ASTM E2309/E2309M-05(2011)e1

(Practice)Standard Practices for Verification of Displacement Measuring Systems and Devices Used in Material Testing Machines

Standard Practices for Verification of Displacement Measuring Systems and Devices Used in Material Testing Machines

SIGNIFICANCE AND USE

Testing machines that apply and measure displacement are used in many industries. They may be used in research laboratories to determine material properties, and in production lines to qualify products for shipment. The displacement measuring devices integral to the testing machines may be used for measurement of crosshead or actuator displacement over a defined range of operation. The accuracy of the displacement value shall be traceable to the National Institute of Standards and Technology (NIST) or another recognized National Laboratory. Practices E2309 provides a procedure to verify these machines and systems, in order that the measured displacement values may be traceable. A key element to having traceability is that the devices used in the verification produce known displacement characteristics, and have been calibrated in accordance with adequate calibration standards.

SCOPE

1.1 These practices cover procedures and requirements for the calibration and verification of displacement measuring systems by means of standard calibration devices for static and quasi-static testing machines. This practice is not intended to be complete purchase specifications for testing machines or displacement measuring systems. Displacement measuring systems are not intended to be used for the determination of strain. See Practice E83.

1.2 These procedures apply to the verification of the displacement measuring systems associated with the testing machine, such as a scale, dial, marked or unmarked recorder chart, digital display, etc. In all cases the buyer/owner/user must designate the displacement-measuring system(s) to be verified.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

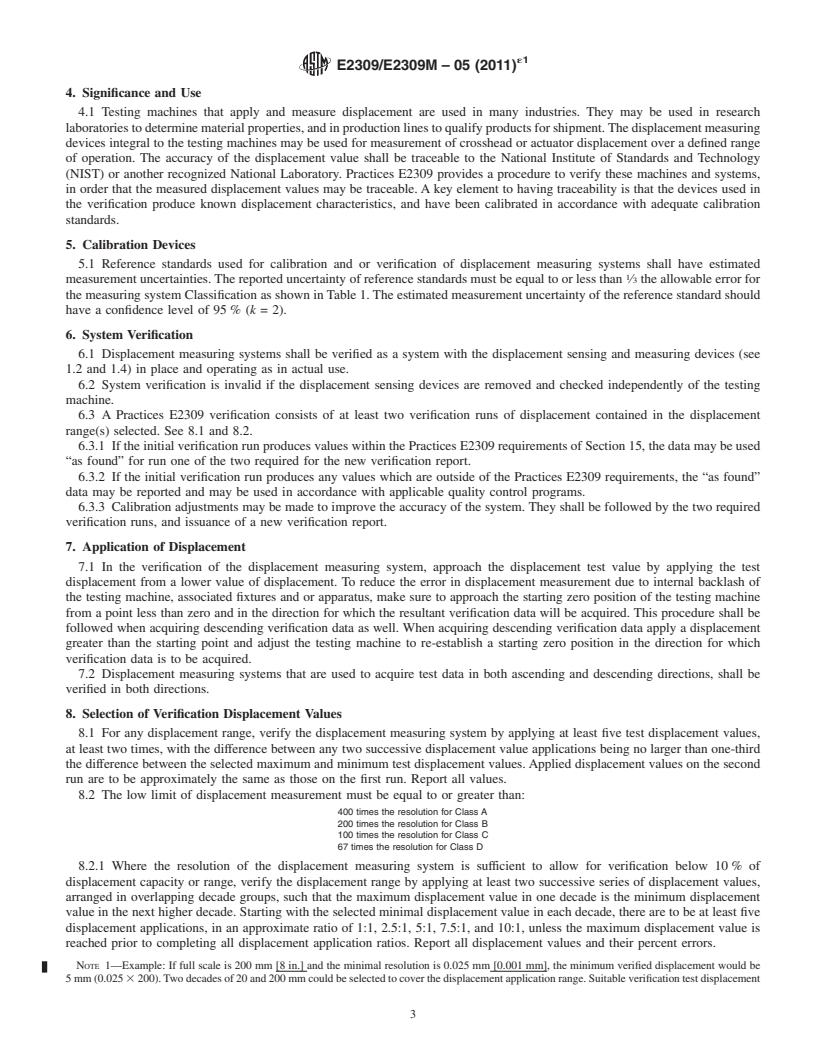

1.4 Displacement values indicated on displays/printouts of testing machine data systemsbe they instantaneous, delayed, stored, or retransmittedwhich are within the Classification criteria listed in Table 1, comply with Practices E2309/E2309M.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:E2309/E2309M −05(Reapproved 2011)

