ISO/DIS 6944-1

(Main)Fire containment -- Elements of building construction

Fire containment -- Elements of building construction

Endiguement du feu -- Éléments de construction

General Information

RELATIONS

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 6944-1

ISO/TC 92/SC 2 Secretariat: ANSI

Voting begins on: Voting terminates on:

2005-11-16 2006-04-17

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Fire containment — Elements of building construction —Part 1:

Ventilation ducts

Endiguement du feu — Éléments de construction —

Partie 1: Conduits de ventilation

(Revision of ISO 6944:1985)

ICS 13.220.50; 91.140.30

In accordance with the provisions of Council Resolution 15/1993 this document is circulated in

the English language only.Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est distribué

en version anglaise seulement.To expedite distribution, this document is circulated as received from the committee secretariat.

ISO Central Secretariat work of editing and text composition will be undertaken at publication

stage.Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.© International Organization for Standardization, 2005

---------------------- Page: 1 ----------------------

ISO/DIS 6944-1

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright noticeThis ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user's country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, photocopying,

recording or otherwise, without prior written permission being secured.Requests for permission to reproduce should be addressed to either ISO at the address below or ISO's

member body in the country of the requester.ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii ISO 2005 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 6944-1

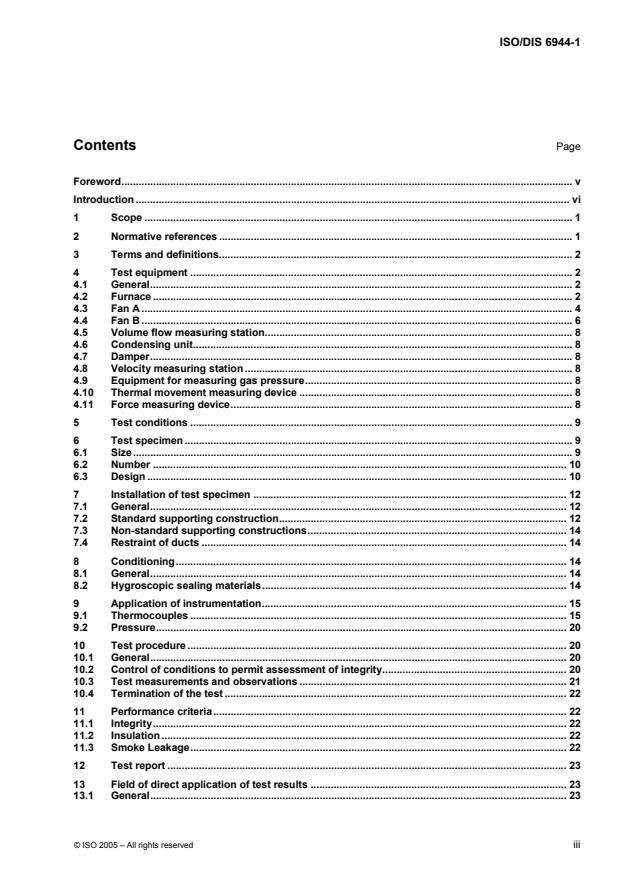

Contents Page

Foreword............................................................................................................................................................. v

Introduction ....................................................................................................................................................... vi

1 Scope..................................................................................................................................................... 1

2 Normative references........................................................................................................................... 1

3 Terms and definitions........................................................................................................................... 2

4 Test equipment..................................................................................................................................... 2

4.1 General................................................................................................................................................... 2

4.2 Furnace.................................................................................................................................................. 2

4.3 Fan A...................................................................................................................................................... 4

4.4 Fan B...................................................................................................................................................... 6

4.5 Volume flow measuring station........................................................................................................... 8

4.6 Condensing unit.................................................................................................................................... 8

4.7 Damper................................................................................................................................................... 8

4.8 Velocity measuring station.................................................................................................................. 8

4.9 Equipment for measuring gas pressure............................................................................................. 8

