EN 1254-8:2021

(Main)Copper and copper alloys - Plumbing fittings - Part 8: Press fittings for use with plastics and multilayer pipes

Copper and copper alloys - Plumbing fittings - Part 8: Press fittings for use with plastics and multilayer pipes

This document specifies product characteristics, assessment methods, compliance criteria of test results and a designation system for fittings with radial and axial press ends for use with plastics and multilayer pipes. The fitting ends have a nominal diameter from 10 mm to 160 mm. The fittings are designed for a service lifetime up to fifty.

This document applies to copper alloy fittings. A non-exhaustive list of these copper alloys is given in CEN/TS 13388.

Adaptor fittings for use with plastics and multilayer pipes may combine press ends with fitting ends defined in the other parts of EN 1254.

Press fittings for use with plastics and multilayer pipes may also have flanged end connections according to EN 1092-3.

Press fittings for use with plastics and multilayer pipes may also have a plated or other decorative surface coating.

Fittings can be produced by machining, metal forming, casting, or fabrication.

Products covered by this document are intended to be used in:

a) liquid applications:

- hot, cold or combined hot and cold water, including systems according to EN 806;

- closed heating systems according to EN 12828;

- cooling systems;

- drainage systems;

- fire protection systems including sprinkler systems according to EN 12845;

- supply systems for points of consumption with liquid fuels according to EN 12514.

b) gas applications:

- natural gas and liquefied petroleum gas systems with a maximum operating pressure less than or equal to 5 bar according to EN 1775;

- compressed air systems.

Kupfer und Kupferlegierungen - Fittings - Teil 8: Pressfittings für den Einsatz mit Kunststoff- und Mehrschichtverbundrohren

Dieses Dokument legt Produkteigenschaften, Bewertungsverfahren, Konformitätskriterien und ein Bezeichnungssystem für Radial- und Axial-Pressfittings für Kunststoff- und Mehrschichtverbundrohre fest. Die Fittingenden haben einen Größenbereich von 10 mm bis 160 mm. Die Fittings sind für eine Lebensdauer von bis zu fünfzig Jahren ausgelegt.

Dieses Dokument gilt für Fittings aus Kupferlegierungen. Eine nicht vollständige Liste dieser Kupferlegierungen ist in CEN/TS 13388 enthalten.

Übergangsfittings für Kunststoff- und Mehrschichtverbundrohre dürfen Pressenden mit in den anderen Teilen der EN 1254 definierten Fittingenden kombinieren.

Pressfittings für Kunststoff- und Mehrschichtverbundrohre dürfen auch Flanschendanschlüsse nach EN 1092-3 aufweisen.

Pressfittings für Kunststoff- und Mehrschichtverbundrohre dürfen auch galvanische oder andere dekorative Oberflächenüberzüge aufweisen.

Fittings können durch Bearbeiten, Metallumformen, Gießen oder Fertigen hergestellt werden.

Die unter diese Norm fallenden Produkte sind für den Einsatz bestimmt in:

a) Flüssigkeitsanwendungen:

- Warm-, Kalt- oder kombinierte Warm-/Kaltwassersysteme nach EN 806;

- geschlossene Heizsysteme nach EN 12828 und Kühlsysteme;

- Entwässerungssysteme;

- Sprinkleranlagen nach EN 12845;

b) Gasanwendungen:

- Erdgas- und Flüssiggasanlagen mit einem maximalen Betriebsdruck von weniger als oder gleich 5 bar nach EN 1775;

- Druckluftsysteme.

Cuivre et alliages de cuivre - Raccords - Partie 8 : Raccords à sertir pour tubes en matières plastiques et multicouches

Le présent document spécifie les caractéristiques de produit, les méthodes d'évaluation, les critères de

conformité des résultats d’essai et un système de désignation pour les raccords pour le sertissage radial

ou axial de tubes en plastique et multicouche. Les extrémités de raccords ont un diamètre nominal

compris entre 10 mm et 160 mm. Les raccords sont conçus pour une durée de vie en service supérieure

à 50 ans.

Le présent document s'applique aux raccords en alliage de cuivre. Une liste non exhaustive de ces alliages

de cuivre figure dans la CEN/TS 13388.

Les raccords adaptateurs utilisés avec des tubes en matières plastiques et multicouches peuvent

combiner des extrémités à sertir avec des extrémités de raccord définies dans les autres parties de

l’EN 1254.

Les raccords à sertir pour tubes en matières plastiques et multicouches peuvent également comporter

des raccordements à brides conformément à l’EN 1092-3.

Les raccords à sertir pour tubes en matières plastiques et multicouches peuvent également avoir une

surface plaquée ou un autre revêtement de surface décoratif.

