prEN 544 rev

(Main)Bitumen shingles with mineral and/or synthetic reinforcements - Product specification and test methods

Bitumen shingles with mineral and/or synthetic reinforcements - Product specification and test methods

This document specifies the properties, performance and methods of test of the finished bitumen shingles prior to them being laid on the roof.

It also includes rules for marking, labelling and provides a clause for assessment and verification of constancy of performance (AVCP).

This document does not include design requirements, installation techniques and roof system performance.

This document applies to bitumen shingles where the watertightness of the system is ensured by overlapping, by different adhesive systems or a combination of these, according to manufacturer’s installation instructions, intended to be laid as covering for pitched roofs and/or wall cladding.

This document applies only to bitumen shingles with a mineral reinforcement, synthetic reinforcement or a mixture of the two.

This document covers shingles with a minimum mass of bitumen of 1 300 g/m2 in case of monolayer shingles and 1 500g/m2 in case of multilayer shingle.

In case of multilayer shingles each layer need to have the same type of reinforcement and same type of coating (ref. to Clause 8).

Bitumenschindeln mit mineralhaltiger Einlage und/oder Kunststoffeinlage - Produktspezifikation und Prüfverfahren

Dieses Dokument legt die Eigenschaften, Leistungsmerkmale und Prüfverfahren für fertige Bitumenschindeln vor der Verlegung auf dem Dach fest.

Ferner enthält es Regeln für die Kennzeichnung und die Beschriftung sowie einen Abschnitt zur Bewertung und Überprüfung der Leistungsbeständigkeit [AVCP (en: Assessment and Verification of the Constancy of Performance)].

Dieses Dokument enthält weder Anforderungen an die Gestaltung noch Hinweise zu Verlegetechniken oder zur Leistung von Dachsystemen.

Dieses Dokument gilt für Bitumenschindeln, die dafür vorgesehen sind, als Eindeckung für geneigte Dächer und/oder als Außenwandverkleidungen eingesetzt zu werden. Die Wasserdichtheit des Systems wird entsprechend den Verlegeanweisungen des Herstellers durch die Überlappung, durch verschiedene Klebesysteme oder durch eine Kombination daraus sichergestellt.

Dieses Dokument gilt nur für Bitumenschindeln mit mineralhaltiger Einlage, Kunststoffeinlage oder einer Mischung aus beiden.

Dieses Dokument gilt für Schindeln mit einer Mindestbitumenmasse von 1 300 g/m2 bei einlagigem Aufbau und 1 500g/m2 bei mehrlagigem Aufbau.

Im Falle von Schindeln mit mehrlagigem Aufbau muss jede Lage die gleiche Art von Einlage und die gleiche Art von Beschichtung aufweisen (siehe Abschnitt 8).

Bardeaux bitumés avec armature minérale et/ou synthétique - Spécifications des produits et méthodes d'essai

Le présent document établit les caractéristiques, les performances et les méthodes d'essai des bardeaux bitumés finis avant leur mise en oeuvre sur le toit.

Il inclut également les règles de marquage et d'étiquetage et prévoit un article traitant de l'évaluation et de la vérification de la constance des performances (EVCP).

Le présent document ne comprend pas les exigences de conception, les méthodes d'installation et les performances des toitures.

Le présent document s'applique aux bardeaux bitumés dont l'étanchéité de la toiture est assurée par recouvrement, par différents systèmes adhésifs ou par une combinaison des deux, selon les instructions d'installation du fabricant, et qui sont destinés à être posés comme couverture de toitures en pente et/ou bardage.

Le présent document s'applique uniquement aux bardeaux bitumés avec armature minérale, armature synthétique ou un mélange des deux.

Le présent document concerne les bardeaux dont la masse minimale de bitume est de 1 300 g/m2 pour un bardeau monocouche et de 1 500 g/m2 pour un bardeau multicouche.

En cas de bardeaux multicouches, chaque couche doit avoir le même type d'armature et le même type de couverture (se reporter à l'Article 8).

Bitumenske skodle, ojačene z mineralnimi in/ali sintetičnimi materiali - Specifikacije za proizvod in preskusne metode

General Information

- Status

- Not Published

- Publication Date

- 24-Jan-2022

- Withdrawal Date

- 24-Jul-2022

- Technical Committee

- CEN/TC 128 - Roof covering products for discontinuous laying and products for wall cladding

- Drafting Committee

- CEN/TC 128/SC 6 - Bitumen shingles and corrugated sheets for roofing

- Current Stage

- 4060 - Closure of enquiry - Enquiry

- Start Date

- 08-Oct-2020

- Completion Date

- 08-Oct-2020

Relations

- Effective Date

- 19-Jan-2023

Overview

The prEN 544 rev standard, developed by CEN, provides a comprehensive product specification and test methods for bitumen shingles reinforced with mineral and/or synthetic materials. This standard focuses on the properties and performance of finished bitumen shingles before they are installed on pitched roofs or used for wall cladding. Importantly, prEN 544 rev addresses material characteristics, test procedures, marking, labelling, and the assessment and verification of constancy of performance (AVCP).

This standard excludes design requirements, installation techniques, and overall roof system performance, concentrating strictly on the product specifications and testing to ensure quality and durability of bitumen shingles within the specified application scope.