4.10 Thermal movement measuring device ............................................................................................... 8

4.11 Force measuring device....................................................................................................................... 8

5 Test conditions..................................................................................................................................... 9

6 Test specimen....................................................................................................................................... 9

6.1 Size......................................................................................................................................................... 9

6.2 Number................................................................................................................................................ 10

6.3 Design.................................................................................................................................................. 10

7 Installation of test specimen ............................................................................................................. 12

7.1 General................................................................................................................................................. 12

7.2 Standard supporting construction.................................................................................................... 12

7.3 Non-standard supporting constructions.......................................................................................... 14

7.4 Restraint of ducts ............................................................................................................................... 14

8 Conditioning........................................................................................................................................ 14

8.1 General................................................................................................................................................. 14

8.2 Hygroscopic sealing materials.......................................................................................................... 14

9 Application of instrumentation.......................................................................................................... 15

9.1 Thermocouples................................................................................................................................... 15

9.2 Pressure............................................................................................................................................... 20

10 Test procedure.................................................................................................................................... 20

10.1 General................................................................................................................................................. 20

10.2 Control of conditions to permit assessment of integrity................................................................ 20

10.3 Test measurements and observations ............................................................................................. 21

10.4 Termination of the test ....................................................................................................................... 22

11 Performance criteria........................................................................................................................... 22

11.1 Integrity................................................................................................................................................ 22

11.2 Insulation............................................................................................................................................. 22

11.3 Smoke Leakage................................................................................................................................... 22

12 Test report........................................................................................................................................... 23

13 Field of direct application of test results ......................................................................................... 23

13.1 General................................................................................................................................................. 23

© ISO 2005 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 6944-1

13.2 Vertical and horizontal ducts............................................................................................................. 23

13.3 Sizes of ducts ...................................................................................................................................... 23

13.4 Pressure difference............................................................................................................................. 24

13.5 Height of vertical ducts ...................................................................................................................... 24

13.6 Suspension devices for horizontal ducts......................................................................................... 25

13.7 Supporting construction.................................................................................................................... 25

13.8 Steel ducts........................................................................................................................................... 25

Annex A (informative) General guidance ....................................................................................................... 26

A.1 General................................................................................................................................................. 26

A.2 Notes on apparatus............................................................................................................................. 26

A.3 Notes on test specimens.................................................................................................................... 26

A.4 Notes on test conditions .................................................................................................................... 28

A.5 Notes on procedure ............................................................................................................................ 28

A.6 Notes on test conditions .................................................................................................................... 28

A.7 Notes on procedure ............................................................................................................................ 29

A.8 Notes on performance criteria........................................................................................................... 29

A.9 Use of alternative elbow ..................................................................................................................... 29

A.10 Avoidance of flame impingement...................................................................................................... 30

iv © ISO 2005 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 6944-1

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 6944-1 was prepared by Technical Committee ISO/TC 92, Fire safety, Subcommittee SC 2, Fire

containment.This edition cancels and replaces ISO 6944 (1985).

ISO 6944 consists of the following parts, under the general title Fire containment — Elements of building

construction: Part 1: Ventilation ducts

Part 2: Grease ducts

© ISO 2005 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/DIS 6944-1

Introduction

The purpose of this test is to measure the ability of a representative duct or duct assembly that is part of an air

distribution system, to resist the spread of fire from one fire compartment to another with fire attack from inside

or outside the duct. It is applicable to vertical and horizontal ducts, with or without branches, taking into

account joints and exhaust openings, as well as suspension devices and penetration points.

This International standard is very similar to EN 1366-1, but includes an alternative arrangement for testing

elbows.The test measures the length of time for which ducts, of specified dimensions, suspended as they would be in

practice, satisfy defined criteria when exposed to fire from (separately) both inside and outside the duct.

