ISO 17484-1:2006

(Main)Plastics piping systems — Multilayer pipe systems for indoor gas installations with a maximum operating pressure up to and including 5 bar (500 kPa) — Part 1: Specifications for systems

Plastics piping systems — Multilayer pipe systems for indoor gas installations with a maximum operating pressure up to and including 5 bar (500 kPa) — Part 1: Specifications for systems

ISO 17484-1:2006 specifies the general requirements and the performance requirements for multilayer pipe systems based on pipes, fittings and their joints intended to be used for gas supply within buildings. PE-X and PE pipes composed of one stress-designed layer, adhesive and a barrier layer are also covered by ISO 17484-1:2006. ISO 17484-1:2006 gives guidance for the design of piping systems consisting of multilayer pipes based on thermoplastics, for which at least 60 % of the wall thickness is polymeric material. Polymeric materials intended for stress-designed layers and all inner layers are required to be polyethylene (PE) and/or crosslinked polyethylene (PE-X). The outer layer of a metal multilayer is required to be PE or PE-X. PE-RT is considered as PE but with specific properties concerning hoop-stress performance. ISO 17484-1:2006 applies to systems that operate at temperatures of - 20 °C up to 60 °C. For the purpose of ISO 17484-1:2006, crosslinked polyethylene (PE-X) and adhesive layers are considered as thermoplastic materials. For sizes greater than 63 mm the requirements of ISO 18225 have to be fulfilled in addition. ISO 17484-1:2006 is applicable for piping systems used in buildings to supply gas with a maximum operating pressure up to and including 500 kPa (5 bar). ISO 17484-1:2006 applies to Category D gaseous fuel, natural gas, and Category E gaseous fuel, LPG vapour, and natural gas or LPG vapour.

Systèmes de canalisations en matières plastiques — Tubes multicouches et leurs assemblages pour une pression maximale de service inférieure ou égale à 5 bar (500 kPa) destinés à l'alimentation en gaz à l'intérieur des bâtiments — Partie 1: Spécifications pour les systèmes

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 17484-1

First edition

2006-10-01

Plastics piping systems — Multilayer pipe

systems for indoor gas installations with

a maximum operating pressure up to and

including 5 bar (500 kPa) —

Part 1:

Specifications for systems

Systèmes de canalisations en matières plastiques — Tubes

multicouches et leurs assemblages pour une pression maximale de

service inférieure ou égale à 5 bar (500 kPa) destinés à l'alimentation

en gaz à l'intérieur des bâtiments —

Partie 1: Spécifications pour les systèmes

Reference number

ISO 17484-1:2006(E)

©

ISO 2006

---------------------- Page: 1 ----------------------

ISO 17484-1:2006(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2006

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2006 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 17484-1:2006(E)

