EN 13523-8:2017

(Main)Coil coated metals - Test methods - Part 8: Resistance to salt spray (fog)

Coil coated metals - Test methods - Part 8: Resistance to salt spray (fog)

This part of The EN 13523 series specifies the procedures for determining the resistance to salt spray (fog) of an organic coating on a metallic substrate (coil coating).

For steel, neutral salt spray (fog) is usually used, and for aluminium, acetic acid salt spray (fog).

Bandbeschichtete Metalle - Prüfverfahren - Teil 8: Beständigkeit gegen Salzsprühnebel

Dieser Teil der Normenreihe EN 13523 legt das Verfahren zum Bestimmen der Beständigkeit einer organischen Beschichtung auf einem metallischen Substrat (Bandbeschichtung) gegen Salzsprühnebel fest.

Neutraler Salzsprühnebel wird im Allgemeinen für Stahl benutzt, Essigsäure Salzsprühnebel für Aluminium.

Tôles prélaquées - Méthodes d'essai - Partie 8 : Résistance au brouillard salin

La présente Partie de l’EN 13523 spécifie les modes opératoires à appliquer pour déterminer la résistance au brouillard salin d’un revêtement organique appliqué sur un subjectile métallique (prélaquage).

Pour l’acier, un brouillard salin neutre est généralement utilisé et pour l’aluminium, un brouillard salin d’acide acétique.

Prevlečene kovine, ki se navijajo - Preskusne metode - 8. del: Odpornost proti slani megli

Ta del standarda EN 13523 določa postopke za določanje odpornosti proti slani megli organske prevleke na kovinski podlagi (prevleke kovin, ki se navijajo).

Za jeklo se običajno uporablja nevtralna slana megla, za aluminij pa slana megla ocetne kisline.

General Information

- Status

- Withdrawn

- Publication Date

- 25-Jul-2017

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 139 - Paints and varnishes

- Drafting Committee

- CEN/TC 139/WG 9 - Testing of coil coated metals

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 24-Apr-2024

- Completion Date

- 14-Apr-2025

Relations

- Replaces

EN 13523-8:2010 - Coil coated metals - Test methods - Part 8: Resistance to salt spray (fog) - Effective Date

- 02-Aug-2017

- Replaced By

EN 13523-8:2024 - Coil coated metals - Test methods - Part 8: Resistance to salt spray (fog) - Effective Date

- 03-May-2023

Frequently Asked Questions

EN 13523-8:2017 is a standard published by the European Committee for Standardization (CEN). Its full title is "Coil coated metals - Test methods - Part 8: Resistance to salt spray (fog)". This standard covers: This part of The EN 13523 series specifies the procedures for determining the resistance to salt spray (fog) of an organic coating on a metallic substrate (coil coating). For steel, neutral salt spray (fog) is usually used, and for aluminium, acetic acid salt spray (fog).

This part of The EN 13523 series specifies the procedures for determining the resistance to salt spray (fog) of an organic coating on a metallic substrate (coil coating). For steel, neutral salt spray (fog) is usually used, and for aluminium, acetic acid salt spray (fog).

EN 13523-8:2017 is classified under the following ICS (International Classification for Standards) categories: 25.220.60 - Organic coatings. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13523-8:2017 has the following relationships with other standards: It is inter standard links to EN 13523-8:2010, EN 13523-8:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase EN 13523-8:2017 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

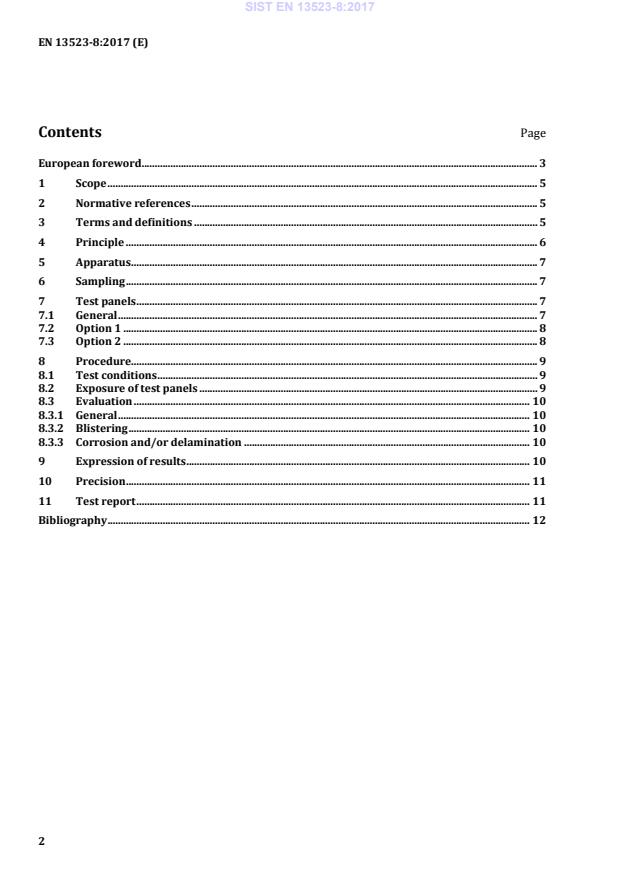

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Bandbeschichtete Metalle - Prüfverfahren - Teil 8: Beständigkeit gegen SalzsprühnebelTôles prélaquées - Méthodes d'essais - Partie 8 : Résistance au brouillard salinCoil coated metals - Test methods - Part 8: Resistance to salt spray (fog)25.220.60Organske prevlekeOrganic coatingsICS:Ta slovenski standard je istoveten z:EN 13523-8:2017SIST EN 13523-8:2017en,fr,de01-december-2017SIST EN 13523-8:2017SLOVENSKI

