

3. Terminology 6.1.1 AC Motor, 1200-rpm , or other suitable drive, with 11

kw (15 hp) as suggested minimum power requirement (Item 5,

3.1 Definitions of Terms Specific to This Standard:

Fig.1).Themotormusthaverighthandrotation(counterclock-

3.1.1 flushing, v—processofcleaningthetestsystembefore

wise rotation as viewed from the shaft end).

testing to prevent cross-contamination.

6.1.2 Test Stand Base, with appropriate, rigid mounting for

3.1.2 torquing, v—process of tightening the pump head

the motor, pump, reservoir, and other components.

bolts to achieve a uniform clamping force.

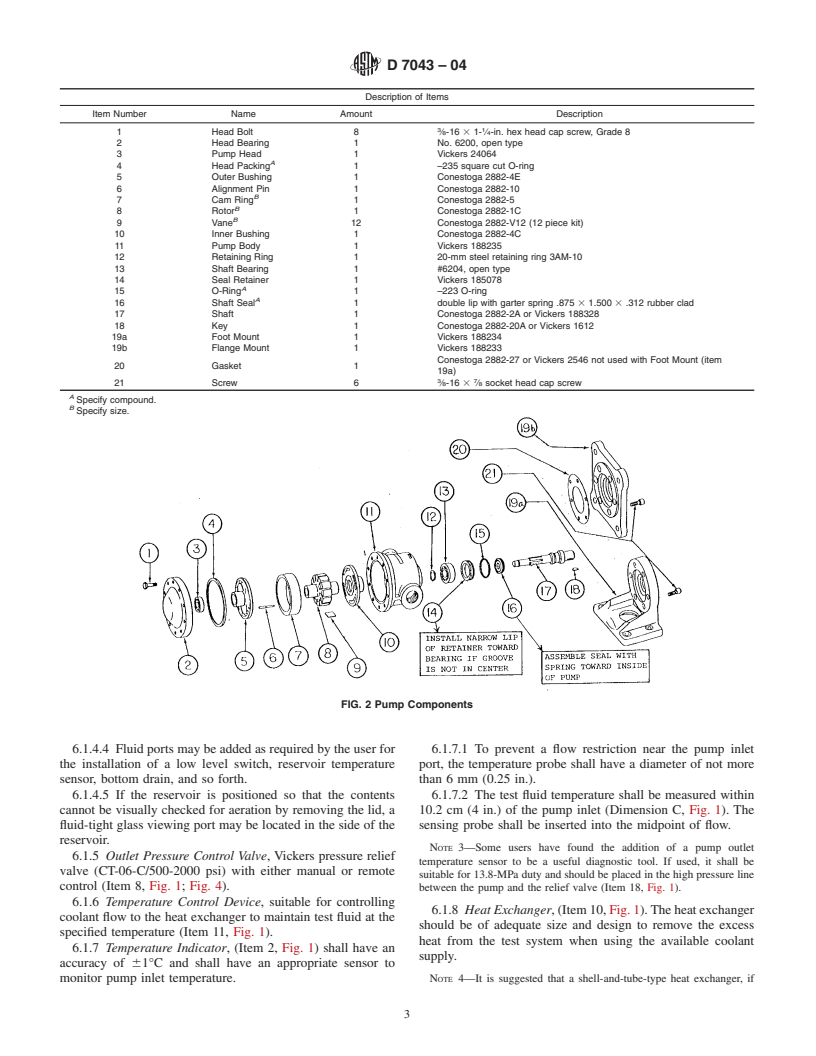

6.1.3 Rotary Vane Pump, replaceable cartridge type. A

4. Summary of Test Method

Vickers 104C or 105C housing is used along with internal

components from Conestoga USA, Inc. The assembly should

4.1 Anamountof18.9 60.5L(5 60.13gal)ofahydraulic

produce 28.4 L/min (7.5 gal/min) flow at 1200 r/min with ISO

fluid are circulated through a rotary vane pump system for 100

Grade 32 fluid at 49°C (120°F), at 6.9 MPa (1000 psi) (Item 3,

h at a pump speed of 1200 6 60 r/min and a pump outlet

Fig. 1; Fig. 2). (Warning—The test pump is rated at 6.9 MPa

pressureof13.8 60.3MPa(2000 640psi).Fluidtemperature

(1000 psi) but is being operated at 13.8 MPa (2000 psi). A

protective shield around the pump is recommended.)

