EN 13785:2005+A1:2008

(Main)Regulators with a capacity of up to and including 100 kg/h, having a maximum nominal outlet pressure of up to and including 4 bar, other than those covered by EN 12864 and their associated safety devices for butane, propane or their mixtures

Regulators with a capacity of up to and including 100 kg/h, having a maximum nominal outlet pressure of up to and including 4 bar, other than those covered by EN 12864 and their associated safety devices for butane, propane or their mixtures

This document defines the constructional and operational characteristics, the safety requirements, test methods and the marking of regulators having a capacity of less than or equal to 100 kg/h, other than the regulators covered by EN 12864, for butane, propane or their mixtures, in the gaseous phase.

Regulators for caravans up to 1,5 kg/h are covered by EN 12864.

NOTE 1 bar = 105 Pa.

This document also applies to the safety devices which are included within regulators covered by this document. The characteristics of these devices are given in annexes A and B.

The requirements apply generally to regulators used in locations where the temperature likely to be reached during use is between -20 °C and +50 °C. When the regulators are used at temperatures below -20 °C it is essential that they comply with special requirements which are defined in annex C.

This document does not include the installation rules for regulators. Reference should be made to national regulations in force in the member countries.

This document only covers type testing.

WARNING NOTICE: The figures in annexes G and H show the types of connections used according to the country of use of the regulators.

The top part of these figures (above the horizontal line) applies to the regulator and is normative.

The bottom part of these figures (below the horizontal line) applies to the part to be connected to the regulator. This is given as a guide for the tests and is not normative.

Druckregelgeräte mit einem höchsten Ausgansdruck von < 4 bar und einem Durchfluss < 100 kg/h, die nicht in EN 12864 geregelt sind, für Butan, Propan oder deren Gemische sowie die dazugehörigen Sicherheitseinrichtungen

Dieses Dokument legt die Bau- und Funktionseigenschaften, die sicherheitstechnischen Anforderungen, Prüfverfahren und Kennzeichnung von Druckregelgeräten mit einem Durchfluss von kleiner oder gleich 100 kg/h, außer den Druckregelgeräten nach EN 12864, für Butan, Propan und deren Gemische fest.

Druckregelgeräte für Freizeitfahrzeuge mit einem Durchfluss bis 1,5 kg/h werden in der EN 12864 geregelt.

ANMERKUNG 1 bar 105 Pa

Dieses Dokument gilt auch für Sicherheitseinrichtungen, die in Druckregelgeräten dieses Dokumentes enthalten sind. Die Besonderheiten dieser Einrichtungen sind in den Anhängen A und B aufgeführt.

Die Anforderungen gelten im Allgemeinen für Druckregelgeräte, die an Orten verwendet werden, bei denen im Betrieb Temperaturen zwischen 20 °C und 50 °C erreicht werden. Bei Anwendung der Geräte bei Temperaturen unterhalb 20 °C ist es notwendig, dass sie den im Anhang C festgelegten Anforderungen entsprechen.

Dieses Dokument enthält keine Installationsvorschriften von Druckregelgeräten. Hierbei sollten Hinweise auf die in den Mitgliedsstaaten geltenden nationalen Bestimmungen gegeben werden.

Dieses Dokument befasst sich nur mit Baumusterprüfungen.

ACHTUNG - Die Bilder in den Anhängen G und H zeigen die Anschlusstypen der Länder, in denen die Druckregelgeräte verwendet werden.

Der obere Bereich dieser Bilder (über der horizontalen Linie) gilt für die Druckregelgeräte und ist normativ.

Der untere Bereich dieser Bilder (unter der horizontalen Linie) gilt für den Teil, der mit dem Druckregelgerät verbunden wird. Dies dient als Hinweis für die Prüfungen und ist nicht normativ.

Détendeurs de débit inférieur ou égal à 100 kg/h, à pression de détente nominale maximale inférieure ou égale à 4 bar, autres que les détendeurs relevant de l'EN 12864, et leurs dispositifs de sécurité associés pour butane, propane ou leurs mélanges

La présente norme européenne a pour but de définir les caractéristiques de construction et de fonctionnement, les exigences de sécurité, les techniques d’essais et le marquage, des détendeurs d'un débit inférieur ou égal à 100 kg/h, autres que les détendeurs objets de l'EN 12864, utilisés pour le butane, le propane ou leurs mélanges, considérés uniquement à l'état gazeux.