All ducts inside the furnace are fully restrained in all directions. Outside the furnace, ducts exposed to fire from

the outside are tested unrestrained, while ducts exposed to fire from the inside (horizontal only) are tested

restrained.The test takes into account the effect of fire exposure from the outside where a 300 Pa underpressure is

maintained in the duct as well as the effect of fire entering the ducts in conditions where forced air movement

may or may not be present by maintaining an air velocity of 3 m/s.Ducts exposed to fire from the inside are supplied with air in a manner which is indicative of the "fan off" and

"fan on" situations which could arise in practice.vi © ISO 2005 – All rights reserved

---------------------- Page: 6 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 6944-1

Fire containment — Elements of building construction —

Part 1:

Ventilation ducts

CAUTION —

The attention of all persons concerned with managing and carrying out this fire resistance test is

drawn to the fact that fire testing may be hazardous and that there is a possibility that toxic and/or

harmful smoke and gases may be evolved during the test. Mechanical and operational hazards may

also arise during the construction of the test elements or structures, their testing and disposal of test

residues.It is strongly recommended that the duct assembly is allowed to cool completely after the fire test

before dismantling to minimise the possibility of ignition of combustible residues.

An assessment of all potential hazards and risks to health shall be made and safety precautions shall

be identified and provided. Written safety instructions shall be issued. Appropriate training shall be

given to relevant personnel. Laboratory personnel shall ensure that they follow written safety

instructions at all times.1 Scope

This International Standard specifies a method for determining the fire resistance of vertical and horizontal

ventilation ducts under standardised fire conditions. The test examines the behaviour of ducts exposed to fire

from the outside (duct A) and fire inside the duct (duct B). This Standard is used in conjunction with ISO 834-1.

This International Standard is not applicable to:a) ducts whose fire resistance depends on the fire resistance performance of a ceiling;

b) ducts containing fire dampers at points where they pass through fire separations;

c) doors of inspection openings, unless included in the duct to be tested;d) two or three sided ducts;

e) fixing of suspension devices to floors or walls.

NOTE Annex A provides general guidance and gives background information.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.ISO 834-1, Fire resistance tests – Elements of building construction – Part 1: General requirements

EN 1366-1, Fire resistance tests for service installations – Part 1: Ducts© ISO 2005 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO/DIS 6944-1

ISO 5167-1, Measurement of fluid flow by means of pressure differential devices – Part 1: Orifice plates,

nozzles and venturi tubes inserted in circular cross-section conduitsISO 5221, Air distribution and air diffusion – Rules to methods of measuring air flow rate in an air handling

duct3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 834-1, ISO 13943 and the following

apply.3.1

fire resisting duct

a duct used for the distribution or extraction of air and designed to provide a degree of fire resistance

3.2suspension device

the components used for suspending and fixing a duct from a floor or supporting a duct from a wall

3.3supporting devices

the wall, partition or floor which the duct passes through in the test

3.4

compensator

a device that is used to prevent damage from the forces generated by expansion

4 Test equipment

4.1 General

In addition to the test equipment specified in ISO 834-1, the following is required:

4.2 FurnaceThis shall be capable of subjecting ventilation ducts to the standard heating and pressure conditions specified

in ISO 834-1 and be suitable for testing ducts in the vertical (see figure 1) or horizontal (see figure 2)

orientation.Dimensions in millimetres

2 © ISO 2005 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/DIS 6944-1

A A

500 500* 500

9 2

Key

1 furnace wall 9 furnace floor

2 sealed end 10 leakage measuring station (see figure 3 for details)

3 fire stopping as in practice 11 gas velocity measuring station (see figure 4

4 fire protection system for details)5 joint in fire protection system 12 duct A

6 furnace roof 13 duct B

7 furnace chamber

8 openings providing a total area of 50% of

duct cross section

W width

H height

D diameter

Note – The drawing shows two ducts being tested together. It is also permitted to test each duct singularly in the furnace.

