ISO 6935-3:2023

(Main)Steel for the reinforcement of concrete - Part 3: Welded fabric

Steel for the reinforcement of concrete - Part 3: Welded fabric

This document specifies technical requirements for factory made sheets or rolls of welded fabric, manufactured from steel wires or bars with diameters from 4 mm to 18 mm and designed for the reinforcement of concrete structures and the ordinary reinforcement of prestressed concrete structures.

Aciers à béton pour armatures passives — Partie 3: Treillis soudés

General Information

Relations

Overview

ISO 6935-3:2023 - "Steel for the reinforcement of concrete - Part 3: Welded fabric" defines technical requirements for factory-made sheets or rolls of welded fabric (welded wire fabric/welded mesh) used as reinforcement in concrete structures. It covers welded fabric manufactured from steel wires or bars with nominal diameters from 4 mm to 18 mm, intended for ordinary reinforcement of reinforced and prestressed concrete.

Keywords: ISO 6935-3, welded fabric, welded mesh, steel reinforcement, reinforcement of concrete, welded wire fabric.

Key topics and technical requirements

- Scope and product types

- Applies to machine-made welded fabric produced by electrical resistance welding from cold-reduced wire, plain bars or ribbed bars (4–18 mm range; plain/ribbed bars typically 6–18 mm).

- Geometry and tolerances

- Defines fabric geometry (length, width, longitudinal/transverse wires, overhang) and two families: regular fabric (uniform diameters and spacing) and designed fabric (custom, by agreement).

- Minimum overhang: 25 mm. Spacing guidance: longitudinal spacing preferably multiples of 50 mm, transverse multiples of 25 mm; minimum spacing 100 mm.

- Permitted deviations: length/width ±25 mm or ±0.5% (whichever greater); spacing ±10 mm or ±5%; diagonal difference ±0.5%.

- Weld quality and permitted defects

- Welds must be shear-resistant; broken welds limited to ≤ 1% of total or ≤ half along any one wire.

- Mechanical and chemical properties

- Chemical and mechanical requirements reference ISO 10544 (cold-reduced wire), ISO 6935‑1 (plain bars) and ISO 6935‑2 (ribbed bars).

- Shear strength of welded joints: at least 30% of specified characteristic yield/proof stress × nominal cross-sectional area of the thickest wire (reducible to 25% by agreement).

- Testing and inspection

- Mechanical tests (tensile, bend, joint shear) performed per ISO 15630‑2. Test pieces taken from delivered fabric, with specific gauge lengths and sampling rules.

- Designation, marking and conformity

- Clauses cover product designation, marking requirements and production/acceptance inspection procedures.

Applications and users

- Practical uses: floor slabs, walls, precast elements, shotcrete or other reinforced concrete applications where welded mesh is specified for distribution and crack control.

- Primary users:

- Structural and civil engineers specifying reinforcement

- Fabric manufacturers and quality control teams

- Contractors and precast producers purchasing welded fabric

- Inspection bodies and procurement professionals verifying conformity

Related standards

- ISO 6935-1 (plain bars), ISO 6935-2 (ribbed bars)

- ISO 10544 (cold-reduced wire for welded fabric)

- ISO 15630-2 (test methods for welded fabric and lattice girders)

ISO 6935-3:2023 provides a concise, standardized basis for producing, testing and specifying welded fabric for reliable steel reinforcement in concrete construction.

Frequently Asked Questions

ISO 6935-3:2023 is a standard published by the International Organization for Standardization (ISO). Its full title is "Steel for the reinforcement of concrete - Part 3: Welded fabric". This standard covers: This document specifies technical requirements for factory made sheets or rolls of welded fabric, manufactured from steel wires or bars with diameters from 4 mm to 18 mm and designed for the reinforcement of concrete structures and the ordinary reinforcement of prestressed concrete structures.

This document specifies technical requirements for factory made sheets or rolls of welded fabric, manufactured from steel wires or bars with diameters from 4 mm to 18 mm and designed for the reinforcement of concrete structures and the ordinary reinforcement of prestressed concrete structures.

