ISO 20155:2017

(Main)Ships and marine technology — Test method of flow induced in-pipe noise source characteristics for a ship-used pump

Ships and marine technology — Test method of flow induced in-pipe noise source characteristics for a ship-used pump

ISO 20155:2017 specifies a test method for determining flow induced in-pipe noise source characteristics of a ship-used pump as a two-port sound source in laboratory conditions by measuring acoustic pressures in the pipe reaches of inlet and outlet. The test method is applicable to all types of centrifugal pumps with a diameter over 50 mm operating under steady conditions. The suitable frequency range of the test method is about 10 Hz to 1 000 Hz, and the upper frequency is dependent on the inner diameter of the pipe, in which the plane acoustic wave propagates.

Navires et technologie maritime — Méthode pour déterminer les caractéristiques des sources de bruit induites par l'écoulement dans les tuyaux d'une pompe de navire

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 20155

First edition

2017-08

Ships and marine technology — Test

method of flow induced in-pipe noise

source characteristics for a ship-

used pump

Navires et technologie maritime — Méthode pour déterminer les

caractéristiques des sources de bruit induites par l’écoulement dans

les tuyaux d’une pompe de navire

Reference number

ISO 20155:2017(E)

©

ISO 2017

---------------------- Page: 1 ----------------------

ISO 20155:2017(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 20155:2017(E)

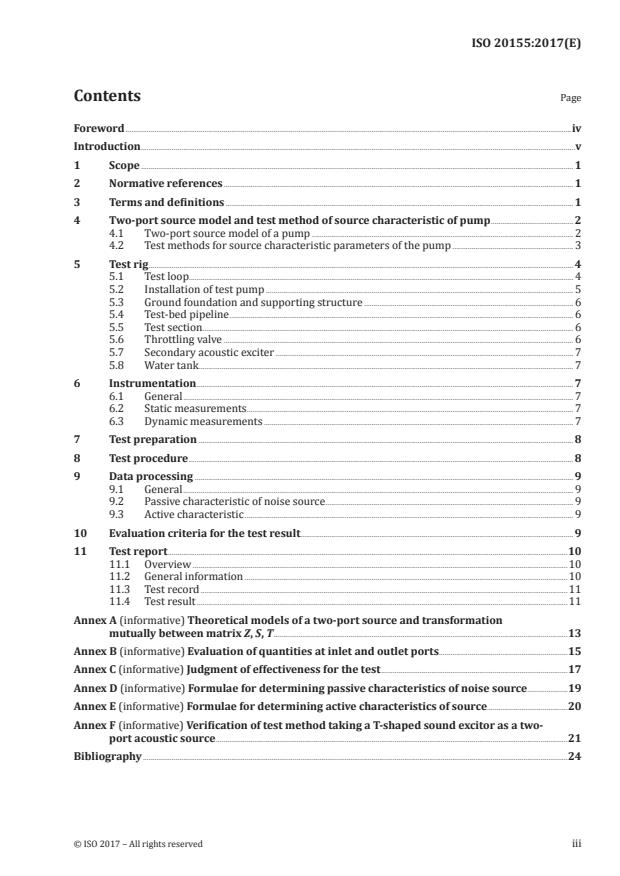

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Two-port source model and test method of source characteristic of pump .2

4.1 Two-port source model of a pump . 2

4.2 Test methods for source characteristic parameters of the pump . 3

5 Test rig . 4

5.1 Test loop . 4

5.2 Installation of test pump . 5

5.3 Ground foundation and supporting structure . 6

5.4 Test-bed pipeline . 6

5.5 Test section . 6

5.6 Throttling valve . 6

5.7 Secondary acoustic exciter . 7

5.8 Water tank. 7

6 Instrumentation . 7

6.1 General . 7

6.2 Static measurements. 7

6.3 Dynamic measurements . 7

7 Test preparation . 8

8 Test procedure . 8

9 Data processing . 9

9.1 General . 9

9.2 Passive characteristic of noise source . 9

9.3 Active characteristic . 9

10 Evaluation criteria for the test result . 9

11 Test report .10

11.1 Overview .10

11.2 General information .10

11.3 Test record .11

11.4 Test result .11

Annex A (informative) Theoretical models of a two-port source and transformation

mutually between matrix Z, S, T .13

Annex B (informative) Evaluation of quantities at inlet and outlet ports.15

Annex C (informative) Judgment of effectiveness for the test .17

Annex D (informative) Formulae for determining passive characteristics of noise source .19