Standard Practices for

Verification of Displacement Measuring Systems and

Devices Used in Material Testing Machines

ThisstandardisissuedunderthefixeddesignationE2309/E2309M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—The units statement (1.3) and the designation were editorially revised in January 2011.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 These practices cover procedures and requirements for

E83Practice for Verification and Classification of Exten-

the calibration and verification of displacement measuring

someter Systems

systemsbymeansofstandardcalibrationdevicesforstaticand

quasi-static testing machines. This practice is not intended to

3. Terminology

be complete purchase specifications for testing machines or

displacement measuring systems. Displacement measuring

3.1 Definitions:

systems are not intended to be used for the determination of 3.1.1 accuracy, n—degree of conformity of a measure to a

strain. See Practice E83.

standard.

3.1.2 error, n—the amount of deviation from a standard.

1.2 These procedures apply to the verification of the dis-

3.1.2.1 Discussion—The word “error” shall be used with

placement measuring systems associated with the testing

numericalvalues,forexample,“Atadisplacementof+1.00in.,

machine, such as a scale, dial, marked or unmarked recorder

the error of the displacement measuring system was +0.001

chart, digital display, etc. In all cases the buyer/owner/user

in.”

must designate the displacement-measuring system(s) to be

3.1.3 tolerance, n—theallowabledeviationfromastandard.

verified.

3.2 Definitions of Terms Specific to This Standard:

1.3 The values stated in either SI units or inch-pound units

3.2.1 calibration, n—in the case of displacement measuring

are to be regarded separately as standard. The values stated in

systems used with testing machines, the process of comparing

each system may not be exact equivalents; therefore, each

thedisplacementindicationofthemachineorsystemundertest

system shall be used independently of the other. Combining

to that of a standard, making adjustments as needed to meet

values from the two systems may result in non-conformance

error requirements.

with the standard.

3.2.2 capacity range, n—inthecaseoftestingmachines,the

1.4 Displacement values indicated on displays/printouts of

range of displacement for which it is designed. Some testing

testing machine data systems—be they instantaneous, delayed,

machines have more than one capacity range, that is, multiple

stored, or retransmitted—which are within the Classification

ranges.

criteria listed in Table 1, comply with Practices E2309/

3.2.3 correction, n—in the case of a testing machine, the

E2309M.

difference obtained by subtracting the measured displacement

1.5 This standard does not purport to address all of the

from the correct value of the applied displacement.

safety concerns, if any, associated with its use. It is the

3.2.4 displacement, n—a movement or measurement of

responsibility of the user of this standard to establish appro-

length expressed in terms of millimeters, inches, etc.

priate safety and health practices and determine the applica-

3.2.5 displacement measuring system, n—a device or set of

bility of regulatory limitations prior to use.

devicescomprisedofadisplacementtransducerandassociated

instrumentation.

These practices are under the jurisdiction of ASTM Committee E28 on

Mechanical Testing and is the direct responsibility of Subcommittee E28.01 on

Calibration of Mechanical Testing Machines and Apparatus. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 15, 2011. Published January 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

published in 2005. Last previous edition approved in 2005 as E2309-05. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E2309-05R11E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E2309/E2309M−05 (2011)

TABLE 1 Classification of Displacement Measuring Systems

Resolution not to Exceed the Greater of: Error not to Exceed the Greater of:

Classification

Relative Error

Fixed Error, mm [in.] % of Reading Fixed Error, mm [in.]

