ISO 11907-1:2019

(Main)Plastics — Smoke generation — Determination of the corrosivity of fire effluents — Part 1: General concepts and applicability

Plastics — Smoke generation — Determination of the corrosivity of fire effluents — Part 1: General concepts and applicability

The document defines terms related to smoke corrosivity as well as smoke acidity and smoke toxicity. It presents the scenario-based approach that controls smoke corrosivity. It describes the test methods to assess smoke corrosivity at laboratory scale and deals with test applicability and post-exposure conditions. This document is applicable to tests of determination of smoke corrosivity from combustion of materials samples.

Plastiques — Production de fumées — Détermination de la corrosivité des effluents du feu — Partie 1: Concepts généraux et applicabilité

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 11907-1

Second edition

2019-07

Plastics — Smoke generation —

Determination of the corrosivity of

fire effluents —

Part 1:

General concepts and applicability

Plastiques — Production de fumées — Détermination de la corrosivité

des effluents du feu —

Partie 1: Concepts généraux et applicabilité

Reference number

©

ISO 2019

© ISO 2019

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2019 – All rights reserved

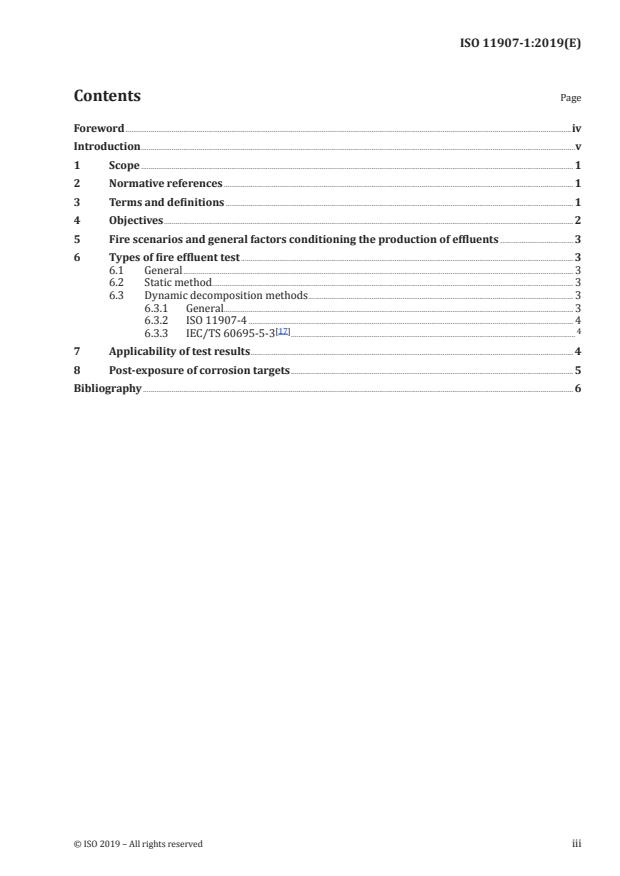

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Objectives . 2

5 Fire scenarios and general factors conditioning the production of effluents .3

6 Types of fire effluent test . 3

6.1 General . 3

6.2 Static method . . 3

6.3 Dynamic decomposition methods . 3

6.3.1 General. 3

6.3.2 ISO 11907-4 . 4

[17] 4

6.3.3 IEC/TS 60695-5-3 . .

7 Applicability of test results . 4

8 Post-exposure of corrosion targets . 5

Bibliography . 6

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 61, Plastics, Subcommittee SC 4, Burning

behaviour.

This second edition cancels and replaces the first edition (ISO 11907-1:1998), which has been technically

revised.

The main changes compared to the previous edition are as follows:

— update of the existing test methods;

— clarification of differences between acidity, corrosivity and toxicity;

— clarification of the importance of fire scenarios and global approach for corrosivity assessment.

A list of all parts in the ISO 11907 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

iv © ISO 2019 – All rights reserved

Introduction

[1][2][3]

Corrosivity of smoke is important in the evaluation of fire damages . This document constitutes

the guidance part of the ISO 11907 series. Clause 3 defines smoke corrosivity as well as smoke acidity

and smoke toxicity. Clause 4 details the objectives of this document. Clause 5 presents the scenario-

based approach that governs smoke corrosivity. Clause 6 categorizes the different test methods to

assess smoke corrosivity at laboratory scale. Clauses 7 and 8 respectively deal with the applicability

and post-exposure conditions.

