ASTM D2155-12

(Test Method)Standard Test Method for Determination of Fire Resistance of Aircraft Hydraulic Fluids by Autoignition Temperature

Standard Test Method for Determination of Fire Resistance of Aircraft Hydraulic Fluids by Autoignition Temperature

SCOPE

1.1 This test method is used for assessing the fire resistance of hydraulic fluids used for aircraft applications by determination of the autoignition temperature of the hydraulic fluid in air at one atmosphere pressure using hypodermic syringe injection.

1.2 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2155 − 12

Standard Test Method for

Determination of Fire Resistance of Aircraft Hydraulic Fluids

1

by Autoignition Temperature

This standard is issued under the fixed designation D2155; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Apparatus

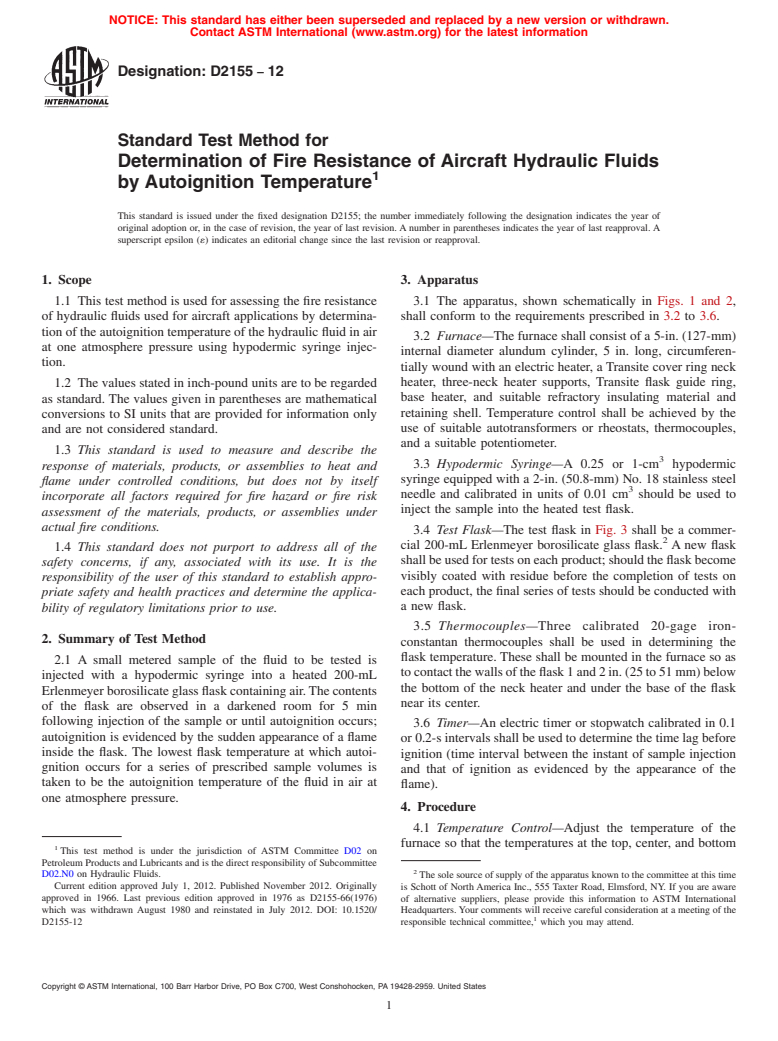

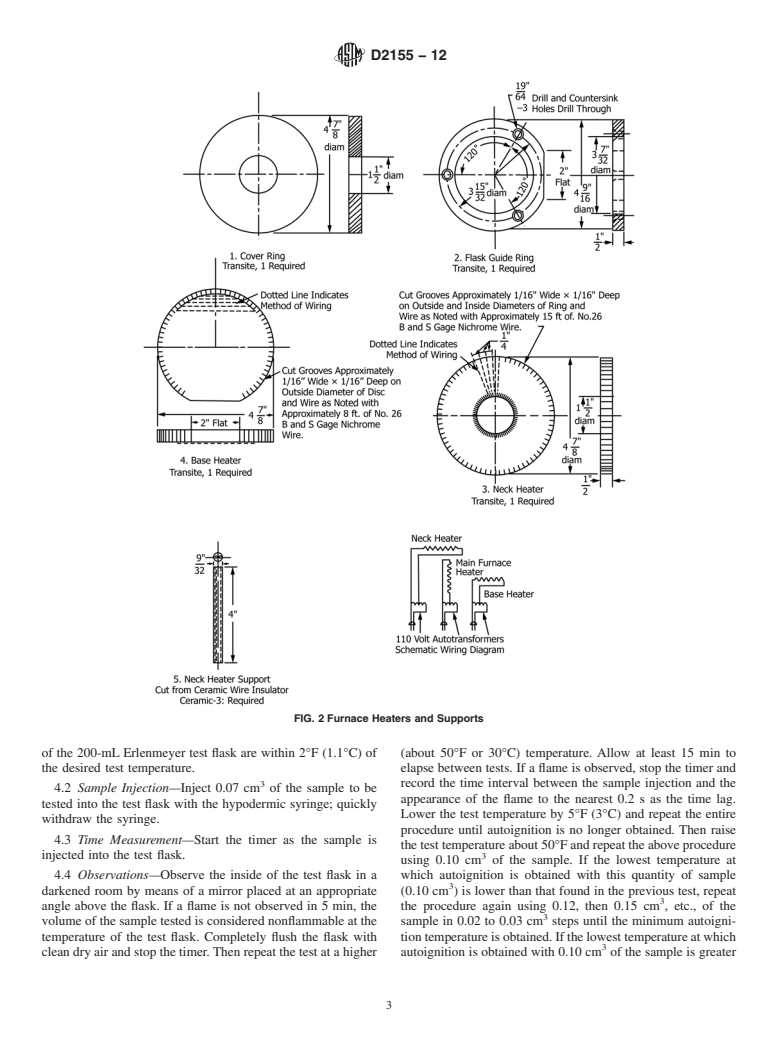

3.1 The apparatus, shown schematically in Figs. 1 and 2,

1.1 This test method is used for assessing the fire resistance

of hydraulic fluids used for aircraft applications by determina- shall conform to the requirements prescribed in 3.2 to 3.6.

tion of the autoignition temperature of the hydraulic fluid in air

3.2 Furnace—The furnace shall consist of a 5-in. (127-mm)

at one atmosphere pressure using hypodermic syringe injec-

internal diameter alundum cylinder, 5 in. long, circumferen-

tion.

tially wound with an electric heater, a Transite cover ring neck

heater, three-neck heater supports, Transite flask guide ring,

1.2 The values stated in inch-pound units are to be regarded

base heater, and suitable refractory insulating material and

as standard. The values given in parentheses are mathematical

retaining shell. Temperature control shall be achieved by the

conversions to SI units that are provided for information only

use of suitable autotransformers or rheostats, thermocouples,

and are not considered standard.

and a suitable potentiometer.

1.3 This standard is used to measure and describe the

3

3.3 Hypodermic Syringe—A 0.25 or 1-cm hypodermic

response of materials, products, or assemblies to heat and

syringe equipped with a 2-in. (50.8-mm) No. 18 stainless steel

flame under controlled conditions, but does not by itself

3

needle and calibrated in units of 0.01 cm should be used to

incorporate all factors required for fire hazard or fire risk

inject the sample into the heated test flask.

assessment of the materials, products, or assemblies under

actual fire conditions.

3.4 Test Flask—The test flask in Fig. 3 shall be a commer-

2

cial 200-mL Erlenmeyer borosilicate glass flask. A new flask