(% of Displacement)

Class A 0.013 [0.0005] ±0.25 ±0.025 [0.001] ±0.5

Class B 0.038 [0.0015] ±0.5 ±0.075 [0.003] ±1.0

Class C 0.064 [0.0025] ±1.0 ±0.125 [0.005] ±2.0

Class D 0.13 [0.005] ±1.5 ±0.25 [0.010] ±3.0

3.2.6 lower limit of verification range, n—the lowest value tionsofmeasurement.Itisexpressedaspercentageofthemean

ofdisplacementatwhichadisplacementmeasuringsystemcan indicated output for the same applied displacement on two

be verified. successive calibrations for the given displacement.

3.2.7 percent error, n—in the case of a displacement mea- 3.2.13 relative reversibility, n—the difference between the

suring system, the ratio, expressed as a percent, of the error to

mean measured displacement obtained for a given applied

the correct value of the applied displacement. displacement applied in an increasing mode and the mean

3.2.7.1 Discussion—The measured displacement, as mea-

indicated displacement obtained for the same given displace-

sured by the testing machine, and the applied displacement, as ment applied in a decreasing mode.

computed from the readings of the verification device, shall be

3.2.14 testing machine, n—a mechanical device for apply-

recorded at each verification displacement data point. The

ing force and displacement to a specimen.

error,andthepercenterror,shallbecalculatedfromthisdataas

3.2.14.1 Discussion—The instrumentation may be either an

follows:

electrical or a mechanical device, that is, a scale or pointer

Error 5 A 2 B system.

PercentError 5 A 2 B /B 3100

@~ ! #

3.2.15 verification, n—in the case of displacement measur-

where: ing systems used with testing machines, the process of com-

paring the displacement indication of the machine or system

A = displacement measured by the machine being verified,

under test to that of a standard and reporting results, without

mm [in.], and

making adjustments.

B = correct value of the applied displacement, mm [in.], as

determined by the calibration device.

3.2.16 verification displacement, n—a displacement with

traceability derived from national standards of length with a

3.2.8 reference standard, n—a standard used to measure

specific uncertainty of measurement, which can be applied to

displacement applied by the testing machine and measured by

displacement measuring systems.

the displacement measuring system to be verified.

3.2.17 verified range of displacement, n—in the case of

3.2.9 resolution of the displacement indicator, n—smallest

testing machines, the range of measured displacement for

changeofdisplacementthatcanbeestimatedorascertainedon

which the testing machine gives results within the permissible

thedisplacementmeasuringapparatusofthetestingmachineor

variations specified.

system, at any applied displacement. Appendix X1 describes a

method for determining resolution.

4. Significance and Use

3.2.10 resolution of analog type displacement indicators

(scales, dials, recorders, etc.), n—the resolution is the smallest 4.1 Testing machines that apply and measure displacement

change in displacement indicated by a displacement of a

are used in many industries. They may be used in research

pointer,orpenline.Theresolutioniscalculatedbymultiplying laboratoriestodeterminematerialproperties,andinproduction

the displacement corresponding to one graduation by the ratio

lines to qualify products for shipment. The displacement

of the width of the pointer or pen line to the center to center

measuringdevicesintegraltothetestingmachinesmaybeused

distance between two adjacent graduation marks.

for measurement of crosshead or actuator displacement over a

defined range of operation. The accuracy of the displacement

3.2.11 resolution of digital type displacement indicators

value shall be traceable to the National Institute of Standards

(numeric, displays, printouts, etc.), n—the resolution is the

and Technology (NIST) or another recognized National Labo-

smallest change in displacement that can be displayed on the

ratory. Practices E2309 provides a procedure to verify these

displacement indicator, at any applied displacement. Appendix

machinesandsystems,inorderthatthemeasureddisplacement

X1 describes a method for determining resolution.

values may be traceable. A key element to having traceability

3.2.11.1 Discussion—If the displacement indication, for ei-

is that the devices used in the verification produce known

ther type of displacement indicator, fluctuates by more than

displacement characteristics, and have been calibrated in ac-

twice the resolution, as described in 3.2.9 or 3.2.10, the

cordance with adequate calibration standards.

resolution, expressed as displacement, shall be equal to one-

half the range of the fluctuation.

