ISO/DIS 16840-3

(Main)Wheelchair seating

Wheelchair seating

Sièges de fauteuils roulants

General Information

RELATIONS

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 16840-3

ISO/TC 173/SC 1 Secretariat: SIS

Voting begins on: Voting terminates on:

2003-08-07 2004-01-07

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Wheelchair seating —Part 3:

Postural support devices — Measurement of static, impact and

repetitive load strengths

Sièges de fauteuils roulants —

Partie 3: Dispositifs de maintien de la posture — Mesure des tenues de route statiques, avec impact et

répétitivesICS 11.180.10

In accordance with the provisions of Council Resolution 15/1993 this document is circulated in

the English language only.Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est distribué

en version anglaise seulement.To expedite distribution, this document is circulated as received from the committee secretariat.

ISO Central Secretariat work of editing and text composition will be undertaken at publication

stage.Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.© International Organization for Standardization, 2003

---------------------- Page: 1 ----------------------

ISO/DIS 16840-3

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright noticeThis ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user's country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, photocopying,

recording or otherwise, without prior written permission being secured.Requests for permission to reproduce should be addressed to either ISO at the address below or ISO's

member body in the country of the requester.ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii ISO 2003 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 16840-3

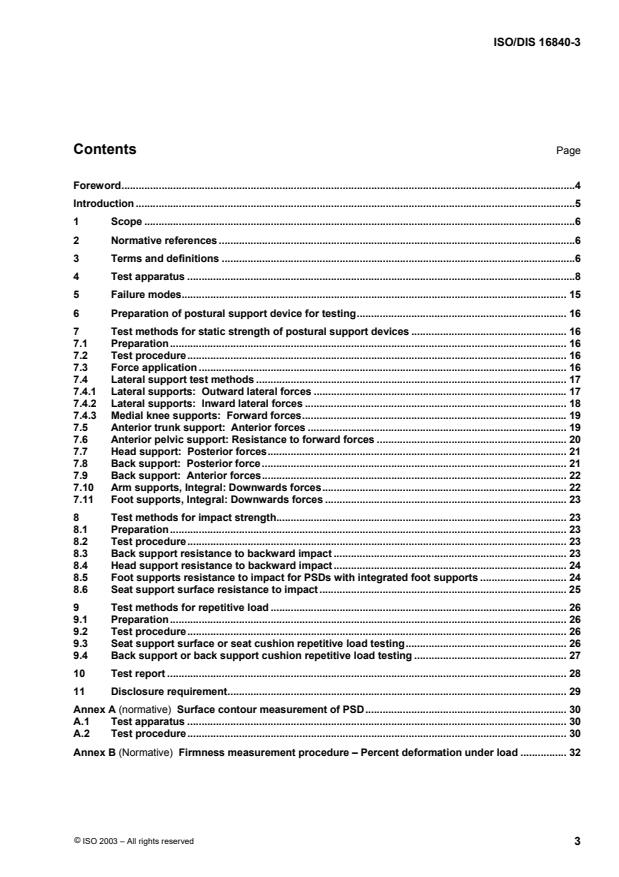

Contents Page

Foreword..............................................................................................................................................................4

Introduction.........................................................................................................................................................5

1 Scope ......................................................................................................................................................6

2 Normative references ............................................................................................................................6

3 Terms and definitions ...........................................................................................................................6

4 Test apparatus .......................................................................................................................................8

5 Failure modes...................................................................................................................................... 15

6 Preparation of postural support device for testing......................................................................... 16

7 Test methods for static strength of postural support devices ...................................................... 16

7.1 Preparation.......................................................................................................................................... 16

7.2 Test procedure.................................................................................................................................... 16

7.3 Force application ................................................................................................................................ 16

7.4 Lateral support test methods ............................................................................................................ 17

7.4.1 Lateral supports: Outward lateral forces ........................................................................................ 17

7.4.2 Lateral supports: Inward lateral forces ........................................................................................... 18

7.4.3 Medial knee supports: Forward forces............................................................................................ 19

7.5 Anterior trunk support: Anterior forces .......................................................................................... 19

7.6 Anterior pelvic support: Resistance to forward forces .................................................................. 20

7.7 Head support: Posterior forces........................................................................................................ 21

7.8 Back support: Posterior force.......................................................................................................... 21

7.9 Back support: Anterior forces.......................................................................................................... 22

7.10 Arm supports, Integral: Downwards forces..................................................................................... 22