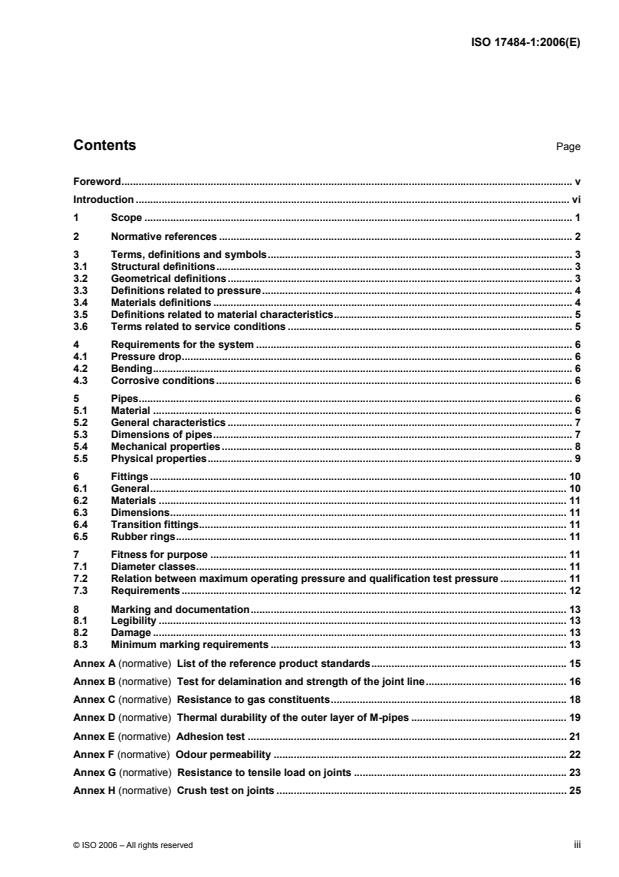

Contents Page

Foreword. v

Introduction . vi

1 Scope . 1

2 Normative references . 2

3 Terms, definitions and symbols. 3

3.1 Structural definitions. 3

3.2 Geometrical definitions. 3

3.3 Definitions related to pressure. 4

3.4 Materials definitions . 4

3.5 Definitions related to material characteristics. 5

3.6 Terms related to service conditions . 5

4 Requirements for the system . 6

4.1 Pressure drop. 6

4.2 Bending. 6

4.3 Corrosive conditions. 6

5 Pipes. 6

5.1 Material . 6

5.2 General characteristics . 7

5.3 Dimensions of pipes. 7

5.4 Mechanical properties. 8

5.5 Physical properties. 9

6 Fittings . 10

6.1 General. 10

6.2 Materials . 11

6.3 Dimensions. 11

6.4 Transition fittings. 11

6.5 Rubber rings. 11

7 Fitness for purpose . 11

7.1 Diameter classes. 11

7.2 Relation between maximum operating pressure and qualification test pressure . 11

7.3 Requirements . 12

8 Marking and documentation. 13

8.1 Legibility . 13

8.2 Damage . 13

8.3 Minimum marking requirements . 13

Annex A (normative) List of the reference product standards. 15

Annex B (normative) Test for delamination and strength of the joint line. 16

Annex C (normative) Resistance to gas constituents. 18

Annex D (normative) Thermal durability of the outer layer of M-pipes . 19

Annex E (normative) Adhesion test . 21

Annex F (normative) Odour permeability . 22

Annex G (normative) Resistance to tensile load on joints . 23

Annex H (normative) Crush test on joints . 25

© ISO 2006 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 17484-1:2006(E)

Annex I (normative) Impact resistance test on joints. 27

Annex J (normative) Thermal cycling test on joints. 29

Annex K (normative) Repeated bending test. 31

Bibliography . 33

iv © ISO 2006 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 17484-1:2006(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 17484-1 was prepared by Technical Committee ISO/TC 138, Plastics pipes, fittings and valves for the

transport of fluids, Subcommittee SC 4, Plastics pipes and fittings for the supply of gaseous fuels.

ISO 17484 consists of the following parts, under the general title Plastics piping systems — Multilayer pipe

systems for indoor gas installations with a maximum operating pressure up to and including 5 bar (500 kPa):

⎯ Part 1: Specifications for systems

A Part 2 dealing with the code of practice is planned.

© ISO 2006 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO 17484-1:2006(E)

Introduction

This part of ISO 17484 was developed in response to worldwide demand for minimum specification for multi-

layered pipes for indoor gas applications.

Multi-layered pipes are delivered generally as a complete system. Pipes, fittings, tools, etc., are not

compatible with components of another brand, generally. An advantage is that all components are perfectly

geared to one another, but for repairing, the lack of compatibility might be problematic in the future.

Fire safety of systems

Depending on the construction of the house, pipework layout and other local circumstances, it is possible that

additional safety devices are required to fulfill the demands of fire safety. Safety aspects of the system will be

described in the planned Part 2.

Code of practice

The planned second part of ISO 17484 will be the code of practice for installation.