5. Calibration Devices

3.2.12 relative repeatability, n—the closeness of the agree-

ment between the results of successive measurements from the 5.1 Reference standards used for calibration and or verifi-

same applied displacement, carried out under the same condi- cationofdisplacementmeasuringsystemsshallhaveestimated

´1

E2309/E2309M−05 (2011)

measurement uncertainties. The reported uncertainty of refer- 8.2 The low limit of displacement measurement must be

ence standards must be equal to or less than ⁄3 the allowable equal to or greater than:

errorforthemeasuringsystemClassificationasshowninTable

400 times the resolution for Class A

200 times the resolution for Class B

1. The estimated measurement uncertainty of the reference

100 times the resolution for Class C

standard should have a confidence level of 95% (k = 2).

67 times the resolution for Class D

8.2.1 Where the resolution of the displacement measuring

6. System Verification

system is sufficient to allow for verification below 10% of

6.1 Displacement measuring systems shall be verified as a

displacement capacity or range, verify the displacement range

system with the displacement sensing and measuring devices

by applying at least two successive series of displacement

(see 1.2 and 1.4) in place and operating as in actual use.

values, arranged in overlapping decade groups, such that the

6.2 System verification is invalid if the displacement sens- maximum displacement value in one decade is the minimum

ing devices are removed and checked independently of the displacement value in the next higher decade. Starting with the

testing machine. selected minimal displacement value in each decade, there are

to be at least five displacement applications, in an approximate

6.3 A Practices E2309 verification consists of at least two

ratio of 1:1, 2.5:1, 5:1, 7.5:1, and 10:1, unless the maximum

verificationrunsofdisplacementcontainedinthedisplacement

displacement value is reached prior to completing all displace-

range(s) selected. See 8.1 and 8.2.

ment application ratios. Report all displacement values and

6.3.1 If the initial verification run produces values within

their percent errors.

the Practices E2309 requirements of Section 15, the data may

NOTE 1—Example: If full scale is 200 mm [8 in.] and the minimal

be used “as found” for run one of the two required for the new

resolution is 0.025 mm [0.001 mm], the minimum verified displacement

verification report.

would be 5 mm (0.025 × 200). Two decades of 20 and 200 mm could be

6.3.2 If the initial verification run produces any values

selected to cover the displacement application range. Suitable verification

test displacement values would then be approximately 5, 10, 15, 20, 50,

which are outside of the Practices E2309 requirements, the “as

100, 150, 200 mm. The largest reported error of the two sets of the test

found” data may be reported and may be used in accordance

runs is the maximum error for the displacement range.

with applicable quality control programs.

6.3.3 Calibration adjustments may be made to improve the

9. Preliminary Procedure

accuracy of the system. They shall be followed by the two

9.1 Alignment:

required verification runs, and issuance of a new verification

9.1.1 When fixturing the calibration device, it is important

report.

to minimize any misalignment. Significant errors can be

7. Application of Displacement inducedduetomisalignment.Gaugeblocksorasquaremaybe

used to ensure that the calibration device operates parallel to

7.1 In the verification of the displacement measuring

the actuator in hydraulic testing machines or perpendicular to

system, approach the displacement test value by applying the

the crosshead in electro-mechanical testing machines.

test displacement from a lower value of displacement. To

reduce the error in displacement measurement due to internal

9.2 Temperature Considerations:

backlash of the testing machine, associated fixtures and or

9.2.1 Where the displacement measuring systems are

apparatus, make sure to approach the starting zero position of

electrical, connect the displacement transducer, indicator,

the testing machine from a point less than zero and in the

interface, etc. using the appropriate cabling used in the actual

direction for which the resultant verification data will be

machine setup. Turn on power and allow the components to

acquired. This procedure shall be followed when acquiring

warm up for a period of time recommended by the manufac-

descending verification data as well. When acquiring descend-

turer.Intheabsenceofanyrecommendations,allowatleast15

ing verification data apply a displacement greater than the

min for the components to be energized.

starting point and adjust the testing machine to re-establish a

9.2.2 Position a temperature measuring device in close

starting zero position in the direction for which verification

proximity to the machine being verified. Allow the displace-

data is to be acquired.

mentmeasuringdeviceandallrelevantpartsoftheverification

equipment to reach thermal stability.