ISO 6935-3:2023 is classified under the following ICS (International Classification for Standards) categories: 77.140.15 - Steels for reinforcement of concrete; 91.080.40 - Concrete structures. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 6935-3:2023 has the following relationships with other standards: It is inter standard links to ISO 6935-3:1992. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 6935-3:2023 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 6935-3

Second edition

2023-11

Steel for the reinforcement of

concrete —

Part 3:

Welded fabric

Aciers à béton pour armatures passives —

Partie 3: Treillis soudés

Reference number

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

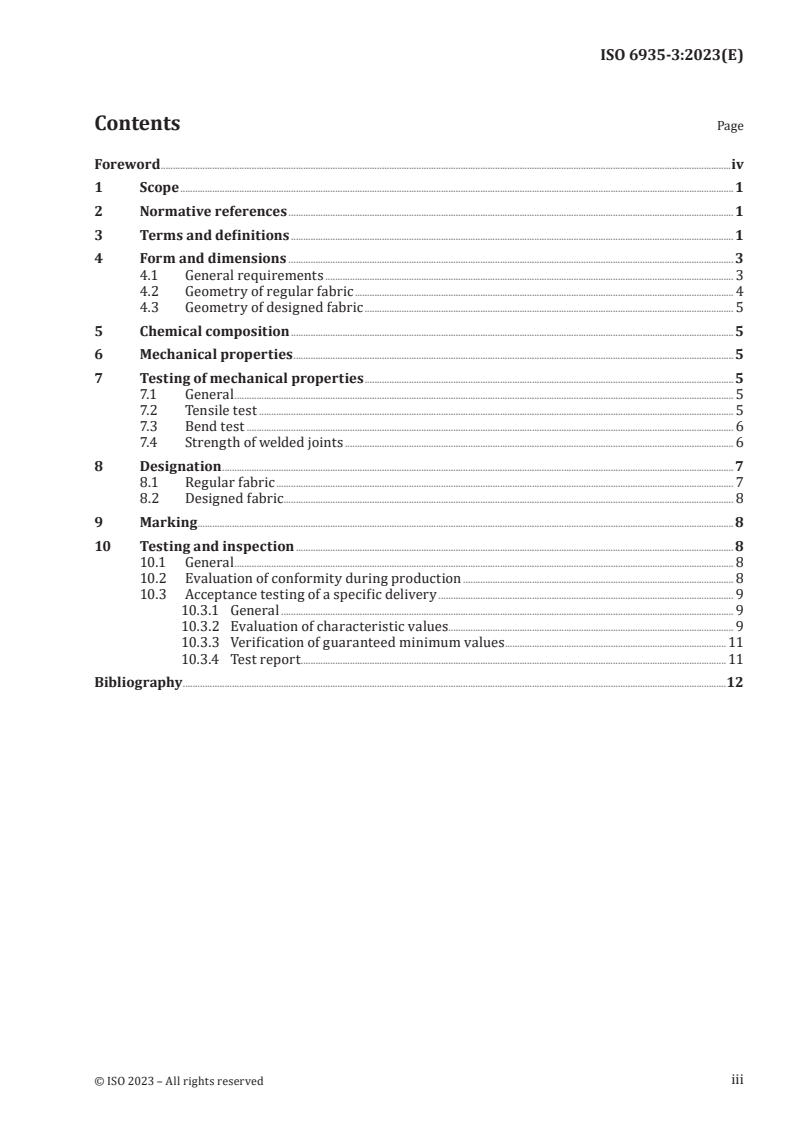

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Form and dimensions . 3

4.1 General requirements . 3

4.2 Geometry of regular fabric . 4

4.3 Geometry of designed fabric . 5

5 Chemical composition .5

6 Mechanical properties .5

7 Testing of mechanical properties .5

7.1 General . 5

7.2 Tensile test . 5

7.3 Bend test . 6

7.4 Strength of welded joints . 6

8 Designation . 7

8.1 Regular fabric . 7

8.2 Designed fabric . 8

9 Marking . . 8

10 Testing and inspection . 8

10.1 General . 8

10.2 Evaluation of conformity during production . 8

10.3 Acceptance testing of a specific delivery . 9

10.3.1 General . 9

10.3.2 Evaluation of characteristic values . . 9

10.3.3 Verification of guaranteed minimum values . 11

10.3.4 Test report . 11

Bibliography .12

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had not received

notice of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 17, Steel, Subcommittee SC 16, Steels for

the reinforcement and prestressing of concrete.