Recommendations on design, construction and protection in case of fire of the gas indoor installation are

given in EN 1775).

References to ISO/TC 138/SC5 work

Test methods referred to in this part of ISO 17484 have been developed by SC 5 as far as possible. However,

not all test methods needed are in the working programme of SC 5. These test methods are placed in

Annexes B to K of this part of ISO 17484. It is planned that these tests will be developed as International

Standards in the future.

For multilayer pipe construction, consisting of a layer of a reference standard material, an adhesive and a non-

stress-designed layer, procedure I and the relevant product standards are followed for all aspects, excluding

the aspects of delamination and, if applicable, oxygen permeation.

For example, layers can have the following purposes:

⎯ ability to withstand the pressure;

⎯ ability to realize interlayer adhesion;

⎯ ability to block or greatly diminish incoming UV and/or sunlight;

⎯ ability to mechanically protect the outside layer;

⎯ ability to control the longitudinal expansion;

⎯ ability to give the multilayer pipe a colour (inside layer or outside layer).

Some characteristics can be combined in one layer.

vi © ISO 2006 – All rights reserved

---------------------- Page: 6 ----------------------

INTERNATIONAL STANDARD ISO 17484-1:2006(E)

Plastics piping systems — Multilayer pipe systems for indoor

gas installations with a maximum operating pressure up to and

including 5 bar (500 kPa) —

Part 1:

Specifications for systems

1 Scope

This part of ISO 17484 specifies the general requirements and the performance requirements for multilayer

pipe systems based on pipes, fittings and their joints intended to be used for gas supply within buildings.

PE-X and PE pipes composed of one stress-designed layer, adhesive and a barrier layer are also covered by

this part of ISO 17484.

This part of ISO 17484 gives guidance for the design of piping systems consisting of multilayer pipes based

on thermoplastics, for which at least 60 % of the wall thickness is polymeric material. Polymeric materials

intended for stress-designed layers and all inner layers are required to be polyethylene (PE) and/or

crosslinked polyethylene (PE-X) in accordance with Annex A of this part of ISO 17484. The outer layer of a

metal multilayer is required to be PE or PE-X. PE-RT is considered as PE but with specific properties

concerning hoop-stress performance (see 5.4.2.).

This part of ISO 17484 applies to systems that operate at temperatures of − 20 °C up to 60 °C.

For the purpose of this part of ISO 17484, crosslinked polyethylene (PE-X) and adhesive layers are

considered as thermoplastic materials.

For sizes greater than 63 mm the requirements of ISO 18225 have to be fulfilled in addition.

This part of ISO 17484 is applicable for piping systems used in buildings to supply gas with a maximum

1)

operating pressure up to and including 500 kPa (5 bar) .

This standard applies to the following fuels:

⎯ Category D gaseous fuel: natural gas; see ISO 13623;

⎯ Category E gaseous fuel: LPG vapour, and natural gas or LPG vapour; see ISO 13623.

2

1) 1 bar = 0,1 MPa = 105 Pa; 1 MPa = 1 N/mm

© ISO 2006 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO 17484-1:2006(E)

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 3:1973, Preferred numbers — Series of preferred numbers

ISO 161-1, Thermoplastics pipes for the conveyance of fluids — Nominal outside diameters and nominal

pressures — Part 1: Metric series

ISO 497:1973, Guide to the choice of series of preferred numbers and of series containing more rounded

values of preferred numbers

ISO 1167 (all parts), Thermoplastics pipes, fittings and assemblies for the conveyance of fluids —

Determination of the resistance to internal pressure

ISO 3126, Plastics piping systems — Plastics components — Determination of dimensions

ISO 3503, Assembled joints between fittings and polyethylene (PE) pressure pipes — Test of leakproofness

under internal pressure when subjected to bending

ISO 8085-3:2001, Polyethylene fittings for use with polyethylene pipes for the supply of gaseous fuels —