7.2 Displacement measuring systems that are used to ac-

9.2.3 Include any bias due to temperature effects in the

quire test data in both ascending and descending directions,

expandeduncertaintystatementassociatedwiththeverification

shall be verified in both directions.

displacement values if required.

8. Selection of Verification Displacement Values

10. Procedure

8.1 For any displacement range, verify the displacement

measuring sys

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:E2309–05 Designation: E2309/E2309M – 05 (Reapproved 2011)

Standard Practices for

Verification of Displacement Measuring Systems and

Devices Used in Material Testing Machines

ThisstandardisissuedunderthefixeddesignationE2309/E2309M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—The units statement (1.3) and the designation were editorially revised in January 2011.

1. Scope

1.1 These practices cover procedures and requirements for the calibration and verification of displacement measuring systems

by means of standard calibration devices for static and quasi-static testing machines. This practice is not intended to be complete

purchasespecificationsfortestingmachinesordisplacementmeasuringsystems.Displacementmeasuringsystemsarenotintended

to be used for the determination of strain. See Practice E83.

1.2 Theseproceduresapplytotheverificationofthedisplacementmeasuringsystemsassociatedwiththetestingmachine,such

as a scale, dial, marked or unmarked recorder chart, digital display, etc. In all cases the buyer/owner/user must designate the

displacement-measuring system(s) to be verified.

1.3Since conversion factors are not required in this practice, either SI units, or inch units, can be used as the standard.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.4 Displacement values indicated on displays/printouts of testing machine data systems—be they instantaneous, delayed,

stored, or retransmitted—which are within the Classification criteria listed in Table 1, comply with Practices E2309/E2309M.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E83 Practice for Verification and Classification of Extensometer Systems

3. Terminology

3.1 Definitions:

3.1.1 accuracy, n—degree of conformity of a measure to a standard.

3.1.2 error, n—the amount of deviation from a standard.

3.1.2.1 Discussion—The word “error” shall be used with numerical values, for example, “At a displacement of +1.00 in., the

error of the displacement measuring system was +0.001 in.”

3.1.3 tolerance, n—the allowable deviation from a standard.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 calibration, n—in the case of displacement measuring systems used with testing machines, the process of comparing the

displacement indication of the machine or system under test to that of a standard, making adjustments as needed to meet error

requirements.

3.2.2 capacity range, n—in the case of testing machines, the range of displacement for which it is designed. Some testing

machines have more than one capacity range, that is, multiple ranges.

3.2.3 correction, n—in the case of a testing machine, the difference obtained by subtracting the measured displacement from

These practices are under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.01 on Calibration of

Mechanical Testing Machines and Apparatus.

Current edition approved Feb. 1, 2005. Published February 2005. DOI: 10.1520/E2309-05.

Current edition approved Jan. 15, 2011. Published January 2011. Originally published in 2005. Last previous edition approved in 2005 as E2309-05. DOI:

10.1520/E2309-05R11E01.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

E2309/E2309M – 05 (2011)

TABLE 1 Classification of Displacement Measuring Systems

Resolution not to Exceed the Greater of: Error not to Exceed the Greater of:

Classification

Relative Error

Fixed Error, mm ( [in.)] % of Reading Fixed Error, mm ( [in.)]

(% of Displacement)

Class A 0.013 (0.0005) 60.25 60.025 (0.001) 60.5

Class A 0.013 [0.0005] 60.25 60.025 [0.001] 60.5

Class B 0.038 (0.0015) 60.5 60.075 (0.003) 61.0

Class B 0.038 [0.0015] 60.5 60.075 [0.003] 61.0

Class C 0.064 (0.0025) 61.0 60.125 (0.005) 62.0

Class C 0.064 [0.0025] 61.0 60.125 [0.005] 62.0

Class D 0.13 (0.005) 61.5 60.25 (0.010) 63.0

Class D 0.13 [0.005] 61.5 60.25 [0.010] 63.0

the correct value of the applied displacement.