STANDARDSIST EN 13523-8:20111DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13523-8

July

t r s y ICS

t wä t t rä x r Supersedes EN

s u w t uæ zã t r s rEnglish Version

Coil coated metals æ Test methods æ Part

zã Resistance to Tôles prélaquées æ Méthodes d 5essais æ Partie

z ã Résistance au brouillard salin

Bandbeschichtete Metalle æ Prüfverfahren æ Teil

zã Beständigkeit gegen Salzsprühnebel This European Standard was approved by CEN on

t s May

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s y CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s u w t uæ zã t r s y ESIST EN 13523-8:2017

(IEC 60454-2) EN ISO 3696, Water for analytical laboratory use - Specification and test methods (ISO 3696) EN ISO 4628-2, Paints and varnishes - Evaluation of degradation of coatings - Designation of quantity and size of defects, and of intensity of uniform changes in appearance - Part 2: Assessment of degree of blistering (ISO 4628-2) EN ISO 4628-8:2012, Paints and varnishes - Evaluation of degradation of coatings - Designation of quantity and size of defects, and of intensity of uniform changes in appearance - Part 8: Assessment of degree of delamination and corrosion around a scribe or other artificial defect (ISO 4628-8:2012) EN ISO 9227:2017, Corrosion tests in artificial atmospheres - Salt spray tests (ISO 9227:2017) EN ISO 17872, Paints and varnishes - Guidelines for the introduction of scribe marks through coatings on metallic panels for corrosion testing (ISO

...

The EN 13523-8:2017 standard is a crucial document in the field of coil coated metals, detailing a specific test method for assessing the resistance of organic coatings on metallic substrates to salt spray (fog). The standard outlines a systematic approach to evaluate this resistance, ensuring that manufacturers adhere to uniform testing protocols that facilitate comparing and verifying the durability of different coatings used in various applications. One of the primary strengths of EN 13523-8:2017 lies in its comprehensive nature. It provides precise guidelines for testing both steel and aluminum substrates, utilizing neutral salt spray (fog) for steel and acetic acid salt spray (fog) for aluminum. This distinction not only reflects the varying properties of these metals but also reinforces the relevance of the standard across a wide range of industries that utilize coil coating technologies. Moreover, the standard's thorough methodology ensures the reproducibility of results, which is critical for manufacturers striving to meet quality assurance benchmarks. By following the prescribed procedures, companies can effectively determine the corrosion resistance of their organic coatings, leading to enhanced product reliability and customer satisfaction. The relevance of this standard cannot be overstated, especially in today's market where the longevity and performance of coated metals are paramount. EN 13523-8:2017 reinforces the importance of quality control and material testing in construction, automotive, and consumer goods industries, among others. It serves not only as a reference point for testing but also as a benchmark for product innovation and improvement, thus supporting the push toward higher industry standards. In summary, the EN 13523-8:2017 standard is a vital resource that establishes a rigorous framework for assessing the resistance of coil coatings to salt spray, ensuring that producers can deliver high-performance products that meet the evolving demands of the market. Its strengths lie in its detailed methodologies and broad applicability, making it an indispensable guide for quality assurance in coil coated metals.

La norme SIST EN 13523-8:2017 traite des méthodes d'essai pour évaluer la résistance des métaux enrobés aux embruns salins, spécifiquement pour les revêtements organiques appliqués sur des substrats métalliques. Cette partie de la série EN 13523 est cruciale pour les fabricants et utilisateurs de métaux enroulés, car elle fournit des lignes directrices claires et standardisées pour évaluer la durabilité des revêtements dans des conditions environnementales difficiles. L'un des points forts de cette norme réside dans sa capacité à établir des protocoles précis pour le test de résistance, en utilisant du brouillard salin neutre pour l'acier et du brouillard salin à l'acide acétique pour l'aluminium. Cela permet de simuler de manière réaliste les conditions d'exposition auxquelles les produits en métal enroulé peuvent être soumis. Cette méthode d'essai est essentielle pour garantir la qualité et la longévité des revêtements, contribuant ainsi à la confiance des consommateurs dans ces matériaux. En matière de pertinence, la norme SIST EN 13523-8:2017 répond à un besoin identifié dans l'industrie des revêtements et des matériaux métalliques, particulièrement dans un contexte où la durabilité et la résistance à la corrosion sont des facteurs déterminants. La normalisation des méthodes de test renforce la comparabilité des résultats entre les différents producteurs et améliore la transparence sur la performance des revêtements. Ainsi, cette norme représente une avancée significative dans la mise en œuvre de tests rigoureux pour le contrôle qualité des revêtements de métaux enroulés. Son adoption favorisera l'innovation et l'amélioration continue dans le secteur, tout en soutenant la compétition sur le marché international en assurant des standards de qualité intégrés.

