ASTM F1809-97

(Guide)Standard Guide for Selection and Use of Etching Solutions to Delineate Structural Defects in Silicon

Standard Guide for Selection and Use of Etching Solutions to Delineate Structural Defects in Silicon

SCOPE

1.1 This guide covers the formulation, selection, and use of chemical solutions developed to reveal structural defects in silicon wafers. Etching solutions identify crystal defects that adversely affect the circuit performance and yield of silicon devices. Sample preparation, temperature control, etching technique, and choice of etchant are all key factors in the successful use of an etching method. This guide provides information for several etching solutions and allows the user to select according to the need. For further information see Appendix X1 and Figs. 1-32. For a test method for counting preferentially etched or decorated surface defects in silicon wafers see Test Method F 1810.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1809 – 97

Standard Guide for

Selection and Use of Etching Solutions to Delineate

Structural Defects in Silicon

This standard is issued under the fixed designation F 1809; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers the formulation, selection, and use of

chemical solutions developed to reveal structural defects in

silicon wafers. Etching solutions identify crystal defects that

adversely affect the circuit performance and yield of silicon

devices. Sample preparation, temperature control, etching tech-

nique, and choice of etchant are all key factors in the successful

use of an etching method. This guide provides information for

several etching solution and allows the user to select according

to the need. For further information see Appendix X1and Figs.

1-32 . For a test method for counting preferentially etched or

decorated surface defects in silicon wafers see Test Method

F 1810.

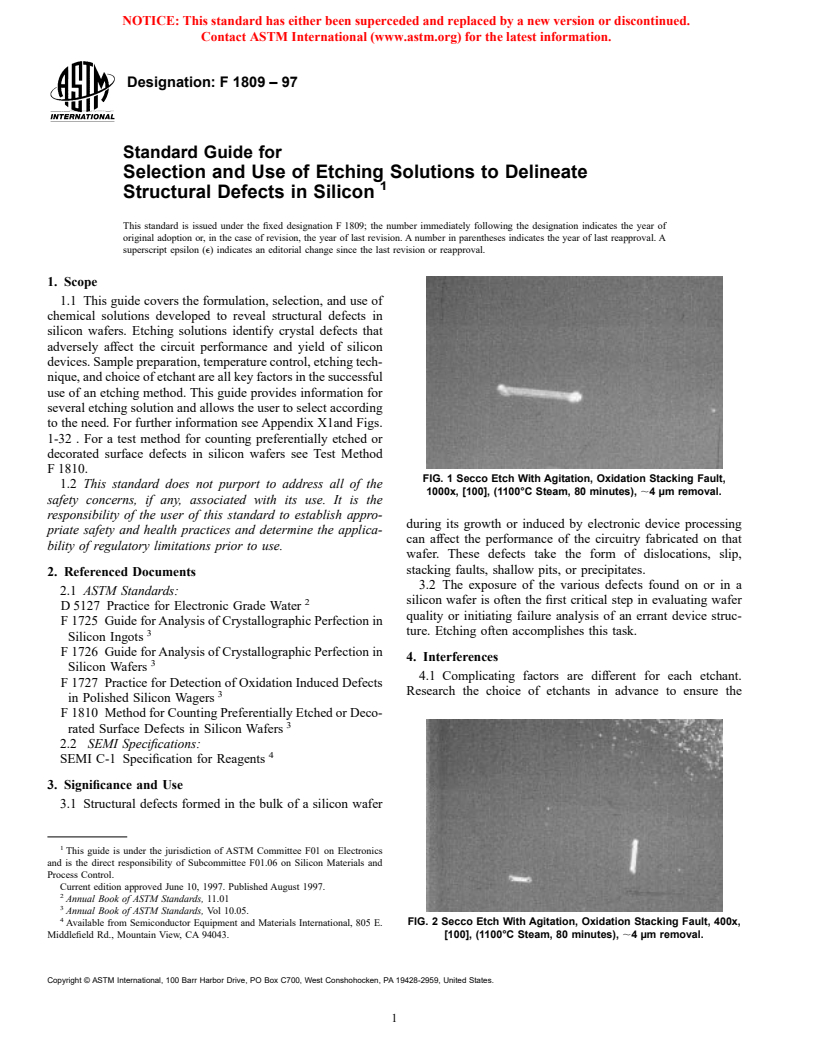

FIG. 1 Secco Etch With Agitation, Oxidation Stacking Fault,

1.2 This standard does not purport to address all of the

1000x, [100], (1100°C Steam, 80 minutes), ;4 μm removal.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

