ASTM D3368-99

(Specification)Standard Specification for FEP-Fluorocarbon Resin Sheet and Film

Standard Specification for FEP-Fluorocarbon Resin Sheet and Film

SCOPE

1.1 This specification covers unfilled, unpigmented FEP-fluorocarbon resin sheet and film less than 3.175 mm (0.125 in.) thick.

1.2 The values stated in SI units as detailed in Practice E380 are to be regarded as the standard and the practices of E380 incorporated herein.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 14, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1-There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3368 – 99

Standard Specification for

FEP-Fluorocarbon Sheet and Film

This standard is issued under the fixed designation D 3368; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 2116 Specification for FEP Fluorocarbon Molding and

Extrusion Materials

1.1 This specification covers unfilled, unpigmented FEP-

D 3892 Practice for Packaging/Packing of Plastics

fluorocarbon resin sheet and film less than 3.175 mm (0.125

D 5740 Guide for Writing Material Standards in the D 4000

in.) thick. Recycled materials are allowed in accordance with

Format

6.2.

E 691 Practice for Conducting an Interlaboratory Study to

1.2 The values stated in SI units as detailed in IEEE/ASTM

Determine the Precision of a Test Method

SI 10 are to be regarded as the standard and the practices of

IEEE/ASTM SI 10 Standard for Use of the International

IEEE/ASTM SI 10 incorporated herein.

System of Units (SI)

1.3 The following safety hazards caveat pertains only to the

2.2 Other Standard:

test methods portion, Section 14, of this specification: This

TAPPI 411 Standard Thickness (Caliper) of Paper and Paper

standard does not purport to address all of the safety concerns,

Products

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

3. Terminology

practices and determine the applicability of regulatory limita-

3.1 Definitions—For definitions of terms used in this speci-

tions prior to use.

fication, see Terminology D 883.

NOTE 1—There is no similar or equivalent ISO standard.

3.1.1 lot, n—one production run or a uniform blend of two

or more production runs.

2. Referenced Documents

2.1 ASTM Standards: 4. Classification

D 149 Test Method for Dielectric Breakdown Voltage and

4.1 This specification covers four types of FEP-

Dielectric Strength of Solid Electrical Insulating Materials

fluorocarbon sheet and film:

at Commercial Power Frequencies

4.1.1 Type I—General purpose.

D 374 Test Methods for Thickness of Solid Electrical Insu-

4.1.2 Type II—Cementable film. Type II materials can be

lation

subdivided into two grades:

D 618 Practice for Conditioning Plastics and Electrical

4.1.2.1 Grade 1—One side cementable, and

Insulating Materials for Testing

4.1.2.2 Grade 2—Two sides cementable.

D 638 Test Method for Tensile Properties of Plastics

4.1.3 Type III—Special film for applications requiring un-

D 882 Test Methods for Tensile Properties of Thin Plastic

usual flexural endurance or extreme thermal and chemical

Sheeting

service.

D 883 Terminology Relating to Plastics

4.1.4 Type IV—Film for mold release applications.

D 1505 Test Method for Density of Plastics by the Density-

4.2 A one-line system may be used to specify materials

Gradient Technique

covered by this specification. The system uses predefined cells

to refer to specific aspects of this specification, which are

illustrated as follows:

This specification is under the jurisdiction of ASTM Committee D-20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials, Section D-20.15.12 on Fluoropolymers. Annual Book of ASTM Standards, Vol 08.02.

Current edition approved Dec. 10, 1999. Published March 2000. Originally Annual Book of ASTM Standards, Vol 08.03.

published as D 3368 – 75. Last previous edition D 3368 – 94. Annual Book of ASTM Standards, Vol 14.02.

2 8

Annual Book of ASTM Standards, Vol 10.02. Annual Book of ASTM Standards, Vol 14.04.

3 9

Annual Book of ASTM Standards, Vol 10.01. Available from the Technical Association of the Pulp and Paper Industry

Annual Book of ASTM Standards, Vol 08.01. (TAPPI), P.O. Box 105113, Atlanta, GA 30348-5113. Phone: 1-800-332-8686.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 3368

5.3 Requests for certification or test results should be made

Specification

Standard Number Type Grade Class Special

at the time of order placement.