Les raccords peuvent être fabriqués par usinage, formage des métaux, moulage ou mécanosoudage.

Les produits couverts par le présent document sont destinés à être utilisés dans :

a) les applications liquides :

- les systèmes d'eau chaude, d'eau froide ou d'eau chaude et d'eau froide combinées, y compris les

systèmes conformes à l’EN 806 ;

- les systèmes de chauffage fermés conformes à l'EN 12828 ;

- les systèmes de refroidissement ;

- les systèmes de purge ;

- les systèmes de protection contre l’incendie, y compris les systèmes d'extinction de type

sprinkleur conformes à l’EN 12845 ;

- les systèmes d'approvisionnement des points de consommation en combustibles liquides selon

l’EN 12514.

b) les applications de gaz :

- les systèmes fonctionnant au gaz naturel et des systèmes fonctionnant au gaz de pétrole liquéfiés

avec une pression maximale de service inférieure ou égale à 5 bar, conformément à l'EN 1775 ;

- les systèmes d’air comprimé.

Baker in bakrove zlitine - Fitingi - 8. del: Fitingi s stiskalnimi priključki za spajanje s plastičnimi in večplastnimi cevmi

General Information

- Status

- Withdrawn

- Publication Date

- 25-May-2021

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 133 - Copper and copper alloys

- Drafting Committee

- CEN/TC 133/WG 8 - Fittings

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 12-Feb-2025

- Completion Date

- 14-Apr-2025

Relations

- Effective Date

- 02-Jun-2021

- Effective Date

- 27-Nov-2024

- Effective Date

- 17-Apr-2024

Frequently Asked Questions

EN 1254-8:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Copper and copper alloys - Plumbing fittings - Part 8: Press fittings for use with plastics and multilayer pipes". This standard covers: This document specifies product characteristics, assessment methods, compliance criteria of test results and a designation system for fittings with radial and axial press ends for use with plastics and multilayer pipes. The fitting ends have a nominal diameter from 10 mm to 160 mm. The fittings are designed for a service lifetime up to fifty. This document applies to copper alloy fittings. A non-exhaustive list of these copper alloys is given in CEN/TS 13388. Adaptor fittings for use with plastics and multilayer pipes may combine press ends with fitting ends defined in the other parts of EN 1254. Press fittings for use with plastics and multilayer pipes may also have flanged end connections according to EN 1092-3. Press fittings for use with plastics and multilayer pipes may also have a plated or other decorative surface coating. Fittings can be produced by machining, metal forming, casting, or fabrication. Products covered by this document are intended to be used in: a) liquid applications: - hot, cold or combined hot and cold water, including systems according to EN 806; - closed heating systems according to EN 12828; - cooling systems; - drainage systems; - fire protection systems including sprinkler systems according to EN 12845; - supply systems for points of consumption with liquid fuels according to EN 12514. b) gas applications: - natural gas and liquefied petroleum gas systems with a maximum operating pressure less than or equal to 5 bar according to EN 1775; - compressed air systems.

This document specifies product characteristics, assessment methods, compliance criteria of test results and a designation system for fittings with radial and axial press ends for use with plastics and multilayer pipes. The fitting ends have a nominal diameter from 10 mm to 160 mm. The fittings are designed for a service lifetime up to fifty. This document applies to copper alloy fittings. A non-exhaustive list of these copper alloys is given in CEN/TS 13388. Adaptor fittings for use with plastics and multilayer pipes may combine press ends with fitting ends defined in the other parts of EN 1254. Press fittings for use with plastics and multilayer pipes may also have flanged end connections according to EN 1092-3. Press fittings for use with plastics and multilayer pipes may also have a plated or other decorative surface coating. Fittings can be produced by machining, metal forming, casting, or fabrication. Products covered by this document are intended to be used in: a) liquid applications: - hot, cold or combined hot and cold water, including systems according to EN 806; - closed heating systems according to EN 12828; - cooling systems; - drainage systems; - fire protection systems including sprinkler systems according to EN 12845; - supply systems for points of consumption with liquid fuels according to EN 12514. b) gas applications: - natural gas and liquefied petroleum gas systems with a maximum operating pressure less than or equal to 5 bar according to EN 1775; - compressed air systems.