during its growth or induced by electronic device processing

priate safety and health practices and determine the applica-

can affect the performance of the circuitry fabricated on that

bility of regulatory limitations prior to use.

wafer. These defects take the form of dislocations, slip,

stacking faults, shallow pits, or precipitates.

2. Referenced Documents

3.2 The exposure of the various defects found on or in a

2.1 ASTM Standards:

2 silicon wafer is often the first critical step in evaluating wafer

D 5127 Practice for Electronic Grade Water

quality or initiating failure analysis of an errant device struc-

F 1725 Guide for Analysis of Crystallographic Perfection in

3 ture. Etching often accomplishes this task.

Silicon Ingots

F 1726 Guide for Analysis of Crystallographic Perfection in

4. Interferences

Silicon Wafers

4.1 Complicating factors are different for each etchant.

F 1727 Practice for Detection of Oxidation Induced Defects

Research the choice of etchants in advance to ensure the

in Polished Silicon Wagers

F 1810 Method for Counting Preferentially Etched or Deco-

rated Surface Defects in Silicon Wafers

2.2 SEMI Specifications:

SEMI C-1 Specification for Reagents

3. Significance and Use

3.1 Structural defects formed in the bulk of a silicon wafer

This guide is under the jurisdiction of ASTM Committee F01 on Electronics

and is the direct responsibility of Subcommittee F01.06 on Silicon Materials and

Process Control.

Current edition approved June 10, 1997. Published August 1997.

Annual Book of ASTM Standards, 11.01

Annual Book of ASTM Standards, Vol 10.05.

FIG. 2 Secco Etch With Agitation, Oxidation Stacking Fault, 400x,

Available from Semiconductor Equipment and Materials International, 805 E.

Middlefield Rd., Mountain View, CA 94043. [100], (1100°C Steam, 80 minutes), ;4 μm removal.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1809

FIG. 3 Secco Etch Without Agitation, Flow Pattern Defect 200x, FIG. 6 Secco Etch With Agitation, Scratch Induced Oxidation

[100], ;8 μm removal. Stacking Faults, 100x, [100], (1100°C Steam, 80 minutes), ;15 μm

removal.

FIG. 4 Secco Etch With Agitation, Expitaxial Stacking Fault, 150x,

[100], ;4 μm removal. FIG. 7 Wright Etch With Agitation, Damaged Induced Oxidation

Stacking Fault, 1000x, [100], (1100°C Steam, 80 minutes).

FIG. 5 Secco Etch With Agitation, Bulk Oxidation Stacking Fault,

200x, [100], (1100°C Steam, 80 minutes), ;15 μm removal. FIG. 8 Wright Etch With Agitation, Bulk Oxidation Stacking Fault,

500x, [100], (1100°C Steam, 80 minutes).

method and solution are compatible with the sample and

objectives. Commonly encountered problems are:

4.1.4 Any solution in which the oxidation rate is greater

4.1.1 Inadvertent etching through the denuded zone of an

oxidized sample delineates irrelevant bulk defects instead of than the oxide dissolution rate may form oxide layers that slow

or even quench the etching process. The presence of these

the surface oxidation induced stacking faults (OISF) expected.