Key Topics

Material Composition

Includes bitumen shingles reinforced with mineral, synthetic, or mixed reinforcements. It specifies bitumen mass minimums of 1300 g/m² for monolayer shingles and 1500 g/m² for multilayer shingles, where multilayer shingles require uniform reinforcement and coating per layer.Geometrical Properties

Defines maximum and minimum dimensions for shingles, such as a maximum width of 1200 mm and minimum height of 250 mm, with strict tolerances of ±3 mm.Mechanical Properties

Detailed requirements for tensile strength and nail shank tear resistance, critical for shingles intended for nailed roofing applications. Tensile strength minimums include 600 N/50 mm in the width/fabrication direction and 400 N/50 mm perpendicular to it, with nail tear resistance exceeding 100 N.Durability Tests

Standards for resistance to UV radiation and blistering ensure long-term performance. UV resistance testing guarantees shingles do not crack or fissure under simulated environmental exposure.Fire Performance

Fire classification tests follow EN 13501-1 and EN 13501-5, providing evaluation criteria for roofs subject to external fire exposure.Marking and Labelling Requirements

The standard includes clear rules for product designation, marking, and labelling so that manufacturers and users can identify and verify product characteristics and compliance effectively.Assessment and Verification of Constancy of Performance (AVCP)

Specifies factory production control requirements and type testing frequencies ensuring consistent product quality.

Applications

Pitched Roofing Covers

Bitumen shingles manufactured under prEN 544 rev are designed for durable weatherproof coverage on inclined roofs, ensuring watertightness through overlapping and adhesive systems per manufacturer instructions.Wall Cladding

The standard also applies to shingles intended as protective and decorative cladding for pitched or vertical surfaces.Building Construction and Renovation

Ideal for architects, builders, roofing contractors, and manufacturers who require detailed product performance standards to meet regulatory and quality assurance demands in European markets.Quality Control and Certification

This document assists manufacturers in establishing production processes compliant with European norms and facilitates certification processes for construction materials under the Construction Products Regulation (EU No. 305/2011).

Related Standards

- EN 1110:2010 – For determining flow resistance to elevated temperatures in bitumen sheets.

- ENV 1187 – Test methods for external fire exposure of roofs.

- EN 1297:2004 – Artificial aging of waterproofing sheets through UV radiation, temperature, and water.

- EN 12039:2016 – Adhesion testing of mineral granules on bitumen sheets.

- EN 12310-1:1999 & EN 12311-1:1999 – Mechanical properties testing for tensile strength and tear resistance.

- EN 13501-1:2018 & EN 13501-5:2016 – Fire classification testing for construction products and external roof fire exposure.

By referencing these complementary standards, prEN 544 rev ensures a cohesive approach to evaluating and certifying bitumen shingles, supporting superior roofing products that meet safety and performance benchmarks.

Keywords: bitumen shingles specification, mineral reinforcement, synthetic reinforcement, roofing shingles test methods, pitched roof shingles, bitumen mass standard, tensile strength shingles, roofing durability standards, AVCP in roofing, CEN roofing standards, fire resistance roofing materials, European bitumen shingles standard.

Frequently Asked Questions

prEN 544 rev is a draft published by the European Committee for Standardization (CEN). Its full title is "Bitumen shingles with mineral and/or synthetic reinforcements - Product specification and test methods". This standard covers: This document specifies the properties, performance and methods of test of the finished bitumen shingles prior to them being laid on the roof. It also includes rules for marking, labelling and provides a clause for assessment and verification of constancy of performance (AVCP). This document does not include design requirements, installation techniques and roof system performance. This document applies to bitumen shingles where the watertightness of the system is ensured by overlapping, by different adhesive systems or a combination of these, according to manufacturer’s installation instructions, intended to be laid as covering for pitched roofs and/or wall cladding. This document applies only to bitumen shingles with a mineral reinforcement, synthetic reinforcement or a mixture of the two. This document covers shingles with a minimum mass of bitumen of 1 300 g/m2 in case of monolayer shingles and 1 500g/m2 in case of multilayer shingle. In case of multilayer shingles each layer need to have the same type of reinforcement and same type of coating (ref. to Clause 8).

This document specifies the properties, performance and methods of test of the finished bitumen shingles prior to them being laid on the roof. It also includes rules for marking, labelling and provides a clause for assessment and verification of constancy of performance (AVCP). This document does not include design requirements, installation techniques and roof system performance. This document applies to bitumen shingles where the watertightness of the system is ensured by overlapping, by different adhesive systems or a combination of these, according to manufacturer’s installation instructions, intended to be laid as covering for pitched roofs and/or wall cladding. This document applies only to bitumen shingles with a mineral reinforcement, synthetic reinforcement or a mixture of the two. This document covers shingles with a minimum mass of bitumen of 1 300 g/m2 in case of monolayer shingles and 1 500g/m2 in case of multilayer shingle. In case of multilayer shingles each layer need to have the same type of reinforcement and same type of coating (ref. to Clause 8).

prEN 544 rev is classified under the following ICS (International Classification for Standards) categories: 91.100.50 - Binders. Sealing materials. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 544 rev has the following relationships with other standards: It is inter standard links to EN 544:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 544 rev is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/121, M/122. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase prEN 544 rev directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2020