Les détendeurs pour caravanes, jusqu’à 1,5 kg/h, sont couverts par l’EN 12864.

NOTE 1 bar = 105 Pa.

La présente norme européenne est également applicable aux dispositifs de sécurité qui sont susceptibles d'équiper les détendeurs visés par la présente norme. Les caractéristiques de ces dispositifs sont données dans les Annexes A et B.

Les spécifications de cette norme européenne s'appliquent en général aux détendeurs utilisés dans les régions où la température susceptible d'être atteinte en service varie entre – 20 °C et 50 °C. Lorsque les détendeurs sont utilisés à des températures situées au-dessous de – 20 °C, ils doivent répondre à des exigences particulières, qui sont définies dans l'Annexe C.

La présente norme ne spécifie pas les règles d'installation des détendeurs. Il y a lieu dans ce domaine de se reporter aux règles d'installation en vigueur dans les pays membres.

La présente norme couvre uniquement les essais de type.

AVERTISSEMENT — Les Figures des Annexes G et H présentent les types de raccordements retenus selon les pays d’utilisation des détendeurs.

La partie supérieure de ces Figures (au dessus du trait horizontal) s’applique au détendeur et est normative.

La partie inférieure de ces Figures (au dessous du trait horizontal) s’applique au composant destiné à être raccordé au détendeur. Celle-ci est donnée à titre indicatif pour le besoin des essais et n’est pas normative.

Regulatorji s pretokom do vključno 100 kg/h z največjim imenskim izhodnim tlakom do vključno 4 bar, ki niso vključeni v SIST EN 12864, in s pripadajočimi varnostnimi napravami za butan, propan ali njuni zmesi (vključno z dopolnilom A1)

General Information

- Status

- Withdrawn

- Publication Date

- 04-Nov-2008

- Withdrawal Date

- 11-Jun-2013

- Technical Committee

- CEN/TC 181 - Dedicated liquified petroleum gas appliances

- Drafting Committee

- CEN/TC 181/WG 8 - Pressure regulators and changeover devices

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 12-Jun-2013

- Completion Date

- 12-Jun-2013

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 22-Dec-2008

- Effective Date

- 19-Jun-2013

Frequently Asked Questions

EN 13785:2005+A1:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Regulators with a capacity of up to and including 100 kg/h, having a maximum nominal outlet pressure of up to and including 4 bar, other than those covered by EN 12864 and their associated safety devices for butane, propane or their mixtures". This standard covers: This document defines the constructional and operational characteristics, the safety requirements, test methods and the marking of regulators having a capacity of less than or equal to 100 kg/h, other than the regulators covered by EN 12864, for butane, propane or their mixtures, in the gaseous phase. Regulators for caravans up to 1,5 kg/h are covered by EN 12864. NOTE 1 bar = 105 Pa. This document also applies to the safety devices which are included within regulators covered by this document. The characteristics of these devices are given in annexes A and B. The requirements apply generally to regulators used in locations where the temperature likely to be reached during use is between -20 °C and +50 °C. When the regulators are used at temperatures below -20 °C it is essential that they comply with special requirements which are defined in annex C. This document does not include the installation rules for regulators. Reference should be made to national regulations in force in the member countries. This document only covers type testing. WARNING NOTICE: The figures in annexes G and H show the types of connections used according to the country of use of the regulators. The top part of these figures (above the horizontal line) applies to the regulator and is normative. The bottom part of these figures (below the horizontal line) applies to the part to be connected to the regulator. This is given as a guide for the tests and is not normative.

This document defines the constructional and operational characteristics, the safety requirements, test methods and the marking of regulators having a capacity of less than or equal to 100 kg/h, other than the regulators covered by EN 12864, for butane, propane or their mixtures, in the gaseous phase. Regulators for caravans up to 1,5 kg/h are covered by EN 12864. NOTE 1 bar = 105 Pa. This document also applies to the safety devices which are included within regulators covered by this document. The characteristics of these devices are given in annexes A and B. The requirements apply generally to regulators used in locations where the temperature likely to be reached during use is between -20 °C and +50 °C. When the regulators are used at temperatures below -20 °C it is essential that they comply with special requirements which are defined in annex C. This document does not include the installation rules for regulators. Reference should be made to national regulations in force in the member countries. This document only covers type testing. WARNING NOTICE: The figures in annexes G and H show the types of connections used according to the country of use of the regulators. The top part of these figures (above the horizontal line) applies to the regulator and is normative. The bottom part of these figures (below the horizontal line) applies to the part to be connected to the regulator. This is given as a guide for the tests and is not normative.

