ASTM C1451-99

(Practice)Standard Practice for Determining Uniformity of Ingredients of Concrete From a Single Source

Standard Practice for Determining Uniformity of Ingredients of Concrete From a Single Source

SCOPE

1.1 This practice covers a procedure for determining the uniformity of properties of concrete materials from a single source. It includes recommendations on sampling, testing, analysis of data, and reporting.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1451–99

Standard Practice for

Determining Uniformity of Ingredients of Concrete From a

Single Source

This standard is issued under the fixed designation C 1451; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This practice covers a procedure for determining the 4.1 This practice provides a systematic procedure for sam-

uniformity of properties of concrete materials from a single pling and calculating uniformity of concrete materials. It will

source. It includes recommendations on sampling, testing, measure variability of a property of an ingredient from a single

analysis of data, and reporting. source, over a period of time. The calculation corrects for the

1.2 The values stated in SI units are to be regarded as the effects of testing error. It is applicable to any property of any

standard. concrete ingredient. Control of uniformity of concrete relates

1.3 This standard does not purport to address all of the to controlling or adapting to variability of the ingredients, but

safety concerns, if any, associated with its use. It is the this practice does not purport to identify the relative impor-

responsibility of the user of this standard to establish appro- tance of these properties.

priate safety and health practices and determine the applica-

5. Sampling

bility of regulatory limitations prior to use.

5.1 All sampling is to be performed by Quality Control or

2. Referenced Documents

testing personnel specifically trained for this purpose.

2.1 ASTM Standards: 5.2 Take random grab samples from a point in the storage

C 125 Terminology Relating to Concrete and Aggregates and handling regime of the material that will accurately reflect

C 219 Terminology Relating to Hydraulic Cement the uniformity of the material as it will be used in concrete.

C 294 Descriptive Nomenclature of Constituents of Natural Practice D 3665 provides general guidance. Additional guid-

Mineral Aggregates ance for specific materials is listed in 5.2.1-5.2.4. The lot size

C 494 Specification for ChemicalAdmixtures for Concrete from which a sample is taken shall be determined prior to

C 638 Descriptive Nomenclature of Constituents of Aggre- initiation of this procedure (Note 1). Identify samples by the

gates for Radiation Shielding of Concrete date on which the material was shipped or received, its source,

C 917 Test Method for Evaluation of Cement Strength and designated type and applicable specifications.

Uniformity from a Single Source

NOTE 1—A lot is defined as the quantity in a typical delivery unit, for

D 75 Practice for Sampling Aggregates

example, a 25-ton truck of aggregate or a 100-ton railroad car.

D 3665 Practice for Random Sampling of Construction

5.2.1 Sample cement in accordance with Test Method

Materials

C 917.

5.2.2 Sample fine and coarse aggregates in accordance with

3. Terminology

Practice D 75.

3.1 Definitions—For definitions of terms relating to this

5.2.3 Sample chemical admixtures in accordance with

practice refer to Terminology C 125, Terminology C 219,

Specification C 494.

Descriptive Nomenclature C 294, and Descriptive Nomencla-

5.2.4 Sample mineral admixtures in accordance with Prac-

ture C 638.

tice C 917.

5.3 The required sampling frequency depends on how the

This practice is under the jurisdiction of ASTM Committee C-9 on Concrete data are being used. A producer might reasonably sample

andConcreteAggregatesandisthedirectresponsibilityofSubcommitteeC09.94on

relatively frequently, for example, every production lot or

Evaluation of Data.

day’s production.Auser might be interested in uniformity of a

Current edition approved Dec. 10, 1999. Published February 2000.

material over a longer time frame, for example, approximately

Annual Book of ASTM Standards, Vol 04.02.

Annual Book of ASTM Standards, Vol 04.01.

Annual Book of ASTM Standards, Vol 04.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