Block Notes

|| | | |

Example: Specification II 1 , 0.051 mm thick 6. Materials and Manufacture

D 3368 – 9_,

6.1 The sheet and film shall be made from FEP-

For this example, the line callout would be Specification

fluorocarbon resin as specified in Specification D 2116 without

D 3368 – 9_, II 1, 0.051 mm thick. This callout would specify

filler or plasticizer.

a film of FEP that is cementable on one side and that has all of

6.2 This specification allows for the use of recycled, repro-

the properties listed for that type and grade in the appropriate

cessed, and reworked FEP materials provided the following:

specified properties or tables, or both, in this specification.

6.2.1 The final physical, mechanical, and performance re-

Inclusion of a class is provided for in the system, but is not

quirements as stated in this specification are met.

used in this particular specification. A comma is used as the

separator between the standard number and the type. Separa-

6.2.2 The toxicological characteristics are essentially unal-

tors are not needed between the type, grade, and class.

tered from that of virgin material.

Provision for special notes is included in the system so that

other information can be provided when required, in this case,

7. Other Requirements

the thickness of the film. When special notes are used, they

7.1 The sheet and film shall conform to the physical,

should be preceded by a comma.

mechanical, and performance property requirements specified

5. Ordering Information

in Table 1. The nominal thickness of sheet or film and thickness

tolerances shall be in accordance with Table 2.

5.1 The sheet and film shall be furnished in the form of

sheets or rolls in accordance with good commercial practice.

7.2 The film and sheet shall be uniform in appearance and

Rolls shall be wound evenly and tightly on substantial cores

shall be sufficiently free of contamination, wrinkles, holes,

suitably restrained to prevent unwinding.

scratches, and other imperfections so as to be functionally

5.2 Dimensions of sheet and film with respect to length,

acceptable. The color shall be uniform and be characteristic of

width, and core diameter shall be upon agreement between the

unpigmented sheet or film that ranges from clear to translucent

purchaser and the manufacturer. The agreement shall apply

and is dependent upon the thickness.

also to the maximum number of splices per roll and tolerances

7.3 Tolerances for width of rolls shall be 61.6 mm

for length and core.

(60.0625 in.) for film or sheet thickness less than 0.508 mm

(0.020 in.) and 63.2 mm (60.125 in.) for sheet thickness equal

See the ASTM Form and Style Manual. Available from ASTM Headquarters.

to or greater than 0.508 mm.