EN 1254-8:2021 is classified under the following ICS (International Classification for Standards) categories: 23.040.40 - Metal fittings. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1254-8:2021 has the following relationships with other standards: It is inter standard links to EN 1254-8:2012, EN 1254-8:2021+A1:2025, EN 1254-8:2021/prA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1254-8:2021 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 98/83/EC; Standardization Mandates: M/131, M/136. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 1254-8:2021 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2021

Nadomešča:

SIST EN 1254-8:2014

Baker in bakrove zlitine - Fitingi - 8. del: Fitingi s stiskalnimi priključki za spajanje

s plastičnimi in večplastnimi cevmi

Copper and copper alloys - Plumbing fittings - Part 8: Press fittings for use with plastics

and multilayer pipes

Kupfer und Kupferlegierungen - Fittings - Teil 8: Pressfittings für den Einsatz mit

Kunststoff- und Mehrschichtverbundrohren

Cuivre et alliages de cuivre - Raccords - Partie 8 : Raccords à sertir pour tubes en

matières plastiques et multicouches

Ta slovenski standard je istoveten z: EN 1254-8:2021

ICS:

23.040.40 Kovinski fitingi Metal fittings

77.150.30 Bakreni izdelki Copper products

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1254-8

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2021

EUROPÄISCHE NORM

ICS 23.040.40 Supersedes EN 1254-8:2012

English Version

Copper and copper alloys - Plumbing fittings - Part 8: Press

fittings for use with plastics and multilayer pipes

Cuivre et alliages de cuivre - Raccords - Partie 8 : Kupfer und Kupferlegierungen - Fittings - Teil 8:

Raccords à sertir pour tubes en matières plastiques et Pressfittings für den Einsatz mit Kunststoff- und

multicouches Mehrschichtverbundrohren

This European Standard was approved by CEN on 23 November 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1254-8:2021 E

worldwide for CEN national Members.