1.4 This standard does not purport to address all of the

shall be used for tests on each product; should the flask become

safety concerns, if any, associated with its use. It is the

visibly coated with residue before the completion of tests on

responsibility of the user of this standard to establish appro-

each product, the final series of tests should be conducted with

priate safety and health practices and determine the applica-

a new flask.

bility of regulatory limitations prior to use.

3.5 Thermocouples—Three calibrated 20-gage iron-

2. Summary of Test Method

constantan thermocouples shall be used in determining the

flask temperature. These shall be mounted in the furnace so as

2.1 A small metered sample of the fluid to be tested is

to contact the walls of the flask 1 and 2 in. (25 to 51 mm) below

injected with a hypodermic syringe into a heated 200-mL

the bottom of the neck heater and under the base of the flask

Erlenmeyer borosilicate glass flask containing air.The contents

near its center.

of the flask are observed in a darkened room for 5 min

following injection of the sample or until autoignition occurs;

3.6 Timer—An electric timer or stopwatch calibrated in 0.1

autoignition is evidenced by the sudden appearance of a flame

or 0.2-s intervals shall be used to determine the time lag before

inside the flask. The lowest flask temperature at which autoi-

ignition (time interval between the instant of sample injection

gnition occurs for a series of prescribed sample volumes is

and that of ignition as evidenced by the appearance of the

taken to be the autoignition temperature of the fluid in air at

flame).

one atmosphere pressure.

4. Procedure

4.1 Temperature Control—Adjust the temperature of the

furnace so that the temperatures at the top, center, and bottom

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

2

D02.N0 on Hydraulic Fluids. The sole source of supply of the apparatus known to the committee at this time

Current edition approved July 1, 2012. Published November 2012. Originally is Schott of North America Inc., 555 Taxter Road, Elmsford, NY. If you are aware

approved in 1966. Last previous edition approved in 1976 as D2155-66(1976) of alternative suppliers, please provide this information to ASTM International

which was withdrawn August 1980 and reinstated in July 2012. DOI: 10.1520/ Headquarters. Your comments will receive careful consideration at a meeting of the

1

D2155-12 responsible technical committee, which you may attend.

Copyright © ASTM International,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.