ASTM F628-12e2

(Specification)Standard Specification for Acrylonitrile-Butadiene-Styrene (ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe With a Cellular Core

Standard Specification for Acrylonitrile-Butadiene-Styrene (ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe With a Cellular Core

ABSTRACT

This specification covers coextruded acrylonitrile-butadiene-styrene (ABS) plastic drain, waste, and vent pipes made to Schedule 40 iron pipe sizes (IPS) with concentric inner and outer solid ABS layers and a closed-cell cellular ABS core. The ABS plastics used to make the pipes shall only be either virgin or reworked as specfieid. Reprocessed or recycled plastics are excluded from this specification. The pipes shall meet specified requirements for dimension such as outside diameter, wall thickness, and length; and for performance such as pipe stiffness, lower confidence limit, flattening resistance, impact strength, bond strength, pigments or screening agents, and solvent cement.

SCOPE

1.1 This specification covers coextruded acrylonitrile-butadiene-styrene (ABS) plastic drain, waste, and vent pipe made to Schedule 40 iron pipe sizes (IPS) and produced by the coextrusion process with concentric inner and outer solid ABS layers and the core consisting of closed-cell cellular ABS. Plastic which does not meet the material requirements specified in Section 5 is excluded from single layer and all coextruded layers.

1.2 Fittings suitable for use with pipe meeting the requirements of this specification are given in Annex A1. Fittings meeting the requirement of Specification D2661 are also acceptable.

1.3 Acrylonitrile-butadiene-styrene plastic which does not meet the definitions of virgin ABS plastic as given in 3.2.4 is excluded, as performance of plastic other than those defined as virgin was not determined. ABS rework plastic which meets the requirements of rework plastic as given in 5.3 is acceptable.

1.4 Reprocessed plastic or recycled plastic as defined in Terminology D883 is excluded.

1.5 Recommendations for storage, joining, and installation are provided in Appendixes X1, X2, and X3, respectively.

1.6 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.7 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´2

Designation:F628 −12 An American National Standard

Standard Specification for

Acrylonitrile-Butadiene-Styrene (ABS) Schedule 40 Plastic

1

Drain, Waste, and Vent Pipe With a Cellular Core

ThisstandardisissuedunderthefixeddesignationF628;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Sections 2, 6.4.4, and the Summary of Changes were editorially corrected in March 2013.

2

ε NOTE—Table 2 was editorially corrected in April 2016.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This specification covers coextruded acrylonitrile-

D618Practice for Conditioning Plastics for Testing

butadiene-styrene (ABS) plastic drain, waste, and vent pipe

D883Terminology Relating to Plastics

madetoSchedule40ironpipesizes(IPS)andproducedbythe

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

coextrusion process with concentric inner and outer solidABS

tics

layers and the core consisting of closed-cell cellular ABS.

3

D1898Practice for Sampling of Plastics (Withdrawn 1998)

Plasticwhichdoesnotmeetthematerialrequirementsspecified

D2122Test Method for Determining Dimensions of Ther-

in Section 5 is excluded from single layer and all coextruded

moplastic Pipe and Fittings

layers.

D2235Specification for Solvent Cement for Acrylonitrile-

Butadiene-Styrene (ABS) Plastic Pipe and Fittings

1.2 Fittings suitable for use with pipe meeting the require-

D2321PracticeforUndergroundInstallationofThermoplas-

ments of this specification are given in Annex A1. Fittings

tic Pipe for Sewers and Other Gravity-Flow Applications

meeting the requirement of Specification D2661 are also

D2412Test Method for Determination of External Loading

acceptable.

Characteristics of Plastic Pipe by Parallel-Plate Loading

1.3 Acrylonitrile-butadiene-styrene plastic which does not

D2444Test Method for Determination of the Impact Resis-

meet the definitions of virgin ABS plastic as given in 3.2.4 is

tance of Thermoplastic Pipe and Fittings by Means of a

excluded, as performance of plastic other than those defined as Tup (Falling Weight)

D2661 Specification for Acrylonitrile-Butadiene-Styrene

virgin was not determined. ABS rework plastic which meets

(ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe

therequirementsofreworkplasticasgivenin5.3isacceptable.

and Fittings

1.4 Reprocessed plastic or recycled plastic as defined in

D3311Specification for Drain, Waste, and Vent (DWV)

Terminology D883 is excluded.

Plastic Fittings Patterns

D3965ClassificationSystemandBasisforSpecificationsfor

1.5 Recommendations for storage, joining, and installation

Rigid Acrylonitrile-Butadiene-Styrene (ABS) Materials

are provided in Appendixes X1, X2, and X3, respectively.

for Pipe and Fittings

1.6 Thetextofthisspecificationreferencesnotes,footnotes,

D5630Test Method for Ash Content in Plastics

and appendixes which provide explanatory material. These

E105Practice for Probability Sampling of Materials

notesandfootnotes(excludingthoseintablesandfigures)shall

E1508 Guide for Quantitative Analysis by Energy-

not be considered as requirements of the specification.