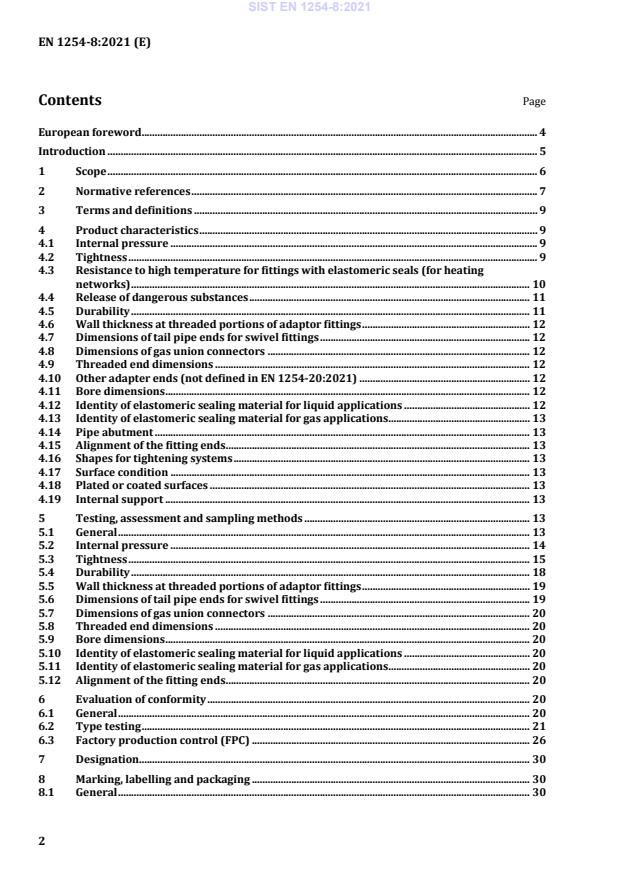

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 7

3 Terms and definitions . 9

4 Product characteristics . 9

4.1 Internal pressure . 9

4.2 Tightness . 9

4.3 Resistance to high temperature for fittings with elastomeric seals (for heating

networks) . 10

4.4 Release of dangerous substances . 11

4.5 Durability . 11

4.6 Wall thickness at threaded portions of adaptor fittings . 12

4.7 Dimensions of tail pipe ends for swivel fittings . 12

4.8 Dimensions of gas union connectors . 12

4.9 Threaded end dimensions . 12

4.10 Other adapter ends (not defined in EN 1254-20:2021) . 12

4.11 Bore dimensions . 12

4.12 Identity of elastomeric sealing material for liquid applications . 12

4.13 Identity of elastomeric sealing material for gas applications . 13

4.14 Pipe abutment . 13

4.15 Alignment of the fitting ends . 13

4.16 Shapes for tightening systems . 13

4.17 Surface condition . 13

4.18 Plated or coated surfaces . 13

4.19 Internal support . 13

5 Testing, assessment and sampling methods . 13

5.1 General . 13

5.2 Internal pressure . 14

5.3 Tightness . 15

5.4 Durability . 18

5.5 Wall thickness at threaded portions of adaptor fittings . 19

5.6 Dimensions of tail pipe ends for swivel fittings . 19

5.7 Dimensions of gas union connectors . 20

5.8 Threaded end dimensions . 20

5.9 Bore dimensions . 20

5.10 Identity of elastomeric sealing material for liquid applications . 20

5.11 Identity of elastomeric sealing material for gas applications . 20

5.12 Alignment of the fitting ends . 20

6 Evaluation of conformity . 20

6.1 General . 20

6.2 Type testing . 21

6.3 Factory production control (FPC) . 26

7 Designation. 30

8 Marking, labelling and packaging . 30

8.1 General . 30

8.2 Additional marking . 30

8.3 Dezincification resistant copper zinc alloys . 31

Bibliography . 32

European foreword

This document (EN 1254-8:2021) has been prepared by Technical Committee CEN/TC 133 “Copper and

copper alloys”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by November 2021, and conflicting national standards

shall be withdrawn at the latest by November 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1254-8:2012.

The main changes compared to EN 1254-8:2012 are:

— improved alignment with plastics and multilayer pipe standards for hot and cold water

applications;

— separation of test methods into part 20.

This part of the standard (EN 1254-8) should be read in conjunction with EN 1254-20:2021.

EN 1254 comprises the following parts under the general title “Copper and copper alloys — Plumbing

fittings”:

— Part 1: Capillary fittings for soldering or brazing to copper tubes

— Part 2: Compression fittings for use with copper tubes

— Part 3: Compression fittings for use with plastics and multilayer pipes

— Part 4: Threaded fittings

— Part 5: Capillary fittings with short ends for brazing to copper tubes

— Part 6: Push-fit fittings for use with metallic tubes, plastics and multilayer pipes

— Part 7: Press fittings for use with metallic tubes

— Part 8: Press fittings for use with plastics and multilayer pipes

— Part 20: Definitions, thread dimensions, test methods, reference data and supporting information

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

Products complying with this document may be used for several fluids including the transport of water

intended for human consumption if they comply with the relevant national, regional or local regulatory

provisions applicable in the place of use.

1 Scope

This document specifies product characteristics, assessment methods, compliance criteria of test results

and a designation system for fittings with radial and axial press ends for use with plastics and

multilayer pipes. The fitting ends have a nominal diameter from 10 mm to 160 mm. The fittings are

designed for a service lifetime up to fifty.

This document applies to copper alloy fittings. A non-exhaustive list of these copper alloys is given in

CEN/TS 13388.

Adaptor fittings for use with plastics and multilayer pipes may combine press ends with fitting ends

defined in the other parts of EN 1254.

Press fittings for use with plastics and multilayer pipes may also have flanged end connections

according to EN 1092-3.

Press fittings for use with plastics and multilayer pipes may also have a plated or other decorative

surface coating.

Fittings can be produced by machining, metal forming, casting, or fabrication.

Products covered by this document are intended to be used in:

a) liquid applications:

— hot, cold or combined hot and cold water, including systems according to EN 806;

— closed heating systems according to EN 12828;

— cooling systems;

— drainage systems;

— fire protection systems including sprinkler systems according to EN 12845;

— supply systems for points of consumption with liquid fuels according to EN 12514.

b) gas applications:

— natural gas and liquefied petroleum gas systems with a maximum operating pressure less than

or equal to 5 bar according to EN 1775;

— compressed air systems.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 549:2019, Rubber materials for seals and diaphragms for gas appliances and gas equipment

EN 681-1:1996, Elastomeric seals — Materials requirements for pipe joint seals used in water and

drainage applications — Part 1: Vulcanized rubber

EN 682, Elastomeric seals — Materials requirements for seals used in pipes and fittings carrying gas and

hydrocarbon fluids

EN 1254-20:2021, Copper and copper alloys — Plumbing fittings — Part 20: Definitions, thread

dimensions, test methods, reference data and supporting information

EN 10226-3, Pipes threads where pressure tight joints are made on the threads — Part 3: Verification by

means of limit gauges

EN 12201-2, Plastics piping systems for water supply, and for drainage and sewerage under pressure -

Polyethylene (PE) — Part 2: Pipes

EN 12201-5, Plastics piping systems for water supply, and for drainage and sewerage under pressure -

Polyethylene (PE) — Part 5: Fitness for purpose of the system

EN 12502-2, Protection of metallic materials against corrosion — Guidance on the assessment of

corrosion likelihood in water distribution and storage systems — Part 2: Influencing factors for copper

and copper alloys

EN ISO 3501, Plastics piping systems — Mechanical joints between fittings and pressure pipes — Test

method for resistance to pull-out under constant longitudinal force (ISO 3501)

EN ISO 3503, Plastics piping systems — Mechanical joints between fittings and pressure pipes — Test

method for leaktightness under internal pressure of assemblies subjected to bending (ISO 3503)

