ASTM D5448/D5448M-93(2000)

(Test Method)Standard Test Method for Inplane Shear Properties of Hoop Wound Polymer Matrix Composite Cylinders

Standard Test Method for Inplane Shear Properties of Hoop Wound Polymer Matrix Composite Cylinders

SCOPE

1.1 This test method determines the inplane shear properties of wound polymer matrix composites reinforced by high-modulus continuous fibers. It describes testing of hoop wound (90°) cylinders in torsion for determination of inplane shear properties.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the test method.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5448/D 5448M – 93 (Reapproved 2000)

Standard Test Method for

Inplane Shear Properties of Hoop Wound Polymer Matrix

Composite Cylinders

This standard is issued under the fixed designation D5448/D5448M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Properties of Hoop Wound Polymer Matrix Composite

Cylinders

1.1 Thistestmethoddeterminestheinplaneshearproperties

D 5450/D 5450M Test Method for Transverse Tensile

of wound polymer matrix composites reinforced by high-

Properties of Hoop Wound Polymer Matrix Composite

modulus continuous fibers. It describes testing of hoop wound

Cylinders

(90°) cylinders in torsion for determination of inplane shear

E4 Practices for Force Verification of Testing Machines

properties.

E6 Terminology Relating to Methods of Mechanical Test-

1.2 The values stated in either SI units or inch-pound units

ing

are to be regarded separately as standard. Within the text the

E111 TestMethodforYoung’sModulus,TangentModulus,

inch-pound units are shown in brackets. The values stated in

and Chord Modulus

each system are not exact equivalents; therefore, each system

E122 PracticeforCalculatingSampleSizetoEstimatewith

must be used independently of the other. Combining values

a Specified Tolerable Error, theAverage for a Characteris-

from the two systems may result in nonconformance with the

tic of a Lot or Process

test method.

E177 Practice for Use of the Terms Precision and Bias in

1.3 This standard does not purport to address all of the

ASTM Test Methods

safety problems, if any, associated with its use. It is the

E251 Test Methods for Performance Characteristics of

responsibility of the user of this standard to establish appro-

Metallic Bonded Resistance Strain Gages

priate safety and health practices and determine the applica-

E456 Terminology Relating to Quality and Statistics

bility of regulatory limitations prior to use.

E691 Practice for Conducting and Interlaboratory Study to

2. Referenced Documents Determine the Precision of a Test Method

E 1237 Guide for Installing Bonded Resistance Strain

2.1 ASTM Standards:

Gages

D792 TestMethodsforDensityandSpecificGravity(Rela-

tive Density) of Plastics by Displacement

3. Terminology

D883 Terminology Relating to Plastics

3.1 Definitions—TerminologyD3878definestermsrelating

D2584 Test Method for Ignition Loss of Cured Reinforced

3 to high-modulus fibers and their composites. Terminology

Resins

D883 defines terms relating to plastics. Terminology E6

D2734 Test Method for Void Content of Reinforced Plas-

3 defines terms relating to mechanical testing. Terminology

tics

E456 and Practice E177 define terms relating to statistics. In

D3171 Test Method for Constituent Content of Composite

4 the event of a conflict between terms, Terminology D3878

Materials

shall have precedence over other standards.

D3878 Terminology for Composite Materials

3.2 Description of Terms Specific to This Standard:

D5229/D5229M Test Method for Moisture Absorption

3.2.1 hoopwound,n—awindingofacylindricalcomponent

Properties and Equilibrium Conditioning of Polymer Ma-

where the filaments are circumferentially oriented.

trix Composite Materials

D5449/D5449M TestMethodforTransverseCompressive

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 14.02.

