ISO 6450:2005

(Main)Rubber- or plastics-coated fabrics - Determination of resistance to liquids

Rubber- or plastics-coated fabrics - Determination of resistance to liquids

ISO 6450:2005 specifies two methods (methods 1 and 2) of evaluating the resistance of fabrics coated with plastics or with vulcanized rubber to the action of liquids by measurement of selected properties of the materials before and after immersion in selected liquids. The difference between the two methods is as follows: In method 1, excess liquid is removed from the test pieces, after immersion, by wiping. In method 2, the test pieces are immersed in a volatile liquid and excess liquid is subsequently removed by drying in an oven.

Supports textiles revêtus de caoutchouc ou de plastique — Détermination de la résistance aux liquides

General Information

Relations

Frequently Asked Questions

ISO 6450:2005 is a standard published by the International Organization for Standardization (ISO). Its full title is "Rubber- or plastics-coated fabrics - Determination of resistance to liquids". This standard covers: ISO 6450:2005 specifies two methods (methods 1 and 2) of evaluating the resistance of fabrics coated with plastics or with vulcanized rubber to the action of liquids by measurement of selected properties of the materials before and after immersion in selected liquids. The difference between the two methods is as follows: In method 1, excess liquid is removed from the test pieces, after immersion, by wiping. In method 2, the test pieces are immersed in a volatile liquid and excess liquid is subsequently removed by drying in an oven.

ISO 6450:2005 specifies two methods (methods 1 and 2) of evaluating the resistance of fabrics coated with plastics or with vulcanized rubber to the action of liquids by measurement of selected properties of the materials before and after immersion in selected liquids. The difference between the two methods is as follows: In method 1, excess liquid is removed from the test pieces, after immersion, by wiping. In method 2, the test pieces are immersed in a volatile liquid and excess liquid is subsequently removed by drying in an oven.

ISO 6450:2005 is classified under the following ICS (International Classification for Standards) categories: 59.080.40 - Coated fabrics. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 6450:2005 has the following relationships with other standards: It is inter standard links to ISO 14890:2013, ISO 6450:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 6450:2005 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 6450

First edition

2005-09-01

Rubber- or plastics-coated fabrics —

Determination of resistance to liquids

Supports textiles revêtus de caoutchouc ou de plastique —

Détermination de la résistance aux liquides

Reference number

©

ISO 2005

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2005

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2005 – All rights reserved

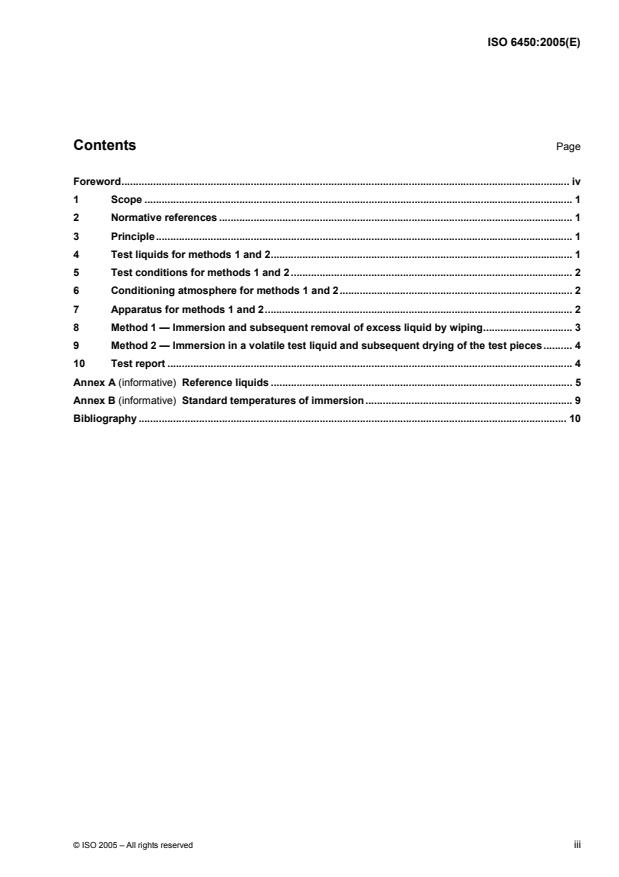

Contents Page

Foreword. iv

1 Scope . 1

2 Normative references . 1

3 Principle. 1

4 Test liquids for methods 1 and 2. 1

5 Test conditions for methods 1 and 2. 2

6 Conditioning atmosphere for methods 1 and 2. 2

7 Apparatus for methods 1 and 2. 2

8 Method 1 — Immersion and subsequent removal of excess liquid by wiping. 3

9 Method 2 — Immersion in a volatile test liquid and subsequent drying of the test pieces. 4

10 Test report . 4

Annex A (informative) Reference liquids . 5

Annex B (informative) Standard temperatures of immersion. 9

Bibliography . 10

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 6450 was prepared by Technical Committee ISO/TC 45, Rubber and rubber products, Subcommittee

SC 4, Products (other than hoses).

iv © ISO 2005 – All rights reserved

INTERNATIONAL STANDARD ISO 6450:2005(E)

Rubber- or plastics-coated fabrics — Determination of

resistance to liquids

1 Scope

This International Standard specifies two methods (methods 1 and 2) of evaluating the resistance of fabrics

coated with plastics or with vulcanized rubber to the action of liquids by measurement of selected properties of

the materials before and after immersion in selected liquids.