4.1.2 Accelerated etching and etching artifacts can result oxide layers (especially for N+ and P+ material) obstructs the

from excessive solution heating during the etching process. interpretation of etched defects. Before evaluation, remove any

4.1.3 Insufficient agitation, bubble formation or particles in surface oxides.

the etching solution can generate artifacts on the silicon surface 4.1.5 The wafer surface becomes rougher with longer etch

that mimic actual defects. Insufficient agitation can alter the time. This rougher surface does not prevent evaluation under

etching rate, increasing or decreasing it depending upon the the microscope, but it greatly reduces the effectiveness of

formulation. visual inspection under bright light.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1809

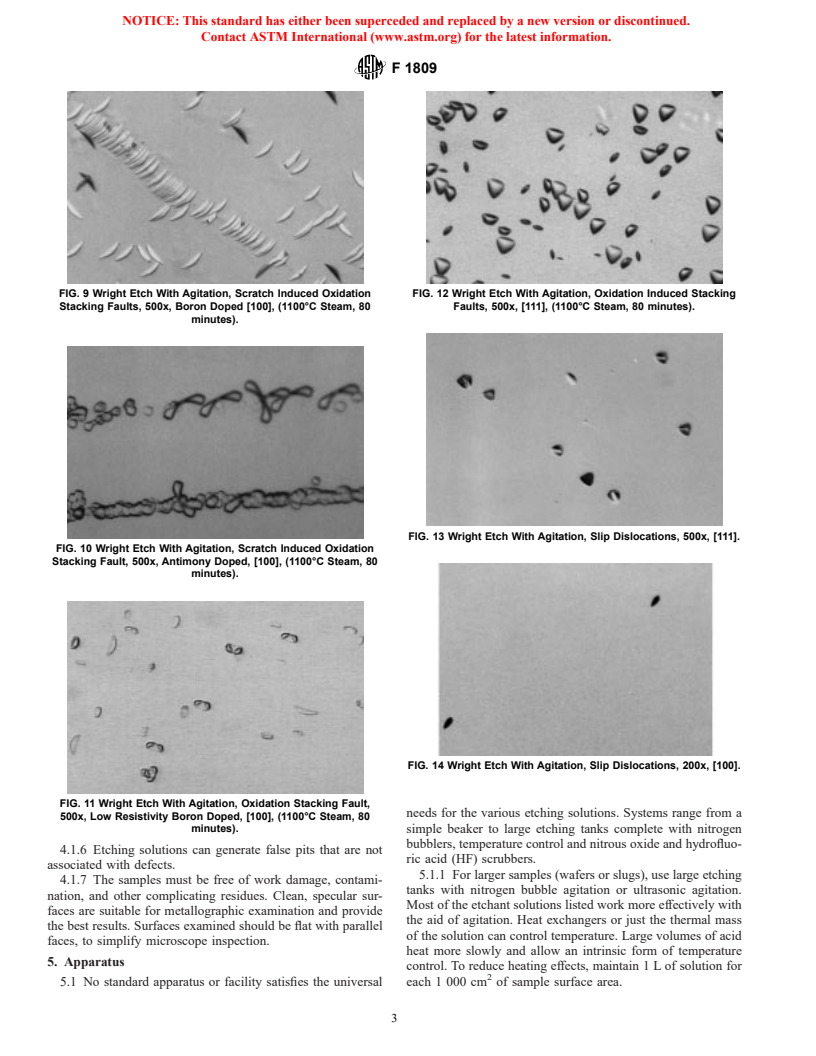

FIG. 9 Wright Etch With Agitation, Scratch Induced Oxidation FIG. 12 Wright Etch With Agitation, Oxidation Induced Stacking

Stacking Faults, 500x, Boron Doped [100], (1100°C Steam, 80 Faults, 500x, [111], (1100°C Steam, 80 minutes).

minutes).

FIG. 13 Wright Etch With Agitation, Slip Dislocations, 500x, [111].

FIG. 10 Wright Etch With Agitation, Scratch Induced Oxidation

Stacking Fault, 500x, Antimony Doped, [100], (1100°C Steam, 80

minutes).

FIG. 14 Wright Etch With Agitation, Slip Dislocations, 200x, [100].