Metric series — Specifications — Part 3: Electrofusion fittings

ISO 9080, Plastics piping and ducting systems — Determination of the long-term hydrostatic strength of

thermoplastics materials in pipe form by extrapolation

ISO 10838 (all parts), Mechanical fittings for polyethylene piping systems for the supply of gaseous fuels

ISO 11357-6, Plastics — Differential scanning calorimetry (DSC) — Part 6: Determination of oxidation

induction time

ISO 12162:1995, Thermoplastics materials for pipes and fittings for pressure applications — Classification and

designation — Overall service (design) coefficient

ISO 13480, Polyethylene pipes — Resistance to slow crack growth — Cone test method

ISO 13623:2000, Petroleum and natural gas industries — Pipeline transportation systems

ISO 14531-1, Plastics pipes and fittings — Crosslinked polyethylene (PE-X) pipe systems for the conveyance

of gaseous fuels — Metric series — Specifications — Part 1: Pipes

ISO 17454:2006, Plastics piping systems — Multilayer pipes — Test method for the adhesion of the different

layers using a pulling rig

ISO 17456:—, Plastics piping systems — Multilayer pipes — Determination of long-term strength

ISO 18225, Plastic piping systems — Multilayer piping systems for outdoor gas installations — Specifications

for systems

EN 713, Plastics piping systems — Mechanical joints between fittings and polyolefin pressure pipes — Test

method for leaktightness under internal pressure of assemblies subjected to bending

EN 1555-3, Plastics piping systems for the supply of gaseous fuels — Polyethylene(PE) — Part 3: Fittings

2 © ISO 2006 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 17484-1:2006(E)

3 Terms, definitions and symbols

For the purposes of this document, the following terms, definitions and symbols apply.

3.1 Structural definitions

3.1.1

construction group A

group composed of multilayer pipes in which all the layers considered to be designed for stress bearing are

made of polymeric materials selected from the list of reference product standards (see Annex A)

3.1.2

construction group B

group composed of multilayer pipes in which all the layers considered to be designed for stress bearing are

made of polymeric materials selected from the list of reference product standards (see Annex A) and including

a stress bearing metallic layer

3.1.3

multilayer pipe

pipe comprising of several stress-designed layers

3.1.4

multilayer M-pipe

multilayer pipe comprising of polymers and one metallic layer of which thickness of the pipe consists of at

least 60 % of polymer layers

3.1.5

multilayer P-pipe

pipe comprised of more than one stress-designed polymeric layer (e.g. PE/PE-X)

3.1.6

layer

homogeneous circumferential section of pipe wall that has chemical and/or mechanical and/or physical

characteristics different from those of its immediate neighbours

3.1.7

inner layer

layer in contact with the conveyed fluid

3.1.8

outer layer

layer exposed to the external environment

3.2 Geometrical definitions

3.2.1

nominal diameter

d

n

specified diameter, assigned to a nominal size (DN/OD or DN/ID)

NOTE The nominal diameter is expressed in units of millimetres.

3.2.2

outside diameter

d

e

diameter, measured through its cross section at any point of a pipe or the fitting end of a fitting, rounded to the

next greater 0,1 mm

© ISO 2006 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO 17484-1:2006(E)

3.2.3

mean outside diameter

measured length of the outer circumference of the pipe divided by π, rounded up to the nearest 0,1 mm

NOTE The value for π is taken to be 3,142.

3.2.4

inside diameter

value of the measurement of the diameter through its cross section at any point of a pipe, rounded to the next

greater 0,1 mm

3.2.5

SDR

m

metal layer standard dimension ratio, the nominal outside diameter (DN or OD) divided by the nominal wall

thickness of the metal layer

3.2.6

wall thickness

difference between the pipe outside diameter used for joining and the pipe bore divided by 2

3.2.7

nominal wall thickness

e

n

wall thickness, corresponding to the minimum wall thickness at any point

NOTE The nominal wall thickness is expressed in units of millimetres.