Bitumenske skodle, ojačene z mineralnimi in/ali sintetičnimi materiali -

Specifikacije za proizvod in preskusne metode

Bitumen shingles with mineral and/or synthetic reinforcements - Product specification

and test methods

Bitumenschindeln mit mineralhaltiger Einlage und/oder Kunststoffeinlage -

Produktspezifikation und Prüfverfahren

Bardeaux bitumés avec armature minérale et/ou synthétique - Spécifications des

produits et méthodes d'essai

Ta slovenski standard je istoveten z: prEN 544

ICS:

91.060.20 Strehe Roofs

91.100.50 Veziva. Tesnilni materiali Binders. Sealing materials

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

prEN 544

NORME EUROPÉENNE

EUROPÄISCHE NORM

July 2020

ICS 91.100.50 Will supersede EN 544:2011

English Version

Bitumen shingles with mineral and/or synthetic

reinforcements - Product specification and test methods

Bardeaux bitumés avec armature minérale et/ou Bitumenschindeln mit mineralhaltiger Einlage

synthétique - Spécifications des produits et méthodes und/oder Kunststoffeinlage - Produktspezifikation und

d'essai Prüfverfahren

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 128.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 544:2020 E

worldwide for CEN national Members.

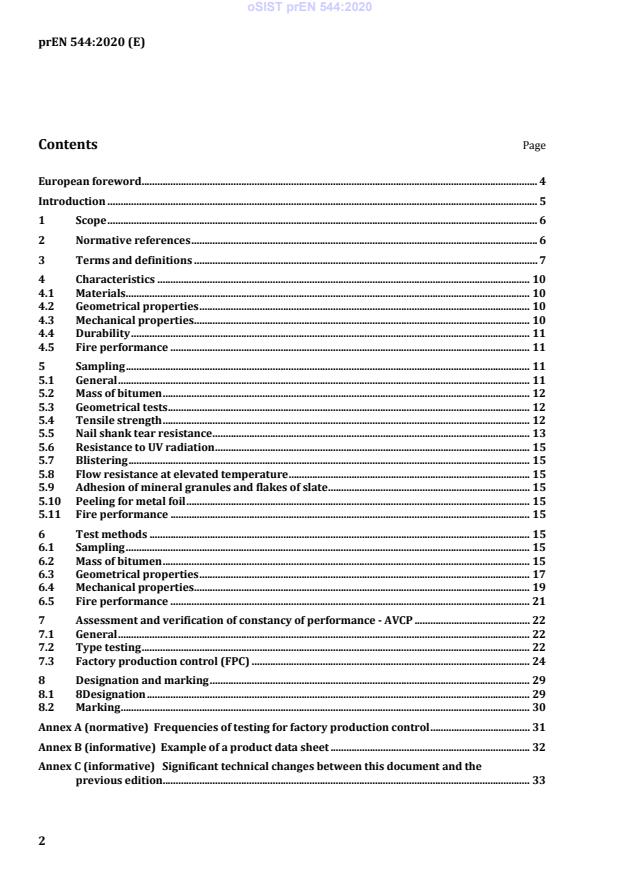

prEN 544:2020 (E)

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Characteristics . 10

4.1 Materials . 10

4.2 Geometrical properties . 10

4.3 Mechanical properties . 10

4.4 Durability . 11

4.5 Fire performance . 11

5 Sampling . 11

5.1 General . 11

5.2 Mass of bitumen . 12

5.3 Geometrical tests . 12

5.4 Tensile strength . 12

5.5 Nail shank tear resistance . 13

5.6 Resistance to UV radiation . 15

5.7 Blistering . 15

5.8 Flow resistance at elevated temperature . 15

5.9 Adhesion of mineral granules and flakes of slate . 15

5.10 Peeling for metal foil . 15

5.11 Fire performance . 15

6 Test methods . 15

6.1 Sampling . 15

6.2 Mass of bitumen . 15

6.3 Geometrical properties . 17

6.4 Mechanical properties . 19

6.5 Fire performance . 21

7 Assessment and verification of constancy of performance - AVCP . 22

7.1 General . 22

7.2 Type testing . 22

7.3 Factory production control (FPC) . 24

8 Designation and marking . 29

8.1 8Designation . 29

8.2 Marking . 30

Annex A (normative) Frequencies of testing for factory production control . 31

Annex B (informative) Example of a product data sheet . 32

Annex C (informative) Significant technical changes between this document and the

previous edition . 33

prEN 544:2020 (E)

Annex D (informative) Use of symbols . 34

Annex ZA (informative) Relationship of this European Standard with Regulation (EU)

No.305/2011 . 38

Bibliography . 43

prEN 544:2020 (E)

European foreword

This document (prEN 544:2020) has been prepared by Technical Committee CEN/TC 128 “Roof

covering products for discontinuous laying and products for wall cladding”, the secretariat of which is

held by NBN.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 544:2011.

In comparison with the previous edition, the technical modifications that have been made are detailed

in Annex C.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association.

For relationship with EU Regulation(s), see informative Annex ZA, which is an integral part of this

document.

prEN 544:2020 (E)

Introduction

The performance of a roof covering manufactured from these products depends not only on the

properties of the product as specified in this document, but also on the design, application and

performance of the roof considered as a whole, in conjunction with the environment and conditions of

use.

prEN 544:2020 (E)

1 Scope

This document specifies the properties, performance and methods of test of the finished bitumen

shingles prior to them being laid on the roof.