EN 13785:2005+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 23.060.40 - Pressure regulators. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13785:2005+A1:2008 has the following relationships with other standards: It is inter standard links to EN 13785:2005/prA1, EN 13785:2005/AC:2007, EN 13785:2005, EN 16129:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13785:2005+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 2009/142/EC, 90/396/EEC; Standardization Mandates: M/BC/CEN/89/6. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 13785:2005+A1:2008 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.L]KRGQLPDruckregelgeräte mit einem höchsten Ausgansdruck von < 4 bar und einem Durchfluss < 100 kg/h, die nicht in EN 12864 geregelt sind, für Butan, Propan oder deren Gemische sowie die dazugehörigen SicherheitseinrichtungenDétendeurs de débit inférieur ou égal à 100 kg/h, à pression de détente nominale maximale inférieure ou égale à 4 bar, autres que les détendeurs relevant de l'EN 12864, et leurs dispositifs de sécurité associés pour butane, propane ou leurs mélangesRegulators with a capacity of up to and including 100 kg/h, having a maximum nominal outlet pressure of up to and including 4 bar, other than those covered by EN 12864 and their associated safety devices for butane, propane or their mixtures23.060.40Pressure regulatorsICS:Ta slovenski standard je istoveten z:EN 13785:2005+A1:2008SIST EN 13785:2005+A1:2009en01-januar-2009SIST EN 13785:2005+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13785:2005+A1

November 2008 ICS 23.060.40 Supersedes EN 13785:2005English Version

Regulators with a capacity of up to and including 100 kg/h, having a maximum nominal outlet pressure of up to and including 4 bar, other than those covered by EN 12864 and their associated safety devices for butane, propane or their mixtures Détendeurs de débit inférieur ou égal à 100 kg/h, à pression de détente nominale maximale inférieure ou égale à 4 bar, autres que les détendeurs relevant de l'EN 12864, et leurs dispositifs de sécurité associés pour butane, propane ou leurs mélanges

Druckregelgeräte mit einem höchsten Ausgansdruck von < 4 bar und einem Durchfluss < 100 kg/h, die nicht in EN 12864 geregelt sind, für Butan, Propan oder deren Gemische sowie die dazugehörigen Sicherheitseinrichtungen This European Standard was approved by CEN on 1 July 2004 and includes Corrigendum 1 issued by CEN on 14 February 2007 and Amendment 1 approved by CEN on 27 September 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13785:2005+A1:2008: ESIST EN 13785:2005+A1:2009