EN ISO 6506-1, Metallic materials — Brinell hardness test — Part 1: Test method (ISO 6506-1)

EN ISO 6507-1, Metallic materials — Vickers hardness test — Part 1: Test method (ISO6507-1)

EN ISO 1167 (all parts), Thermoplastics pipes, fittings and assemblies for the conveyance of fluids —

Determination of the resistance to internal pressure (ISO 1167)

EN ISO 13056, Plastics piping systems — Pressure systems for hot and cold water — Test method for

leaktightness under vacuum (ISO13056)

EN ISO 15874-2, Plastics piping systems for hot and cold water installations — Polypropylene (PP) —

Part 2: Pipes (ISO 15874-2)

EN ISO 15874-5, Plastics piping systems for hot and cold water installations — polypropylene (PP) —

Part 5: Fitness for purpose of the system (ISO 15874-5)

EN ISO 15875-2, Plastics piping systems for hot and cold water installations — Cross-linked polyethylene

(PE-X) — Part 2: Pipes (ISO 15875-2)

EN ISO 15875-5, Plastics piping systems for hot and cold water installations — Crosslinked polyethylene

(PE-X) — Part 5: Fitness for purpose of the system (ISO 15875-5)

EN ISO 15876-2, Plastics piping systems for hot and cold water installations — Polybutylene (PB) —

Part 2: Pipes (ISO 15876-2)

EN ISO 15876-5, Plastics piping systems for hot and cold water installations — Polybutylene (PB) —

Part 5: Fitness for purpose of the system (ISO 15876-5)

EN ISO 15877-2, Plastics piping systems for hot and cold water installations — Chlorinated poly(vinyl

chloride) (PVC-C) — Part 2: Pipes (ISO 15877-2)

EN ISO 15877-5, Plastics piping systems for hot and cold water installations — Chlorinated poly(vinyl

chloride) (PVC-C) — Part 5: Fitness for purpose of the system (ISO 15877-5)

EN ISO 19892, Plastics piping systems — Thermoplastics pipes and associated fittings for hot and cold

water — Test method for resistance of joints to pressure cycling (ISO 19892)

EN ISO 19893, Plastics piping systems — Thermoplastics pipes and fittings for hot and cold water — Test

method for the resistance of mounted assemblies to temperature cycling (ISO 19893)

EN ISO 21003-2, Multilayer pipe systems for hot and cold water installations inside buildings — Part 2:

Pipes (ISO 21003-2)

EN ISO 21003-5, Multilayer pipe systems for hot and cold water installations inside buildings — Part 5:

Fitness for purpose of the system (ISO 21003-5)

EN ISO 22391-2, Plastics piping systems for hot and cold water installations — Polyethylene of raised

temperature resistance (PE-RT) — Part 2: Pipes (ISO 22391-2)

EN ISO 22391-5, Plastics piping systems for hot and cold water installations — Polyethylene of raised

temperature resistance (PE-RT) — Part 5: Fitness for purpose of the system (ISO 22391-5)

ISO 7-2, Pipe threads where pressure tight joints are made on the threads — Part 2: Verification by means

of limit gauges

ISO 228-2, Pipe threads where pressure tight joints are not made on the threads — Part 2: Verification by

means of limit gauges

ISO 2859-1:1999, Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed

by acceptance quality limit (AQL) for lot-by-lot inspection

ISO 9924-1, Rubber and rubber products — Determination of the composition of vulcanizates and uncured

compounds by thermogravimetry — Part 1: Butadiene, ethylene-propylene copolymer and terpolymer,

isobutene-isoprene, isoprene and styrene-butadiene rubbers

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 1254-20:2021 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

4 Product characteristics

4.1 Internal pressure

4.1.1 For liquid applications

When tested according to the method in 5.2.1 fittings shall show no signs of leakage or permanent

distortion.

4.1.2 For fuel gas applications

When tested according to the method in 5.2.2 fittings shall show no signs of leakage or permanent

distortion.

4.1.3 For compressed air applications

When tested according to the method in 5.2.3 fittings shall show no signs of leakage or permanent

distortion.

4.2 Tightness

4.2.1 Integrity of fabricated fitting bodies or having an 'as cast' microstructure

This requirement only applies to fitting bodies with an 'as cast' microstructure (excluding continuously

cast materials) or fabricated by welding or brazing.

When tested according to the method in 5.3.1.1 fitting bodies shall show no visual indication of leakage.

4.2.2 Requirements for liquid applications

4.2.2.1 Leak tightness under internal hydrostatic pressure

Fittings assessed as indicated in 4.1.1 are considered to be leak tight under internal hydrostatic

pressure.