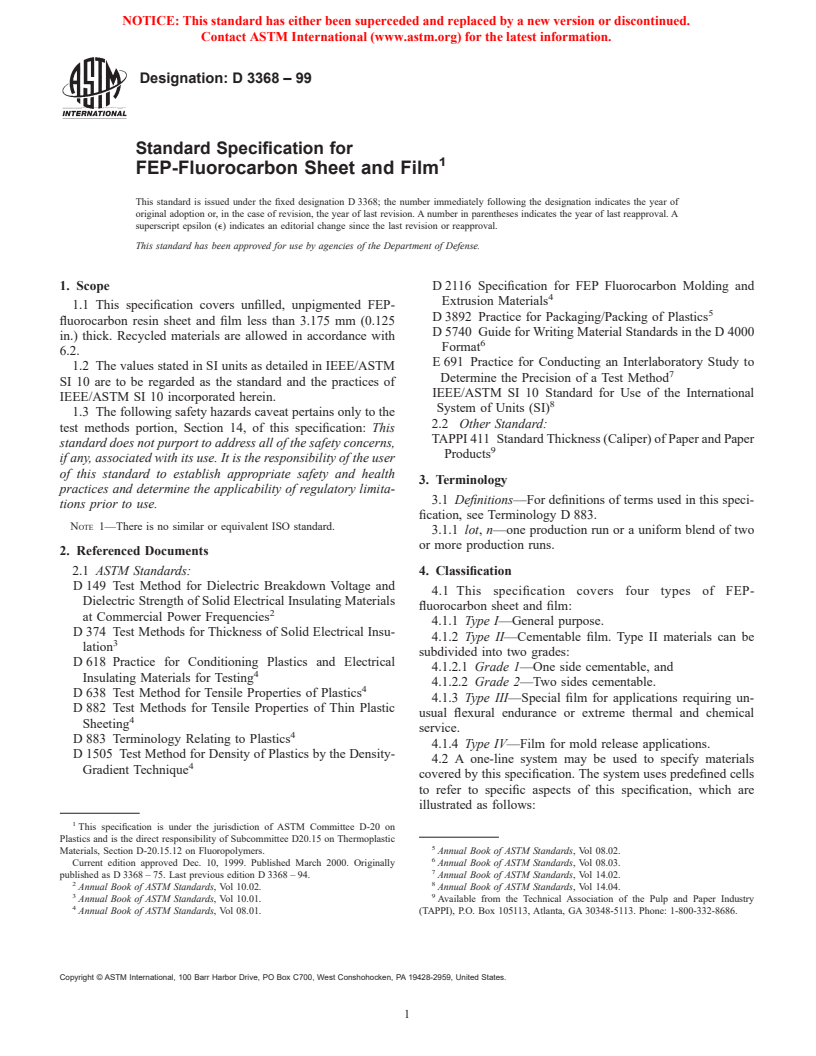

TABLE 1 Detail Requirements for Property Values

Type I Type II Type III Type IV

Tensile Strength, min, MPa (psi), at nominal thickness, mm (in.):

0.0127 (0.0005) 13.8 (2000) 13.8 (2000) . 11.0 (1600)

0.025 to 3.175 (0.001 to 0.125) 17.25 (2500) 17.25 (2500) 17.25 (2500) 14.5 (2100)

Elongation at Break, min, %, at nominal thickness, mm (in.):

0.0127 to 0.025 (0.0005 to 0.001) 175 175 . 150

0.051 to 3.175 (0.002 to 0.125) 250 250 250 250

Dimensional Change on Heating, max, %, at nominal thickness, mm (in.):

0.0127 to 0.025 (0.0005 to 0.001) 65 65 . 65

0.051 (0.002) 63 63 64 63

0.076 to 0.508 (0.003 to 0.020) 62 62 63 .

0.762 to 1.524 (0.030 to 0.060) . . 64 .

2.285 to 3.175 (0.090 to 0.125) . . 65 .

Cementability, min, peel strength, kg/m (g/in.), at nominal thickness, mm (in.):

0.0127 (0.0005) . 6.69 (170) . .

0.025 (0.001) . 11.8 (300) . .

0.051 (0.002) . 29.5 (750) . .

0.076 (0.003) . 31.5 (800) . .

0.102 (0.004) . 47.2 (1200) . .

0.127 (0.005) . 78.7 (2000) . .

0.254 (0.010) . 94.5 (2400) . .

0.508 (0.020) . 94.5 (2400) . .

Dielectric Strength, min, kV/mm (V/mil), at nominal thickness, mm (in.):

0.127 to 0.025 (0.0005 to 0.001) 160 (4000) 160 (4000) . .

0.051 (0.002) 140 (3500) 140 (3500) . .

0.076 (0.003) 120 (3000) 120 (3000) . .

0.102 (0.004) 110 (2750) 110 (2750) . .

0.127 (0.005) 100 (2500) 100 (2500) . .

0.254 (0.010) 72 (1800) 72 (1800) . .

0.356 (0.014) 64 (1600) 64 (1600) . .

0.508 (0.020) 56 (1400) 56 (1400) . .

