ASTM C133-97(2015)

(Test Method)Standard Test Methods for Cold Crushing Strength and Modulus of Rupture of Refractories

Standard Test Methods for Cold Crushing Strength and Modulus of Rupture of Refractories

SIGNIFICANCE AND USE

3.1 The cold strength of a refractory material is an indication of its suitability for use in refractory construction. (It is not a measure of performance at elevated temperatures.)

3.2 These test methods are for determining the room temperature flexural strength in 3-point bending (cold modulus of rupture) or compressive strength (cold crushing strength), or both, for all refractory products.

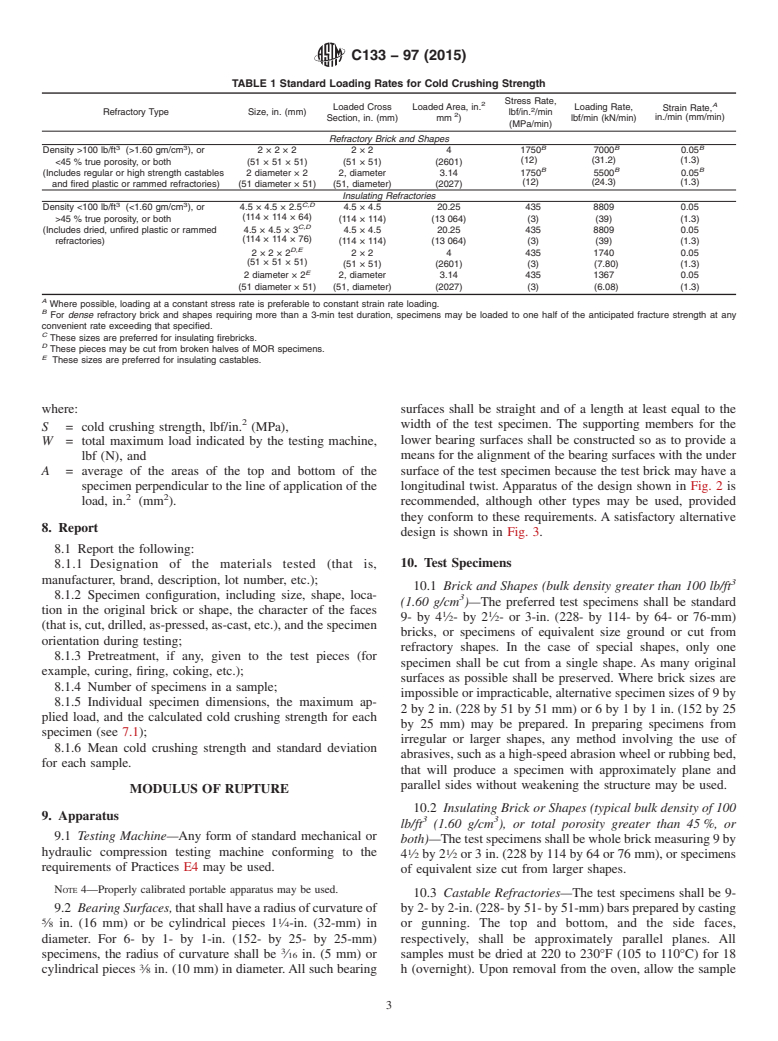

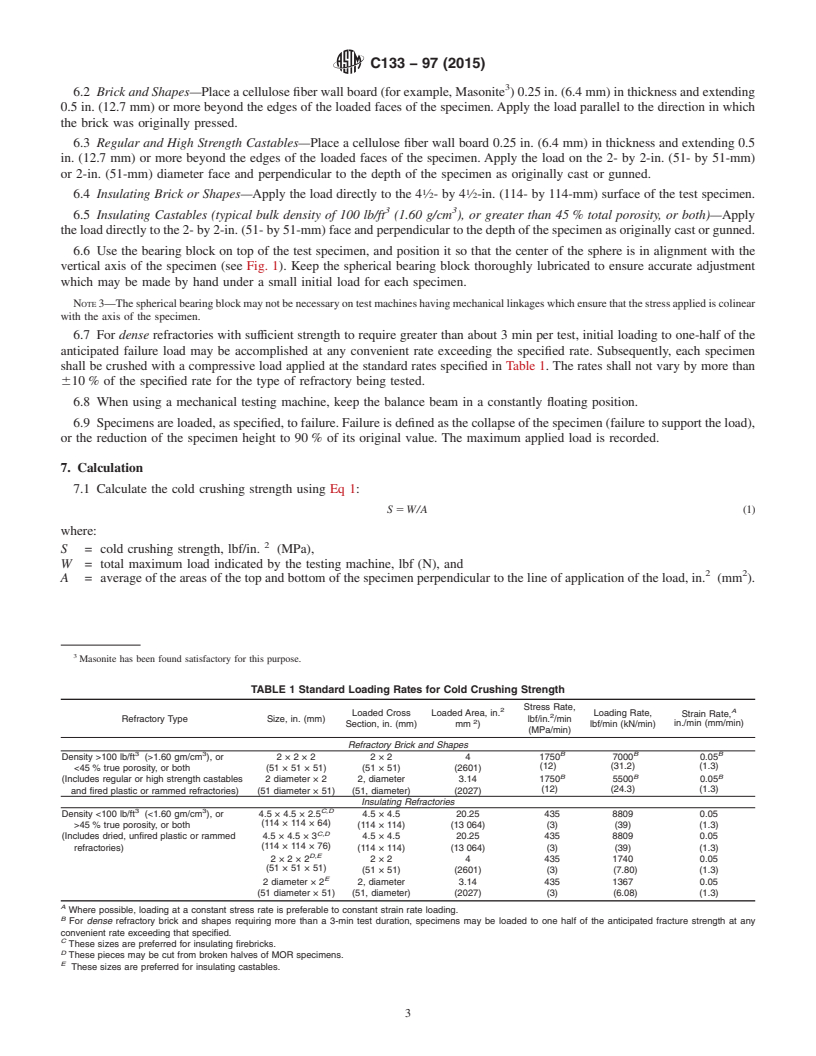

3.3 Considerable care must be used to compare the results of different determinations of the cold crushing strength or modulus of rupture. The specimen size and shape, the nature of the specimen faces (that is, as-formed, sawed, or ground), the orientation of those faces during testing, the loading geometry, and the rate of load application, may all significantly affect the numerical results obtained. Comparisons of the results between different determinations should not be made if one or more of these parameters differ between the two determinations.

3.4 The relative ratio of the largest grain size to the smallest specimen dimension may significantly affect the numerical results. For example, smaller, cut specimens containing large grains may present different results than the bricks from which they were cut. Under no circumstances should 6- by 1- by 1-in. (152- by 25- by 25-mm) specimens be prepared and tested for materials containing grains with a maximum grain dimension exceeding 0.25 in. (6.4 mm).

3.5 This test method is useful for research and development, engineering application and design, manufacturing process control, and for developing purchasing specifications.

SCOPE

1.1 These test methods cover the determination of the cold crushing strength and the modulus of rupture (MOR) of dried or fired refractory shapes of all types.

1.2 The test methods appear in the following sections:

Test Method

Sections

Cold Crushing Strength

4 to 9

Modulus of Rupture

10 to 15