Annex E (informative) Formulae for determining active characteristics of source .20

Annex F (informative) Verification of test method taking a T-shaped sound excitor as a two-

port acoustic source .21

Bibliography .24

© ISO 2017 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 20155:2017(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO’s adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: w w w . i s o .org/ iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 8, Ships and marine technology,

Subcommittee SC 8, Ship design.

iv © ISO 2017 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 20155:2017(E)

Introduction

In hydraulic fluid power systems of ships, power is transmitted through a liquid under pressure.

Pumps are components that convert rotary mechanical power into hydraulic fluid power. During the

process of converting mechanical power into hydraulic power, flow and pressure fluctuations and

structure-borne vibrations are generated. These fluid-borne and structure-borne vibrations, which

are generated primarily by the unsteady flow produced by the pump, are transmitted through the

connected piping system.

The fluid-borne vibration generated by a pump is called pressure ripple or flow induced noise. For

pumps used for coolant and drainage in ships, flow induced noise can be transmitted along the piping

and radiated into the surrounding water area through a pipe mouth outboard the ship, which produces

noise pollution and disturbs the environment including marine mammals.

The level of flow induced noise for a pump depends upon not only the characteristics of the pump itself,

but also the circuit in which the pump is installed. Thus, the determination of flow induced noise by

a pump is complicated by the interaction between the pump and the circuit. The directly measured

data using hydrophones inserted in pipe reaches connecting the pump cannot reflect noise source

characteristics of the pump. The method adopted to measure the flow induced noise of a pump should

be such as to eliminate the interaction.

ISO 10767-1 and ISO 10767-2 provide the test methods for the positive displacement pump with the

precision and simplified method, respectively, where the pump is treated as a single port acoustic

source and its source characteristics expressed by two parameters of source strength as well as source

impedance can be obtained. For other common pumps with two ports, the sound field between the

inlet and outlet of a pump is inter-coupling, source characteristics cannot be fully expressed by two

parameters, but expressed by up to six parameters, i.e. source pressures at the inlet and outlet of a

pump and four elements in a 2 × 2 impedance matrix. There is a need to establish a new standard about

a test method for noise source characteristics of a pump, based on two-port acoustic source model.

The source characteristics of flow induced noise are used for evaluating the hydrodynamic noise feature

of the pump. The measured results can be compared for pumps of different types and manufacture.

This will enable the pump designer to evaluate the effects of design modifications and help hydraulic

system designers to avoid selecting pumps having high noise levels.

The method is based upon the application of plane wave transmission line theory to the analysis of

noise propagation in hydraulic systems. By adopting a two-port model with noise source and evaluating

the impedance characteristics of the pump using a secondary-source method, it is possible to obtain the

source strength of the pump, independent of the circuit that the pump locates.

© ISO 2017 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 20155:2017(E)

Ships and marine technology — Test method of flow

induced in-pipe noise source characteristics for a ship-

used pump

1 Scope

This document specifies a test method for determining flow induced in-pipe noise source characteristics

of a ship-used pump as a two-port sound source in laboratory conditions by measuring acoustic

pressures in the pipe reaches of inlet and outlet.

The test method is applicable to all types of centrifugal pumps with a diameter over 50 mm operating

under steady conditions.