Density at 23°C, g/cm 2.13 to 2.17 2.13 to 2.17 2.13 to 2.17 2.13 to 2.17

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 3368

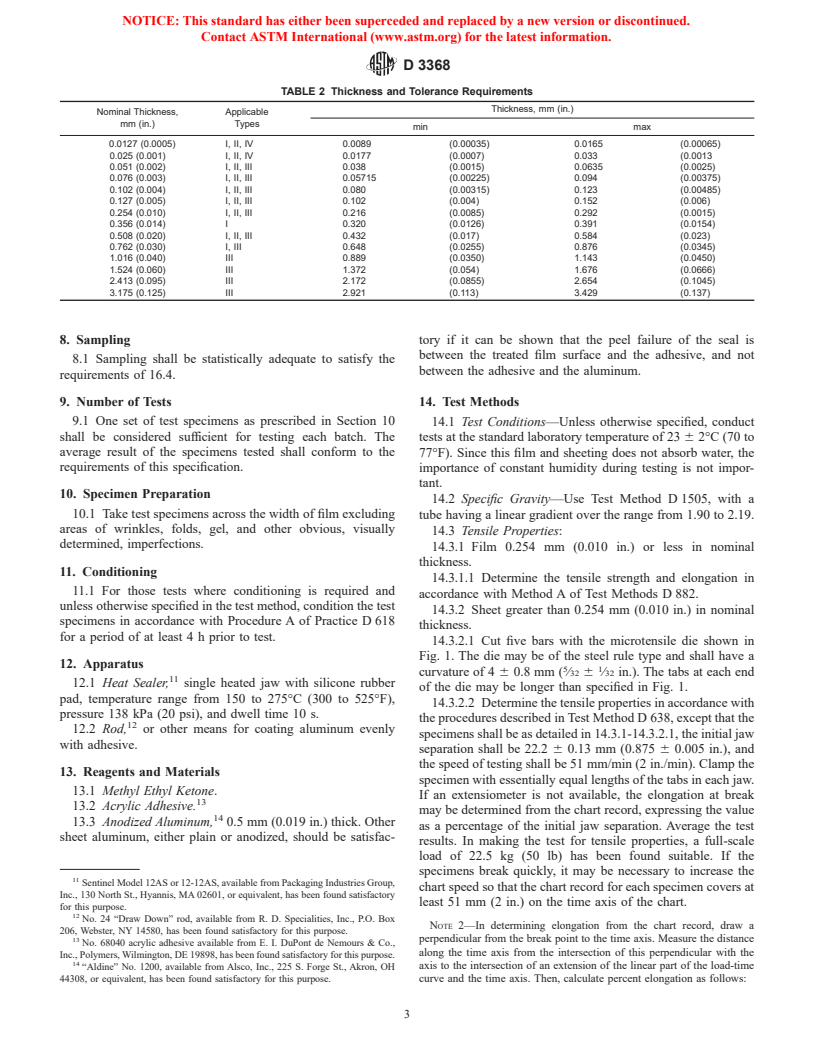

TABLE 2 Thickness and Tolerance Requirements

Thickness, mm (in.)

Nominal Thickness, Applicable

mm (in.) Types

min max

0.0127 (0.0005) I, II, IV 0.0089 (0.00035) 0.0165 (0.00065)

0.025 (0.001) I, II, IV 0.0177 (0.0007) 0.033 (0.0013

0.051 (0.002) I, II, III 0.038 (0.0015) 0.0635 (0.0025)

0.076 (0.003) I, II, III 0.05715 (0.00225) 0.094 (0.00375)

0.102 (0.004) I, II, III 0.080 (0.00315) 0.123 (0.00485)

0.127 (0.005) I, II, III 0.102 (0.004) 0.152 (0.006)

0.254 (0.010) I, II, III 0.216 (0.0085) 0.292 (0.0015)

0.356 (0.014) I 0.320 (0.0126) 0.391 (0.0154)

0.508 (0.020) I, II, III 0.432 (0.017) 0.584 (0.023)

0.762 (0.030) I, III 0.648 (0.0255) 0.876 (0.0345)

1.016 (0.040) III 0.889 (0.0350) 1.143 (0.0450)

1.524 (0.060) III 1.372 (0.054) 1.676 (0.0666)

2.413 (0.095) III 2.172 (0.0855) 2.654 (0.1045)

3.175 (0.125) III 2.921 (0.113) 3.429 (0.137)

8. Sampling tory if it can be shown that the peel failure of the seal is

between the treated film surface and the adhesive, and not

8.1 Sampling shall be statistically adequate to satisfy the

between the adhesive and the aluminum.

requirements of 16.4.

9. Number of Tests 14. Test Methods

9.1 One set of test specimens as prescribed in Section 10

14.1 Test Conditions—Unless otherwise specified, conduct

shall be considered sufficient for testing each batch. The

tests at the standard laboratory temperature of 23 6 2°C (70 to

average result of the specimens tested shall conform to the

77°F). Since this film and sheeting does not absorb water, the

requirements of this specification. importance of constant humidity during testing is not impor-

tant.