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C133 − 97 (Reapproved 2015)

Standard Test Methods for

Cold Crushing Strength and Modulus of Rupture of

1

Refractories

This standard is issued under the fixed designation C133; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3.2 These test methods are for determining the room tem-

perature flexural strength in 3-point bending (cold modulus of

1.1 These test methods cover the determination of the cold

rupture) or compressive strength (cold crushing strength), or

crushing strength and the modulus of rupture (MOR) of dried

both, for all refractory products.

or fired refractory shapes of all types.

1.2 The test methods appear in the following sections: 3.3 Considerable care must be used to compare the results

of different determinations of the cold crushing strength or

Test Method Sections

modulusofrupture.Thespecimensizeandshape,thenatureof

Cold Crushing Strength 4 to 9

the specimen faces (that is, as-formed, sawed, or ground), the

Modulus of Rupture 10 to 15

orientation of those faces during testing, the loading geometry,

1.3 The values stated in inch-pound units are to be regarded

and the rate of load application, may all significantly affect the

as standard. The values given in parentheses are mathematical

numericalresultsobtained.Comparisonsoftheresultsbetween

conversions to SI units that are provided for information only

different determinations should not be made if one or more of

and are not considered standard.

these parameters differ between the two determinations.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.4 Therelativeratioofthelargestgrainsizetothesmallest

responsibility of the user of this standard to establish appro- specimen dimension may significantly affect the numerical

priate safety and health practices and determine the applica-

results. For example, smaller, cut specimens containing large

bility of regulatory limitations prior to use.

grains may present different results than the bricks from which

theywerecut.Undernocircumstancesshould6-by1-by1-in.

2. Referenced Documents

(152- by 25- by 25-mm) specimens be prepared and tested for

2

materials containing grains with a maximum grain dimension

2.1 ASTM Standards:

exceeding 0.25 in. (6.4 mm).

