ASTM D1200-23

(Test Method)Standard Test Method for Viscosity by Ford Viscosity Cup

Standard Test Method for Viscosity by Ford Viscosity Cup

SIGNIFICANCE AND USE

5.1 This test method is useful for the determination of package and application viscosities of a number of paints and other coatings and in the thinning of these materials, but is limited to Newtonian or near-Newtonian liquids.

5.2 There are other types of apparatus for measuring viscosity in the laboratory that produce more accurate results.

SCOPE

1.1 This test method covers the determination of the viscosity of Newtonian or near-Newtonian paints, varnishes, lacquers, and related liquid materials with the Ford-type efflux viscosity cup. If the material is non-Newtonian, that is, shear-thinning or thixotropic, Test Method D2196 should be used.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1200 − 23

Standard Test Method for

1

Viscosity by Ford Viscosity Cup

This standard is issued under the fixed designation D1200; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3.1.1 Newtonian liquid, n—a liquid in which the viscosity is

independent of the shear stress or shear rate. If the ratio of

1.1 This test method covers the determination of the viscos-

shear stress to shear rate is not constant, the liquid is non-

ity of Newtonian or near-Newtonian paints, varnishes,

Newtonian.

lacquers, and related liquid materials with the Ford-type efflux

3.1.2 Near-Newtonian liquid, n—a liquid in which the

viscosity cup. If the material is non-Newtonian, that is,

variation of viscosity with shear rate is small and the effect on

shear-thinning or thixotropic, Test Method D2196 should be

viscosity of mechanical disturbances such as stirring is negli-

used.

gible.

1.2 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

4. Summary of Test Method

only.

4.1 The Ford viscosity cup is filled level full with the liquid

1.3 This standard does not purport to address all of the

under test, and the time for the material to flow through one of

safety concerns, if any, associated with its use. It is the

the standard orifices is measured.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

5. Significance and Use

mine the applicability of regulatory limitations prior to use.

5.1 This test method is useful for the determination of

1.4 This international standard was developed in accor-

package and application viscosities of a number of paints and

dance with internationally recognized principles on standard-

other coatings and in the thinning of these materials, but is

ization established in the Decision on Principles for the

limited to Newtonian or near-Newtonian liquids.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5.2 There are other types of apparatus for measuring vis-

Barriers to Trade (TBT) Committee.

cosity in the laboratory that produce more accurate results.

2. Referenced Documents

6. Apparatus

2

2.1 ASTM Standards:

6.1 Ford Viscosity Cups—Nos. 1, 2, 3, 4, and 5 Ford

D2196 Test Methods for Rheological Properties of Non-

viscosity cups made of corrosion- and solvent-resistant mate-

Newtonian Materials by Rotational Viscometer

rials assembled as complete units (Note 1), and conforming to

E1 Specification for ASTM Liquid-in-Glass Thermometers

the dimensional requirements shown in Fig. 1. The orifice

dimensions are considered as a guide only as the combination

3. Terminology

of cup and orifice dimensions must permit conformance to the

flow formula for each cup as listed in the Appendix.

3.1 Definitions:

NOTE 1—If the orifice is removed from the cup for any reason the cup

should be recalibrated before use as described in the Appendix.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

6.2 Thermometer—Saybolt Viscosity Thermometer con-

and Related Coatings, Materials, and Applications and is the direct responsibility of

forming to the requirements for Thermometer 17C (19 °C to

Subcommittee D01.24 on Physical Properties of Liquid Paints & Paint Materials.

27 °C) or 17F (66 °F to 80 °F) as prescribed in Specification

Current edition approved June 1, 2023. Published June 2023. Originally

E1. In addition, temperature measuring devices such as non-

approved in 1952. Last previous edition approved in 2018 as D1200 – 10 (2018).