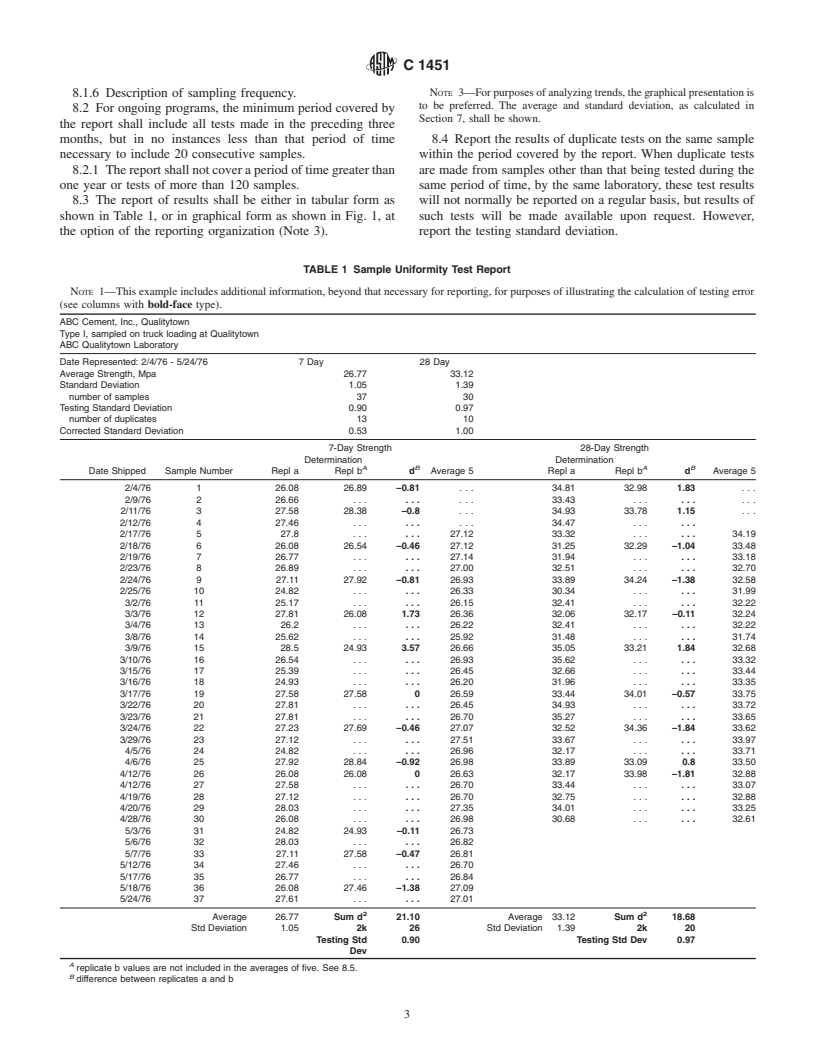

C1451

representing the frequency of purchase for a particular appli- 7. Calculation

cation. These two sampling frequencies might indicate differ-

7.1 The calculations shall include the following (Note 2):

ent levels of uniformity, therefore, it is important that the

NOTE 2—Values for averages and standard deviations can be calculated

sampling program used be described in the report (Section 8).

by other methods that are available in MNL 7 (STP 150). Electronic

calculators are available for obtaining these statistics directly.

6. Procedure

7.1.1 Average Measurement:

6.1 General—Test all samples in accordance with the ap-

propriateASTM Test Method for the particular property being

x 1 x 1 . 1 x

1 2 n

x¯ 5 (1)

measured. Variation within a single source is estimated by first

n

calculating total variation from test data on grab samples, and

where:

then correcting this by subtracting variation inherent in the test

x¯ 5 average measurement,

method (testing error). Best results are obtained if all tests are

x , x , . x 5 individual measurements, and

1 2 n

conducted in the same laboratory, but guidance is provided if it

n 5 number of individual tests.

is necessary to use data from more than one laboratory.

7.1.2 Standard Deviation:

6.2 Total Variation—Testallsamplesinaccordancewiththe

2 2 2

appropriateASTM StandardTest Method for the particular test

~x – x¯! 1 ~x – x¯! 1 . 1 ~x – x¯!

1 2 n

s 5ŒF G (2)

property being measured. Calculate the total variation among

~n–1!

the samples, as directed in 7.1.2.

where:

6.3 Testing Error—Testing error is comprised of compo-

s 5 standard deviation in units of measurement.

t

nents due to within-laboratory variation and between-

7.1.3 Testing Error: The standard deviation in testing is

laboratory variation. If results are obtained from only one

calculated as follows:

laboratory, then between-laboratory variation makes no contri-

bution. If data are obtained from more than one laboratory, it is

d

(

s 5 (3)

Œ

e

preferable to keep data from each one separate during data

2k

analysis, pooling estimates of parameters at the end of the

where:

analysis.

s 5 standard deviation estimated from tests of duplicate

6.3.1 If no within-laboratory testing standard deviation e

measurements made in a single laboratory from the

history has been established, duplicate tests made from a single

sample,

sample are required to determine this parameter. Samples must

d 5 difference between duplicate determinations, and

betestedinduplicateondifferentdaysuntilatleasttensamples

k 5 number of sets of duplicate determinations.

have been tested in duplicate. Calculate the standard deviation

7.1.4 Coeffıcient of Variation: The coefficient of variation

and the coefficient of variation, as outlined in 7.1.3 and 7.1.4.

for testing is calculated as follows,

If the testing error exceeds the level of error reported in the

s

precision statement for the applicable test method, but is less

e

CV~%! 5 · 100 (4)

x¯

than 1.5 times this value, continue duplicate tests at this same

rate. When the testing error is equal to or below the testing

7.1.5 Single-Source Standard Deviation:

error reported in the precision statement, reduce the frequency

Standard deviation of material from a single source, cor-

of duplicate testing. If the testing error exceeds 1.5 times the

rected for testing error is calculated as follows:

testing error reported in the precision statement, the data is of

2 2

s 5 =s – s (5)

c e

unacceptable precision, and the laboratory procedure and

equipment should be thoroughly examined. Use the results of

where:

duplicate tests, indicating acceptable precision to estimate the

s 5 standard deviation corrected for testing error,

c

single laboratory testing variation for all other types of similar

s 5 standard deviation for all tests inc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.