1 7

This test method is under the jurisdiction of ASTM Committee D30 on High If the term represents a physical quantity, its analytical dimensions are stated

Modulus Fibers and Their Composites and is the direct responsibility of Subcom- immediately following the term (or letter symbol) in fundamental dimension form,

mittee D30.04 on Lamina and Laminate Test Methods. usingthefollowingASTMstandardsymbologyforfundamentaldimensions,shown

Current edition approved Aug. 15, 1993. Published October 1993. within square brackets: [M] for mass, [L] for length, [T] for time, [u] for

Annual Book of ASTM Standards, Vol 08.01. thermodynamic temperature, and [ nd] for nondimensional quantities. Use of these

Annual Book of ASTM Standards, Vol 08.02. symbolsisrestrictedtoanalyticaldimensionswhenusedwithsquarebrackets,asthe

Annual Book of ASTM Standards, Vol 15.03. symbols may have other definitions when used without the brackets.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5448/D 5448M – 93 (2000)

−1 −2

3.2.2 inplaneshearmodulus,G [MT T ],n—theelastic 6. Interferences

shear modulus of a unidirectional material in the plane defined

6.1 Material and Specimen Preparation—Poor material

by axes parallel and perpendicular to the reinforcing fibers.

fabrication practices, lack of control of fiber alignment, and

u

3.2.3 inplaneshearstrainatfailure, g [nd],n—thevalue

damage induced by improper coupon machining are known

of inplane shear strain at failure when an inplane shear load is

causes of high material data scatter in composites.

applied to the material.

6.2 BondingSpecimenstoTestFixtures—Ahighpercentage

−2 −1

3.2.4 inplane shear strength, t ,[ MT L ], n—the

of failures in or near the bond between the test specimen and

strengthofaunidirectionalmaterialwhenaninplaneshearload

the test fixture, especially when combined with high material

is applied to the material.

data scatter, is an indicator of specimen bonding problems.

3.2.5 specimen—asinglepartcutfromawindingthatmeets

Specimen-to-fixture bonding is discussed in 11.5.

the specifications of Fig. 1. Each winding may yield several

6.3 System Alignment—Excessive bending or axial loading

specimens.

will cause premature failure, as well as highly inaccurate shear

3.2.6 winding—an entire part completed by one winding

modulus determination. Every effort should be made to elimi-

operation and then cured.

nate excess bending and axial loading from the test system.

Bending and axial loading may occur due to misaligned grips,

4. Summary of Test Method

misalignedspecimensinthetestfixtures,orfromdeparturesof

4.1 A thin walled hoop wound cylinder nominally 100 mm

the specimens from tolerance requirements. The alignment

[4 in.] in diameter and 140 mm [5 ⁄2 in.] in length is bonded

should always be checked as discussed in 12.2.

into two end fixtures. The specimen/fixture assembly is

mounted in the testing machine and monotonically loaded in

7. Apparatus

inplane shear while recording load. The inplane shear strength

7.1 Micrometers, suitable ball type for reading to within

can be determined from the maximum load carried prior to

0.025 6 0.010 mm [0.001 6 0.0004 in.] of the specimen inner

failure. If the cylinder strain is monitored with strain gages

and outer diameters. Flat anvil type or micrometer calipers of

then the stress-strain response, the inplane shear strain at

similar resolution may be used for the overall specimen length

failure, and the inplane shear modulus can be derived.

and the gage length (the free length between the fixtures).