The difference between the two methods is as follows:

⎯ In method 1, excess liquid is removed from the test pieces, after immersion, by wiping.

⎯ In method 2, the test pieces are immersed in a volatile liquid and excess liquid is subsequently removed

by drying in an oven.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 2231, Rubber- or plastics-coated fabrics — Standard atmospheres for conditioning and testing

ISO 2286-1, Rubber- or plastics-coated fabrics — Determination of roll characteristics — Part 1: Methods for

determination of length, width and net mass

3 Principle

This International Standard provides a procedure for exposing test pieces to the influence of liquids under

defined conditions of temperature and time. Selected properties are determined in accordance with the

relevant test method standards. Test pieces are then immersed in selected liquid(s) and the properties

determined again. The percentage change or the values before and after immersion are measures of the

resistance of the material to the selected liquid(s).

4 Test liquids for methods 1 and 2

SAFETY PRECAUTIONS — Appropriate safety precautions should be taken when preparing and

handling test liquids, especially those known to be toxic, corrosive or flammable. Products giving off

fumes should be handled only under an efficiently ventilated hood, corrosive products should not be

allowed to come into contact with the skin or ordinary clothing, and flammable products should be

kept away from any source of ignition.

In addition, attention is drawn to the damage which can be caused by corrosive test liquids to test

equipment (e.g. clamps or jaws).

As commercial liquids may not have an entirely constant composition, a standard immersion liquid consisting

of a well-defined chemical compound or a mixture of such compounds should preferably be used. Suitable

liquids are given in Annex A.

If a commercial liquid is used, the test report shall mention all the available information about its origin,

composition, properties, e.g. viscosity, aniline point, etc., and batch number.

NOTE For test purposes, it is usually desirable to use the liquid(s) with which the coated fabric will come into contact

during use. When determining the effect of solutions of chemicals, the concentration of the solution should be appropriate

to the proposed application.

5 Test conditions for methods 1 and 2

5.1 Temperature

Where appropriate, use an immersion temperature T approximating to that encountered during use. Maintain

the immersion temperature at T ± 2 °C.

Preferred immersion temperatures are given in Annex B.

5.2 Immersion period

The following immersion periods are recommended:

22 h ± 0,25 h; 46 h ± 0,25 h; 72 h ± 2 h; 168 h ± 2 h; multiples of 7 days ± 2 h

NOTE When determining changes in physical properties, it is advisable to use a period of immersion which is long

enough to ensure that equilibrium is reached. To determine this equilibrium point, it is recommended that preliminary

measurements be carried out using several different periods of immersion, recording the results as a function of time.

Whenever practicable, the total period of immersion should extend well beyond the point at which the change in a property

reaches its maximum value.

5.3 Light

Immersion tests shall be conducted in the absence of direct light.

5.4 Time lapse between manufacturing and testing

The minimum time lapse between manufacturing and testing shall be 16 h.

6 Conditioning atmosphere for methods 1 and 2

Before immersion, test pieces shall be conditioned in one of the atmospheres defined in ISO 2231, unless

otherwise specified in the standard relevant to the property to be determined.

7 Apparatus for methods 1 and 2

The apparatus to be used is determined by the temperature of immersion, the volatility of the test liquid, the

dimensions of the test pieces and the number required for determining the selected property. At temperatures

appreciably below the boiling point of the test liquid, use a stoppered vessel, e.g. a glass bottle or tube, of

such dimensions that the test pieces remain completely immersed in the specified volume of test liquid and all

surfaces are completely exposed to the liquid without any restriction. At temperatures near the boiling point of

the test liquid, fit the vessel with a reflux condenser, or other suitable means of minimizing evaporation of the

test liquid, instead of the stopper.

2 © ISO 2005 – All rights reserved

8 Method 1 — Immersion and subsequent removal of excess liquid by wiping

8.1 Preparation of test pieces

Select properties that are considered relevant to the end-use (for example, tensile strength, coating adhesion,

mass per unit area, tear resistance and/or low-temperature properties).

For each property, cut from the usable width of the roll (as defined in ISO 2286-1) two sets of test pieces as

specified in the relevant test method standard (some commonly used test method standards are given in the

Bibliography).

Condition all the test pieces in accordance with Clause 6.

8.2 Determination of original properties before immersion

Determine the selected properties on the first set of test pieces using the relevant test method standards.

8.3 Immersion

Place the test pieces, suitably separated, in a vessel as described in Clause 7, with a volume of test liquid

(see Clause 4) that is at least 15 times the combined volume of the test pieces and sufficient to keep them

totally immersed. If the conditions of the test do not necessitate the use of a reflux condenser, stopper the

vessel. Maintain the test liquid at the test temperature T, within a tolerance of ± 2 °C, during the whole of the

exposure period.

8.4 Preparation of test pieces for redetermination of properties

At the end of the immersion period, bring the test pieces, if necessary, to the test temperature, preferably by

quickly transferring them to a fresh portion of test liquid at this temperature and allowing to stand for 5 min to

10 min.

Take the test pieces out of the test liquid and remove any liquid remaining on the surface of the test pieces

using a suitable method. The method of removing the liquid may vary with the nature of the liquid. When

mobile, volatile liquids like iso-octane and toluene are used, wipe the test pieces with a filter paper or a piece

of lint-free fabric. Some difficulty may be experienced in removing viscous, non-volatile liquids completely by

this method, and it may be necessary to dip the test pieces quickly in a suitable volatile liquid such as

methanol and wipe them again with filter paper or lint-free fabr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...