Dispersive Spectroscopy

E122PracticeforCalculatingSampleSizetoEstimate,With

1.7 The values stated in inch-pound units are to be regarded

Specified Precision, the Average for a Characteristic of a

as the standard. The values given in parentheses are for

Lot or Process

information only.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Piping Systems and is the direct responsibility of Subcommittee F17.63 on DWV. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 15, 2012. Published January 2013. Originally the ASTM website.

3

approved in 1979. Last previous edition approved in 2008 as F628–08. DOI: The last approved version of this historical standard is referenced on

10.1520/F0628-12E02. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´2

F628−12

commonly found in normal use may be encountered and temperatures in

F402 Practice for Safe Handling of Solvent Cements,

excess of 180°F (82°C) may be encountered.

Primers, and Cleaners Used for Joining Thermoplastic

NOTE 2—This specification does not include requirements for pipe

Pipe and Fittings

intended to be used to vent combustion gases.

F412Terminology Relating to Plastic P

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´2 ´2

Designation: F628 − 12 F628 − 12

Standard Specification for

Acrylonitrile-Butadiene-Styrene (ABS) Schedule 40 Plastic

1

Drain, Waste, and Vent Pipe With a Cellular Core

This standard is issued under the fixed designation F628; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Sections 2, 6.4.4, and the Summary of Changes were editorially corrected in March 2013.

2

ε NOTE—Table 2 was editorially corrected in April 2016.

1. Scope*

1.1 This specification covers coextruded acrylonitrile-butadiene-styrene (ABS) plastic drain, waste, and vent pipe made to

Schedule 40 iron pipe sizes (IPS) and produced by the coextrusion process with concentric inner and outer solid ABS layers and

the core consisting of closed-cell cellular ABS. Plastic which does not meet the material requirements specified in Section 5 is

excluded from single layer and all coextruded layers.

1.2 Fittings suitable for use with pipe meeting the requirements of this specification are given in Annex A1. Fittings meeting

the requirement of Specification D2661 are also acceptable.

1.3 Acrylonitrile-butadiene-styrene plastic which does not meet the definitions of virgin ABS plastic as given in 3.2.4 is

excluded, as performance of plastic other than those defined as virgin was not determined. ABS rework plastic which meets the

requirements of rework plastic as given in 5.3 is acceptable.

1.4 Reprocessed plastic or recycled plastic as defined in Terminology D883 is excluded.

1.5 Recommendations for storage, joining, and installation are provided in Appendixes X1, X2, and X3, respectively.

1.6 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes

and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.7 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

3

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2235 Specification for Solvent Cement for Acrylonitrile-Butadiene-Styrene (ABS) Plastic Pipe and Fittings

D2321 Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

D2444 Test Method for Determination of the Impact Resistance of Thermoplastic Pipe and Fittings by Means of a Tup (Falling

Weight)

D2661 Specification for Acrylonitrile-Butadiene-Styrene (ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe and Fittings

D3311 Specification for Drain, Waste, and Vent (DWV) Plastic Fittings Patterns

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.63 on DWV.

Current edition approved Nov. 15, 2012. Published January 2013. Originally approved in 1979. Last previous edition approved in 2008 as F628 – 08. DOI:

10.1520/F0628-12.10.1520/F0628-12E02.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´2