Figure 1 — Test arrangement for vertical ductsDimensions in millimetres

© ISO 2005 – All rights reserved 3

200

2000 2000

---------------------- Page: 9 ----------------------

ISO/DIS 6944-1

500

10 14

3 7

2500

7 7

2000

Key

1 furnace wall 11 furnace chamber

2 duct with 90° elbow 12 openings providing a total area of 50% of duct

3 sealed end cross section

4 fire stopping as in practice 13 sealed end of elbow

5 fire protection system 14 200 mm minimum supporting construction

6 location of restraint positions 15 leakage measuring station (see figure 3 for

7 joints in fire protection system details)8 duct A 16 gas velocity measuring station (see figure 4 for

9 duct B details)

10 supporting construction

W Width or diameter

Note – The drawing shows two ducts being tested together. It is also permitted to test each duct singularly in the furnace.

Figure 2 — Test arrangement for horizontal ducts4.3 Fan A

This shall be able to produce at the start and throughout the test an underpressure of (300 ± 15) Pa within

duct A (see figure 3) and shall be connected either directly, or by a suitable length of flexible ducting, to the

measuring station described in 4.5.4 © ISO 2005 – All rights reserved

500*

250

500

w w

---------------------- Page: 10 ----------------------

ISO/DIS 6944-1

Key

1 pressure sensor to furnace 12 support for flow measuring system

2 pressure sensor on centre line of duct 13 thermocouple 1,5 mm diameter

3 office plate, venture or similar 14 flow straightener (where necessary)

4 pressure differential (300 Pa) 15 flange

5 pressure sensor in laboratory 16 support for duct outside furnace

6 pressure differential control box 17 test duct

7 pressure control dilution damper 18 thermocouple located 2d from 3

8 pneumatic actuator manual control 19 condensing device

© ISO 2005 – All rights reserved 5

2 5

14 9

12 12

18 8

---------------------- Page: 11 ----------------------

ISO/DIS 6944-1

9 balancing damper 20 horizontal duct A

10 fan 21 vertical duct A

11 flexible connecting duct

Figure 3 — Leakage measuring station for duct A

4.4 Fan B

This shall be able to produce an air velocity when extracting gas from duct B (see figure 4), of at least 3 m/s

measured at ambient temperature in the duct before the test. It shall be connected either directly, or by a

suitable length of flexible ducting, to the velocity measuring station described in 4.8. The fan shall be provided

with a by-pass vent that can be opened prior to the damper described in 4.7 being shut.

6 © ISO 2005 – All rights reserved---------------------- Page: 12 ----------------------

ISO/DIS 6944-1

Key

1 pressure sensor to furnace 11 thermocouple 1,5 mm diameter

2 pressure sensor on centre line of duct 12 support for velocity measuring station near

3 pressure sensor in laboratory duct4 pressure differential control box 13 flange

5 pressure control dilution damper 14 support for duct outside furnace

6 pneumatic actuator manual control 15 inlet nozzle

7 balancing damper 16 test duct

8 fan 17 flow straightener (if required)

© ISO 2005 – All rights reserved 7

2 3

12 10

---------------------- Page: 13 ----------------------

ISO/DIS 6944-1

9 flexible connecting duct 18 horizontal duct A

10 support for velocity measuring station near 19 vertical duct A

flexible duct 20 pressure differential 300 Pa

Figure 4 — Gas velocity station for duct B

4.5 Volume flow measuring station

This shall consist of a venturi, orifice plate, or other suitable device and (where necessary) an air flow

straightener, installed in straight lengths of pipe, all sized to ISO 5167-1 and ISO 5221. It shall be connected

to the end of duct A outside the furnace to determine the volume flow rate of gas passing through duct A

during the test. The measuring device shall be capable of measuring to an accuracy of ± 5 %. Regardless of

whether vertical or horizontal ducts are being tested, the volume flow measuring station shall always be used

in a horizontal orientation.4.6 Condensing unit

This shall be installed between the end of duct A and the flow measuring device and shall allow for drainage.

