ISO 23523:2021

(Main)Test methods for discrete polymer fibre for fibre-reinforced cementitious composites

Test methods for discrete polymer fibre for fibre-reinforced cementitious composites

This document specifies the test methods for discrete polymer fibre for fibre-reinforced cementitious composites (FRCC). This document defines the test methods for discrete polymer fibre, such as diameter, length, tensile strength, initial modulus of elasticity, density, melting point, moisture content and alkaline durability as basic items. These are test methods intended for certification of a fibre and not for quality control or field acceptance.

Méthodes d'essai des fibres polymères distinctes pour les composites à base de ciment renforcés par des fibres

General Information

Overview

ISO 23523:2021 - Test methods for discrete polymer fibre for fibre-reinforced cementitious composites (FRCC) - specifies standardized laboratory test methods for characterizing discrete polymer fibres used in cementitious matrices. The standard defines how to determine basic geometric, mechanical, thermal and durability properties of polymer fibres (e.g., aramid, polyamide, polyester, polyethylene, polypropylene, PVA) to support fibre certification (not quality control or field acceptance).

Key topics and requirements

ISO 23523:2021 covers test methods and reporting requirements for the following key properties:

Fibre geometry

- Diameter - consecutive fibre and chopped fibre methods

- Length - procedures and measurement reporting

Mechanical properties

- Tensile strength - specimen sampling and tensile test procedure

- Initial modulus of elasticity - determination from tensile test data

Physical properties

- Density - referenced procedures (e.g., ISO 1183 series methods)

- Moisture content - conditioning and mass-based determination under standard atmosphere (20 ± 2 °C, RH 65 ± 4 %)

Thermal and durability properties

- Melting point - thermal analysis referenced (e.g., DSC per ISO 11357-3)

- Alkaline durability - exposure procedures, tensile retentions, calculations and reporting

Test documentation

- Sampling, conditioning, apparatus requirements, calculation methods and standardized test reports for certification purposes.

The standard emphasizes properties of the smallest fibre unit dispersed in FRCC and excludes matrix-dependent properties such as bond strength, creep and fatigue.

Practical applications and users

ISO 23523:2021 is intended primarily for:

- Fibre manufacturers and suppliers - to certify and declare standardized fibre properties for civil engineering use

- Materials and testing laboratories - to perform reproducible laboratory measurements for certification

- Design and construction engineers - to compare fibre options and design FRCC mixes (e.g., selecting fibre length: 4–12 mm for mortar, ≥20 mm for concrete with coarse aggregate)

- Standards bodies and procurement teams - to define acceptance criteria and technical specifications in contracts and product standards

Using ISO 23523 test results helps engineers predict reinforcing performance (influence of tensile strength, initial modulus and aspect ratio), calculate fibre volume fraction (using density), and assess performance in fire scenarios (melting point) and alkaline environments.

Related standards

- ISO 1183‑1/2/3 - density determination methods for plastics

- ISO 11357‑3 - DSC for melting point determination

- ISO 2062 - textile fibre breaking force and elongation (related but not comprehensive for FRCC)

- ISO 19044, ISO 21022, ISO 21914 - test methods for composites (complementary context)

Keywords: ISO 23523:2021, polymer fibre test methods, FRCC, fibre diameter, tensile strength, initial modulus, melting point, alkaline durability, fibre certification.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 23523