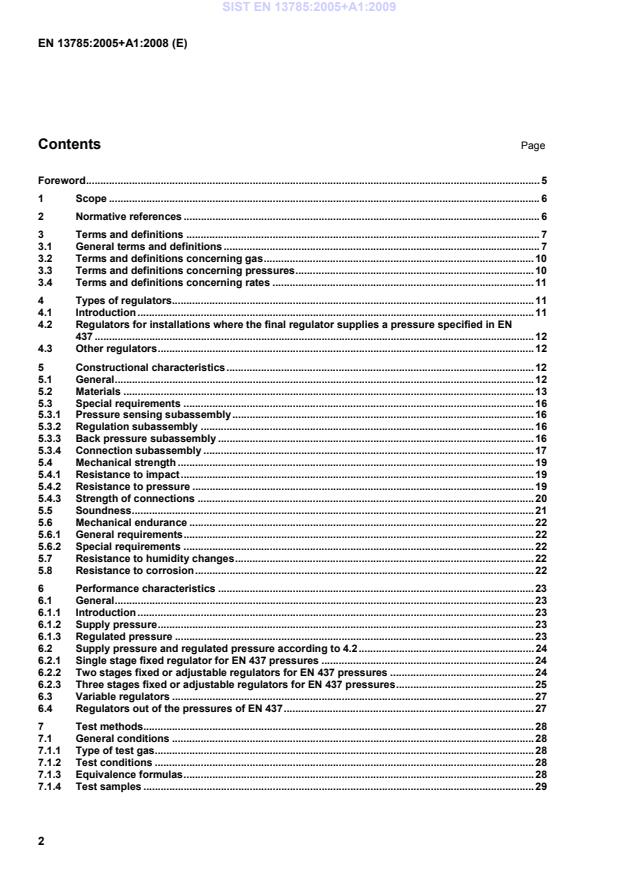

Special requirements for regulators fitted with pressure or rate operated

safety devices.42 A.1 Regulators fitted with an over-pressure relief.42 A.1.1 Definition.42 A.1.2 Constructional characteristics.42 A.1.3 Performance characteristics.42 A.1.4 Test methods.43 A.1.5 Regulator marking.43 A.2 Regulators fitted with an over-pressure shut off safety valve.43 A.2.1 Definition.43 A.2.2 Constructional characteristics.43 A.2.3 Performance characteristics.44 A.2.4 Test methods.44 A.3 Regulators fitted with an under-pressure shut off safety device.45 A.3.1 Definition.45 A.3.2 Constructional and performance characteristics.45 A.3.3 Test methods.46 A.4 Regulators fitted with an excess flow valve.46 A.4.1 Definition.46 A.4.2 Performance characteristics.46 A.4.3 Test methods.46 A.4.4 User and maintenance instructions.47 A.5 Regulators fitted with a regulated pressure limiter.47 A.5.1 Definition.47 A.5.2 Constructional and performance characteristics.47 A.5.3 Test methods.48 A.5.4 User and maintenance instructions.48 Annex B (normative)

Special requirements for regulators fitted with a thermal cut out.49 B.1 Definition.49 B.2 Constructional characteristics.49 B.3 Performance characteristics.49 B.4 Test methods.49 Annex C (normative)

Special requirements for low pressure regulators under extreme temperature conditions (temperatures below -20 °C).51 Annex D (normative)

Method for measuring leaks at test pressures less than or equal to 16 bar.52 D.1 Scope.52 D.2 Diagram of the test bench.52 D.3 Coefficient K.53 D.3.1 Method.53 D.3.2 Calculations.53 SIST EN 13785:2005+A1:2009

Complementary test requirements for non metallic thermoplastic or thermal setting materials used in the construction of regulators.55 E.1 Scope.55 E.2 Materials.55 E.3 Special conditions for carrying out the tests mentioned in the body of the document.55 E.3.1 Resistance to impact (see 5.4.1 and 7.2.1).55 E.3.2 Mechanical resistance of connections (see 5.4.3 and 7.2.3).55 E.3.3 Soundness (see 5.5 and 7.2.5).56 E.4 Special requirements.56 E.4.1 Resistance to hydrocarbons.56 E.4.2 Resistance to cracking under stress and when chemical agents are present.56 E.4.3 Characteristics relating to fire resistance.56 E.4.4 Accelerated ageing.57 E.5 Sampling and order of tests.57 Annex F (normative)

Requirements for elastomeric reinforced diaphragms.58 Annex G (normative)

Inlet connections.59 Annex H (normative)

Outlet connections.106 Annex I (informative)

Test method for resistance to corrosion.136 I.1 Principle.136 I.2 Reagents.136 I.2.1 Saline solution.136 I.2.2 Compressed air.136 I.2.3 Salt mist.137 I.3 Apparatus.137 I.3.1 Spraying chamber.137 I.3.2 Sprayers.137 I.3.3 Heating device.138 I.3.4 Salt solution supply device.138 I.3.5 Compressed air supply device.138 I.3.6 Mist collectors.138 I.4 Test method.139 I.4.1 Method of exposure of regulators.139 I.4.2 Duration of tests.139 I.4.3 Checks.139 I.4.4 Cleaning of regulators.139 I.5 Results.139 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 90/396/EEC.142 Bibliography.144