The gas temperature adjacent to the flow measuring device shall be measured by a 2 mm sheathed

thermocouple with an insulated hot junction, arranged pointing downwards to allow for draining moisture. Its

measuring junction shall be located at the centre line of the measuring duct and at a distance equal to twice

the diameter of the measuring duct downstream from the flow measuring device. The temperature measured

by this thermocouple shall not exceed 40 C.4.7 Damper

This shall be installed between the fan and the velocity measuring station to shut off the air flow in duct B

during evaluation of integrity in the "fan-off" condition.4.8 Velocity measuring station

This shall determine air velocity in duct B and shall consist of one or two inlet nozzle(s), or other suitable

device, installed in a straight length of pipe sized to ISO 5167-1 and ISO 5221, connected to the end of both

the vertical and horizontal duct B outside the furnace.4.9 Equipment for measuring gas pressure

This shall be provided in the furnace and inside duct A.

4.10 Thermal movement measuring device

This shall be provided for measuring expansion or contraction of duct A and shall have an accuracy of ± 1

mm.4.11 Force measuring device

This shall be provided for measuring forces at the point of applying restraint in duct B (see figure 5).

Dimensions in millimetres8 © ISO 2005 – All rights reserved

---------------------- Page: 14 ----------------------

ISO/DIS 6944-1

Key

1 allow movement in both directions

2 resist movement in both directions

3 location of measuring device for restraint forces

4 duct

5 stiff load cells (used for applying and measuring restraint)

6 furnace

Figure 5 — Restraint of duct B outside the furnace

5 Test conditions

The heating conditions and the furnace atmosphere shall conform to those given in ISO 834-1.

The furnace pressure shall be controlled to 15 ± 3 Pa throughout the test at the mid-height position of the

ducts.Details of test conditions within the ducts during the test are given in clause 10.

6 Test specimen6.1 Size

6.1.1 General

Ducts of sizes other than those given in tables 1 and 2 have restricted the direct field of application (see

clause 13).© ISO 2005 – All rights reserved 9

2000

---------------------- Page: 15 ----------------------

ISO/DIS 6944-1

6.1.2 Length

The minimum lengths of the parts of the test specimen inside and outside the furnace shall be as given in

table 1. (see also figures 1 and 2):Table 1 – Minimum length of test specimen

Orientation Minimum length (m)

Inside furnace Outside furnace

Horizontal 4,0 2,5

Vertical 2,0 2,0

6.1.3 Cross-section

The standard sizes of ducts given in table 2 shall be tested unless only smaller cross-sections are used:

Table 2 – Cross-section of test specimenDuct Rectangular Circular

width (mm) height (mm) diameter (mm)

A 1000 ± 10 500 ± 10 800 ± 10

B 1000 ± 10 250 ± 10 630 ± 10

6.2 Number

One test specimen shall be tested for each type of installation to be evaluated.

6.3 Design

6.3.1 General

The test shall be made on a test specimen representative of the complete duct assembly on which information

is required. The edge conditions and the method of fixing or support inside and outside the furnace shall be

representative of that used in practice.Ducts shall be arranged as shown in figures 1 and 2.

6.3.2 Minimum separation

There is no limit to the number of ducts that may be tested simultaneously in the same furnace, provided that

there is sufficient space to do so, in accordance with the dimensions shown in figures 1 and 2.

There shall be a separation of (500 ± 50) mm between the top of a horizontal duct and the ceiling. A minimum

separation of 500 mm shall be provided between the underside of a horizontal duct and the floor. Similarly,

there shall be a minimum separation of at least 500 mm between the sides of ducts and furnace walls.

10 © ISO 2005 – All rights reserved---------------------- Page: 16 ----------------------

ISO/DIS 6944-1

6.3.3 Configuration of duct A (horizontal only)

The horizontal duct A shall include one sharp bend, a T-piece and a 5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.