7.2 Inplane Shear Fixture—The inplane shear fixture con-

5. Significance and Use

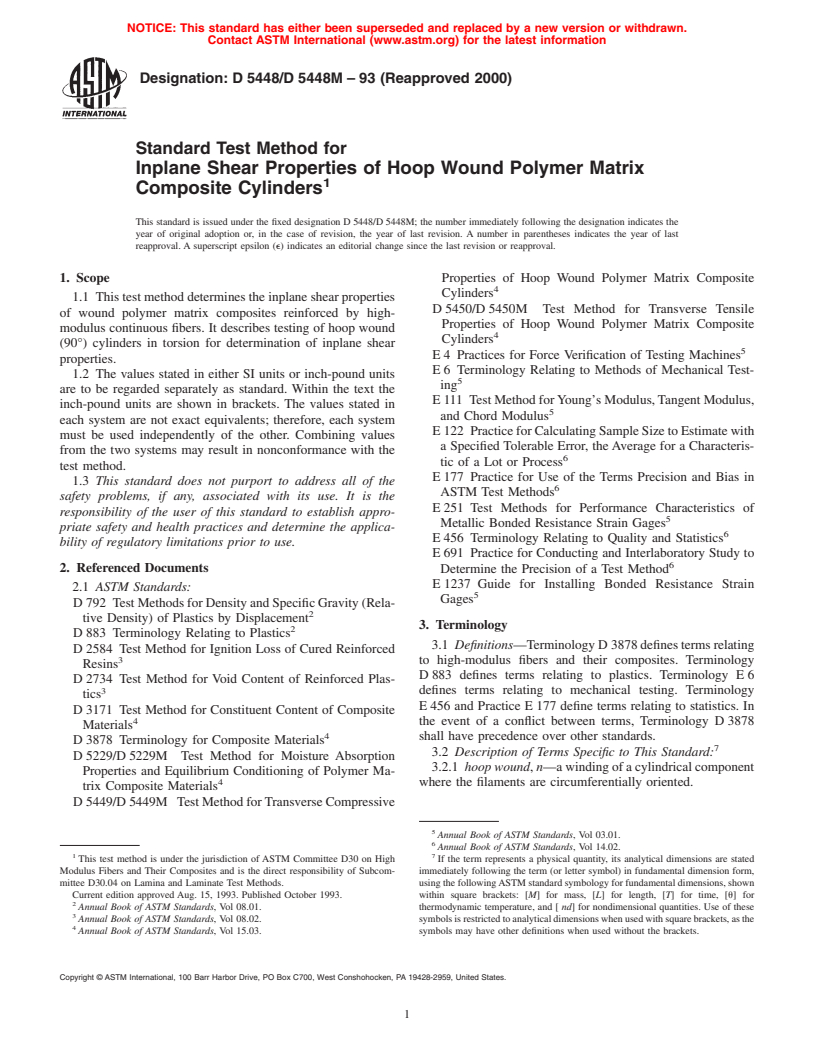

sists of a steel outer shell, insert, and adaptor. An assembly

5.1 This test method is designed to produce inplane shear

drawing for these components and the test fixture is shown in

property data for material specifications, research and devel-

Fig. 1.

opment, quality assurance, and structural design and analysis.