DOI: 10.1520/D1200-23.

mercury liquid-in-glass thermometers, thermocouples, or plati-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

num resistance thermometers that provide equivalent or better

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

accuracy and precision, that cover the temperature range for

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. thermometer 17C and 17F, may be used.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1200 − 23

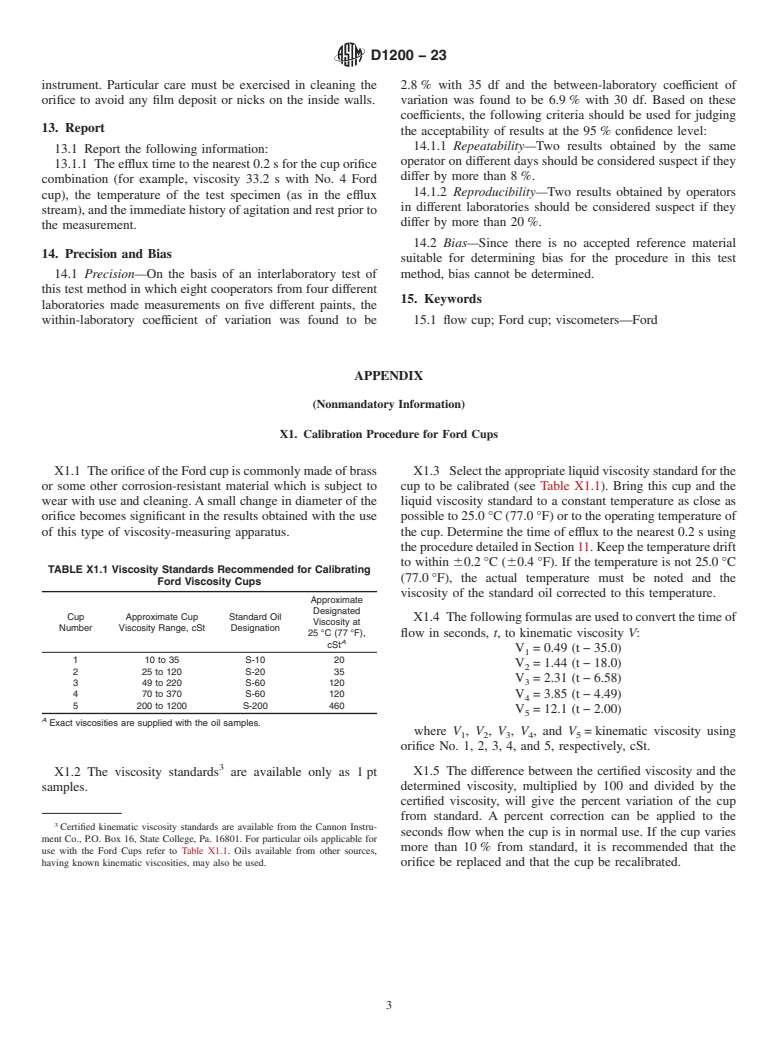

10. Conditioning

10.1 Bring the material to a t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1200 − 10 (Reapproved 2018) D1200 − 23

Standard Test Method for

1

Viscosity by Ford Viscosity Cup

This standard is issued under the fixed designation D1200; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers the determination of the viscosity of Newtonian or near-Newtonian paints, varnishes, lacquers, and

related liquid materials with the Ford-type efflux viscosity cup. If the material is non-Newtonian, that is, shear-thinning or

thixotropic, Test Method D2196 should be used.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D2196 Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational Viscometer

E1 Specification for ASTM Liquid-in-Glass Thermometers

3. Terminology

3.1 Definitions:

3.1.1 Newtonian liquid, n—a liquid in which the viscosity is independent of the shear stress or shear rate. If the ratio of shear stress

to shear rate is not constant, the liquid is non-Newtonian.

3.1.2 Near-Newtonian liquid, n—a liquid in which the variation of viscosity with shear rate is small and the effect on viscosity

of mechanical disturbances such as stirring is negligible.

4. Summary of Test Method

4.1 The Ford viscosity cup is filled level full with the liquid under test, and the time for the material to flow through one of the

standard orifices is measured.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.24 on Physical Properties of Liquid Paints & Paint Materials.

Current edition approved Nov. 1, 2018June 1, 2023. Published December 2018June 2023. Originally approved in 1952. Last previous edition approved in 20142018 as

D1200 – 10 (2014).(2018). DOI: 10.1520/D1200-10R18.10.1520/D1200-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1200 − 23

5. Significance and Use

5.1 This test method is useful for the determination of package and application viscosities of a number of paints and other coatings

and in the thinning of these materials, but is limited to Newtonian or near-Newtonian liquids.