This test method is under the jurisdiction of ASTM Committee D02 on

NOTE 1—This method has been written for the use of Conestoga USA

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

Inc. internals along with aVickers housing and head. If components from

D02.N0 on Hydraulic Fluids.

Current edition approved July 1, 2004. Published July 2004.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Vickers is a part of Eaton Hydraulics, Hydraulic Supply Company, 300

Standards volume information, refer to the standard’s Document Summary page on International Parkway, Sunrise, FL 33325.

the ASTM website. Conestoga USA Inc., P.O. Box 3052, Pottstown, PA 19464.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7043–04

FIG. 1 System Schematic

other manufacturers are used, refer to Test Method D2882–00 for

The reservoir can be square or rectangular (with a flat bottom)

preparation and selection guidelines.

or cylindrical (with a spherical or cone shaped bottom) and

must be designed so as to avoid air entrainment in the fluid.

6.1.3.1 The replaceable cartridge consists of the cam ring,

therotor,twobushings,asetoftwelvevanes,andanalignment

NOTE 2—A suitable reservoir design is presented in Test Method

pin.

D2882–00.

6.1.3.2 The individual cartridge parts are purchased sepa-

6.1.4.2 To promote deaeration and thermal mixing of the

rately. Conestoga USA, Inc. part numbers for these items are:

fluid, fluid residence time in the reservoir should be maxi-

cam ring No. 2882-5, alignment pin No. 2882-10, rotor No.

mized. To achieve this, the baffle shall be designed so that

2882-1C, bronze bushings No. 2882-4C and 2882-4E, and

returning fluid will follow an indirect path from the return port

vane kit (12 vanes) No. 2882-V12.

to the outlet port.

6.1.3.3 There are to be no modifications to the pump

housing such as plugging the drain hole in the pump body or 6.1.4.3 To avoid air entrainment, the reservoir shall be

drilling and tapping a hole in the head for an external drain. designed so that the return line enters well below the fluid

6.1.4 Reservoir, (Item 1, Fig. 1). level,fluidflowdoesnotcascadeoverthebaffle,andtherewill

6.1.4.1 The reservoir shall be equipped with a removable be a minimum of 15 cm (6 in.) of fluid depth above the pump

baffle and a close fitting lid, all of stainless steel construction. inlet line.

D7043–04

Description of Items

Item Number Name Amount Description

3 1

1 Head Bolt 8 ⁄8-16 3 1- ⁄4-in. hex head cap screw, Grade 8

2 Head Bearing 1 No. 6200, open type

3 Pump Head 1 Vickers 24064

A

4 Head Packing 1 –235 square cut O-ring

5 Outer Bushing 1 Conestoga 2882-4E

6 Alignment Pin 1 Conestoga 2882-10

B

7 Cam Ring 1 Conestoga 2882-5

B

8 Rotor 1 Conestoga 2882-1C

B

9 Vane 12 Conestoga 2882-V12 (12 piece kit)

10 Inner Bushing 1 Conestoga 2882-4C

11 Pump Body 1 Vickers 188235

12 Retaining Ring 1 20-mm steel retaining ring 3AM-10

13 Shaft Bearing 1 #6204, open type

14 Seal Retainer 1 Vickers 185078

A

15 O-Ring 1 –223 O-ring

A

16 Shaft Seal 1 double lip with garter spring .875 3 1.500 3 .312 rubber clad

17 Shaft 1 Conestoga 2882-2A or Vickers 188328

18 Key 1 Conestoga 2882-20A or Vickers 1612

19a Foot Mount 1 Vickers 188234

19b Flange Mount 1 Vickers 188233

Conestoga 2882-27 or Vickers 2546 not used with Foot Mount (item

20 Gasket 1

19a)

3 7

21 Screw 6 ⁄8-16 3 ⁄8 socket head cap screw

A

Specify compound.