SIST EN 13523-8:2017 표준은 금속 기판에서의 유기 코팅의 염수 분무(안개)에 대한 저항성을 평가하기 위한 테스트 방법을 명시하고 있습니다. 이 표준은 EN 13523 시리즈의 일부로, 코일 코팅의 내구성을 확보하는데 필수적인 정보입니다. 이 표준의 주요 강점 중 하나는 강철에 대한 중성 염수 분무와 알루미늄에 대한 아세트산 염수 분무 방법의 차별성을 다룬 것입니다. 이러한 명확한 절차는 다양한 금속 소재의 적용을 보장하며, 다양한 환경 조건에서의 내식성을 효과적으로 평가할 수 있게 합니다. 또한, SIST EN 13523-8:2017 표준은 해당 코팅이 다양한 산업 분야에서 사용될 경우 그 품질과 성능을 보장하는 데 중요한 역할을 합니다. 이 표준은 제조업체와 사용자가 최적의 내염성 코팅을 선정하고 이를 통해 제품의 내구성을 강화할 수 있도록 안내합니다. 따라서 이 표준은 코일 코팅된 금속의 품질 관리와 환경 적합성을 위한 필수적인 기준으로 자리 잡고 있으며, 산업 전반에 걸쳐 그 중요성이 더욱 부각되고 있습니다.

Die Norm EN 13523-8:2017, die sich mit der Bestimmung der Widerstandsfähigkeit gegen Salznebel (Fog) von organischen Beschichtungen auf metallischen Substraten, insbesondere im Bereich der Coil-Beschichtungen, beschäftigt, bietet einen klaren und umfassenden Ansatz zur Bewertung dieser wichtigen Eigenschaft. Die Standardisierung legt präzise Verfahren fest, die sowohl für beschichteten Stahl als auch für beschichtetes Aluminium gelten. Ein Hauptstärkenmerkmal dieser Norm ist die Differenzierung in den Testmethoden, bei denen für Stahl neutraler Salznebel und für Aluminium Salznebel mit Acetatsäure verwendet wird. Diese spezifische Anpassung an die Materialeigenschaften sorgt für relevante und realitätsnahe Testergebnisse, die für Hersteller und Anwender von beschichteten Metallen von größter Bedeutung sind. Darüber hinaus hebt sich die EN 13523-8:2017 durch ihre Relevanz in der Industrie ab. Die Widerstandsfähigkeit gegen Salznebel ist ein Schlüsselkriterium für die Langlebigkeit und Funktionalität von Oberflächenbeschichtungen in harten Umgebungen. Dies macht die Norm nicht nur zu einem unverzichtbaren Instrument für Qualitätskontrollen, sondern auch zu einem wertvollen Referenzdokument in Forschungs- und Entwicklungsprozessen. Insgesamt stellt die EN 13523-8:2017 einen wichtigen Rahmen für die Bewertung der Korrosionsbeständigkeit von Metallbeschichtungen dar und sichert so die Qualität und Zuverlässigkeit von Produkten in unterschiedlichsten Anwendungsbereichen. Die sorgfältige Made in Europe Standardisierung gewährleistet außerdem, dass die Norm international Anerkennung findet und somit die Wettbewerbsfähigkeit in einem globalisierten Markt unterstützt.

SIST EN 13523-8:2017は、金属基材に施された有機コーティングの耐塩スプレー(霧)に関するテスト方法を規定したドキュメントです。この規格は、コイルコーティングに関連する重要な指針を提供しており、特にスチールとアルミニウムのコーティングの評価において、耐久性や品質を測定するための標準化された手法を求めています。 この規格の強みは、その包括的な技術的枠組みです。中性塩スプレー(霧)の使用は、スチール素材に対するコーティングの耐食性を評価する効果的な方法であり、一方で、酢酸塩スプレー(霧)の使用はアルミニウムに特有の腐食メカニズムを考慮するためのものです。このように、異なる金属素材に対して適切なテスト方法を適用することで、実践的な信頼性を高めています。 さらに、SIST EN 13523-8:2017は、国際的な標準と整合性が取れているため、グローバルな市場における競争力向上にも寄与します。この標準を遵守することにより、製造者は製品の信頼性と品質を証明し、市場での信頼を得ることができます。 規格の適用範囲にわたるテスト方法の詳細な説明は、業界関係者にとって非常に有用です。特に、製品開発や品質管理において、コーティングの防食性能を確実に評価するための明確なガイドラインを提供しています。このように、SIST EN 13523-8:2017は、コイルコーティングされた金属製品における耐久性と性能の評価において、不可欠な役割を果たしています。それによって、業界全体の基準向上に寄与しています。

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...