It also includes rules for marking, labelling and provides a clause for assessment and verification of

constancy of performance (AVCP).

This document does not include design requirements, installation techniques and roof system

performance.

This document applies to bitumen shingles where the watertightness of the system is ensured by

overlapping, by different adhesive systems or a combination of these, according to manufacturer’s

installation instructions, intended to be laid as covering for pitched roofs and/or wall cladding.

This document applies only to bitumen shingles with a mineral reinforcement, synthetic reinforcement

or a mixture of the two.

This document covers shingles with a minimum mass of bitumen of 1 300 g/m in case of monolayer

shingles and 1 500g/m in case of multilayer shingle.

In case of multilayer shingles each layer need to have the same type of reinforcement and same type of

coating (ref. to Clause 8).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1110:2010, Flexible sheets for waterproofing - Bitumen sheets for roof waterproofing - Determination

of flow resistance at elevated temperature

ENV 1187, Test methods for external fire exposure to roofs

EN 1297:2004, Flexible sheets for waterproofing - Bitumen, plastic and rubber sheets for roof

waterproofing - Method of artificial ageing by long term exposure to the combination of UV radiation,

elevated temperature and water

EN 12039:2016, Flexible sheets for waterproofing - Bitumen sheets for roof waterproofing -

Determination of adhesion of granules

EN 12310-1:1999, Flexible sheets for waterproofing - Part 1: Bitumen sheets for waterproofing -

Determination of resistance to tearing (nail shank)

EN 12311-1:1999, Flexible sheets for waterproofing - Part 1: Bitumen sheets for roof waterproofing -

Determination of tensile properties

EN 13501-1:2018, Fire classification of construction products and building elements — Part 1:

Classification using data from reaction to fire tests

EN 13501-5:2016, Fire classification of construction products and building elements - Part 5:

Classification using data from external fire exposure to roofs tests

prEN 544:2020 (E)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

shingle

reinforced flat bitumen material, of a global rectangular shape, of width W and height H, having or not

bitumen adhesive points or areas

Note 1 to entry: This material can have a solid part and several tabs.

Note 2 to entry: These tabs can be rectangular and separated by slits of height h1 (see Figure 1).

Note 3 to entry: This material can be composed out of one layer (monolayer shingle) or several layer

(multilayer or laminated shingles).

Note 4 to entry: In case of multilayer shingles, the layers are bonded by an adhesive and the overlapping of the

lower layer by the upper layer in the visible part will amount to a minimum of 40 %.

a) Example of monolayer shingle

b) Example of monolayer shingle

prEN 544:2020 (E)

c) Example of monolayer shingle

d) Example of multilayer shingle

Key

H height

W width

h height of slits

Figure 1 — Different shapes of shingles

3.2

tab

part of the flat material separated by slits and intended to be visible on the roof

3.3

slit

gap separating the tabs

3.4

reinforcement

substance incorporated into the bitumen material ensuring its dimensional stability and mechanical

resistance

3.5

impregnation

saturation of the reinforcement by bitumen

prEN 544:2020 (E)

3.6

mass of bitumen

bitumen or modified bitumen (in general all material soluble in the test described in 6.2) used for

impregnation, coating and adhesive if any

3.7

upperside surfacing

factory-applied protection of the face of the material exposed to the weather provided by, for example,

mineral granules, flakes of slate or a metal foil

3.8

underside surfacing

factory-applied protection of the concealed underside of the material, either continuous or

discontinuous, by means of sand, talc, paper, plastic film or any other material

3.9

adhesive point; strip

point, or continuous or discontinuous strip, intended to ensure the adhesion of the tabs after

installation on the roof

3.10

self-adhesive area

self-adhesive area intended to ensure adhesion of the tabs to the lower course of shingles to contribute

to water tightness

3.11

protection strip

plastic film or non-adhesive paper intended to prevent the self-adhesive points or areas from sticking

prior to being laid on the roof

3.12

guiding tab or cuts

small extension/indentations or cuts at the edge of the shingle to allow for proper alignment during

application

3.13

blister

elevation of the surface of varied contour and dimensions, with a cavity beneath it

3.14

production batch

amount of product manufactured to the same specification within a maximum period of 24 h for each

production line

3.15

manufacturer's limiting value

MLV

value stated by the manufacturer to be met during testing

Note 1 to entry: The manufacturer’s limiting value can be a minimum or a maximum value according to

statements made under product characteristics of this document.

prEN 544:2020 (E)

4 Characteristics

4.1 Materials

4.1.1 Mass of bitumen

When measured according to 6.2, the minimum mass of bitumen shall be 1 300 g/m , in case of

monolayer shingle and 1 500 g/m in case of multilayer shingle.

4.1.2 Upperside surfacing

The upperside surfacing shall be continuous, adhered to the bitumen and shall not reveal any bitumen

which might spoil the appearance and durability of the product.

This upperside surfacing shall protect the bitumen from UV radiation.

4.1.3 Underside surfacing

Underside surfacing shall be such that the shingles may be removed individually from their packaging

without being damaged.

4.2 Geometrical properties

4.2.1 Shapes

The overall dimensions ignoring any guiding tabs and indents, when measured according to 6.3, shall be

as follows:

— Width W : maximum 1 200 mm;

— Height H : minimum 250 mm.