B

Specify size.

FIG. 2 Pump Components

6.1.4.4 Fluid ports may be added as required by the user for 6.1.7.1 To prevent a flow restriction near the pump inlet

the installation of a low level switch, reservoir temperature port, the temperature probe shall have a diameter of not more

sensor, bottom drain, and so forth. than 6 mm (0.25 in.).

6.1.4.5 If the reservoir is positioned so that the contents

6.1.7.2 The test fluid temperature shall be measured within

cannot be visually checked for aeration by removing the lid, a 10.2 cm (4 in.) of the pump inlet (Dimension C, Fig. 1). The

fluid-tight glass viewing port may be located in the side of the sensing probe shall be inserted into the midpoint of flow.

reservoir.

NOTE 3—Some users have found the addition of a pump outlet

6.1.5 Outlet Pressure Control Valve, Vickers pressure relief

temperature sensor to be a useful diagnostic tool. If used, it shall be

valve (CT-06-C/500-2000 psi) with either manual or remote

suitable for 13.8-MPa duty and should be placed in the high pressure line

control (Item 8, Fig. 1; Fig. 4).

between the pump and the relief valve (Item 18, Fig. 1).

6.1.6 Temperature Control Device, suitable for controlling

6.1.8 Heat Exchanger,(Item10,Fig.1).Theheatexchanger

coolant flow to the heat exchanger to maintain test fluid at the

should be of adequate size and design to remove the excess

specified temperature (Item 11, Fig. 1).

heat from the test system when using the available coolant

6.1.7 Temperature Indicator, (Item 2, Fig. 1) shall have an

supply.

accuracy of 61°C and shall have an appropriate sensor to

monitor pump inlet temperature. NOTE 4—It is suggested that a shell-and-tube-type heat exchanger, if

D7043–04

FIG. 3 Cartridge Kit

FIG. 4 Relief Valve

used,shouldbeconnectedinreverse(thehydraulicfluidispassedthrough

6.1.9.1 The pressure indicator should be snubbed (Item 7,

the tubes and not around them) so that the interior of the heat exchanger

Fig. 1) to prevent damage from pulsations or sudden fluctua-

can be effectively cleaned between tests.

tions of system pressure.

6.1.9 Pressure Indicator (Item 6, Fig. 1), to measure pump

6.1.10 Filter Unit (Item 9, Fig. 1), 3-µm (minimum Beta 3

dischargepressureshallhaveanaccuracyofatleast 60.3MPa

ratio of 100) replaceable fiberglass element with housing.Two

(640psi)at13.8MPa.Thegageshallbesuitablefor13.8-MPa

new filter elements are required for each test.

duty.

D7043–04

6.1.10.1 The filter housing shall be non-bypassing and shall 6.2.7 The fluid return line and fittings (from the pressure

be provided with dual pressure gages (Items 13, Fig. 1)or control valve to the filter, flow counter, heat exchanger, and

another suitable indicator to monitor pressure across the filter reservoir) shall be rated for 3-MPa (400-psi) duty and have a

to warn of impending collapse of the element. minimum internal diameter of 15 mm (0.6 in.).

6.1.10.2 If dual pressure gages are used to monitor filter

NOTE 8—Some users find the addition of a shut off valve on the return

pressure,theratedcollapsepressureofthefilterelementshould

line (Item 16, Fig. 1) to be a useful addition to the piping since it allows

be known.The collapse pressure should be within the range of filter changes and other system maintenance to be performed without

draining the reservoir.

the gage.

6.1.11 Flow Measuring Device, (Item 12, Fig. 1) with an 6.2.7.1 (Warning—If a shut-off valve is installed in the

accuracy of at least 60.4 L/min (0.1 gpm).

fluid return line, the user shall take procedural steps to ensure

that this valve has been opened before the pump is started. If

6.1.12 While not required, it is suggested that low-level,

the valve is not opened, low-pressure system components may

high-pressure, high-temperature, and low-flow safety switches

rupture.)

be incorporated into the system.