First edition

2021-03

Test methods for discrete polymer

fibre for fibre-reinforced cementitious

composites

Méthodes d'essai des fibres polymères distinctes pour les composites à

base de ciment renforcés par des fibres

Reference number

©

ISO 2021

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

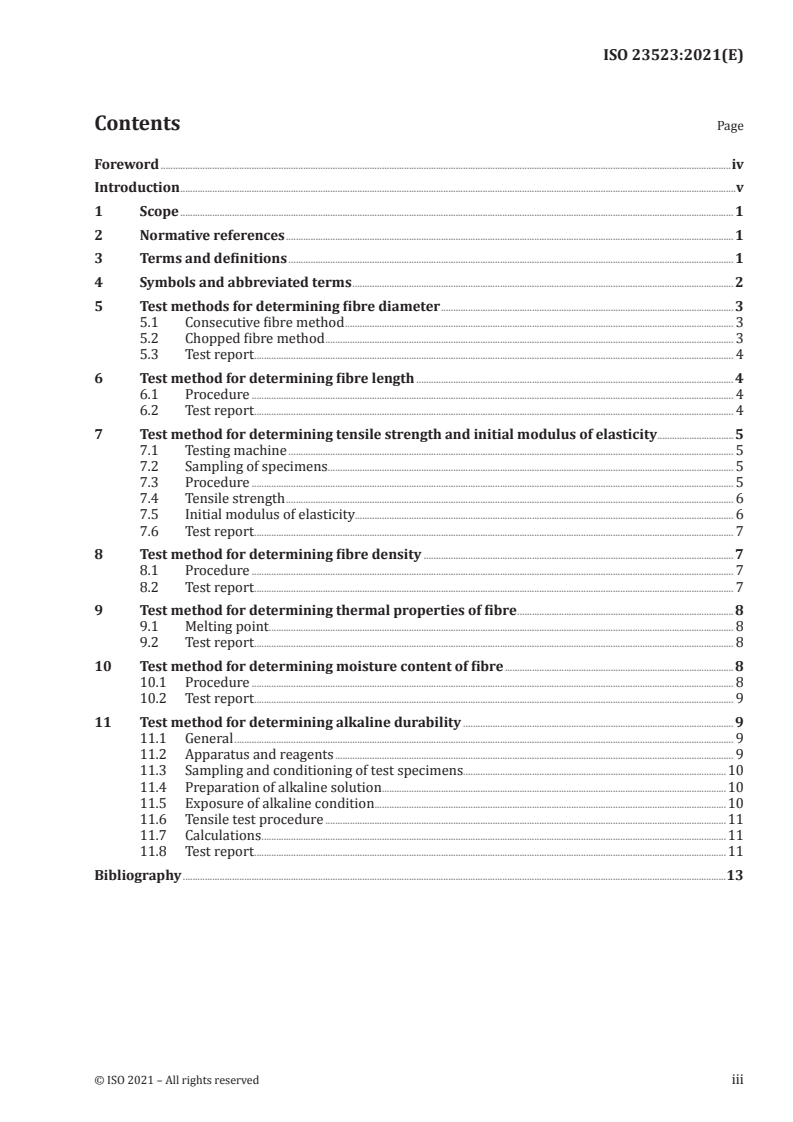

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols and abbreviated terms . 2

5 Test methods for determining fibre diameter . 3

5.1 Consecutive fibre method . 3

5.2 Chopped fibre method . 3

5.3 Test report . 4

6 Test method for determining fibre length . 4

6.1 Procedure . 4

6.2 Test report . 4

7 Test method for determining tensile strength and initial modulus of elasticity .5

7.1 Testing machine . 5

7.2 Sampling of specimens . 5

7.3 Procedure . 5

7.4 Tensile strength . 6

7.5 Initial modulus of elasticity. 6

7.6 Test report . 7

8 Test method for determining fibre density . 7

8.1 Procedure . 7

8.2 Test report . 7

9 Test method for determining thermal properties of fibre . 8

9.1 Melting point . 8

9.2 Test report . 8

10 Test method for determining moisture content of fibre . 8

10.1 Procedure . 8

10.2 Test report . 9

11 Test method for determining alkaline durability . 9

11.1 General . 9

11.2 Apparatus and reagents . 9

11.3 Sampling and conditioning of test specimens.10

11.4 Preparation of alkaline solution .10

11.5 Exposure of alkaline condition .10

11.6 Tensile test procedure .11

11.7 Calculations .11

11.8 Test report .11

Bibliography .13

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 71, Concrete, reinforced concrete and pre-

stressed concrete, Subcommittee SC 6, Non-traditional reinforcing materials for concrete structures.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

iv © ISO 2021 – All rights reserved

Introduction

Polymer fibre in this document means a fibre made with macromolecule substances as raw material

such as aramid fibre, polyamide fibre, polyester fibre, polyethylene fibre, polypropylene fibre,

polyvinylalcohol fibre. For fibre-reinforced cementitious composites (FRCC), many kinds of and types

of polymer fibres are designed and produced on various demands. However, standards of discrete

polymer fibres for FRCC in the civil engineering field are not specified yet despite the need for it.