7.11 Foot supports, Integral: Downwards forces .................................................................................... 23

8 Test methods for impact strength..................................................................................................... 23

8.1 Preparation.......................................................................................................................................... 23

8.2 Test procedure.................................................................................................................................... 23

8.3 Back support resistance to backward impact ................................................................................. 23

8.4 Head support resistance to backward impact................................................................................. 24

8.5 Foot supports resistance to impact for PSDs with integrated foot supports .............................. 24

8.6 Seat support surface resistance to impact ...................................................................................... 25

9 Test methods for repetitive load ....................................................................................................... 26

9.1 Preparation.......................................................................................................................................... 26

9.2 Test procedure.................................................................................................................................... 26

9.3 Seat support surface or seat cushion repetitive load testing........................................................ 26

9.4 Back support or back support cushion repetitive load testing ..................................................... 27

10 Test report ........................................................................................................................................... 28

11 Disclosure requirement...................................................................................................................... 29

Annex A (normative) Surface contour measurement of PSD...................................................................... 30

A.1 Test apparatus .................................................................................................................................... 30

A.2 Test procedure.................................................................................................................................... 30

Annex B (Normative) Firmness measurement procedure – Percent deformation under load ................ 32

ISO 2003 – All rights reserved---------------------- Page: 3 ----------------------

ISO/DIS 16840-3

Foreword

The ISO (International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee has

been established has the right to be represented on that committee. International organizations, governmental

and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are circulated to the member bodies for

voting. Publication as an International Standard requires approval by at least 75% of the member bodies

casting a vote.Attention is drawn to the possibility that some of the elements of this part of ISO 16840 may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 16840-3 was prepared by Technical Committee ISO/TC 173, Technical system

and aids for disabled or handicapped persons, Subcommittee SC 1, Wheelchairs.4 ISO 2003 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/DIS 16840-3

Introduction

Postural Support Devices (PSD), constructed as additional components to wheelchair seating or as

wheelchair seating in its own right, are widely available and used extensively for people with disabilities. The

selection or prescription of the most appropriate PSD is partially dependent on knowledge of their ability to

withstand static, impact and repeated loads. This standard is intended to specify test methods to provide this

information.The tests involve mounting the PSD on rigid test fixtures to simulate mounting on a wheelchair. Forces are

then applied to simulate static, impact and repeated loads encountered during normal use. The rigid test

fixture is utilized to provide a worst-case situation, which is repeatable and avoids destroying multiple

wheelchairs during testing. There are no minimum performance requirements currently specified in this part of

ISO 16840. Unless otherwise stated tests are performed at increasing loads until one of more failures occur.

This standard does not test the strength of postural support devices to withstand crash conditions in a vehicle.

Test methods for this purpose can be found in ISO 10542-1 and ISO16840-4.ISO 2003 – All rights reserved

---------------------- Page: 5 ----------------------

ISO/DIS 16840-3

Wheelchair seating —

Part 3:

Postural support devices — Measurement of static, impact and

repetitive load strengths

1 Scope

This part of ISO 16840 specifies test methods and disclosure requirements for the static, impact, and

repetitive load strength of postural support devices (PSD) with associated attachment hardware. Postural

Support Devices include Seating Systems as defined in ISO 7176-26: Wheelchairs Part 26 - Nomenclature,

Terms and Definitions.It applies to postural support devices with associated attachment hardware intended for use with wheelchairs.

NOTE This standard does not test the strength of postural support devices to withstand crash conditions in a vehicle.

2 Normative referencesThe following standards, through reference in this text, constitute provisions of this part of ISO 16840. At the

time of publication, the editions indicated were valid. All standards are subject to revision and parties to

agreements, based on this part of ISO 16840, are encouraged to investigate the possibility of applying the

most recent editions of the standards listed below. Members of IEC and ISO maintain registers of currently

valid International Standards. ISO 7176-7: 1997, Wheelchairs — Part 7: Method of measurement of seating and wheel dimensions.

ISO 7176-8:1997, Wheelchairs — Part 8: Requirements and test methods for static, impact and fatigue

strengths. ISO 7176-15: Wheelchairs — Part 15: Requirements for information disclosure, documentation and

labeling. ISO DIS 7176-26 : Wheelchairs Part 26 - Nomenclature, Terms and Definitions

ISO 898-7:1992, Mechanical proportions of fasteners – Part 7: Torsion test with minimum torques for

bolts and screws with nominal diameters 1mm to 10mm. ISO 10542-1:Technical systems and aids for disabled or handicapped persons — Wheelchair tiedown

and occupant-restraint systems — Part 1: Requirements and test methods for all systems.