The tolerances on dimensions W and H (see Figure 1) declared by the manufacturers, measured in

accordance with 6.3.2 and 6.3.3, shall be:

— ± 3 mm on width W;

— ± 3 mm on height H.

4.2.2 Surface of overlapping

The minimum surface of overlapping of multilayer shingles in the visible part should be 40 %.

4.3 Mechanical properties

4.3.1 Tensile strength

Measured under the test conditions described in 6.4.1, the minimum tensile strength shall be as shown

in Table 1.

Table 1 — Minimum tensile strength

In the direction of the shingle width or

600 N / 50 mm

direction of fabrication

In the direction of the shingle height or

perpendicular to the direction of 400 N / 50 mm

fabrication

prEN 544:2020 (E)

4.3.2 Nail shank tear resistance

Measured under the test conditions described in 6.4.2, the minimum value of the tear resistance shall be

100 N.

This characteristic only applies to materials intended to be nailed.

4.4 Durability

4.4.1 Resistance to UV radiation

Measured under the test conditions described in 6.4.3, there shall be no cracking or fissuring.

4.4.2 Resistance to blistering

Resistance to blistering test is only relevant for shingles with other reinforcement than type 3, type 4,

type 6 or type 7 (see 8.1).

Measured under the test conditions described in 6.4.4, there shall not be any blisters on the shingle

surface.

4.4.3 Flow resistance at elevated temperature

Measured under the test conditions described in 6.4.5, the flow resistance shall be less than or equal to

2 mm for each test piece.

4.4.4 Adhesion of mineral granules or flakes of slate

Where the top surface of the shingle is protected with embedded mineral granules, the granule

adhesion shall be determined in accordance with 6.4.6.

Each value shall be below the manufacturer’s limited value (maximum value) and shall not exceed 2,5 g.

4.4.5 Resistance to peeling for metal-surfaced shingles

Measured under the test conditions described in 6.4.7, the resistance shall be at least 0,2 N/mm for each

test piece.

4.5 Fire performance

4.5.1 Reaction to fire

This characteristic shall be declared when subject to regulatory requirements and may be declared

otherwise. When declared, the reaction to fire shall be tested and classified in accordance with 6.5.1.

4.5.2 External fire performance

This characteristic shall be declared when subject to regulatory requirements and may be declared

otherwise. When declared, the external fire performance shall be assessed according to 6.5.2.

5 Sampling

5.1 General

5.1.1 Cutting of test pieces

The test pieces shall be taken from different shingles chosen at random.

prEN 544:2020 (E)

Test pieces are cut using a cutting tool or hollow punch, as far as possible excluding hand-held scissors,

avoiding, for some particular tests, self-adhesive areas with their protective film or paper.

5.1.2 Marking of test pieces

Every test piece shall have on its underside:

— reference identifying the batch from which the test sample was taken;

— where appropriate, a reference identifying the direction of cutting, if this is specified in the

procedures described below.

5.2 Mass of bitumen

For the measurement of the mass of the bitumen, three test pieces of (50 × 100) mm shall be cut from

different shingles.

The test pieces shall be cut from the exposed area with adhesive system if any.

In case of multilayer shingles, two test pieces shall be taken one from the monolayer part and one from

the multilayer part of the shingles.

5.3 Geometrical tests

5.3.1 Shapes

For the measurement of length and width five different shingles chosen at random shall be taken.

5.3.2 Surface of overlapping of multilayer shingles

To measure the minimum surface of overlapping, take three different shingles chosen at random.

5.4 Tensile strength

For the measurement of the tensile strength, cut two series of test pieces from different shingles:

— five in the direction of width,

— five in the direction of height.

These test pieces shall have dimensions 50 mm × minimum 250 mm.

prEN 544:2020 (E)

Key

H height

W width

h height of slits

Figure 2 — Multilayer shingle

5.5 Nail shank tear resistance

The nail shank tear resistance shall be determined in accordance with EN 12310-1 parallel to the

shingle height.

For the measurement of nail shank tear resistance, cut five test pieces from different shingles in

direction of height. These test pieces shall have a dimension of 50 mm × minimum 150 mm (50 mm in

the direction of width and minimum 150 mm in the direction of height).

The nail position in the test specimen shall be at the vertical height corresponding to the intended

nailing position in the manufacturer‘s installation instructions (see Figure 3).

It is essential to apply the nail in the test to the same vertical position as presented in the installation

instructions of the product.

prEN 544:2020 (E)

a) Nail position with single layer shingles

b) Nail position with multilayers shingles

Key

1 nailing position according to the instructions given in 5.5

2 nailing of the sample

H height

W width

h height of slits

Figure 3 — Example of cutting the sample for the resistance to tearing (nail shank) test

prEN 544:2020 (E)

5.6 Resistance to UV radiation

For testing of resistance to UV radiation, cut one test piece from the shingle, of minimum 200 mm in the

direction of width and minimum 50 mm in the direction of height.

5.7 Blistering

For the measurement of blistering, cut five test pieces of (125 × 225) mm from different shingles.

5.8 Flow resistance at elevated temperature

For the measurement of flow resistance, cut five test pieces of (100 × 115) mm from the exposed area

of different shingles.