If the fibre suppliers can show the principal fibre properties such as geometry and standardized basic

mechanical properties, the engineer can design, manufacture and practice more effectively. Therefore,

although the standard of the fibre itself is useful for users, construction engineers and others, it is

expected to be used primarily by more fibre suppliers than those.

The status of the existing standards is as follows;

1) Test methods for composites exist, i.e. ISO 19044, ISO 21022 and ISO 21914. However, they are not

for polymer fibre itself. Breaking force and elongation at break for the fibre itself are specified in

ISO 2062, but other material properties of fibres, such as initial modulus of elasticity and thermal

properties, are not specified.

2) Existing standards for fibres are intended for clothing textiles, ropes or strips. Test methods and

unit system are different from those in the civil engineering field. The traditional unit system for

textile is the Tex system, in which sectional size of fibre is expressed by weight per length. The

unit system is different from that used in the civil engineering field. It would be very convenient to

express them in SI units such as Newtons – millimetres.

The purpose of each testing item is described below.

For a fibre design, the fibre shape and mechanical properties are important for selection. The fibre

length is selected upon the matrix composition. For example, a 4 mm to 12 mm length fibre is suitable

for a uniform matrix such as cement mortar, and 20 mm or longer is required for concrete that includes

coarse aggregates. The fibre diameter is also important because it influences the fibre dispersion

through the fibre aspect ratio (length/diameter). The tensile strength and initial modulus of elasticity

are key parameters that influence the reinforcing performance of the fibre through the fibre-to-matrix

bond. On the other hand, the bonding strength, friction and surface treatment of fibre, in spite of their

importance, are not included in this document as they are strongly related to the matrix properties

and are generally difficult to estimate. In addition, creep and fatigue properties are not included in this

document either because the needs of these properties depend on the application situations of the FRCC.

In terms of fibre usage, the fibre reinforcement performance in the FRCC is related to the fibre

volume fraction, which is calculated from the fibre weight according to the fibre density. In the use of

moisturized fibre products for a uniform fibre dispersion, the existence of water can have a significant

effect on the hydration of the cementitious matrix. Thus, the fibre moisture content needs to be

accurately estimated.

For the operation stage of the FRCC, their thermal properties and durability against chemicals are

of particular concern. For instance, in case of high strength cementitious composites, the polymer

fibre can melt during a fire to introduce small cavity so as to release the high internal pressure and

consequently reduce the risk of an explosive failure of the cement matrix. Therefore, for fire protection

applications, a relatively low melting point of the fibre is considered as apriority. In addition, fibres for

the FRCC need to have high durability against alkaline conditions. Thus, the melting point and alkaline

durability are two important parameters of the fibres.

The fibre properties are defined in this document as the properties of the smallest fibre unit that disperses

in the FRCC. In actual application, fibres can also exist in the form of bundle even within the FRCC.

INTERNATIONAL STANDARD ISO 23523:2021(E)

Test methods for discrete polymer fibre for fibre-

reinforced cementitious composites

1 Scope

This document specifies the test methods for discrete polymer fibre for fibre-reinforced cementitious

composites (FRCC).