4.2.2.2 Leak tightness under vacuum

When tested according to the method in 5.3.2.1 the change in pressure shall not be greater than

0,05 bar at the conclusion of the test.

4.2.2.3 Leak tightness under temperature cycling (for heating networks)

When tested according to the method in 5.3.2.2 fittings shall show no signs of leakage or permanent

distortion.

4.2.2.4 Resistance to pull-out

When tested according to the method in 5.3.1.2 the joint assemblies shall withstand the pull-out force

without being separated and shall show no signs of leakage when subjected to the subsequent leak

tightness under internal hydrostatic pressure test as described in 5.2.1.

4.2.2.5 Leak tightness under internal hydrostatic pressure while subject to bending

When tested according to the method in 5.3.2.3 fittings shall show no signs of leakage or permanent

distortion.

4.2.2.6 Leak before press

If the manufacturer claims this feature, then when tested according to the method in 5.3.2.4 fittings

shall leak at least one water drop per second.

4.2.3 Requirements for gas applications

4.2.3.1 Leak tightness under internal pneumatic pressure

Fittings assessed as indicated in 4.1.2 and 4.1.3 are considered to be leak tight under internal pneumatic

pressure.

4.2.3.2 Resistance to pull-out

When tested according to the method in 5.3.1.2 the joint assemblies shall withstand the pull-out force

without being separated and shall show no signs of leakage when subsequently tested according to the

method in 5.2.2 and/or 5.2.3 according to the application, fittings shall show no signs of leakage or

permanent distortion.

4.2.3.3 Leak tightness under temperature cycling for fuel gas applications

When tested according to the test method in 5.3.3.1 fittings shall show no signs of leakage.

4.2.3.4 Leak before press

If the manufacturer claims this feature, then when tested according to the method in 5.3.3.2 fittings

shall leak at least one bubble per second when tested pneumatically.

4.2.3.5 Press fitting with elastomeric seals for fuel gas application inside buildings

The main aspect for the durability of tightness for fuel gas application inside buildings is the ozone

behaviour of the elastomer. Therefore the elastomer shall be ozone resistant and comply with the

requirements of EN 549 class B2 or higher.

4.2.3.6 Press fitting with elastomeric seals for fuel gas application outside buildings

The main aspect for the durability of tightness for fuel gas application outside buildings depends on the

elastomeric sealing element. Therefore, the elastomer shall comply with the requirements of EN 682

types GAL or GBL.

4.3 Resistance to high temperature for fittings with elastomeric seals (for heating

networks)

The main aspect for the resistance to high temperature liquid applications depends on the elastomeric

sealing element. Therefore the elastomer shall have the appropriate characteristics as specified in

EN 681-1. The elastomeric sealing elements shall conform to the requirements of EN 681-1:1996,

Table 3 for continuous hot water supply up to 110 °C except for Isoprene-Isobutylene Copolymer (IIR)

where a volume change in water up to and including 15 % is permitted.

4.4 Release of dangerous substances

National regulations on dangerous substances may require verification and declaration on release, and

sometimes content, when construction products covered by this document are placed on those markets.

In the absence of European harmonized test methods, verification and declaration on release/content

should be done taking into account national provisions in the place of use.

NOTE An informative database covering European and national provisions on dangerous substances is

available at the Construction website on EUROPA accessed through: http://ec.europa.eu/growth/tools-

databases/cp-ds.

4.5 Durability

4.5.1 Durability of internal pressure: Resistance to stress corrosion

Fittings manufactured from copper and copper-tin-zinc alloys (CuSnZnPb) shall be considered to be

resistant to stress corrosion according to EN 12502-2 and copper-zinc-silicon alloys containing ≥ 2 % Si

are also considered to be resistant.

Fittings manufactured from CuZn-alloys shall be considered to be resistant to stress corrosion when the

product has a hardness HBW 2,5/62,5 ≤ 110 measured according to EN ISO 6506-1 or a hardness

HV ≤ 134 measured according to EN ISO 6507-1.

Fittings manufactured from copper alloys with a zinc content of 10 % or greater not mentioned above

shall be tested and assessed according to 5.4.1, and shall show no evidence of cracking.

4.5.2 Durability of tightness

4.5.2.1 Resistance to dezincification

This requirement only applies where a fitting is declared to be resistant to dezincification.

The resistance to dezincification of alloy fittings can be obtained by the correct material selection and

processing of that material.

Alloys containing 15 % or less zinc provide a good resistance to dezincification and don't need to be

tested.

Representative material samples, prior to machining, shall be tested. When tested according to 5.4.2.1,

the mean and maximum depth of dezincification in any direction shall be expressed in µm and shall

meet the acceptance criteria listed below for resistance to dezincification:

— for grade A: maximum 200 µm;

— for grade B: mean not to exceed 200 µm and maximum not to exceed 400 µm.