The suitable frequency range of the test method is about 10 Hz to 1 000 Hz, and the upper frequency is

dependent on the inner diameter of the pipe, in which the plane acoustic wave propagates.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 10767-1:2015, Hydraulic fluid power — Determination of pressure ripple levels generated in systems

and components — Part 1: Method for determining source flow ripple and source impedance of pumps

IEC 60565, Underwater acoustics — Hydrophones — Calibration in the frequency range 0,01 Hz to 1 MHz

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http:// www .electropedia .org/

— ISO Online browsing platform: available at http:// www .iso .org/ obp

3.1

two-port source

test object with inlet and outlet which are inter-coupling acoustically

3.2

passive characteristic

acoustic characteristic of a test object only acting as a transmission path, which can be indicated by

different manners such as a transfer matrix, impedance matrix, scattering matrix, etc.

3.3

active characteristic

acoustic characteristic of a test object which provides acoustic energy into a piping system

Note 1 to entry: Depending on the adopted theoretical model, active characteristics can be represented by

acoustic pressure source, volume velocity source, etc.

© ISO 2017 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 20155:2017(E)

3.4

test section

pipe reaches which are used to fix the hydrophones, measuring the in-pipe noise from the acoustic source

3.5

static pressure in pipe

fluid pressure in pipe as fluid is in still, which is one of the parameters describing the working conditions

of the test object

3.6

working flowrate

fluid volume or mass per unit time, which is one of the working parameters of the test object

3.7

pressure drop/hydraulic loss

static pressure difference between the inlet and outlet as the fluid passes through the test object, which

is a reference parameter for analysis use

3.8

foundation

platform built by ferroconcrete, used to install the experimental facility and test objects, including

ground basis, guide rail for convenient mount of pipeline

4 Two-port source model and test method of source characteristic of pump

4.1 Two-port source model of a pump

It is assumed that only plane wave would transmit in the pipeline, and the noise source characteristic

of a pump could be described by linear superposition of active and passive characteristic. Based on

the electro-acoustic analogy and acoustic transmission line theory, there are three different models

to characterize a two-port source, which can be called “Transmission model”, “Impedance model” and

“Scattering model”. They are illustrated in Annex A.

4 5

13

P , Q P , Q P , Q

s s o o

i i

p p

so

si

2

Key

1 flow

2 source

3 pipe

4 inlet

5 outlet

Figure 1 — Two-port noise source model

2 © ISO 2017 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 20155:2017(E)

Adopting the impedance model, the radiating sound from the inlet and outlet into pipe can be expressed

by Formula (1):

P ZZ Q P Q P

o 11 12 o so o so

= + =Z + (1)

P ZZ Q P Q P

i 21 22 i si i si

where

is the real sound source of a pump providing sound pressure and volumetric velocity into

PQ,

ss

the inlet and outlet of the pump, while the connected pipes are unlimited or anechoic;

is the sound pressure and volumetric velocity at the outlet of acoustic source,

PQ,

oo

respectively;

is the sound pressure and volumetric velocity at the inlet of acoustic source,

PQ,

ii

respectively;

is the sound pressure source which indicate radiating sound from the inlet and outlet

PP,

so si

into pipe;

ZZ

11 12

Z is the impedance matrix, Z = .

ZZ

21 22

4.2 Test methods for source characteristic parameters of the pump

Using the secondary-source method, turn on the secondary acoustic source on one side (inlet or outlet),

get and register signals from the four hydrophones. Then, move it to another side and turn it on, register

signals of the four hydrophones again. By this procedure, matrix parameter Z can be derived. Finally,

turn off the source, active characteristic parameters p and q of the pump can be obtained utilizing

s s

the result of matrix parameter Z.

Key

1 secondary source 1

2 secondary source 2

3 test pump

4 hydrophones H to H

1 6

Figure 2 — Sketch of dual-position acoustic source methods

In Figure 2, H to H are six hydrophones along the pipe mounted at positions x to x , correspondingly.