10. Specimen Preparation

14.2 Specific Gravity—Use Test Method D 1505, with a

10.1 Take test specimens across the width of film excluding tube having a linear gradient over the range from 1.90 to 2.19.

areas of wrinkles, folds, gel, and other obvious, visually

14.3 Tensile Properties:

determined, imperfections.

14.3.1 Film 0.254 mm (0.010 in.) or less in nominal

thickness.

11. Conditioning

14.3.1.1 Determine the tensile strength and elongation in

11.1 For those tests where conditioning is required and

accordance with Method A of Test Methods D 882.

unless otherwise specified in the test method, condition the test

14.3.2 Sheet greater than 0.254 mm (0.010 in.) in nominal

specimens in accordance with Procedure A of Practice D 618

thickness.

for a period of at least 4 h prior to test.

14.3.2.1 Cut five bars with the microtensile die shown in

Fig. 1. The die may be of the steel rule type and shall have a

12. Apparatus

5 1

curvature of 4 6 0.8 mm ( ⁄32 6 ⁄32 in.). The tabs at each end

12.1 Heat Sealer, single heated jaw with silicone rubber

of the die may be longer than specified in Fig. 1.

pad, temperature range from 150 to 275°C (300 to 525°F),

14.3.2.2 Determine the tensile properties in accordance with

pressure 138 kPa (20 psi), and dwell time 10 s.

the procedures described in Test Method D 638, except that the

12.2 Rod, or other means for coating aluminum evenly

specimens shall be as detailed in 14.3.1-14.3.2.1, the initial jaw

with adhesive.

separation shall be 22.2 6 0.13 mm (0.875 6 0.005 in.), and

the speed of testing shall be 51 mm/min (2 in./min). Clamp the

13. Reagents and Materials

specimen with essentially equal lengths of the tabs in each jaw.

13.1 Methyl Ethyl Ketone.

If an extensiometer is not available, the elongation at break

13.2 Acrylic Adhesive.

may be determined from the chart record, expressing the value

13.3 Anodized Aluminum, 0.5 mm (0.019 in.) thick. Other

as a percentage of the initial jaw separation. Average the test

sheet aluminum, either plain or anodized, should be satisfac-

results. In making the test for tensile properties, a full-scale

load of 22.5 kg (50 lb) has been found suitable. If the

specimens break quickly, it may be necessary to increase the

Sentinel Model 12AS or 12-12AS, available from Packaging Industries Group,

chart speed so that the chart record for each specimen covers at

Inc., 130 North St., Hyannis, MA 02601, or equivalent, has been found satisfactory

least 51 mm (2 in.) on the time axis of the chart.

for this purpose.

No. 24 “Draw Down” rod, available from R. D. Specialities, Inc., P.O. Box

NOTE 2—In determining elongation from the chart record, draw a

206, Webster, NY 14580, has been found satisfactory for this purpose.

13 perpendicular from the break point to the time axis. Measure the distance

No. 68040 acrylic adhesive available from E. I. DuPont de Nemours & Co.,

along the time axis from the intersection of this perpendicular with the

Inc., Polymers, Wilmington, DE 19898, has been found satisfactory for this purpose.

axis to the intersection of an extension of the linear part of the load-time

“Aldine” No. 1200, available from Alsco, Inc., 225 S. Forge St., Akron, OH

44308, or equivalent, has been found satisfactory for this purpose. curve and the time axis. Then, calculate percent elongation as follows:

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 3368

FIG. 1 Test Specimen and Die

Elongation 5 100d/~22.2 or 0.875!m (1) smooth and bubble-free. Methyl ethyl ketone may be used for

thinning the adhesive if necessary, and for cleaning the

equipment.

where:

14.6.3 Cut the coated sheets into strips 38.1 by 127 mm (1.5

d = distance on chart, mm (in.),

m = hart speed magnification, by 5 in.) and store in a desiccator. It is not advisable to prepare

= chart speed/crosshead speed (both in same units), and

more thana2or 3-month supply of coated aluminum at one

22.2 = factor when d is in millimetres, or

time, as the adhesive slowly

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.