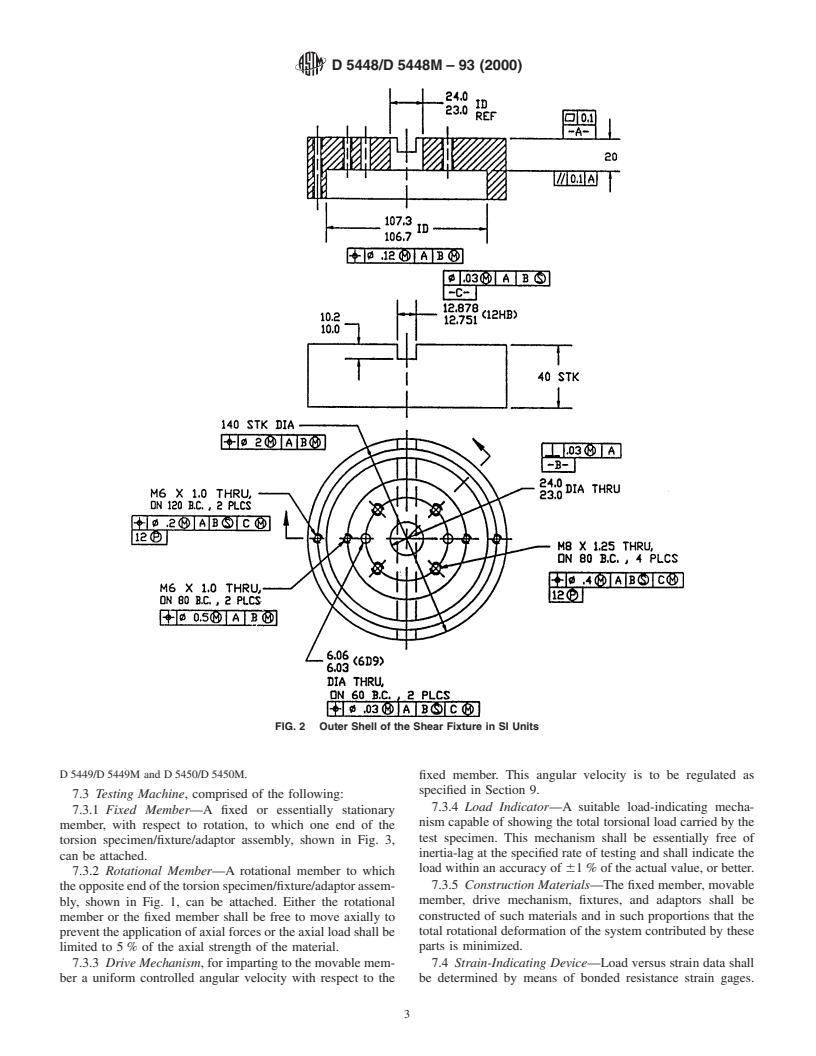

7.2.1 Outer Shell—The outer shell (SI units, see Fig. 2;

Factors that influence the inplane shear response and should

inch-pound units, see Fig. 3) is circular with a concentric

therefore be reported are material, method of material prepa-

circular hollow in one face, a groove along the diameter of the

ration, specimen preparation, specimen conditioning, environ-

other face, and a center hole through the thickness. Along the

ment of testing, specimen alignment and gripping, speed of

diameter perpendicular to the groove, three pairs of small

testing, void content, and fiber volume fraction. Properties, in

eccentric holes are placed at three radial distances. The two

the test direction, that may be obtained from this test method

outer pairs of holes are threaded. Four additional threaded

are as follows:

holes are placed at the same radial distance as the innermost

u

5.1.1 Inplane Shear Strength, t ,

pairofholesat90°intervalsstarting45°fromthediameterthat

u

5.1.2 Inplane Shear Strain at Failure, g , and

passes through the center groove.

5.1.3 Inplane Shear Modulus, G .

7.2.2 Insert—Thefixtureinsertiscircularwithacenterhole

through the thickness (SI units, see Fig. 4; inch-pound units,

see Fig. 5). Two sets of holes are placed along a concentric

centerline.These holes align with the innermost set of holes in

the outer shell. The set of 4 holes at 90° intervals are

counterbored. The insert is fastened inside the hollow of the

outer shell to form the concentric groove used to put the

specimen in the fixture.

7.2.3 Adaptor—Theadaptoriscircularwithasquarecentral

torque nut raising out of one face, a flange along a diameter on

the other face, and a central hole (SI units, see Fig. 6;

inch-pound units, see Fig. 7). Two bolt holes are placed

equidistantfromtheadaptorcenteronadiameterperpendicular

to the centerline of the flange. The adaptor is fastened to the

outer shell.The flange of the adaptor fits into the groove of the

outer shell. The complete inplane shear specimen/fixture as-

sembly is seen in Fig. 1.

NOTE 1—The outer shell and insert for the compression fixture are the

FIG. 1 Assembly Drawing for the Shear Fixture and Specimen same outer shell and insert used for the fixtures in Test Methods

D 5448/D 5448M – 93 (2000)

FIG. 2 Outer Shell of the Shear Fixture in SI Units

D5449/D5449M and D5450/D5450M.

fixed member. This angular velocity is to be regulated as

specified in Section 9.

7.3 Testing Machine, comprised of the following:

7.3.4 Load Indicator—A suitable load-indicating mecha-

7.3.1 Fixed Member—A fixed or essentially stationary

nism capable of showing the total torsional load carried by the

member, with respect to rotation, to which one end of the

test specimen. This mechanism shall be essentially free of

torsion specimen/fixture/adaptor assembly, shown in Fig. 3,

inertia-lag at the specified rate of testing and shall indicate the

can be attached.

load within an accuracy of 61% of the actual value, or better.