ISO Guide 2, Guide to Expression of Uncertainty in Measurement. ISBN 92-67-10188-9

ISO 554-1976(E), Standard atmospheres for conditioning and / or testing - Specifications

3 Terms and definitionsFor the purposes of this part of ISO 16840 the definitions given in ISO DIS 7176-26, ISO 7176-7:1997 and the

following definitions apply:6 ISO 2003 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/DIS 16840-3

3.1

elastic attachment hardware

hardware that allows a PSD to move under force and return to its original position when the force is removed

EXAMPLE A PSD designed with a spring that allows movement.3.2

deformable support surface

support surface which actively conforms to the shape of the body part being supported

NOTE The surface may or may not return to its original shape but remains conforming over time.

EXAMPLE Foam and fluid cushions are examples of deformable support surfaces.3.3

passive movement support surface

support surface which moves with minimal resistance to follow the body part being supported

NOTE Passive support surfaces do not necessarily move back to a specific position.

EXAMPLE A mobile arm support is a passive movement support surface that allows movement with minimal

resistance.3.4

active movement support surface

support that is powered to change its configuration and its subsequent support forces

EXAMPLE An alternating pressure cushion or an electronically operated back support surface that reclines.

3.5continuous lateral support

a support surface which has a depth that extends at least 75 mm forward/upward of its uncompressed

adjacent support surface and has an angle between the adjacent support surface and the lateral support

which is less than or equal to 120° as shown in Figure 1.NOTE 1 Figure 2 shows a backrest with a contoured surface which is not considered to be a lateral

support.NOTE 2 If there are difficulties in establishing the location of the adjacent support surface, use the backrest, seat or

legrest reference planes as defined in ISO 7176-7.Figure 1 — Top view cross section of a back support with lateral supports

ISO 2003 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/DIS 16840-3

Figure 2 — Top view cross section of a back support with a contour not considered a lateral support

3.6discontinuous lateral support

a support surface which is separate from the adjacent support surface. An example is shown in Figure 3.

Figure 3 — Lateral support discontinuous with the adjacent support surface4 Test apparatus

4.1 Rigid test fixtures, structures for securing or positioning postural support devices during testing as

specified below. The tolerances for the length, width, depth and radius measurements are ± 5% of the

dimension unless otherwise stated.4.1.1 Rigid test frame, a means to simulate a wheelchair frame for securing a PSD which allows the full

range of angle adjustment of PSD attachment hardware. An informative example of a rigid test frame is shown

in Figure 4.8 © ISO 2003 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/DIS 16840-3

Figure 4 — Example of rigid test frame

4.1.2 Rigid surrogate support surface, a means of securing attachment hardware for PSDs intended to

be used with rigid flat support surfaces but which are provided without rigid flat support surfaces. An

informative example of a rigid surrogate support surface is shown in Figure 5. Holes may be drilled or other

modifications made to accommodate the mounting of a variety of attachment hardware.

rFigure 5 — Example of Rigid surrogate support surface for testing attachment hardware

4.1.3 Curved rigid surface, A means to simulate in a rigid material, the curved surface of a sling

upholstery seat or back support. The surface is used to secure seat cushions, and back supports or back

support cushions, that are intended to be used with sling upholstery. An informative example of a Curved

Rigid Surface with a radius of 1000 mm ± 100 mm is shown in Figure 6.ISO 2003 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/DIS 16840-3

cFigure 6 — Example of Curved rigid surface with a radius of 1000 mm that simulates a surface with

sling upholstery4.1.4 Rigid Flat Surface, a means to simulate in a rigid material, the surface of a flat seat or back support.

The surface is used to secure seat cushions, and back supports or back support cushions, that are intended

to be used with a flat support surface.4.2 Surrogate attachment hardware, structures to secure PSDs, intended to be used with attachment

hardware, but provided without attachment hardware. Surrogate attachment hardware allows the attachment

of PSDs to a rigid test fixture. An informative example of surrogate attachment hardware is shown in Figure 7.