If any of the test pieces do not meet the criteria for the chosen grade, a second lot of test samples from

the same batch shall be selected and the test repeated. If any of the second lot of test pieces fail, then the

batch represented shall be deemed not to conform to the requirements of this document.

4.5.2.2 Resistance to pressure cycling for liquid applications

When tested according to the method in 5.4.2.2 fittings shall show no signs of leakage.

4.5.3 Durability of resistance to high temperature (for heating networks)

When tested according to the method in 5.4.3 to one or more of the specified test durations, the

compression set of the sealing material shall be expressed as a percentage.

4.6 Wall thickness at threaded portions of adaptor fittings

This requirement only applies to adaptor fittings with an interface thread.

When assessed according to the method specified in 5.5 the minimum wall thickness at the interface

thread shall be as expressed in EN 1254-20:2021, 4.1 for the relevant diameters.

4.7 Dimensions of tail pipe ends for swivel fittings

This requirement only applies to tail pipe ends for swivel fittings.

When assessed according to the method specified in 5.6 the dimensions shall be as expressed in

EN 1254-20:2021, 4.2 for the thread size.

4.8 Dimensions of gas union connectors

This requirement only applies to fittings with gas union connectors.

When assessed according to the method specified in 5.7 the dimensions shall be as expressed in

EN 1254-20:2021, 4.3 for corresponding nominal size.

4.9 Threaded end dimensions

This requirement only applies to fitting bodies with threaded ends.

When assessed according to the method specified in 5.8 the thread shall be in accordance with

EN 1254-20:2021, 4.4.

4.10 Other adapter ends (not defined in EN 1254-20:2021)

Other adapter ends, when assembled in accordance with the manufacturer's instructions and pressure

tested according to the method in 5.2 for the intended application, shall show no signs of leakage or

permanent distortion. When re-tested in accordance with the test method in 5.2 for the intended

application after disconnection and reconnection, it shall again show no signs of leakage or permanent

distortion. If after disconnection the sealing element shows signs of damage, it shall be replaced before

the second test.

4.11 Bore dimensions

To minimize flow resistance, minimum bore dimensions are required.

When assessed according to the method in 5.9, the minimum bore, including any internal pipe support,

shall be greater or equal to the values expressed in EN 1254-20:2021, 4.5, Table 10, for the relevant

nominal diameters.

Where an internal support is not required, the minimum bore of the fitting shall be greater than or

equal to the min bore of the corresponding pipe.

For unequal ended or adaptor fittings, the smallest diameter shall apply provided that this diameter

does not restrict other outlets.

4.12 Identity of elastomeric sealing material for liquid applications

During type testing, the method in 5.10 shall be used to establish the master reference thermogram for

the chosen sealing material.

The results of subsequent tests of the sealing material, carried out according to the method in 5.10, shall

be compared to the master reference thermogram to establish that the material is the same; any

differences shall be investigated. Results shall be retained for future comparison.

The identity relates to the elastomeric material and is independent of the fitting type, size or pattern.

4.13 Identity of elastomeric sealing material for gas applications

During type testing, the method in 5.11 shall be used to establish the master reference spectra for the

chosen sealing material.

The results of subsequent tests of the sealing material, carried out according to the method in 5.11, shall

be compared to the master reference spectra to establish that the material is the same; any differences

shall be investigated. Results shall be retained for future comparison.

The identity relates to the elastomeric material and is independent of the fitting type, size or pattern.

4.14 Pipe abutment

This requirement does not apply to threaded ends.

Fitting ends are usually manufactured with an abutment to limit pipe insertion and to retain a loose

supporting sleeve, if used.

Fittings may be produced for special purposes, particularly useful for repairs, where the fitting ends do

not incorporate abutments, allowing the fitting to slide along the pipe.

The dimensions of the abutment shall be such that it will stop the smallest possible pipe. The abutment

shall also satisfy the minimum bore requirement as stated in 4.10.

4.15 Alignment of the fitting ends

When tested according to the method in 5.12, the alignment of the fitting ends with reference to the

specified axis shall be within ± 2°.

4.16 Shapes for tightening systems

When visually inspected, fittings with threads shall have a shape or suitable features for the

transmission of tightening torques.

4.17 Surface condition

Wh

...