7.3.2 Rotational Member—A rotational member to which

7.3.5 Construction Materials—The fixed member, movable

theoppositeendofthetorsionspecimen/fixture/adaptorassem-

member, drive mechanism, fixtures, and adaptors shall be

bly, shown in Fig. 1, can be attached. Either the rotational

constructed of such materials and in such proportions that the

member or the fixed member shall be free to move axially to

total rotational deformation of the system contributed by these

preventtheapplicationofaxialforcesortheaxialloadshallbe

parts is minimized.

limited to 5% of the axial strength of the material.

7.3.3 Drive Mechanism, for imparting to the movable mem- 7.4 Strain-Indicating Device—Load versus strain data shall

ber a uniform controlled angular velocity with respect to the be determined by means of bonded resistance strain gages.

D 5448/D 5448M – 93 (2000)

FIG. 3 Outer Shell for the Shear Fixture in Inch-Pound Units

Each strain gage shall be 6.3 mm [0.25 in.] in length. Strain consulted regarding surface preparation guidelines and recom-

gage rosettes (0°/45°/90°) shall be used to correct for gage

mended bonding agents for composites, pending the develop-

misalignment. Gage calibration certification shall comply with ment of a set of standard practices for strain gage installation

Test Method E251. Some guidelines on the use of strain gages

surface preparation of fiber-reinforced composite materials.

oncompositesarepresentedin7.4.1-7.4.4.Ageneralreference

7.4.2 Gage Resistance—Consideration should be given to

on the subject is Tuttle and Brinson.

the selection of gages having larger resistance to reduce

7.4.1 Surface Preparation—The surface preparation of

heating effects on low-conductivity materials. Resistances of

fiber-reinforced composites discussed in Guide E1237 can

350Vorhigherarepreferred.Additionalconsiderationsshould

penetrate the matrix material and cause damage to the rein-

be given to the use of the minimum possible gage excitation

forcing fibers, resulting in improper coupon failures. Reinforc-

voltage consistent with the desired accuracy (1 to 2 V is

ingfibersshouldnotbeexposedordamagedduringthesurface

recommended) to further reduce the power consumed by the

preparation process. The strain gage manufacturer should be

gage. Heating of the coupon by the gage may affect the

performance of the material directly, or it may affect the

indicated strain due to a difference between the gage tempera-

Tuttle, M. E. and Brinson, H. F., “Resistance-Foil Strain-Gage Technology as

ture compensation factor and the coefficient of thermal expan-

Applied to Composite Materials,” Experimental Mechanics, Vol 24, No. 1, March

1984, pp. 54–64; errata noted in Vol 26, No. 2, January 1986, pp. 153–154. sion of the coupon material.

D 5448/D 5448M – 93 (2000)

FIG. 4 Insert of the Shear Fixture in SI Units

7.4.3 Temperature Considerations—Consideration of some ent testing laboratory conditions. This chamber shall be ca-

form of temperature compensation is recommended, even pable of maintaining the gage section of the test specimen at

when testing at standard laboratory atmosphere. Temperature

the required test environment during the mechanical test.

compensationisrequiredwhentestinginnonambienttempera-

ture environments.

8. Sampling and Test Specimens

7.4.4 Transverse Sensitivity—Consideration should be

8.1 Sampling—At least five specimens per test condition

given to the transverse sensitivity of the selected strain gage.

should be tested unless valid results can be gained through the

The strain gage manufacturer should be consulted for recom-

use of fewer specimens, such as in the case of a designed

mendations on transverse sensitivity corrections and effects on

experiment. For statistically significant data, the procedures

composites.

outlined in Practice E122 should be consulted. The method of

7.5 Conditioning Chamber—When conditioning materials

sampling shall be reported.

at nonlaboratory environments, a temperature/vapor-level con-

8.2 Geometry—The test specimen shall be as shown in Fig.

trolled environment conditioning chambe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.