C862Practice for Preparing Refractory Concrete Specimens

by Casting

3.5 Thistestmethodisusefulforresearchanddevelopment,

C1054Practice for Pressing and Drying Refractory Plastic

engineering application and design, manufacturing process

and Ramming Mix Specimens

control, and for developing purchasing specifications.

E4Practices for Force Verification of Testing Machines

COLD CRUSHING STRENGTH

3. Significance and Use

3.1 The cold strength of a refractory material is an indica-

4. Apparatus

tionofitssuitabilityforuseinrefractoryconstruction.(Itisnot

4.1 Testing Machine—Any form of standard mechanical or

a measure of performance at elevated temperatures.)

hydraulic compression testing machine conforming to the

requirements of Practices E4 may be used.

1

These test methods are under the jurisdiction of ASTM Committee C08 on

NOTE 1—For low-strength materials (such as insulating bricks or

Refractories and are the direct responsibility of Subcommittee C08.01 on Strength.

castables), a sensitivity of 20 lbf (67 kN) or less is required. The use of a

Current edition approved March 1, 2015. Published May 2015. Originally

hydraulic testing machine is also preferred over the mechanical type for

ε1

approved in 1937. Last previous edition approved in 2008 as C133–97 (2008) .

these materials.

DOI: 10.1520/C0133-97R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 Spherical Bearing Block—The plane surface of the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

spherical bearing block (see Fig. 1) shall have an area which is

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. equal to or greater than the cross section of the test specimen.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C133 − 97 (2015)

6. Procedure

6.1 At least five specimens from an equivalent number of

refractory shapes compose a sample.

NOTE 2—For relatively weak specimens like insulating castables or

insulating firebricks, a minimum sample size of ten specimens is pre-

ferred.

6.2 Brick and Shapes—

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: C133 − 97 (Reapproved 2008) C133 − 97 (Reapproved 2015)

Standard Test Methods for

Cold Crushing Strength and Modulus of Rupture of

1

Refractories

This standard is issued under the fixed designation C133; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—Superfluous Section 9 was deleted in April 2009.

1. Scope

1.1 These test methods cover the determination of the cold crushing strength and the modulus of rupture (MOR) of dried or fired

refractory shapes of all types.

1.2 The test methods appear in the following sections:

Test Method Sections

Cold Crushing Strength 4 to 9

Modulus of Rupture 10 to 15

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C862 Practice for Preparing Refractory Concrete Specimens by Casting

C1054 Practice for Pressing and Drying Refractory Plastic and Ramming Mix Specimens

E4 Practices for Force Verification of Testing Machines

3. Significance and Use

3.1 The cold strength of a refractory material is an indication of its suitability for use in refractory construction. (It is not a

measure of performance at elevated temperatures.)

3.2 These test methods are for determining the room temperature flexural strength in 3-point bending (cold modulus of rupture)

or compressive strength (cold crushing strength), or both, for all refractory products.

3.3 Considerable care must be used to compare the results of different determinations of the cold crushing strength or modulus

of rupture. The specimen size and shape, the nature of the specimen faces (that is, as-formed, sawed, or ground), the orientation

of those faces during testing, the loading geometry, and the rate of load application, may all significantly affect the numerical

results obtained. Comparisons of the results between different determinations should not be made if one or more of these

parameters differ between the two determinations.

3.4 The relative ratio of the largest grain size to the smallest specimen dimension may significantly affect the numerical results.

For example, smaller, cut specimens containing large grains may present different results than the bricks from which they were

cut. Under no circumstances should 6- by 1- by 1-in. (152- by 25- by 25-mm) specimens be prepared and tested for materials

containing grains with a maximum grain dimension exceeding 0.25 in. (6.4 mm).

1

These test methods are under the jurisdiction of ASTM Committee C08 on Refractories and are the direct responsibility of Subcommittee C08.01 on Strength.

Current edition approved Aug. 1, 2008March 1, 2015. Published September 2008May 2015. Originally approved in 1937. Last previous edition approved in 20032008

ε1

as C133 – 97 (2003).(2008) . DOI: 10.1520/C0133-97R08E01.10.1520/C0133-97R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C133 − 97 (2015)

3.5 This test method is useful for research and development, engineering application and design, manufacturing process control,

and for developing purchasing specifications.

COLD CRUSHING STRENGTH

4. Apparatus

4.1 Testing Machine—Any form of standard mechanical or hydraulic compression testing machine conforming to the

requirements of Practices E4 may be used.

NOTE 1—For low-strength materials (such as insulating bricks or castables), a sensitivity of 20 lbf (67 kN) or less is required. The use of a hydraulic

testing machine is also preferred over the mecha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.