기사 제목: EN 1254-8:2021 - 구리 및 구리 합금 - 배관 피팅 - 파이프와 다중계층 파이프용 프레스 피팅을 위한 파트 8 기사 내용: 이 문서는 플라스틱과 다중계층 파이프와 함께 사용하기 위한 방사 및 축대 프레스 엔드가 있는 피팅의 제품 특성, 평가 방법, 시험 결과의 준수 기준 및 지정 시스템을 규정합니다. 이 피팅 엔드는 10mm에서 160mm의 명목 직경을 가지고 있습니다. 이 피팅은 50년의 서비스 수명을 대상으로 설계되었습니다. 이 문서는 구리 합금 피팅에 적용됩니다. 이 구리 합금의 비상 한계 목록은 CEN / TS 13388에서 제공됩니다. 플라스틱과 다중계층 파이프와 함께 사용하기 위한 어댑터 피팅은 EN 1254의 다른 부분에서 정의된 피팅 엔드와 프레스 엔드를 결합할 수 있습니다. 플라스틱과 다중계층 파이프와 함께 사용하기 위한 프레스 피팅은 EN 1092-3에 따라 플랜지 엔드 연결을 가질 수도 있습니다. 플라스틱과 다중계층 파이프와 함께 사용하기 위한 프레스 피팅은 도금이나 기타 장식적인 표면 코팅을 가질 수도 있습니다. 피팅은 가공, 금속 성형, 주조 또는 조립 방법을 통해 생산될 수 있습니다. 이 문서에 포함된 제품은 다음 용도로 사용될 것을 목적으로 합니다: a) 액체 응용: - EN 806에 따른 시스템을 포함한 뜨거운, 차가운 또는 차가운 물; - EN 12828에 따른 닫힌 난방 시스템; - 냉각 시스템; - 배수 시스템; - EN 12845에 따른 스프링클러를 포함한 소화 시스템; - EN 12514에 따른 액체 연료 소비점 공급 시스템. b) 가스 응용: - EN 1775에 따른 최대 작동 압력이 5bar 이하인 천연 가스 및 액화 석유 가스 시스템; - 압축공기 시스템.

記事タイトル:EN 1254-8:2021 - 銅および銅合金 - 配管フィッティング - 第8部:プラスチックおよびマルチレイヤーパイプ用プレスフィッティング 記事内容:この文書は、プラスチックおよびマルチレイヤーパイプと使用するためのラジアルおよび軸方向のプレスエンドを持つフィッティングの製品特性、評価方法、試験結果の適合基準、および指定システムを規定しています。フィッティングのエンドは、10mmから160mmの名目径を持ちます。このフィッティングは、最大50年間の使用寿命を目指して設計されています。 この文書は銅合金フィッティングに適用されます。適用可能な銅合金の一部については、CEN / TS 13388でリストが提供されています。 プラスチックおよびマルチレイヤーパイプと使用するためのアダプターフィッティングは、EN 1254の他の部分で定義されたフィッティングエンドとプレスエンドを組み合わせることができます。 プラスチックおよびマルチレイヤーパイプと使用するためのプレスフィッティングは、EN 1092-3に準拠したフランジエンド接続を持つ場合もあります。 プラスチックおよびマルチレイヤーパイプと使用するためのプレスフィッティングは、めっきや他の装飾表面コーティングを持つ場合もあります。 フィッティングは、加工、金属成形、鋳造、または組立によって製造されることがあります。 この文書でカバーされる製品は、次の用途で使用することを目的としています: a)液体アプリケーション: - EN 806に準拠したシステムを含む、温水、冷水、または温冷水; - EN 12828に準拠した閉鎖暖房システム; - 冷却システム; - 排水システム; - EN 12845に準拠した防火システムおよびスプリンクラーシステム; - EN 12514に準拠した液体燃料の消費供給システム。 b)ガスアプリケーション: - EN 1775に準拠し、最大作動圧力が5bar以下の天然ガスおよび液化石油ガスシステム; - 圧縮空気システム。

The article discusses the EN 1254-8:2021 standard which focuses on copper and copper alloy plumbing fittings. Specifically, it outlines the characteristics, assessment methods, compliance criteria, and designation system for fittings with radial and axial press ends. These fittings are designed for use with plastics and multilayer pipes, with a nominal diameter range of 10 mm to 160 mm. The document applies to copper alloy fittings, with a list of applicable alloys provided in CEN/TS 13388. It also mentions that adaptor fittings may combine press ends with fitting ends defined in other parts of EN 1254 and can have flanged end connections or a plated/decorative surface coating. The fittings can be produced using machining, metal forming, casting, or fabrication methods. The products covered by this standard are suitable for use in various liquid applications, such as hot/cold water systems, heating and cooling systems, drainage systems, fire protection systems, and supply systems for liquid fuels. They can also be used in gas applications, including natural gas and liquefied petroleum gas systems with a maximum operating pressure of 5 bar or less, as well as compressed air systems.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...