F628 − 12

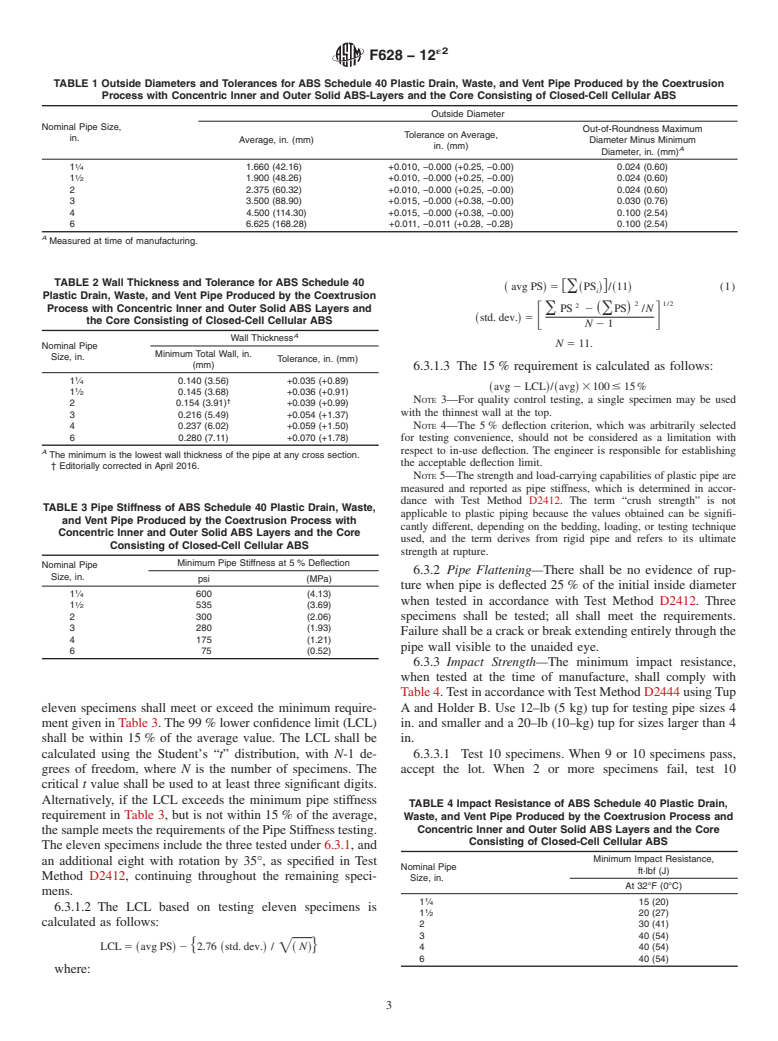

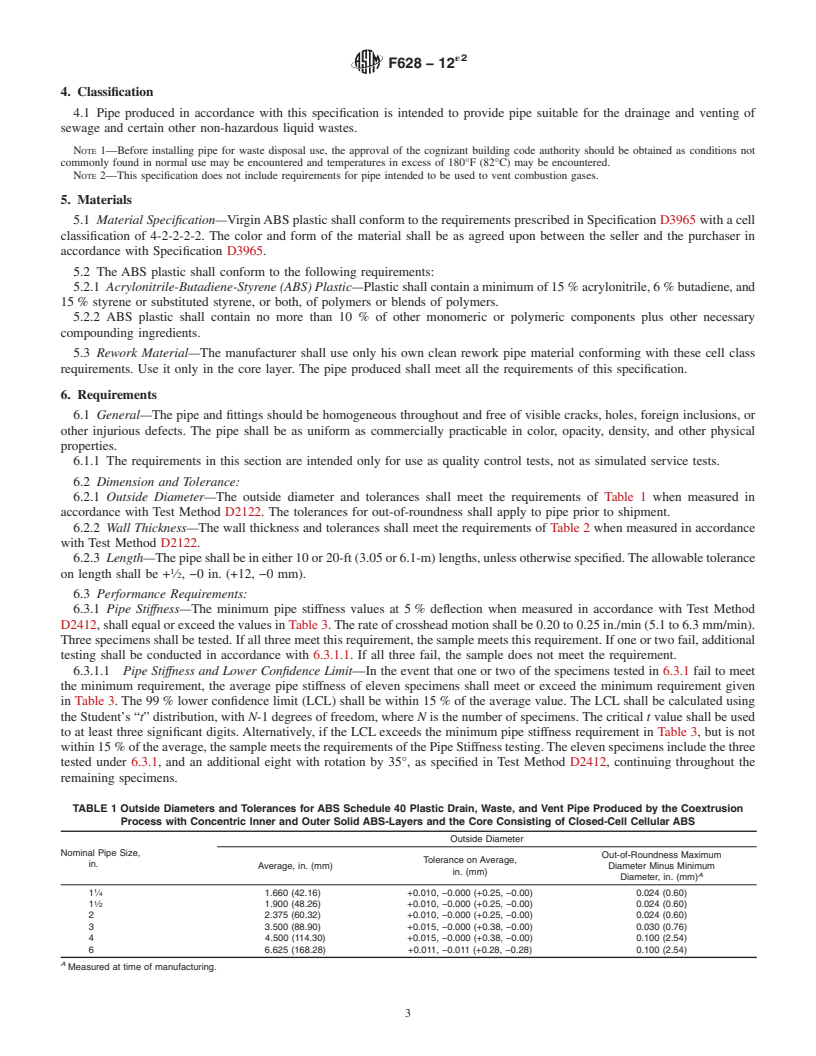

TABLE 2 Wall Thickness and Tolerance for ABS Schedule 40

Plastic Drain, Waste, and Vent Pipe Produced by the Coextrusion

Process with Concentric Inner and Outer Solid ABS Layers and

the Core Consisting of Closed-Cell Cellular ABS

A

Wall Thickness

Nominal Pipe

Minimum Total Wall, in.

Size, in.

Tolerance, in. (mm)

(mm)

1

1 ⁄4 0.140 (3.56) +0.035 (+0.89)

1

1 ⁄2 0.145 (3.68) +0.036 (+0.91)

2 0.154 (3.39) +0.039 (+0.99)

†

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.