FIG. 11 Wright Etch With Agitation, Oxidation Stacking Fault,

needs for the various etching solutions. Systems range from a

500x, Low Resistivity Boron Doped, [100], (1100°C Steam, 80

minutes). simple beaker to large etching tanks complete with nitrogen

bubblers, temperature control and nitrous oxide and hydrofluo-

4.1.6 Etching solutions can generate false pits that are not

ric acid (HF) scrubbers.

associated with defects.

5.1.1 For larger samples (wafers or slugs), use large etching

4.1.7 The samples must be free of work damage, contami-

tanks with nitrogen bubble agitation or ultrasonic agitation.

nation, and other complicating residues. Clean, specular sur-

Most of the etchant solutions listed work more effectively with

faces are suitable for metallographic examination and provide

the aid of agitation. Heat exchangers or just the thermal mass

the best results. Surfaces examined should be flat with parallel

of the solution can control temperature. Large volumes of acid

faces, to simplify microscope inspection.

heat more slowly and allow an intrinsic form of temperature

5. Apparatus

control. To reduce heating effects, maintain 1 L of solution for

5.1 No standard apparatus or facility satisfies the universal each 1 000 cm of sample surface area.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1809

FIG. 15 Wright Etch With Agitation, Shallow Pits (Haze), 500x, FIG. 18 Copper-3 Etch With Agitation, Shallow Pits (Haze), 500x,

Boron Doped [100], (1100°C Steam, 80 minutes). p type, 10 ohm-cm, [111], (1100°C Steam, 80 minutes), 2 μm

removal

FIG. 16 Wright Etch, Etching Stain-Artifact, 200x, Boron Doped.

FIG. 19 Copper-3 Etch Without Agitation, Oxidation Stacking

Fault, 1000x, p type, 10 ohm-cm, [111], (1100°C Steam, 80

minutes), 1 μm removal.

FIG. 17 Copper-3 Etch With Agitation, Oxidation Stacking Fault,

500x, p type, 10 ohm-cm, [100] (1100°C Steam, 80 minutes), 2 μm

removal.

FIG. 20 Copper-3 Etch Without Agitation, Oxidation Stacking

Fault, 1000x, p type, 10 ohm-cm, [100], (1100°C Steam, 80

5.1.2 Maintain proper environmental controls. Make provi-

minutes), 1 μm removal.

sions to dispose of nitrous oxides, HF fumes, and any solid

wastes evolved whatever system is chosen. Chromium and

6.2 Purity of Water—Reference to water means either

copper-based etching solutions produce solid waste and gas-

eous byproducts. Chromium-free etching solutions produce no distilled or deionized water, meeting the requirements of Type

I water as defined by Guide D 5127.

measurable solid waste but do generate nitrous oxides and HF

fumes. 6.3 Volume of components describes all solutions in parts of

a standard assay. The formulas give solid or dissolved compo-

6. Reagents and Materials

nents in grams per 100 mm of total solution.

6.1 All chemicals for which such specifications exist shall 6.4 All formulations employ a Standard Solution Conven-

conform to SEMI Specification C-1. tion (SSC) that specifies each solution component as an

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1809

FIG. 21 Copper-3 Etch Without Agitation, Dislocations, 500x, p FIG. 24 Copper-3 Etch Without Agitation, Slip Dislocations, 100x,

type, 10 ohm-cm [111], 10 μm removal. p type, 10 ohm-cm, [100], 10 μm removal.

FIG. 22 Copper-3 Etch Without Agitation, Dislocations, 500x, p FIG. 25 Modified Dash Etch, Oxidation Induced Stacking Faults

type, 10 ohm-cm, [100], 10 μm removal. and Dislocations, 400x, [100], p type, 10 ohm-cm, (1100°C, O ,8

hour), ;4 μm removal.