1) Only applicable to the German version. SIST EN 13785:2005+A1:2009

Key 1 Pressure sensing subassembly

2 Regulation subassembly

3 Back pressure subassembly

4 Mechanical connection subassembly

5 Connection subassembly

Figure 1 - Principal parts of a regulator

• the supply pressure of the regulator is equal to the pressure of the LPG supply container(s); • the regulator supplies a gas appliance. 2 – Two stages

• the supply pressure of the first regulator is equal to the pressure of the LPG supply container(s); • the supply pressure of the second and the third regulator depends on the regulated pressure of the upstream regulator and on the pressure losses in the intermediate upstream line; • the third regulator supplies a gas appliance. 4.2 Regulators for installations where the final regulator supplies a pressure specified in EN 437 The last regulator, which supplies a gas appliance for pressures specified by EN 437 shall be a fixed regulator (see 3.1.2). It is recommended that all the other regulators of the installation are fixed regulators. For interchangeability the recommended nominal value of intermediate regulated pressures (pd) are the following: 3 – 1,5 – 1 – 0,75 – 0,5 – 0,4 – 0,3 – 0,15 bar These settings accommodate pressure losses in the interstage pipe work. In general systems are designed with a pressure loss of up to 15 %. However in some cases where additional equipment (i.e limiter) is fitted, pressure losses of 50 % are found. 4.3 Other regulators To supply appliances with pressures which are different from those specified by EN 437 fixed, variable or adjustable regulators are used. 5 Constructional characteristics 5.1 General Regulators shall be designed, manufactured and assembled in such a way that their operation is satisfactory under the installation and service conditions specified by the manufacturer. The safety devices, if incorporated in or onto the regulators covered by this document shall be designed and constructed in accordance with the provisions of annexes A and B. All the parts of a regulator shall be free from sharp corners or edges capable of causing damage, deterioration, injury or faulty operation. Parts shall be clean internally and externally. SIST EN 13785:2005+A1:2009

200 mbar and of a rate smaller than 4 kg/h, directly fitted onto the cylinder using a quick coupling with self closing valve and non threaded outlet connection, non metallic (thermoplastic or thermal setting) materials may be used if the characteristics meet the requirements of this document as well as the complementary special requirements defined in annex E. Internal parts and parts of the cover not relating to pressure (except for connections, see Figure 2) may be made of non metallic (thermoplastic or thermal setting) materials provided that they meet the following requirements: the materials used shall meet the requirements of annex E; the whole regulator shall withstand the various tests specified in the body of the document; the regulator, with non metallic parts removed, shall resist a pressure test as in 7.2.2.3 remaining sound in the sense of 5.5 and without causing any danger. !Zinc alloys shall only be used if they are of the Zn Al4 or Zn Al4 Cu1 quality, in accordance with ISO 301. Brass alloys shall comply with EN 12164 or EN 12165. SIST EN 13785:2005+A1:2009

Key 1 Cover 2 Body 3 Connections Figure 2 - Regulator diagram showing the metallic parts SIST EN 13785:2005+A1:2009

...

EN 13785:2005+A1:2008 표준은 부탄, 프로판 또는 이들의 혼합물과 같은 기체의 조절 장치에 대한 중요한 기준을 제시합니다. 이 표준의 주요 내용은 100 kg/h 이하의 용량을 가진 조절 장치의 구조적, 운영적 특성, 안전 요구사항, 시험 방법 및 마킹에 대한 세부 사항을 정의한다는 점에서 뛰어난 중요성을 가집니다. 이 표준이 제공하는 강점 중 하나는 조절 장치의 안전 장치에 대한 명확한 규정이 포함되어 있다는 것입니다. 이는 Annex A와 B에서 자세히 설명되며, 안전 장치의 특성을 명시하고 있어 전체적인 안전성을 보장합니다. 또한, 조절 장치가 사용되는 온도 범위가 -20°C에서 +50°C 사이에 있을 때의 요구사항을 명확히 하여 넓은 온도 범위에서도 안정적으로 작동할 수 있도록 도와줍니다. -20°C 이하의 특수 요구사항은 Annex C에 언급되어 있으며, 이는 극한의 환경에서도 조절 장치의 기능을 보장합니다. EN 13785는 또한 설치 규정에 관한 내용은 포함하지 않고, 회원국의 현행 국가 규정을 참조할 것을 권장하는 점에서도 실용성을 제공합니다. 이는 각 국가의 상황에 맞는 안전한 설치를 보장할 수 있도록 합니다. 결국, EN 13785:2005+A1:2008 표준은 조절 장치의 품질과 안전성을 보장하기 위한 필수적인 기준으로, 부탄 및 프로판과 같은 기체의 조정에 대한 명확한 지침을 제공합니다. 이 문서의 규정은 조절 장치의 유형 시험에만 적용되며, 다양한 국가에서 사용되는 연결 방식에 대한 가이드라인을 제공하는 것도 중요한 특징입니다.