Figure 7 — Example of surrogate attachment hardware4.3 Loading pads, structures that are specified below for the application of loads to Postural Support

Devices.4.3.1 Seat loading pad, a rigid indentor with a surface as specified for the Tapered Uniform Geometry

Skeli (TUGS) indenter in ISO 16840-2.10 ISO 2003 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/DIS 16840-3

4.3.2 200 mm x 200 mm convex loading pad, a loading pad made of a rigid material such as metal or

hardwood as shown in Figure 8.Figure 8 — Example of 200x200 convex loading pad

4.3.3 200 mm x 100 mm convex loading pad, a loading pad made of a rigid material such as metal or

hardwood as shown in Figure 9.Figure 9 — Example of 200 mm x 100 mm convex loading pad

ISO 2003 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/DIS 16840-3

4.3.4 Adjustable convex loading pad, a loading pad with convex surface elements and adjustable width

as shown in Figure 10.Figure 10 — Example of adjustable convex loading pad

4.3.5 Adjustable upper torso loading pad, a loading pad of adjustable size to simulate the upper torso as

shown in Figure 11.Figure 11 — Example of upper torso loading pad

12 © ISO 2003 – All rights reserved

---------------------- Page: 12 ----------------------

ISO/DIS 16840-3

4.3.6 50 mm x 100 mm convex loading pad, a loading pad made of a rigid material such as metal or

hardwood as shown in Figure 12.Figure 12 — Example of 50 mm x 100 mm convex loading pad

4.3.7 100 mm x 200 mm convex loading pad, a loading pad made of a rigid material such as metal or

hardwood as shown in Figure 13.Figure 13 — Example of 100 mm x 200 mm convex loading pad

4.3.8 75 mm x 75 mm concave loading pad, a loading pad made of a rigid material such as metal or

hardwood as shown in Figure 14.Figure 14 — Example of 75 mm x 75 mm concave loading pad

ISO 2003 – All rights reserved

---------------------- Page: 13 ----------------------

ISO/DIS 16840-3

4.3.9 75 mm convex hemi-spherical loading pad, a loading pad made of a rigid material such as metal or

hardwood as shown in Figure 15.Figure 15 — Example of 75 mm convex hemi-spherical loading pad

4.4 Static loading device, a structure for applying a static load to a PSD, which is capable of:

a) measuring the applied load to an accuracy of ± 3%;b) applying loads up to a maximum as specified in Table 1;

c) maintaining the applied load for a minimum duration of 2 s;

d) applying the load sufficiently slowly that it does not create an impact load;

e) applying the initial load at a specified angle to within ± 5°;

f) measuring the movement of the loading pad during load application.

NOTE Preloading up to 5 Newtons force may assist with setup and accuracy of measuring load angles.

Table 1Maximum user mass (kg) Maximum Test load (N)

Up to 75 1500

76-100 2000

Any greater mass up to Mass x 20

200

4.5 Impact loading device, structures for applying an impact load to the PSD as specified below.

4.5.1 Seat support surface, back support and head support impact loading device, a means of

applying an impact load to the PSD, consisting of:a) an impact pendulum as specified in 5.5 of ISO 7176-8;

b) a means to measure the angle of the longitudinal axis of the pendulum prior to being dropped to an

accuracy of ± 1°.4.5.2 Foot support impact loading device, an impact loading device consisting of:

a) an impact pendulum as specified in 5.7 of ISO 7176-8;14 ISO 2003 – All rights reserved

---------------------- Page: 14 ----------------------

ISO/DIS 16840-3

b) a means to measure the angle of the longitudinal axis of the pendulum prior to being dropped to an

accuracy of ± 1°.4.6 Repetitive static loading device, a structure for repeatedly applying a load to the PSD, which is

capable of:a) applying load magnitudes up to the values specified in Table 2;

b) applying loads sufficiently slowly that it does not create an impact load;

c) avoiding a frequency of loading that is the resonant frequency of any active postural support device.

NOTE Preloading may assist with setup and accuracy of measuring load angles.Table 2

Maximum user mass (kg) Test load (N)

Up to 75 750

76-100 1000

Any greater mass up to Mass x 10

200

4.7 Test environment, an environment within which to conduct the tests and which can be maintained at

23°C ±2°C, with relative humidity of 50% ±5% as defined in to ISO 554-1976(E).5 Failure modes

Testing is conducted either until a device is considered to have failed or until completion of a test after which

the device is inspected for failure. The following are specifications of failure of a device.

a) fractures, or visible cracks, tears or broken stitches.NOTE Cracks in surface finishes, such as paint, that do not extend into the structure of the material do not constitute

a failure.b) any detached nut, bolt, screw, locking pin, component or similar item.

c) slippage in the position or adjustment of a PSD of more than 5 mm at the point of loading compared to its

original set up.d) displacement or disconnection of any electrical connector.

e) any parts intended to be removable, foldable or adjustable ceasing to operate as described by the

manufacturer.f) any power-operated PSDs ceasing to operate as described by the manufacturer.

g) any multiposition or adjustable PSD becoming permanently displaced more than 5 mm at the point of

loading from the preset position.h) any component or assembly of parts exhibiting permanent deformation or maladjustment that adversely

affects the function of the PSD.i) the applied load starting to decrease as a result of the PSD beginning to yield or deform.