5.9 Adhesion of mineral granules and flakes of slate

For the measurement of the granules and flakes of slate adhesion, cut five test pieces more than

(285 × 50) mm from the area of the shingle which is intended to be exposed on the roof, 10 mm away

from the side edges, with the 285 mm dimension being in the direction of shingle width.

If the dimension of the exposed area is not large enough, the test specimen shall be composed of two

parts joined together.

In case of multilayer shingles, the test shall be performed on each layer.

5.10 Peeling for metal foil

For the measurement of peeling, cut five test pieces of (100 × 200) mm from different shingles.

5.11 Fire performance

5.11.1 Reaction to fire

For reaction fire testing sufficient shingles shall be chosen to allow either the test specimen to be

prepared or for test pieces to be cut.

5.11.2 External fire performance

For external fire performance sufficient shingles shall be chosen to form the test specimen.

6 Test methods

6.1 Sampling

All sampling shall be in accordance with Clause 5.

6.2 Mass of bitumen

6.2.1 General

Two different tests methods are available for the determination of the mass of bitumen:

— Extraction method,

— Calcination method.

prEN 544:2020 (E)

6.2.2 Extraction method

6.2.2.1 Test conditions

Temperature : (23 ± 2) °C,

relative humidity : (50 ± 20) % RH,

test piece conditioning : minimum 2 h.

6.2.2.2 Equipment

— Soxhlet extractor or similar,

— balance accurate to ± 0,01 g,

— drying oven at controlled temperature (105 ± 2) °C,

— trichloroethylene, perchloroethylene, methylene chloride, toluene or xylene solvents.

6.2.2.3 Procedure

The test piece is placed in a container (the test piece may be cut into strips provided that any fragment

of material which become detached are recovered and placed in the container) which has been

previously dried and weighed (M ) and provided with a cotton plug or other appropriate closure.

Reweigh the container with the test piece and the closure (M ) and place in the extractor. Arrange so

that the opening fitted with the closure projects beyond the level of the solvent.

Continue the extraction until the solvent is colourless in the extractor.

Remove the container for drying, initially in air (30 min), then in a drying oven controlled at a

temperature of (105 ± 2) °C until a constant mass for the sample is achieved (constant mass means that

the difference between two consecutive weightings is less than or equal to 0,05 g).

Weigh the container fitted with the closure (M ).

Repeat this procedure for the two remaining test pieces.

6.2.2.4 Expression of results

In the extraction test, the following masses are determined for each test piece:

— test piece M – M ,

2 1

— mass of bitumen M – M .

2 3

For each test piece, express the final result in grams per square metre. Calculate the arithmetic mean

value of the test specimens (three for monolayer and two for multilayer).

6.2.3 Calcination method

6.2.3.1 Test conditions

Test piece conditioning : 2 h.

prEN 544:2020 (E)

6.2.3.2 Equipment

— Calcination oven at controlled temperature (575 ± 25) °C,

— balance accurate to ± 0,01 g,

6.2.3.3 Procedure

The test piece is placed in a container which has previously dried. Put the test piece in the container and

weigh them together (P1).

Put the sample with the container in a calcinating oven at 600°C for 2 h.

After, weigh the sample with the container (P2).

Repeat this procedure for the two remaining test pieces.

6.2.3.4 Expression of results

In the ashing test, the masses are determined for each test piece:

Mass of bitumen: P1 – P2.

For each test piece, express the final result in grams per square metre. Calculate the arithmetic mean

value of the test specimens (three for monolayer and two for multilayer).

6.3 Geometrical properties

6.3.1 Equipment

The equipment shall give a result with an accuracy of at least ± 0,5 mm.

6.3.2 Check on widths

6.3.2.1 Procedure

Widths W and W (see Figure 4) shall be measured.

1 2

prEN 544:2020 (E)

Figure 4 — Check on widths

6.3.2.2 Expression of results

The results shall be expressed as the two individual measurements rounded to the nearest millimetre.

Each value shall be compared with the dimensional requirements.

6.3.3 Check on heights

6.3.3.1 Procedure

Heights H and H (see Figure 5) shall be measured.

1 2

Figure 5 — Check on heights

6.3.3.2 Expression of results

The results shall be expressed as the two individual measurements rounded to the nearest millimetre.

Each value shall be compared with the dimensional requirements.

prEN 544:2020 (E)

6.3.4 Surface of multilayer overlapping

6.3.4.1 Procedure

The measurement of the value 1 to 4 have to be taken in the middle of the height of the exposed area

(X). See Figure 6.

Figure 6 — Measurement

6.3.4.2 Expression of result

The sum of the widths 1 to 4 shall be more than 40 % of (W).

6.4 Mechanical properties

6.4.1 Tensile strength

6.4.1.1 Procedure

The procedure shall be in accordance with EN 12311-1.

6.4.1.2 Expression of results

Record the maximum value at break and the elongation recorded at break for each of the five test pieces

in the direction of the width and height.

Calculate the arithmetic mean of the five tests in each direction.

6.4.2 Nail shank tear resistance

6.4.2.1 Test conditions, equipment and procedure

Test conditions, equipment and procedure shall be in accordance with EN 12310-1.

6.4.2.2 Expression of results

Record the maximum resistance force for each test.

Calculate the arithmetic mean of the five tests carried out in the height direction.

prEN 544:2020 (E)

NOTE This test does not give results directly corresponding to the application conditions in practice. The

total number of nails to bond one shingle and how the nails are applied vary from one product to another.