1 6 1 6

© ISO 2017 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 20155:2017(E)

The procedure for measuring source characteristics is given as follows.

a) Turn on the secondary acoustic source at the inlet for the following result:

()1 ()1

P Q

ZZ

o o

11 12

= (2)

()1 ()1

ZZ

21 22

P Q

i i

(1)

where superscript indicates the corresponding quantities obtained by turning on the secondary

sound source at the first time, and they can be obtained by means of calculation using formulae in

Annex B, which correlate the quantities with the measured signals from hydrophones.

b) Turn on the secondary acoustic source at the outlet for the following result:

()2 ()2

P Q

ZZ

o 11 12 o

= (3)

()2 ()2

ZZ

P 21 22 Q

i i

(2)

where superscript indicates the corresponding quantities obtained by turning on the secondary

sound source at the second time.

c) Combine Formulae (2) and (3) and solve the equation system, the impedance matrix Z can be

calculated.

()12() (112)( )

PP ZZ Q Q

oo 11 12 o o

= (4)

()12() ()12()

ZZ

PP 21 22 QQ

ii ii

d) Turn off the secondary acoustic source, and let the measured pump operate under the needed

conditions, the active source parameters, i.e. sound pressure source PP, can be obtained

so si

according to Formula (5).

P P ZZ Q

so o 11 12 o

= − (5)

P P ZZ Q

si i 21 22 i

At the right side of Formula (5), P , P and Q , Q are obtained by calculation using the measured

o i o i

signals from hydrophones during pump operation.

5 Test rig

5.1 Test loop

Figure 3 shows the schematic of test circuit of flow induced in-pipe noise source characteristic of

the pump.

4 © ISO 2017 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 20155:2017(E)

Key

1 pump 6 water tank

2 hydrophone 7 flexible insertion

3 vibration 8 vibroisolator

4 secondary acoustic excitor 9 foundation

5 throttling valve

Figure 3 — Sketch of test circuit for measuring flow-noise source characteristic of the pump

In the schematic diagram, a water tank is used for separating sound waves from the inlet and outlet

of pump. A throttling valve is used for flowrate adjustment and located between the water tanks for

reducing the effect on source characteristic measurement of the pump. A secondary acoustic exciter

can provide an external acoustic source for determination of passive features of the pump, and the

vibration damper can suppress the vibration of the test section from the neighbouring pipe reaches.

Hydrophones are mounted in test sections at the inlet and outlet of the pump for measuring the acoustic

pressure in the pipeline.

5.2 Installation of test pump

The test pump should be installed as recommended by the manufacturer and mounted in such a manner

that the response of the mounting-to-pump vibration is minimized.

In order to reduce vibration disturbance from the ground and the connected pipe, the pump should

be installed on the foundation through vibration isolators and connected to the pipeline with flexible

insertions. The isolators and flexible insertions should be chosen close to the actual conditions.

The prime mover and associated drive couplings shall not generate torsional vibration in the pump

shaft. If necessary, the pump and the driving unit shall be isolated from each other to eliminate vibration

generated by the prime mover.

© ISO 2017 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 20155:2017(E)

5.3 Ground foundation and supporting structure

Ground foundation should be made of reinforced concrete and isolated to the surrounding ground in

the laboratory such as foundations of other auxiliary equipment. A supporting structure of the pipeline

is also required to be rigidly connecting the pipeline with the ground foundation.

5.4 Test-bed pipeline

The pipeline shall be composed of uniform, rigid, straight metal pipes at each port of the pump.

The inner diameters of the test pipeline at inlet and outlet should be equal to that of the inlet and outlet

of the test pump respectively. In the case of the inequality of inner diameter between the test pump

and pipeline, the adaptor connecting the pump ports to the pipe shall have an internal diameter which

does not differ from the pipe diameter by more than 10 % at any point. Any such variations in internal

diameter shall occur over a length not exceeding twice the internal diameter of the pipe. The adaptor

shall be arranged in order to prevent the formation of air pockets in it.

The bending section in the pipeline of Figure 3 shall adopt bends with bending radii larger than twice

the radii of the pipe to reduce hydrodynamic noise arising from the flow over it.

The total length of the uniform straight pipeline in front of the inlet flange of the test pump should be

10 times larger than pipe diameter.