ISO 2003 – All rights reserved---------------------- Page: 15 ----------------------

ISO/DIS 16840-3

6 Preparation of postural support device for testing

6.1 Secure the postural support device to the rigid test fixture specified in 4.1 according to the PSD

manufacturer’s instructions for attachment to a wheelchair.6.2 If a postural support device is provided with its attachment hardware as a system from a manufacturer,

set up the support device and attachment hardware together as a unit. Secure separate postural support

devices intended to be attached with hardware but supplied without hardware, using surrogate attachment

hardware as specified in 4.2.NOTE Various fasteners e.g. Hook and Loop can be used to assist maintaining the position of postural support

devices for testing providing they do not interfere with the test procedure. The loading pad may be connected to an inertial

arrestor to prevent injury if the postural support device breaks under test loads.

6.3 Adjust all postural support devices, including passive and active supports to a configuration, which

minimizes their ability to withstand static, impact and repeated loads but which remain within the limits of

adjustment specified by the manufacturer.NOTE The worst case situation for some PSDs might be at full extension and full lateral offset which would cause a

situation of maximum moment arm.6.4 Tighten all fastenings as specified in the manufacturer’s instructions. If not specified, tighten to the

minimum torque as specified in ISO 898-7.NOTE Further information may be obtained through the website http://www.iso.ch/iso/en/ISOOnline.frontpage and

searching for “bolts” and downloading Fasteners1.pdf for a list of specific ISO standards concerning fasteners.

6.5 Set up any active postural support devices as specified by the manufacturer.6.6 Place the test PSD in the test environment for at least 30 min before testing.

NOTE As the PSD is tested to failure in static, impact and repeated load testing, there is no specified order

of testing and a new PSD may be used for each test.7 Test methods for static strength of postural support devices

7.1 Preparation

Prepare the test postural support device as specified in Clause 6.

NOTE A new PSD may be used for each test.

7.2 Test procedure

Conduct the following tests in the test environment specified in 4.7.

Select and, if necessary, modify the most appropriate loading pad from 4.3, unless otherwise specified in the

test procedure. Record the loading pad used in each test procedure.Apply a test load as specified in 7.3 to each of the postural support devices according to the relevant

procedures in 7.4 to 7.11.7.3 Force application

The procedure is as follows.

a) Align the loading pad to apply the test load at the centre of the PSD perpendicular to the support surface.

16 ISO 2003 – All rights reserved---------------------- Page: 16 ----------------------

ISO/DIS 16840-3

b) Slowly increase the load so as not to create an impact load, until one or more of the failure modes listed

in Clause 5 occurs, or until the load reaches the maximum recommended load as specified in Table 1.

c) Record and report the load at which failure occurs and the type of failure. Record and report the rigid test

fixture used for each test.7.4 Lateral support test methods

The following tests apply, but are not limited, to the following lateral support devices:

lateral trunk supports; lateral pelvic supports;

lateral upper leg supports;

lateral knee supports;

lateral lower leg supports;

lateral head support;

medial knee supports.

NOTE These tests do not apply to lateral support surfaces that are continuous with an adjacent support surface, and

that extend less than 75 mm anterior from the mid-line of the support surface, or at an angle greater than 120° as shown in

Figure 2.7.4.1 Lateral supports: Outward lateral forces

a) Identify if the lateral support is continuous or discontinuous as specified in 3.5 and 3.6.

b) Select and if necessary modify an appropriate sized loading pad as specified in 4.3.

c) For continuous lateral supports apply the test load as specified in 7.3 but at a point which is 75% ± 10mm

of the total depth of the support, measured from the adjacent support surface as shown in Figure 16. If

there are difficulties in establishing the location of the uncompressed adjacent support surface, use the

backrest, seat or leg rest reference planes as defined in ISO 7176-7.d) For discontinuous lateral supports, apply the test load as specified in 7.3 to the centre ± 10 mm of the

support s...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.