This document defines the test methods for discrete polymer fibre, such as diameter, length, tensile

strength, initial modulus of elasticity, density, melting point, moisture content and alkaline durability

as basic items. These are test methods intended for certification of a fibre and not for quality control or

field acceptance.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1183-1, Plastics — Methods for determining the density of non-cellular plastics — Part 1: Immersion

method, liquid pycnometer method and titration method

ISO 1183-2, Plastics — Methods for determining the density of non-cellular plastics — Part 2: Density

gradient column method

ISO 1183-3, Plastics — Methods for determining the density of non-cellular plastics — Part 3: Gas

pyknometer method

ISO 11357-3, Plastics — Differential scanning calorimetry (DSC) — Part 3: Determination of temperature

and enthalpy of melting and crystallization

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

fibre-reinforced cementitious composite

FRCC

concrete or mortar containing short discrete fibres that are distributed in the matrix

3.2

standard atmosphere

condition of an atmosphere with temperature of (20 ± 2) °C and relative humidity of (65 ± 4) %

3.3

standard condition

condition in standard atmosphere (3.2) for a period of at least 24 h

3.4

tenacity

tensile strength of fibre in cN/dtex

3.5

filament yarn

long and continuous fibre which has not been cut for fibre diameter determination or cut to the

product length

3.6

consecutive fibre

long and continuous fibre for fibre diameter determination which is longer than the chopped fibre (3.7)

products

3.7

chopped fibre

short fibre which is cut to the product length

3.8

individual fibre

smallest unit of fibre structure in fibre-reinforced cementitious composite

Note 1 to entry: "tex" expresses the unit that shows the sectional size of the individual fibre in weight (grams)

per 1 000 m of fibre.

4 Symbols and abbre

...

Frequently Asked Questions

ISO 23523:2021 is a standard published by the International Organization for Standardization (ISO). Its full title is "Test methods for discrete polymer fibre for fibre-reinforced cementitious composites". This standard covers: This document specifies the test methods for discrete polymer fibre for fibre-reinforced cementitious composites (FRCC). This document defines the test methods for discrete polymer fibre, such as diameter, length, tensile strength, initial modulus of elasticity, density, melting point, moisture content and alkaline durability as basic items. These are test methods intended for certification of a fibre and not for quality control or field acceptance.

This document specifies the test methods for discrete polymer fibre for fibre-reinforced cementitious composites (FRCC). This document defines the test methods for discrete polymer fibre, such as diameter, length, tensile strength, initial modulus of elasticity, density, melting point, moisture content and alkaline durability as basic items. These are test methods intended for certification of a fibre and not for quality control or field acceptance.

ISO 23523:2021 is classified under the following ICS (International Classification for Standards) categories: 83.120 - Reinforced plastics; 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

You can purchase ISO 23523:2021 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

記事のタイトル:ISO 23523:2021 - 繊維強化セメント複合材料用の離散型ポリマー繊維の試験方法 記事の内容:この文書では、繊維強化セメント複合材料(FRCC)で使用される離散型ポリマー繊維の試験方法について規定しています。この文書では、直径、長さ、引張強さ、初期弾性率、密度、融点、水分含有量、アルカリ耐久性など、基本的な項目に関する離散型ポリマー繊維の試験方法を定義しています。これらの試験方法は、繊維の認証のために使用されるものであり、品質管理や現場での受け入れには使用されません。

기사 제목: ISO 23523:2021 - 섬유보강 시멘트 복합재료용 이산성 고분자 섬유에 대한 시험 방법 기사 내용: 이 문서는 섬유보강 시멘트 복합재료(FRCC)에 사용되는 이산성 고분자 섬유의 시험 방법을 규정합니다. 이 문서에서는 지름, 길이, 인장강도, 초기 탄성률, 밀도, 용융점, 수분 함량 및 알칼리 내구성과 같은 기본 항목에 대한 이산성 고분자 섬유의 시험 방법을 정의합니다. 이러한 시험 방법은 섬유의 인증을 위한 것이며 품질 관리나 현장 수용성을 위한 것이 아닙니다.

ISO 23523:2021 is a standard that outlines the test methods for discrete polymer fibers used in fiber-reinforced cementitious composites (FRCC). The document defines various test methods for these fibers, including measurements of diameter, length, tensile strength, initial modulus of elasticity, density, melting point, moisture content, and alkaline durability. These test methods are primarily used for certifying the fibers and not for quality control or field acceptance purposes.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...