3.2.8

mean wall thickness

e

m

arithmetic mean of at least four measurements regularly spaced around the same cross-sectional plane of the

pipe, including the measured minimum and maximum values obtained, rounded up to the nearest 0,1 mm

3.3 Definitions related to pressure

3.3.1

design pressure

p

D

highest pressure related to the circumstances for which the system has been designed and intended to be

used

3.3.2

predicted design pressure

p

CD

pressure that represents the predicted design pressure after a lifetime of 50 years, using the 97,5 % reference

line

NOTE The predicted design pressure is expressed in units of kilopascals (bars).

3.4 Materials definitions

3.4.1

virgin material

material in a form such as granules or powder that has not been subjected to use or processing other than

that required for its manufacture and to which no reprocessable or recyclable material has been added

4 © ISO 2006 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 17484-1:2006(E)

3.4.2

own reprocessable material

material prepared from rejected unused pipes and fittings, including trimmings from the production of pipes

and fittings that can be reprocessed in a manufacturer’s plant after having been previously processed by the

same manufacturer by a process such as moulding or extrusion and for which the complete formulation is

known

3.4.3

reference product standard

International Standard or draft International Standard prepared by Technical Committee ISO/TC 138/SC 4,

applicable for non-multilayer pipes, to which this part of ISO 17484 can refer for clauses related to the

materials, components (e.g. fittings), and fitness for purpose of the system

3.4.4

stress-designed layer

plastics materials used for layers intended to be stress bearing shall be restricted to the reference material

standards

3.5 Definitions related to material characteristics

3.5.1

long-term hydrostatic strength

long-term pressure strength

quantity with the dimensions of stress, which represents the predicted mean strength at a temperature T and a

time t

NOTE The long-term hydrostatic strength is expressed in units of megapascals.

3.5.2

P

LPL

lower confidence limit of the predicted hydrostatic pressure, which represents the 97,5 % (one-sided) lower

confidence limit of the predicted hydrostatic pressure at a temperature T and a time t

NOTE The lower confidence limit of the predicted hydrostatic pressure is expressed in units of kilopascals (bars).

3.5.3

MRP

minimum required pressure, equal to the estimated long-term pressure resistance of a pipe at a temperature

of 20 °C and a time 50 years, rounded to the nearest lower value of the R10 series of ISO 3:1973 and

ISO 497:1973

3.5.4

overall service (design) coefficient

C factor

overall coefficient with a value greater than 1, which takes into consideration service conditions as well as

properties of the components of a piping system other than those represented in the lower confidence limit

NOTE The minimum value of C for various materials is given in 5.2.3.

3.6 Terms related to service conditions

3.6.1

gaseous fuel

any fuel which is in the gaseous state at a temperature of 15 °C and a pressure of 100 kPa (1 bar)

© ISO 2006 – All rights reserved 5

---------------------- Page: 11 ----------------------

ISO 17484-1:2006(E)

3.6.2

category D gaseous fuels

natural gas

NOTE Categories of gaseous fuels and liquid fuel are defined in detail in ISO 13623:2000.

3.6.3

category E gaseous fuels

LPG vapour

NOTE Categories of gaseous fuels and liquid fuel are defined in detail in ISO 13623:2000.

3.6.4

maximum operating pressure

MOP

maximum pressure at which a system can be operated continuously under normal conditions

4 Requirements for the system

4.1 Pressure drop

The manufacturer shall provide information on the pressure drop in the system.

4.2 Bending

Special attention shall be paid to the pressure drop of bends. Bending properties of the pipe shall be stated by

the manufacturer.

4.3 Corrosive conditions

Components exposed to corrosive conditions shall be manufactured from a corrosion-resistant material or

protected against corrosion.

5 Pipes

5.1 Material

5.1.1 General

All stress-designed and polymeric inner layers shall be composed of reference materials in accordance with

the reference product standards specified in Annex A. It is not necessary for the outer layer to be made of a

reference material.