3.2.4 displacement, n—a movement or measurement of length expressed in terms of millimeters, inches, etc.

3.2.5 displacement measuring system, n—a device or set of devices comprised of a displacement transducer and associated

instrumentation.

3.2.6 lower limit of verification range, n—the lowest value of displacement at which a displacement measuring system can be

verified.

3.2.7 percent error, n—in the case of a displacement measuring system, the ratio, expressed as a percent, of the error to the

correct value of the applied displacement.

3.2.7.1 Discussion—The measured displacement, as measured by the testing machine, and the applied displacement, as

computed from the readings of the verification device, shall be recorded at each verification displacement data point. The error,

and the percent error, shall be calculated from this data as follows:

Error 5 A 2 B

PercentError 5 @~A 2 B!/B# 3100

where:

A = displacement measured by the machine being verified, mm (in.),[in.], and

B = correct value of the applied displacement, mm (in.),[in.], as determined by the calibration device.

3.2.8 reference standard, n—a standard used to measure displacement applied by the testing machine and measured by the

displacement measuring system to be verified.

3.2.9 resolution of the displacement indicator, n—smallest change of displacement that can be estimated or ascertained on the

displacementmeasuringapparatusofthetestingmachineorsystem,atanyapplieddisplacement.AppendixX1describesamethod

for determining resolution.

3.2.10 resolution of analog type displacement indicators (scales, dials, recorders, etc.), n—theresolutionisthesmallestchange

in displacement indicated by a displacement of a pointer, or pen line.The resolution is calculated by multiplying the displacement

corresponding to one graduation by the ratio of the width of the pointer or pen line to the center to center distance between two

adjacent graduation marks.

3.2.11 resolution of digital type displacement indicators (numeric, displays, printouts, etc.), n—the resolution is the smallest

change in displacement that can be displayed on the displacement indicator, at any applied displacement.Appendix X1 describes

a method for determining resolution.

3.2.11.1 Discussion—Ifthedisplacementindication,foreithertypeofdisplacementindicator,fluctuatesbymorethantwicethe

resolution, as described in 3.2.9 or 3.2.10, the resolution, expressed as displacement, shall be equal to one-half the range of the

fluctuation.

3.2.12 relative repeatability, n—the closeness of the agreement between the results of successive measurements from the same

applied displacement, carried out under the same conditions of measurement. It is expressed as percentage of the mean indicated

output for the same applied displacement on two successive calibrations for the given displacement.

3.2.13 relative reversibility, n—the difference between the mean measured displacement obtained for a given applied

displacementappliedinanincreasingmodeandthemeanindicateddisplacementobtainedforthesamegivendisplacementapplied

in a decreasing mode.

3.2.14 testing machine, n—a mechanical device for applying force and displacement to a specimen.

3.2.14.1 Discussion—The instrumentation may be either an electrical or a mechanical device, that is, a scale or pointer system.

3.2.15 verification, n—inthecaseofdisplacementmeasuringsystemsusedwithtestingmachines,theprocessofcomparingthe

displacementindicationofthemachineorsystemundertesttothatofastandardandreportingresults,withoutmakingadjustments.

3.2.16 verification displacement, n—a displacement with traceability derived from national standards of length with a specific

uncertainty of measurement, which can be applied to displacement measuring systems.

3.2.17 verified range of displacement, n—in the case of testing machines, the range of measured displacement for which the

testing machine gives results within the permissible variations specified.