FIG. 23 Copper-3 Etch Without Agitation, Slip Dislocations, 100x,

p type, 10 ohm-cm, [111], 10 μm removal. FIG. 26 Modified Dash Etch, Oxidation Induced Stacking Faults

and Dislocations, 400x, [111], n type, 10 ohm-cm, (1100°C, O ,8

hour), ;4 μm removal.

acceptable assay 6 some tolerance. Formulations of the stan-

7. Hazards

dard assay follow this example: A HF/HNO /Acetic solution,

7.1 The chemicals used in these etching solutions are

in the 1:1:2 ratio is the same as 25 %(49 %HF) + 25 %(70

potentially harmful. Handle and use them in a chemical

%HNO + 50 %(glacial acetic) by volume. The specified

exhaust fume hood, with the utmost care.

chemicals shall have the following nominal assay:

7.2 Hydrofluoric acid solutions are particularly hazardous.

Chemical Assay, %

7.3 Release of chromic acid or solutions of chromic acid

Acetic acid, glacial > 99.7

into domestic sewer systems is usually not allowed. Chromates

Chromium trioxide > 98

are extreme biological and ecological hazards. Chromic acid is

Copper nitrate > 98

Hydrofluoric acid 49 6 0.25 a strong oxidizing agent and should not contact organic

Nitric acid 70 to 71

solvents or other easily oxidized materials.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1809

FIG. 27 Modified Dash Etch, Oxidation Induced Stacking Faults, FIG. 30 Modified Dash Etch, Slip Dislocations, Epitaxial Stacking

400x, [100], p type, 0.007 ohm-cm, (1100°C, O , 8 hour), ;5μm Faults and Shallow Pits, n/n+ Epitaxy, 400x, [111], ;4μm

removal. removal.

FIG. 28 Modified Dash Etch, Oxidation Induced Stacking Faults, FIG. 31 Modified Dash Etch, Damage Induced Slip Dislocations, p

400x, [100], p type, <0.02 ohm-cm, (1100°C, O , 8 hour), ;5μm type, 400x, [100], (1100°C, O , 1 min), ;4 μm removal.

2 2

removal.

FIG. 32 Modified Dash Etch, Damage Induced Slip Dislocations, n

FIG. 29 Modified Dash Etch, Slip Dislocations p/p+ Epitaxy, 400x, type, 400x, [111], (1100°C, O , 1 min), ;4 μm removal.

[100], ;4 μm removal.

published references and suggested applications. Each solution

has advantages and disadvantages and this guide does not

7.4 Safety or protective gear should be worn while handling

endorse one in favor of another. Selection of an etchant

these acid solutions or their components. Safety requirements

solution should be based upon: etch rate, etchant life, solution

vary, but the essentials are: plastic gloves, safety glasses, face

heating, environmental harm, ease of interpretation, and range

shield, acid gown, and shoe covers. The handling of large

of use.

quantities of powdered chromic acid may require a respirator

or other breathing apparatus. NOTE 1—Although this guide does not require a specific solution,

attempt to use chromium-free etches when possible for environmental

8. Procedure

reasons.

8.1 Selection of Etching Solutions: 8.1.2 The following tables show two broad categories of

8.1.1 Table 1 and Table 2 contain a partial list of the many solutions. The first, Table 1, is the group of solutions that

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1809

contain chromium compounds. These do well for their in- process or occurring naturally due to exposure to air.

tended application but can be harmful to the environment. Use

8.2.2 Immediately before defect etching, submerge the

these highly contaminated etching solutions with caution.

sample in concentrated HF solution for 1 min or until the

Release into the environment of hexavalent chromium waste is

surface becomes hydrophobic to remove surface oxide layers.

a recognized hazard. Exposure can cause cancer. The second

8.2.3 Rinse and hold the samples in deionized water until

group inTable 2 lists the chromium-free etching solutions.

transferred to the etching solution.

Although uses may be limited, they should be considered

8.3 Defect Etching:

whenever appropriate.

8.3.1 As stated in Section 5, no standard design for etching

8.1.3 Investigate local environmental and safety require-

systems exists. This example describes a simple system:

ments before selecting an etchant solution. Identify the sample

8.3.1.1 Place the specimen in the bottom of a Hf-proof

orientation, type, resistivity level, and primary defects of

interest; this information helps the user in ranking the various beaker with the surface to be inspected facing upward.

possible solutions and then in selecting the most appropri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.