[4]

ISO 11907-4 describes a dynamic test procedure. Any standard method within the ISO 11907 series

should be used solely to measure and describe the properties of materials, products or systems in

response to heat or flame under controlled laboratory conditions and should not be considered or used

by itself for describing or appraising the fire hazard of materials, products or systems under actual fire

conditions or as the sole source on which regulations pertaining to corrosivity of fire effluents are based.

[5] [6]

NOTE Two other methods, named ISO 11907-2 and ISO 11907-3 , existed in the past but are no longer

used. Related International Standards have been withdrawn.

Smoke corrosivity represents the measured effect of material or product reduction in functionality due

to the corrosive effects of smoke. These corrosive effects are an essential factor in the assessment of the

extent and cost of fire damage. All fire effluents and effects, including the released heat, are corrosive

to some degree. Their potential to cause damage depends on a series of factors including:

— the rate of fire growth, which determines effluent concentrations;

— the volume into which the effluents disperse;

— the conditions of ventilation of the enclosure, including windows, smoke vents and mechanical

ventilation;

— the nature of the combustible materials involved in the fire;

— the nature and composition of the exposed surfaces;

— the time of exposure;

— the conditions where pyrolysis occurs (heat flux, oxygen) as well as where combustion occurs;

— the specific environmental conditions at the exposed surfaces (temperature and humidity);

— the efficacy of active and passive fire protection, extinction and smoke management systems.

The corrosive effects of combustion products are not connected to the effect of fire effluents to people

such as fire effluents toxicity.

The corrosive effects of fire effluents are not only material or product dependent, but also a systemic

parameter. A scenario-based approach is then needed for assessment, i.e. using CFD models in a fire

safety engineering approach. Corrosivity tests at laboratory scale might be relevant to assess the

corrosion behaviour of smoke. In any given corrosivity test, the effects of the combustion products on

the target depend on:

— their concentration;

— their chemical and physical nature;

— the chemical and physical nature of the corrosion target;

— the time of exposure and post-exposure conditions;

— the environmental conditions at the target-effluent interface (humidity, temperature, flow regime);

— condensation phenomena at the target;

— adsorption by smoke particles of corrosive effluents;

— interactions between the fire effluent and surrounding surfaces;

— nature of any cleaning of the target after the exposure.

In the fire, the effluents are carried by buoyancy to regions remote from the fire zone itself, so the

potential for corrosion exists even in these areas the smoke reaches. Some particulates and effluent

species can also be adsorbed onto on particulates and can deposit on surfaces as the effluents are

transported.

Thus, the corrosion potential in the fire zone is, in general,significantly different from that in any given

remote area. Given the extent of damage generally occurring within the fire enclosure itself, non-

thermal damage by corrosion is likely to be of most significance outside the room of origin of the fire

(except in the case of smouldering fires).

The corrosive effects can be broken down into three different processes:

— metal loss from chemical corrosion;

— leakage current from electrolytic corrosion;

— high contact resistance due to galvanic corrosion.

Additional short-circuit effect due to particulates deposition is also of high concern.

Targets used in ISO 11907-4 measures only metal loss corrosion.

vi © ISO 2019 – All rights reserved

INTERNATIONAL STANDARD ISO 11907-1:2019(E)

Plastics — Smoke generation — Determination of the

corrosivity of fire effluents —

Part 1:

General concepts and applicability

1 Scope

The document defines terms related to smoke corrosivity as well as smoke acidity and smoke toxicity.

It presents the scenario-based approach that controls smoke corrosivity. It describes the test methods

to assess smoke corrosivity at laboratory scale and deals with test applicability and post-exposure

conditions. This document is applicable to tests of determination of smoke corrosivity from combustion

of materials samples.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 13943, Fire safety — Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 13943 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1

smoke corrosivity

measured effect of material or product reduction in functionality due to the corrosive effects of smoke

3.2

smoke acidity

pH level of fire effluents found in smoke condensate and smoke particles

Note 1 to entry: Smoke acidity relates generally to consequences of the exposure of a given quantity of liquid,

generally water, to fire effluents in terms of change of pH. This is an indicator of the acidity of the effluent, and

such measurement is often completed with measurement of conductimetry of the same solution.

3.3

corrosion

breaking down or destruction of a material, especially a metal, through chemical reactions

3.4

corrosion damage

physical and/or chemical damage or impaired function caused by chemical action

[SOURCE: ISO 13943:2017, 3.69]

3.5

corrosion target

sensor used to determine the degree of corrosion damage (3.4), under specified conditions

Note 1 to entry: The sensor may be a product or a component. It may also be a reference mate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...