6.4.3 Resistance to UV radiation

6.4.3.1 Test conditions and equipment

Test conditions and equipment shall be in accordance with EN 1297.

6.4.3.2 Procedure

The procedure shall be in accordance with EN 1297 with 60 cycles.

6.4.3.3 Expression of results

The surface appearance shall be observed to determine whether cracking or fissuring has occurred.

6.4.4 Resistance to blistering

6.4.4.1 Test conditions and equipment

— Ventilated oven at (80 ± 2) °C,

— water bath at (23 ± 2) °C.

6.4.4.2 Procedure

The test specimens shall be conditioned at (23 ± 2) °C for a minimum of 16 h.

Place the test piece in the oven at 80 °C for (110 ± 3) min and immediately immerse the test piece in the

water bath at (23 ± 2) °C for (10 ± 1) min. Repeat these operations for a further three cycles, i.e. a total

of 8 h. Keep the test piece immersed in water (16 ± 1) h. Perform this heating and immersion three

times, i.e. a total of three days.

6.4.4.3 Expression of results

The surface appearance shall be observed to determine whether blistering has occurred.

6.4.5 Flow resistance at elevated temperature

6.4.5.1 Test conditions and equipment

Test conditions and equipment shall be in accordance with EN 1110, the only difference being:

— oven temperature (90 ± 2) °C.

6.4.5.2 Procedure

The procedure shall be in accordance with EN 1110, with the particular test conditions described in

6.4.6.1.

6.4.5.3 Expression of results

The flow resistance shall be expressed in millimetres for each test piece.

prEN 544:2020 (E)

6.4.6 Adhesion of mineral granules and flakes of slate

6.4.6.1 Test conditions and equipment

Test conditions and equipment shall be in accordance with EN 12039.

6.4.6.2 Procedure

The procedure shall be in accordance with EN 12039.

6.4.6.3 Expression of results

Determine the loss of granules or flakes of slate: mass in grams.

6.4.7 Resistance to peeling metal foil

6.4.7.1 Test conditions and equipment

Test conditions and equipment shall be in accordance with EN 12311-1. In addition a spatula is needed.

6.4.7.2 Procedure

Start delamination of the metal foil by pushing a hot spatula into the product to a depth of about 20 mm.

Continue the delamination of the metal foil with the help of the hot spatula to obtain about 120 mm of

delaminated metal foil.

Clamp the delaminated metal foil in one of the grips of the tensile machine.

Clamp the opposite edge without metal foil in the other grip, protecting the grip with paper or similar.

Peel the metal foil off the shingle at 180°.

6.4.7.3 Expression of results

Calculate the arithmetic mean value in N/mm of the peeling force test.

6.5 Fire performance

6.5.1 Reaction to fire

The reaction to fire of bitumen shingles shall be tested and classified in accordance with the provisions

of EN 13501-1. Where a specific test method requires it, products shall be mounted and fixed in the test

apparatus in a manner representative of the product's intended end use conditions.

6.5.2 External fire performance

The external fire performance of bitumen shingles shall be tested according to one or more of the

methods described in ENV 1187 and shall be classified in accordance with the provisions of

EN 13501-5. Products shall be mounted and fixed in the test apparatus in a manner representative of

the product's intended end use conditions.

prEN 544:2020 (E)

7 Assessment and verification of constancy of performance - AVCP

7.1 General

The compliance of bitumen shingles with mineral and/or synthetic reinforcements with the

requirements of this standard and with the declared values shall be demonstrated by:

— determination of the product type;

— factory production control by the manufacturer, including product assessment.

The manufacturer shall always retain the overall control and shall have the necessary means to take

responsibility for the product.

7.2 Type testing

7.2.1 General

All the performances related to characteristics included in this standard other than the essential

characteristic may be determined when the manufacturer claims compliance with them, unless the

standard gives provisions for declaring them without performing tests (e.g. use of previously existing

data, CWFT and conventionally accepted performance).

For the purposes of testing, the manufacturer's products may be grouped into families, where it is

considered that the results for one or more characteristics from any one product within the family are

representative for that same characteristics for all products within that same family

Tests previously performed in accordance with the provisions of this standard, may be taken into

account provided that they were made to the same or a more rigorous test method, under the same

AVCP system on the same product or products of similar design, construction and functionality, such

that the results are applicable to the product in question.

Note: Products may be in different families for different characteristics.

Note: Reference to the test method standards should be made to allow the selection of a suitable

representative sample.

In addition, the determination of the product type shall be performed for all characteristics included in

the standard for which the manufacturer declares performances:

— at the beginning of the production of a new or modified bitumen shingles with mineral and/or

synthetic reinforcements (unless a member of the same family), or

— at the beginning of a new or modified method of production (where this may affect the stated

properties); or

they shall be repeated for the appropriate characteristic(s), whenever a change occurs in the bitumen

shingles with mineral and/or synthetic reinforcements design, in the raw material or in the supplier of

the components, or in the production process (subject to the definition of a family), which would affect

significantly one or more of the characteristics.

Where components are used whose characteristics have already been determined, by the component

manufacturer, on the basis of compliance with other product standards, these characteristics need not

be re-assessed. The specifications of these components shall be documented, as shall be included in the

inspection scheme for ensuring their compliance.