Materials intended for the stress-bearing layers shall conform to the material requirements of the reference

product standard(s) specified in Annex A. The pipe manufacturer shall declare the reference material standard

applicable to his product, as listed in Annex A.

5.1.2 Reprocessable materials

Clean own reprocessable material (except PE-X) of the same polymer type from products manufactured to the

reference product standard may be added to the virgin material.

6 © ISO 2006 – All rights reserved

---------------------- Page: 12 ----------------------

ISO 17484-1:2006(E)

5.1.3 Metallic materials

Aluminium materials used shall be in accordance with EN 573-3.

5.1.4 Product classification and construction group

Multilayer pipes may include polymeric or metallic layers that have several purposes, including the ability to

withstand the pressure.

For the purpose of this part of ISO 17484, multilayer pipes are classified in two groups: construction group A

and construction group B as defined in 3.1. For these definitions, adhesives are not considered as stress-

bearing layers.

The pipe manufacturer shall declare the construction group of the multilayer pipe.

5.2 General characteristics

5.2.1 General

When viewed without magnification, the internal and external surfaces of pipes shall be smooth, clean and

free from scoring, cavities and other surface defects to an extent that would prevent conformance with this

part of ISO 17484. The ends of the pipe shall be cut cleanly and square to the axis of the pipe.

The following information shall be provided:

⎯ outside diameter;

⎯ wall thickness;

⎯ thickness of the inner layer;

⎯ thickness of the metal layer;

⎯ thickness of the outer layer;

⎯ tolerances.

Dimensions shall be measured in accordance with ISO 3126.

5.2.2 Multilayer pipe construction

The joint line of the metallic layer shall be continuously welded.

5.2.3 Minimum overall service (design) coefficient

The minimum overall service (design) coefficient (C factor) is 2, as used to calculate the design pressure, p ,

D

taking into account the maximum operating temperature.

5.3 Dimensions of pipes

The outside diameter shall be accordance with ISO 161-1.

All layers shall be of sufficient thickness so that the composite pipe fulfills the requirements of this part of

ISO 17484.

© ISO 2006 – All rights reserved 7

---------------------- Page: 13 ----------------------

ISO 17484-1:2006(E)

5.4 Mechanical properties

5.4.1 Long-term pressure strength

5.4.1.1 General

The long-term pressure strength of the multilayer pipes shall be measured or calculated, as applicable.

Consequently, two procedures for the determination of long-term pressure strength of multilayer pipes are

defined in this part of ISO 17484: procedure I and procedure II.

Requirement for the predicted design pressure: P shall be equal to or greater than the relevant MOP.

CD

The operating temperature shall be taken into account.

The viscoelastic behaviour of PE-X and PE are similar; therefore, procedure I may be applied to P-pipes using

layers of both materials. It shall be taken into account that the results of procedure I are generally rather

conservative. Reference lines for PE-X can be found in ISO 10146.

NOTE The minimum overall service (design) coefficients for each material can be found in the relevant product

standard (see Annex A).

5.4.1.2 Procedure I — Calculation method

This method shall only be used for P-pipes.

The long-term pressure strength shall be calculated using the reference lines of each individual pressure-

bearing polymer layer according to of ISO 17456:—, Annex A. The addition rule related to each pressure-

bearing layer assumes similar elastic behaviour of each material used and that complete interlayer adhesion

exists, with design coefficients coming from the reference product standards.

The cumulative P shall be equal to or greater than the relevant MOP.

D

For details of confirmation testing, see 5.4.1.4.

5.4.1.3 Procedure II — Testing method

This method can be used for both multilayer P- and multilayer M-pipes.

At least one diameter of every “similar construction type” shall be tested in accordance with ISO 9080. For M-

pipes, the diameter with the highest SDR of the metal layer shall be tested.

m

The parameters p and MRP for each pipe construction shall be determined in accordance

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.