5.2 There are other types of apparatus for measuring viscosity in the laboratory that produce more accurate results.

6. Apparatus

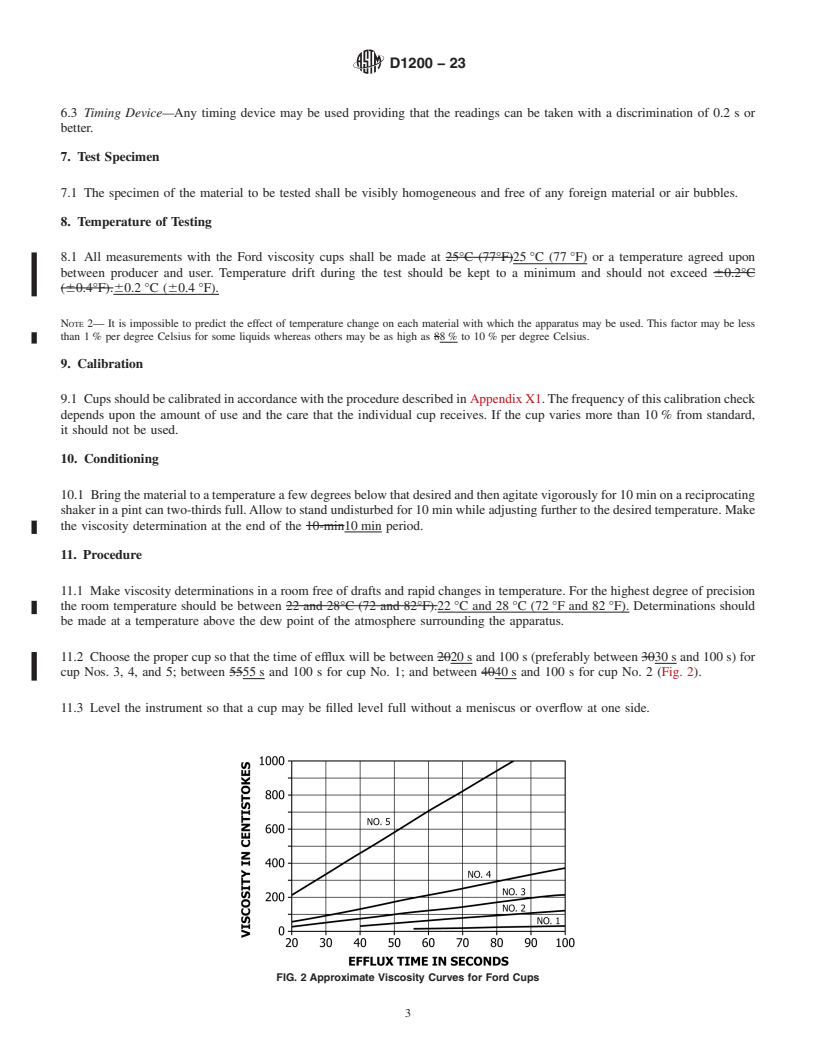

6.1 Ford Viscosity Cups—Nos. 1, 2, 3, 4, and 5 Ford viscosity cups made of corrosion- and solvent-resistant materials assembled

as complete units (Note 1), and conforming to the dimensional requirements shown in Fig. 1. The orifice dimensions are considered

as a guide only as the combination of cup and orifice dimensions must permit conformance to the flow formula for each cup as

listed in the Appendix.

NOTE 1—If the orifice is removed from the cup for any reason the cup should be recalibrated before use as described in the Appendix.

6.2 Thermometer—Saybolt Viscosity Thermometer conforming to the requirements for Thermometer 17C (19 to 27°C) or 17F (66

to 80°F)(19 °C to 27 °C) or 17F (66 °F to 80 °F) as prescribed in Specification E1. In addition, temperature measuring devices such

as non-mercury liquid-in-glass thermometers, thermocouples, or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.