Products marked in accordance with appropriate harmonized European specifications may be

presumed to have the performances stated with the marking, although this does not replace the

prEN 544:2020 (E)

responsibility on the bitumen shingles with mineral and/or synthetic reinforcements designer to

ensure that the bitumen shingles with mineral and/or synthetic reinforcements as a whole is correctly

designed and its component products have the necessary performance values to meet the design.

7.2.2 Test samples, testing and compliance criteria

The number of samples of bitumen shingles with mineral and/or synthetic reinforcements to be

tested/assessed shall be in accordance with Table 2.

Table 2 — Number of samples to be tested and compliance criteria

Product characteristic Clause Minimum frequencies of testing per

production week month year

batch

Mass of bitumen 6.2 1

Height and width 6.3 1

b

Tensile strength 6.4.1 1

b

Nail shank tear resistance 6.4.2 1

a

Resistance to UV 6.4.3 0

Blistering 6.4.4 1

Flow resistance at elevated temperature 6.4.5 1

c

Adhesion of granules and flakes of slate 6.4.6 1

Peeling of metal foil 6.4.7 1

a

Reaction to fire 6.5.1 0

a

External fire performance 6.5.2 0

a

Indirect control, e.g. of raw materials and the production process, with a frequency sufficient to ensure that

the results from initial type testing remains representative for current production. This frequency shall be given

in the manufacturer’s FPC system documentation.

b

In the case where a manufacturer is continuously producing numerous different shingles which contain the

same carrier (type and mass) and the same type of coating, the frequency of these tests which relate essentially

to the carrier, may be considered on the total number of these different shingles.

c

In the case where a manufacturer is continuously producing numerous differently reinforced shingles

and/or shingles which differ only by the presence of incorporated protection, whilst using the same type of

coating and having a similar nominal thickness, the frequency for these tests, which relate essentially to the

type of coating, may be considered on the total number of these different shingles.

7.2.3 Test reports

The results of the determination of the product type shall be documented in test reports. All test reports

shall be retained by the manufacturer for at least 10 years after the last date of production of the

bitumen shingles with mineral and/or synthetic reinforcements to which they relate.

7.2.4 Shared other party results

It is in principle applicable to all systems of assessment and evaluation of constancy of performance.

A manufacturer may use the results of the product type determination obtained by someone else (e.g.

by another manufacturer, as a common service to manufacturers, or by a product developer), hereafter

prEN 544:2020 (E)

called “other party ITT results”, to justify his own declaration of performance regarding a product that

is manufactured according to the same design (e.g. dimensions) and with raw materials, constituents

and manufacturing methods of the same kind, provided that:

— the results are known to be valid for products with the same characteristics relevant for

performance;

— in addition to any information essential for confirming that the product has such same

characteristics, the other party who has carried out the determination of the product type

concerned or has had it carried out, has expressly accepted to transmit to the manufacturer the

results and the test report to be used for the latter’s product type determination, as well as

information regarding production facilities and the production control process that can be taken

into account for FPC;

— the manufacturer using other party results accepts remaining responsible for the product being in

compliance with the declared performances;

— he ensures that the product has the same characteristics relevant for performance as the one that

has been subjected to the determination of the product type, and that there are no significant

differences with regard to production facilities and the production control process compared to

that used for the product that was subjected to the determination of the product type; and

— he keeps available a copy of the determination of the product type report that also contains the

information needed for verifying that the product is manufactured according to the same design

and with raw materials, constituents and manufacturing methods of the same kind.

7.3 Factory production control (FPC)

7.3.1 General

The manufacturer shall establish, document and maintain an FPC system to ensure that the products

placed on the market comply with the declared performance of the essential characteristics.

The FPC system shall consist of procedures, regular inspections and tests and/or assessments and the

use of the results to control raw and other incoming materials or components, equipment, the

production process and the product. All the elements, requirements and provisions adopted by the

manufacturer shall be documented in a systematic manner in the form of written policies and

procedures.

This production control system documentation shall ensure a common understanding of the evaluation

of the constancy of performance and enable the achievement of the required product performances and

the effective operation of the production control system to be checked. Factory production control

therefore brings together operational techniques and all measures allowing maintenance and control of

the compliance of the product with the declared performances of the essential characteristics.

7.3.2 Requirements

7.3.2.1 General

The manufacturer is responsible for organizing the effective implementation of the FPC system. Tasks

and responsibilities in the production control organization shall be documented and this

documentation shall be kept up-to-date.

The responsibility, authority and the relationship between personnel that manages, performs or verifies

work affecting product constancy, shall be defined. This applies in particular to personnel that needs to

prEN 544:2020 (E)

initiate actions preventing product non-constancies from occurring, actions in case of non-constancies

and to identify and register product constancy problems.

Personnel performing work affecting product constancy of performance shall be competent on the basis

of appropriate education, training, skills and experience for which records shall be maintained.

In each factory the manufacturer may delegate the action to a person having the necessary authority to:

— identify procedures to demonstrate constancy of performance of the product at appropriate stages;

— identify and record any instance of non-constancy;

— identify procedures to correct instances of non-constancy.

The manufacturer shall draw up and keep up-to-date documents defining the factory production

control. The manufacturer's documentation and procedures shoul

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...