´1

E2309/E2309M – 05 (2011)

4. Significance and Use

4.1 Testing machines that apply and measure displacement are used in many industries. They may be used in research

laboratoriestodeterminematerialproperties,andinproductionlinestoqualifyproductsforshipment.Thedisplacementmeasuring

devices integral to the testing machines may be used for measurement of crosshead or actuator displacement over a defined range

of operation. The accuracy of the displacement value shall be traceable to the National Institute of Standards and Technology

(NIST) or another recognized National Laboratory. Practices E2309 provides a procedure to verify these machines and systems,

in order that the measured displacement values may be traceable.Akey element to having traceability is that the devices used in

the verification produce known displacement characteristics, and have been calibrated in accordance with adequate calibration

standards.

5. Calibration Devices

5.1 Reference standards used for calibration and or verification of displacement measuring systems shall have estimated

measurement uncertainties.The reported uncertainty of reference standards must be equal to or less than ⁄3 the allowable error for

the measuring system Classification as shown inTable 1.The estimated measurement uncertainty of the reference standard should

have a confidence level of 95% (k = 2).

6. System Verification

6.1 Displacement measuring systems shall be verified as a system with the displacement sensing and measuring devices (see

1.2 and 1.4) in place and operating as in actual use.

6.2 System verification is invalid if the displacement sensing devices are removed and checked independently of the testing

machine.

6.3 A Practices E2309 verification consists of at least two verification runs of displacement contained in the displacement

range(s) selected. See 8.1 and 8.2.

6.3.1 IftheinitialverificationrunproducesvalueswithinthePracticesE2309requirementsofSection15,thedatamaybeused

“as found” for run one of the two required for the new verification report.

6.3.2 If the initial verification run produces any values which are outside of the Practices E2309 requirements, the “as found”

data may be reported and may be used in accordance with applicable quality control programs.

6.3.3 Calibration adjustments may be made to improve the accuracy of the system. They shall be followed by the two required

verification runs, and issuance of a new verification report.

7. Application of Displacement

7.1 In the verification of the displacement measuring system, approach the displacement test value by applying the test

displacement from a lower value of displacement. To reduce the error in displacement measurement due to internal backlash of

the testing machine, associated fixtures and or apparatus, make sure to approach the starting zero position of the testing machine

from a point less than zero and in the direction for which the resultant verification data will be acquired. This procedure shall be

followed when acquiring descending verification data as well. When acquiring descending verification data apply a displacement

greater than the starting point and adjust the testing machine to re-establish a starting zero position in the direction for which

verification data is to be acquired.

7.2 Displacement measuring systems that are used to acquire test data in both ascending and descending directions, shall be

verified in both directions.

8. Selection of Verification Displacement Values

8.1 For any displacement range, verify the displacement measuring system by applying at least five test displacement values,

at least two times, with the difference between any two successive displacement value applications being no larger than one-third

the difference between the selected maximum and minimum test displacement values.Applied displacement values on the second

run are to be approximately the same as those on the first run. Report all values.

8.2 The low limit of displacement measurement must be equal to or greater than:

400 times the resolution for Class A

200 times the resolution for Class B

100 times the resolution for Class C

67 times the resolution for Class D

8.2.1 Where the resolution of the displacement measuring system is sufficient to allow for verification below 10% of

displacement capacity or range, verify the displacement range by applying at least two successive series of displacement values,

arranged in overlapping decade groups, such that the maximum displacement value in one decade is the minimum displacement

value in the next higher decade. Starting with the selected minimal displacement value in each decade, there are to be at least five

displacement applications, in an approximate ratio of 1:1, 2.5:1, 5:1, 7.5:1, and 10:1, unless the maximum displacement value is

reached prior to completing all displacement application ratios. Report all displacement values and their percent errors.

NOTE 1—Example: If full scale is 200 mm [8 in.] and the minimal resolution is 0.025 mm [0.001 mm], the minimum verified displacement would be

5mm(0.025 3200).Twodecadesof20and200mmcouldbeselectedtocoverthedisplacementapplicationrange.Suitableverificationtestdisplacement

´1

E2309/E2309M – 05 (2011)

values would then be approximately 5, 10, 15, 20, 50, 100, 150, 200 mm.The largest reported error of the two sets of the test runs is the maximum error

for the displacement range.

9. Preliminary Procedure

9.1 Alignment:

9.1.1 Whenfixturingthecalibrat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.