ISO 10468:2003

(Main)Glass-reinforced thermosetting plastics (GRP) pipes - Determination of the long-term specific ring creep stiffness under wet conditions and calculation of the wet creep factor

Glass-reinforced thermosetting plastics (GRP) pipes - Determination of the long-term specific ring creep stiffness under wet conditions and calculation of the wet creep factor

ISO 10468:2003 specifies a method for determining both the long-term specific ring creep stiffness and the wet creep factor for glass-reinforced thermosetting plastics (GRP) pipes.

Tubes en plastiques thermodurcissables renforcés de verre (PRV) — Détermination de la rigidité annulaire spécifique à long terme en fluage en conditions mouillées et calcul du facteur de fluage mouillé

General Information

Relations

Frequently Asked Questions

ISO 10468:2003 is a standard published by the International Organization for Standardization (ISO). Its full title is "Glass-reinforced thermosetting plastics (GRP) pipes - Determination of the long-term specific ring creep stiffness under wet conditions and calculation of the wet creep factor". This standard covers: ISO 10468:2003 specifies a method for determining both the long-term specific ring creep stiffness and the wet creep factor for glass-reinforced thermosetting plastics (GRP) pipes.

ISO 10468:2003 specifies a method for determining both the long-term specific ring creep stiffness and the wet creep factor for glass-reinforced thermosetting plastics (GRP) pipes.

ISO 10468:2003 is classified under the following ICS (International Classification for Standards) categories: 23.040.20 - Plastics pipes. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 10468:2003 has the following relationships with other standards: It is inter standard links to ISO/R 1710:1970, ISO 10468:2003/Amd 1:2010, ISO 10468:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 10468:2003 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 10468

First edition

2003-12-01

Glass-reinforced thermosetting plastics

(GRP) pipes — Determination of the

long-term specific ring creep stiffness

under wet conditions and calculation of

the wet creep factor

Tubes en plastiques thermodurcissables renforcés de verre (PRV) —

Détermination de la rigidité annulaire spécifique à long terme en fluage

en conditions mouillées et calcul du facteur de fluage mouillé

Reference number

©

ISO 2003

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2003

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2003 — All rights reserved

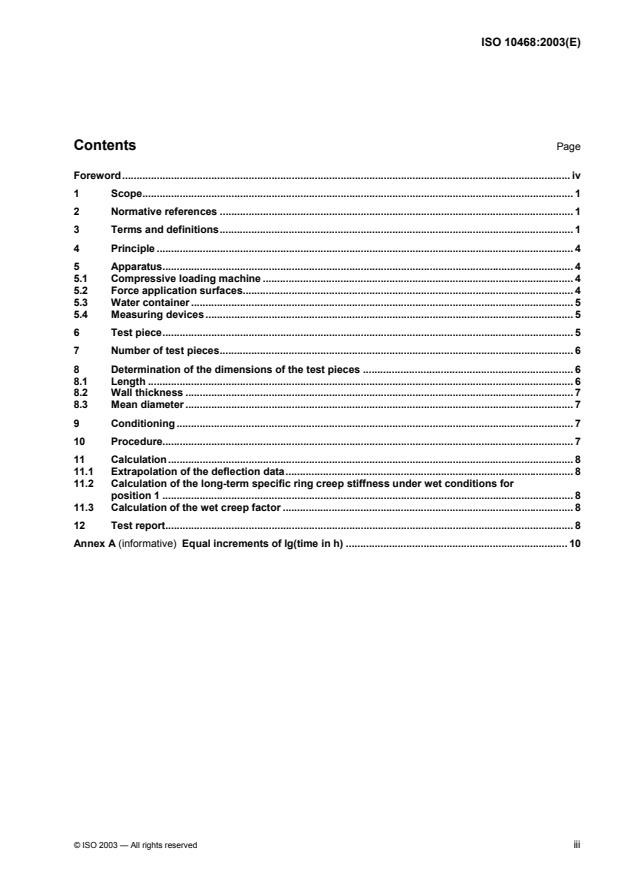

Contents Page

Foreword. iv

1 Scope. 1

2 Normative references. 1

3 Terms and definitions. 1

4 Principle. 4

5 Apparatus. 4

5.1 Compressive loading machine . 4

5.2 Force application surfaces. 4

5.3 Water container. 5

5.4 Measuring devices. 5

6 Test piece. 5

7 Number of test pieces. 6

8 Determination of the dimensions of the test pieces . 6

8.1 Length. 6

8.2 Wall thickness. 7

8.3 Mean diameter. 7

9 Conditioning. 7

10 Procedure. 7

11 Calculation. 8

11.1 Extrapolation of the deflection data. 8

11.2 Calculation of the long-term specific ring creep stiffness under wet conditions for

position 1 . 8

11.3 Calculation of the wet creep factor . 8

12 Test report. 8

Annex A (informative) Equal increments of lg(time in h) . 10

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 10468 was prepared by Technical Committee ISO/TC 138, Plastics pipes, fittings and valves for the

transport of fluids, Subcommittee SC 6, Reinforced plastics pipes and fittings for all applications.