6.1.13 Acheck should be made to ensure that the flush and

NOTE 9—Someusersfindtheadditionofavalveonthepumpinletline

(Item 15, Fig. 1) to be a useful addition to the piping since it allows filter

test fluid are not incompatible with hoses, seals, or any other

changes and other system maintenance to be performed without draining

materials in the system.

the reservoir. A full flow type of valve with an orifice of at least 25 mm

NOTE 5—The use of galvanized iron, aluminum, zinc, and cadmium (1 in.) is recommended.

should be avoided because of their high potential for corrosion in the

6.2.7.2 (Warning—If a shut-off valve is installed in the

presence of many non-petroleum hydraulic fluids.

pump inlet line, the user shall take procedural steps to ensure

6.1.14 Flexible Motor Coupling, (Item 4, Fig. 1).

that this valve has been opened before the pump is started. If

the valve is not opened, the pump will cavitate.)

6.2 The various components of the test system shall be

placed in the system as indicated in Fig. 1.

7. Reagents and Materials

6.2.1 The test system shall be arranged and provided with

7.1 Warning—Use adequate safety provisions with all

necessary drain valves so that complete draining is possible

solvents.

with no fluid trap areas.

7.2 Aliphatic Naphtha, Stoddard Solvent , or equivalent is

6.2.2 Goodhydraulicspipingpracticesshouldbeusedwhen

satisfactory. (Warning—Combustible. Vapor harmful.)

constructing the test system to avoid air ingestment points and

7.3 Precipitation Naphtha (Warning—Extremely flam-

flow restrictions.

mable. Harmful if inhaled. Vapors can cause flash fire.).

6.2.3 The pump should be mounted so that its internal

7.4 Isopropanol (Warning—flammable.).

surfaces can easily be inspected and cleaned, alignment can be

7.5 Warning—In instances when the solvents listed in

checked, and the operator has comfortable access when torqu-

Section 7 are not effective, alternative solvents may be used. It

ing the head.

is the responsibility of the user to determine the suitability of

6.2.4 The reservoir shall be located above the pump so that

alternative solvents and any hazards associated with their use.

the fluid level in the reservoir will be between 61 and 66 cm

(24 to 26 in.) above the center line of the pump when the test

8. Test Stand Maintenance

system is fully charged with test fluid (Dimension A, Fig. 1).

8.1 Sensors and shut-off switches should be checked peri-

6.2.4.1 The reservoir should be mounted so that it can be

odically for proper calibration and operation in accordance

cleaned and filled with ease and the contents may be readily

with good engineering practice as determined by the user.

inspected by removal of the reservoir lid.

8.2 Itisrecommendedthatthepumpshaft(Item17,Fig.2),

6.2.5 The inlet line (from the reservoir to the pump intake)

seals (Items 4, 15, 16, Fig. 2), and bearings (Items 3, 13, Fig.

shall have an internal diameter of at least 25 mm (1 in.) and

2) be replaced after every five runs (or sooner if high weight

shall have a straight horizontal run of at least 15 cm (6 in.) to

loss, vibration, cavitation, or visual deterioration is encoun-

whereitconnectstothepumpinletport(DimensionB,Fig.1).

tered).

If a hose is used, it shall be rated for vacuum service.

8.2.1 Avarietyofsealcompoundsisavailableforthepump.

It is the responsibility of the user to determine the best seal

NOTE 6—Some users have found the addition of a compound pressure

composition to use with any given fluid.

gage near the pump inlet port to be a useful diagnostic tool (Item 17, Fig.

8.3 Inspect the pump body and head.

1). However, exercise care to ensure that any ports added to the inlet line

do not become air ingestment points. 8.3.1 Visuallyexaminethepumpheadandtheinteriorofthe

NOTE 7—Whentubingisusedforthepumpinletline,someusersprefer pump body (Items 2 and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.