The standard EN 13785:2005+A1:2008 outlines critical constructional and operational characteristics for regulators with a capacity of up to and including 100 kg/h, specifically focusing on those having a maximum nominal outlet pressure of up to and including 4 bar, which are not encompassed by EN 12864. This framework is essential for ensuring safety, reliability, and functionality in regulators designed for butane, propane, or their mixtures in gaseous form. One of the strengths of this standard is its comprehensive safety requirements, which extend not only to the regulators themselves but also to the associated safety devices. By defining specific test methods and operational characteristics, the standard ensures that manufacturers can produce regulators that meet stringent safety criteria. The inclusion of detailed markings requirements further enhances product identification and compliance in the market. The standard effectively addresses the operational range of temperature, stipulating that regulators should perform safely within -20 °C to +50 °C, while also providing guidelines for those operating below -20 °C through annex C. This attention to temperature tolerance is vital for user safety and equipment reliability, particularly in varying climatic conditions. Furthermore, the standard's clarity in delineating the scope – excluding installation rules which are to be governed by national regulations – allows for a focused approach to regulator manufacturing while encouraging adherence to local safety legislations. The type testing requirement ensures that all regulators meet uniform standards before they are introduced to the market. Additionally, the warning notice regarding the types of connections specific to each country adds value by providing essential guidance for ensuring compatibility and safety in practical applications. Overall, EN 13785:2005+A1:2008 is a pivotal standard that helps to promote safety and quality in the manufacture of gas regulators for butane, propane, and their mixtures, making it highly relevant for industry stakeholders involved in the production and regulation of gas equipment.

SIST EN 13785:2005+A1:2009は、ガス調整器に関する重要な標準であり、その対象範囲と内容は特に明確に定義されています。この標準は、容量が100 kg/h以下であり、最大名目出口圧力が4 bar以下のブタン、プロパン、またはその混合物用の調整器に焦点を当てています。他の標準であるEN 12864に含まれる調整器とは異なり、この文書は特定の安全要件、試験方法、そしてマーキングに関する詳細を提供しています。 この標準の強みは、ガス調整器の構造的および操作的特性、安全要件を明確に示している点です。この文書は、使用中の温度範囲が-20°Cから+50°Cに達する可能性のある場所で使用される調整器に対して一般的な要求事項を設定しており、特定の温度条件下での使用に関する特別な要件も附属書Cで定義されています。これは、調整器の信頼性と安全性を高めるために非常に重要です。 また、附属書AおよびBに記載されている安全デバイスの特性により、調整器に関連する安全装置が包括的にカバーされているため、ユーザーは安心して使用することができます。この標準は、種類試験のみに焦点を当てているため、初期の評価段階において特に役立ちます。 さらに、附属書GおよびHに示される接続タイプの図は、調整器の使用国に従った重要な情報を提供しています。これにより、国ごとの調整器の適用方法に対する理解が深まり、実際の使用時における適切な接続が確保されます。 全体として、SIST EN 13785:2005+A1:2009は、100 kg/h以下のガス調整器の安全かつ効果的な運用を保証するための重要な指針を提供しており、その適用可能性と整合性はガス産業において極めて重要です。