iv © ISO 2003 — All rights reserved

INTERNATIONAL STANDARD ISO 10468:2003(E)

Glass-reinforced thermosetting plastics (GRP) pipes —

Determination of the long-term specific ring creep stiffness

under wet conditions and calculation of the wet creep factor

1 Scope

This International Standard specifies a method for determining both the long-term specific ring creep stiffness

and the wet creep factor for glass-reinforced thermosetting plastics (GRP) pipes.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 7685:1998, Plastics piping systems — Glass-reinforced thermosetting plastics (GRP) pipes —

Determination of initial specific ring stiffness

ISO 10928:1997, Plastics piping systems — Glass-reinforced thermosetting plastics (GRP) pipes and

fittings — Methods for regression analysis and their use

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

vertical compressive force

F

vertical force, expressed in newtons, applied to a horizontal pipe to cause a vertical deflection

3.2

specific ring stiffness

S

physical characteristic of a pipe, expressed in newtons per square metre, that is a measure of the resistance

to ring deflection per metre length under external load and is defined by Equation (1):

E× I

S= (1)

d

m

where

E is the apparent modulus of elasticity, in newtons per square metre, determined by testing in

accordance with ISO 7685;

I is the second moment of area in the longitudinal direction per metre length, in metres to the fourth

power per metre (m /m), i.e.

e

I= (2)

e being the wall thickness of the pipe, in metres;

d is the mean diameter of the pipe, in metres (see 3.3).

m

3.3

mean diameter

d

m

diameter, expressed in metres, of the circle corresponding with the middle of the pipe wall cross-section and

given by either of the following equations:

dd=+e (3)

mi

dd=−e (4)

me

where

d is the internal diameter, in metres;

i

d is the external diameter, in metres;

e

e is the wall thickness of the pipe, in metres.

3.4

initial specific ring stiffness

S

value of S, expressed in newtons per square metre, determined by testing in accordance with ISO 7685

3.5

long-term specific ring creep stiffness at position 1

S

x, 1, creep, wet

value of S, expressed in newtons per square metre, at a reference position, position 1 (see 10.2), at x years,

obtained by extrapolation of long-term stiffness measurements at a constant force under wet conditions

(see 3.2 and 10.2)

3.6

calculated long-term specific ring creep stiffness under wet conditions

S

x, creep, wet

calculated value of S, expressed in newtons per square metre, at x years obtained using Equation (5):

SS=×α (5)

xx, creep, wet 0 , creep, wet

where

x is the elapsed time, in years, specified in the referring standard;

α is the wet creep factor (see 3.7);

x, creep, wet

S is the initial specific ring stiffness, in newtons per square metre.

3.7

wet creep factor

α

x, creep, wet

ratio of the long-term specific ring creep stiffness to the initial specific ring stiffness, both at a reference

position, position 1 (see 10.2), and given by Equation (6):

S

x,1, creep,wet

α = (6)

x, creep, wet

S

0, 1

2 © ISO 2003 — All rights reserved

where

S is the initial specific ring stiffness at position 1, in newtons per square metre, determined

0, 1

in accordance with ISO 7685;

S is the long-term specific ring creep stiffness at position 1, in newtons per square metre.

x, 1, creep, wet

3.8

vertical deflection

y

vertical change in diameter of a pipe in a horizontal position, expressed in metres, in response to a vertical

compressive force (see 3.1)

3.9

long-term vertical deflection

y

x, 1, wet

value of the vertical deflection y, expressed in metres, at the reference position, position 1 (see 10.2), at

x years under wet conditions

3.10

deflection coefficient

f

dimensionless factor which takes into account general second-order theory as applied to deflection and is

given by Equation (7):

−5

fy=+1860 2 500× /d×10 (7)

()

1m

where

y is the long-term vertical deflection at position 1, in metres;

d is the mean diameter (see 3.3) of the pipe, in metres.

m

3.11

calculated strain

ε

calc, 1

strain on the inner surface at the crown and invert of a pipe at the reference position, position 1, given in

percent by Equation (8):

e y

4,28×× ×100

dd

mm

ε = (8)

calc,1

y

1+

2× d

m

where

y is the vertical deflection at position 1, in metres;

d is the mean diameter of the pipe (see 3.3), in metres;

m

e is the wall thickness of the pipe, in metres.

4 Principle

A cut length of pipe supported horizontally is loaded throughout its length to compress it diametrically to a

prescribed level of strain calculated using Equation 8. The force application surfaces are either bearing plates

or beam bars.

The pipe is immersed in water at a given temperature for a period of time during which the force remains

constant and the vertical deflection is measured at intervals. The long-term specific ring creep stiffness is

estimated by extrapolation.

The wet creep factor is then determined from the long-term specific ring creep stiffness and the initial specific

ring stiffness of the same test piece. The declared wet creep factor is the average of the results from two test

pieces.

NOTE It is assumed that values for the following test parameters will be set by the standard making reference to this

International Standard:

a) the method for measuring the initial specific ring stiffness, i.e. method A or B of ISO 7685:1998 (see 3.4);

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...