5.5 Test section

Each of the two test sections as a straight pipe reach is fixed on the inlet and outlet of the test pump

respectively, with the length more than 2 m, the inner diameters, D, equal to that of inlet and outlet

pipe of the test pump. The test section should be fabricated with a tube of wall thickness greater than

5 % of the inner diameters, D. In the test section, two or three hydrophones with equal interval are

fixed on the pipe. Each hydrophone is put in a plug mounted on the pipe. In order to reduce interference

from turbulence over the inner wall of the pipe, the hydrophones shall be mounted such that their

diaphragms are flush with the inner wall of the pipe to within ±0,5 mm. The sealing ring in the plug

should be used between the hydrophone and plug body to prevent water leakage.

The distance between two or two of three hydrophones depends on the maximum frequency of the

measurement frequency range and shall be given by Formula (6), to within 1 %:

5

B ×10 /ρ

eff

xx−= (6)

21

()67× f

0,max

where

is the maximum frequency of the measurement frequency range, in hertz;

f

0,max

is the effective bulk modulus, in bars;

B

eff

ρ is the density, in kilograms per cubic meter.

Meanwhile, in order to avoid turbulent fluctuation pressure from the pump impacting directly on

hydrophone, the nearest hydrophone should be positioned at a distance larger than 3 to 5 times pipe

inner diameter from the test pump.

5.6 Throttling valve

The throttling valve should meet the need of flowrate adjustment. From the point of acoustic

measurement, it should have a low noise level and no cavitation should appear under the test working

conditions.

6 © ISO 2017 – All rights reserved

---------------------- Page: 11 ----------------------

ISO 20155:2017(E)

5.7 Secondary acoustic exciter

The secondary acoustic exciter is composed of a vibration exciter of electromagnetic type and a piston

with a bar connecting them. The piston is driven by the exciter and produces acoustic plane waves by

its oscillatory motion in the working medium. The intensity of acoustic waves should be 10 dB higher

than the background noise in the frequency spectrum to ensure sufficient signal-noise-ratio.

5.8 Water tank

A water tank should have a volume at least 30 times the connected pipeline.

6 Instrumentation

6.1 General

The source characteristic test of a pump includes a static and dynamic measurement. A static

measurement is mainly used to define working parameters of the pump. A dynamic measurement is

used to collect sound pressure signals generated by the test pump radiating into the pipeline.

6.2 Static measurements

In static measurement, some quantities should be measured, which include flowrate and static pressure

of fluid in the pipe, shaft rotational speed of pump and pressure drop across the pump, temperature of

working medium, etc.

The requirement of instrumentation for static measurements shall be in accordance with

ISO 10767-1:2015, 4.1.

6.3 Dynamic measurements

The instruments for dynamic measurements consist of a transducer, a signal conditioner and data

acquisition or signal analyser. A hydrophone is used to measure the sound pressure in the pipe. A charge

amplifier or measuring amplifier is chosen as a signal conditioner.

Transducers shall be chosen to meet the requirements for working in the allowable environment (such

as static pressure, temperature, magnetic field, anti-corrosion, etc.) and needed frequency range. The

natural frequency of the hydrophone shall be higher than 30 kHz and nonlinearity less than ±1 %. In

the test frequency range, the amplitude inhomogeneity of hydrophone should be less than 0,2 dB, and

the inhomogeneity of phase frequency characteristic less than 0,5°.

Figure 4 shows the schematic diagram of dynamic measurement system.

Key

1 hydrophone

2 charge/measuring amplifier

3 data acquisition or signal analyser

4 computer

Figure 4 — Schematic diagram of dynamic measurement system

© ISO 2017 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO 20155:2017(E)

A Piezoelectric mini-type hydrophone can be adopted. The hydrophone outputs the charge, which is

imported into the data acquisition or signal analyser. With the computer, a signal can be recorded and

analysed. Using the post-processing analysis software, final results can be obtained.

Hydrophones shall be calibrated in accordance with the requirements of IEC 60565.

7 Test preparation

A test circuit should be assembled with a layout shown in Figure 3. Each component of a test circuit

shall be chosen, designed, and mounted according to requirements described in Clause 5.

Each two or three hydrophones shall be install

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.