La norme SIST EN 13785:2005+A1:2009 aborde spécifiquement les régulateurs ayant une capacité allant jusqu'à 100 kg/h, avec une pression nominale maximale de sortie ne dépassant pas 4 bar. Cette norme se distingue par son approche exhaustive des caractéristiques de construction et de fonctionnement des régulateurs, en incluant également les exigences de sécurité, les méthodes d'essai et le marquage nécessaire pour les appareils utilisés avec le butane, le propane ou leurs mélanges dans la phase gazeuse. Un des points forts de cette norme est sa capacité à établir des exigences de sécurité précises. En définissant les conditions d'utilisation, notamment la plage de température de -20 °C à +50 °C, elle garantit que les régulateurs fonctionnent de manière fiable dans une variété d'environnements. De plus, pour les situations où des températures inférieures à -20 °C sont prévues, les exigences spéciales précisées dans l'annexe C renforcent la sécurité et la performance des appareils. La norme fait également un usage judicieux des annexes A et B pour décrire les dispositifs de sécurité inclus dans les régulateurs, rendant la documentation à la fois informative et exhaustive. Cela permet aux fabricants et utilisateurs de disposer des informations nécessaires pour assurer la conformité et la sécurité des produits. En outre, bien que la norme ne traite pas des règles d'installation, elle rappelle judicieusement aux utilisateurs qu'ils doivent se référer aux réglementations nationales en vigueur, ce qui souligne son respect des divers contextes réglementaires à travers les pays membres. Cela renforce sa pertinence et son adaptabilité dans le cadre des différentes législations. Enfin, les annexes G et H fournissent des indications claires sur les types de connexions à utiliser selon le pays, ce qui facilite la compréhension pour les tests et l'implémentation des régulateurs tout en séparant clairement les aspects normatifs des guides. En somme, la norme SIST EN 13785:2005+A1:2009 représente une ressource précieuse, répondant aux besoins de sécurité et de performance dans l'utilisation de régulateurs de butane et propane, tout en restant pertinente face à l'évolution des standards et des exigences de l'industrie.

Der Standard EN 13785:2005+A1:2008 bietet umfassende Richtlinien für Regler mit einer Kapazität von bis zu und einschließlich 100 kg/h, die einen maximalen Nennausgangsdruck von bis zu und einschließlich 4 bar aufweisen. Diese Vorgaben sind entscheidend für die Sicherheit und Zuverlässigkeit der Geräte, die mit Butan, Propan oder deren Mischungen betrieben werden. Die Spezifikationen in diesem Dokument sind besonders relevant, da sie die Konstruktions- und Betriebseigenschaften, die Sicherheitsanforderungen sowie die Prüfmethoden und die Kennzeichnung der Regler detailliert definieren. Ein herausragender Aspekt des Standards ist die Berücksichtigung der Sicherheitsgeräte, die in den Reglern integriert sind. Die in den Anhängen A und B beschriebenen Eigenschaften dieser Sicherheitsvorrichtungen sorgen dafür, dass die Benutzer auf die verschiedenen Sicherheitsmechanismen aufmerksam gemacht werden, die die sichere Nutzung dieser Regler gewährleisten. Diese zusätzlichen Informationen sind für die Konstrukteure und Hersteller von Reglern von unschätzbarem Wert. Der Standard legt auch spezifische Anforderungen für den Temperaturbereich fest, in dem die Regler verwendet werden können. Die Angabe eines Einsatztemperaturbereichs von -20 °C bis +50 °C macht ihn besonders vielgestaltig und anpassungsfähig. Für Anwendungen in extremen Temperaturen unter -20 °C sind spezielle Anforderungen definiert, die in Anhang C erläutert werden. Dies zeigt das Engagement des Standards, sowohl die Sicherheit als auch die Funktionalität unter einer Vielzahl von Betriebsbedingungen zu garantieren. Ebenso stärkt die klare Trennung zwischen den normativen Vorschriften und den Informationen zur Verbindungstechnik, wie sie in den Anhängen G und H dargestellt sind, die Benutzerfreundlichkeit des Dokuments. Die normative Klassifikation erleichtert es den Herstellern, sich an die spezifischen Anforderungen je nach Land zu halten, was die Einhaltung nationaler Vorschriften unterstützt. Zusammenfassend lässt sich sagen, dass der Standard EN 13785:2005+A1:2008 durch seine detaillierten Anforderungen und Sicherheitsvorschriften sowohl für Hersteller als auch für Anwender von Reglern von großer Bedeutung ist. Die Einhaltung dieser Norm verbessert nicht nur die Sicherheit, sondern auch die Effizienz im Betrieb von Geräten in der Gasversorgung, was ihn zu einem unverzichtbaren Dokument in dieser Branche macht.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...