This second edition cancels and replaces the first edition (ISO 6935-3:1992), which has been technically

revised. It also incorporates the Technical Corrigendum ISO 6935-3:1992/Cor 1:2000.

The main changes are as follows:

— Clauses 1, 2, 3 and 4 have been revised;

— Figure 1 has been replaced with a new figure.

A list of all parts in the ISO 6935 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

INTERNATIONAL STANDARD ISO 6935-3:2023(E)

Steel for the reinforcement of concrete —

Part 3:

Welded fabric

1 Scope

This document specifies technical requirements for factory made sheets or rolls of welded fabric,

manufactured from steel wires or bars with diameters from 4 mm to 18 mm and designed for

the reinforcement of concrete structures and the ordinary reinforcement of prestressed concrete

structures.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 6935-1, Steel for the reinforcement of concrete — Part 1: Plain bars

ISO 6935-2, Steel for the reinforcement of concrete — Part 2: Ribbed bars

ISO 10544, Cold-reduced steel wire for the reinforcement of concrete and the manufacture of welded fabric

ISO 15630-2, Steel for the reinforcement and prestressing of concrete — Test methods — Part 2: Welded

fabric and lattice girders

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

characteristic value

value having a prescribed probability of not being attained in a hypothetical unlimited test series

Note 1 to entry: Equivalent to “fractile”, which is defined in ISO 3534-1:2006.

Note 2 to entry: A nominal value is used as the characteristic value in some circumstances.

[SOURCE: ISO 16020:2005, 2.4.10, modified —Note 2 to entry has been added.]

3.2

fabric

geometrical arrangement of longitudinal and transverse wires that are arranged substantially at right

angles to each other and welded together at all points of intersection

Note 1 to entry: See Figure 1.

Key

b spacing of the longitudinal wire

b spacing of the transverse wire

u overhang of the longitudinal wire

u overhang of the longitudinal wire

u overhang of the transverse wire

u overhang of the transverse wire

B width of fabric (length of the transverse wire)

L length of fabric (length of the longitudinal wire)

Figure 1 — Geometric characteristics of fabric

3.3

inspection

activities such as measuring, examining, testing, gauging one or more characteristics of a product or

service and comparing these with specified requirements to determine conformity

3.4

length of fabric

longest side of the fabric, irrespective of the manufacturing direction

3.5

longitudinal wire

wire in the manufacturing direction of the fabric

3.6

nominal cross-sectional area

cross-sectional area equivalent to the area of a circular plain bar of the same nominal diameter

[SOURCE: ISO 16020:2005, 2.2.15, modified — “wire” has been removed from the definition.]

3.7

overhang

length of longitudinal or transverse wires beyond the centre of the outer crossing wire in a fabric

Note 1 to entry: For twin wire fabric, the overhang is measured from the tangent line of the adjacent wires, see

Figure 2.

3.8

spacing

centre-to-centre distance of wires in a fabric

Note 1 to entry: For twin wire fabric, the spacing is measured between the tangents of the adjacent wires, see

Figure 2.

Figure 2 — Wire spacing, b, and overhang, u

3.9

transverse wire

wire perpendicular to the manufacturing direction of the fabric

3.10

twin wires

two wires of the same type and size placed adjacently and in contact with each other as a pair

3.11

width of fabric

shortest side of the fabric, irrespective of the manufacturing direction

3.12

wire

material from which the fabric is welded

Note 1 to entry: For the purposes of this document, the term “wire” also includes bars within the size range

specified in 4.1.1.

4 Form and dimensions

4.1 General requirements

4.1.1 The fabric shall be made of either

— cold-reduced wires with nominal diameters in the range from 4 mm to 18 mm and with mass and

geometry in accordance with ISO 10544,

— plain bars with nominal diameters of 6 mm to 18 mm (recommended: 6 mm, 8 mm, 10 mm and

12 mm, 18 mm plain bars may be used by agreement between the manufacturer and purchaser) and

with mass in accordance with ISO 6935-1, or

— ribbed bars with nominal diameters of 6 mm to 18 mm (recommended: 6 mm, 8 mm, 10 mm and

12 mm, 18 mm ribbed bars may be used by agreement between the manufacturer and purchaser)

and with mass and geometry in accordance with ISO 6935-2.

4.1.2 All fabric shall be machine made, and the joints at the in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...